|

市场调查报告书

商品编码

1714094

振动测试设备市场:全球2025-2035年Global Vibration Test Equipment Market 2025-2035 |

||||||

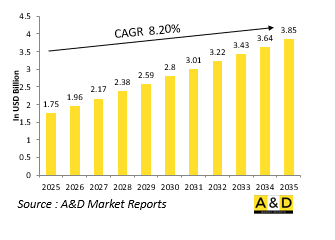

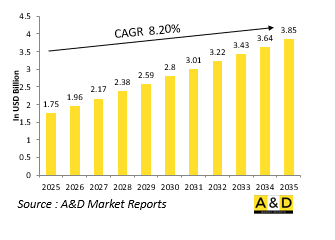

全球振动测试设备市场规模预计将从 2025 年的 17.5 亿美元增长到 2035 年的 38.5 亿美元,预测期内的复合年增长率为 8.20%。

震动测试设备市场:简介

震动测试设备在国防工业中发挥着至关重要的作用。这是为了确保关键任务系统即使在紧张的操作条件下也能保持其机械稳健性、结构完整性和性能可靠性。从飞机航空电子设备和飞弹部件到强化通讯系统和移动地面车辆,国防平台在部署期间都暴露在恶劣的振动环境中。国防振动测试设备市场处于机械工程和任务保证的交叉点,提供复製现实世界中遇到的衝击、碰撞和持续振动的模拟能力。随着国防系统变得越来越复杂和小型化,并具有精确的公差和多领域能力,对先进测试基础设施的需求也随之增加。振动测试设备用于产品生命週期的各个阶段,从原型验证到最终产品认证和线上升级。国防承包商、政府实验室和航空航天测试中心依靠这些仪器来验证是否符合 MIL-STD-810 和 NATO STANAG 等国际军事标准。市场涵盖多种技术,包括电动振动台、液压振动台和多轴系统,这些技术越来越多地与数位数据采集系统集成,以实现高精度分析。随着国防部门转向快速系统部署和延长生命週期战略,振动测试设备对于降低开发风险和确保战备状态变得至关重要。

震动测试设备市场:科技的影响

技术的进步正在重新定义国防部门使用的振动测试设备的功能和性能指标。现代系统现在整合了高解析度感测器、即时控制软体和基于机器学习的分析,以提供更准确、更适应性更强的测试环境。最具变革性的转变之一是数位孪生技术的引入。该技术透过组件和系统的虚拟复製品模拟振动场景,以在不造成物理破坏的情况下识别结构弱点。这些数位模拟透过高频加速度计和应变计捕获的实体测试资料进行验证,从而形成反馈迴路,改善设计并增强预测性维护模型。此外,转向多轴振动平台可以同时在不同的向量(X、Y 和 Z)上进行激励,以更真实地模拟真实世界的战场动态,无论是在空中、海上或陆地。高负载电磁振动器的使用也越来越多,它可以透过冷却系统和动态负载控制的创新来复製极端的发射、飞行和运输条件。此外,支援人工智慧的软体现在可以根据感测器回馈自动即时调整测试参数,从而减少测试时间并提高准确性。随着国防研发朝着更灵活和更快的开发週期发展,技术增强的振动测试系统对于在日益动态的军事环境中实现可靠性保证、结构认证和系统弹性至关重要。

震动测试设备市场的关键推动因素:

多种战略和营运因素正在推动全球国防部门对先进振动测试设备的需求。其中最突出的是现代防御系统日益增加的复杂性和性能要求。其中许多包含紧凑的电子组件、高精度导引装置和模组化结构元件,所有这些都必须承受不可预测的环境和机械应力。随着军方追求更轻、更灵活和电子整合的系统,确保这些组件在振动下保持其功能完整性不是一种选择,而是一种必要。随着各国逐步淘汰传统平台并转向需要新测试协议的下一代车辆、飞弹和飞机,这种情况尤其如此。此外,对高超音速武器、可重复使用太空系统和无人作战飞机(UCAV)的投资增加,引入了新的振动测试参数,包括高速通过、大气再入和极端温度变化——这些条件对敏感子系统施加了独特的机械应力。此外,政府国防合约越来越要求遵守环境测试标准,从而需要使用高性能、可认证的振动测试解决方案。最后,国防工业越来越重视透过结构健康监测和预测性维护来延长资产生命週期,这在很大程度上依赖于能够在灾难性故障发生之前模拟操作磨损和评估材料疲劳的测试设备。这些因素结合在一起,将振动测试从常规验证过程转变为国防系统工程和生命週期管理中的战略功能。

本报告调查了全球振动测试设备市场,并总结了当前的市场状况、技术趋势、市场影响因素分析、市场规模趋势和预测、按地区进行的详细分析、竞争格局以及主要公司的概况。

目录

全球震动测试设备市场:目录

全球震动测试设备市场:报告定义

全球震动测试设备市场:细分

按地区

按类型

依装置类型

依用途

未来10年全球震动测试设备市场分析

全球震动测试设备市场:市场技术

全球震动测试设备市场:预测

全球震动测试设备市场趋势及各区域预测

北美

促进因素、阻碍因素与课题

抑制因子

市场预测与情境分析

主要公司

供应商层级格局

企业基准测试

欧洲

中东

亚太地区

南美洲

全球震动测试设备市场:国家分析

美国

国防计画

最新消息

专利

目前技术成熟度

市场预测与情境分析

加拿大

义大利

法国

德国

荷兰

比利时

西班牙

瑞典

希腊

澳洲

南非

印度

中国

俄罗斯

韩国

日本

马来西亚

新加坡

巴西

全球振动测试设备市场:机会矩阵

全球振动测试设备市场:专家对报告的看法

概述

关于航空和国防市场报告

The Global Vibration Test Equipment market is estimated at USD 1.75 billion in 2025, projected to grow to USD 3.85 billion by 2035 at a Compound Annual Growth Rate (CAGR) of 8.20% over the forecast period 2025-2035.

Introduction to Vibration Test Equipment Market:

Vibration test equipment plays a critical role in the defense industry by ensuring the mechanical robustness, structural integrity, and performance reliability of mission-critical systems under operational stress conditions. From aircraft avionics and missile components to ruggedized communication systems and mobile ground vehicles, defense platforms are subject to harsh vibration environments during deployment. The global defense vibration test equipment market exists at the intersection of mechanical engineering and mission assurance, providing simulation capabilities that replicate shock, impact, and sustained vibration encountered in real-world scenarios. As defense systems become increasingly complex and miniaturized, with tighter tolerances and multi-domain functionality, the need for advanced testing infrastructure has intensified. Vibration test equipment is used across multiple phases of the product lifecycle-from prototype validation to final product certification and ongoing system upgrades. Defense contractors, government laboratories, and aerospace test centers rely on these tools to verify compliance with international military standards such as MIL-STD-810 and NATO STANAG protocols. The market includes a range of technologies, including electrodynamic shakers, hydraulic vibration tables, and multi-axis systems, which are increasingly integrated with digital data acquisition systems for high-fidelity analysis. As the defense sector pivots toward rapid system deployment and lifecycle extension strategies, vibration test equipment is becoming indispensable in reducing development risk and enhancing combat-readiness assurance.

Technology Impact in Vibration Test Equipment Market:

Technological advancements are redefining the capabilities and performance metrics of vibration test equipment used in the defense sector. Modern systems now integrate high-resolution sensors, real-time control software, and machine learning-based analytics to deliver more precise and adaptable testing environments. One of the most transformative shifts has been the incorporation of digital twin technology, where virtual replicas of components or systems are subjected to simulated vibration scenarios to identify structural vulnerabilities without physical destruction. These digital simulations are then validated with physical test data captured through high-frequency accelerometers and strain gauges, enabling a feedback loop that refines design and enhances predictive maintenance models. Additionally, the transition to multi-axis vibration platforms has allowed for simultaneous excitation along different vectors-X, Y, and Z axes-thereby providing more realistic simulations of actual battlefield motion, whether it be in airborne, seaborne, or land-based conditions. Innovations in cooling systems and dynamic load control have also expanded the use of high-force electrodynamic shakers capable of replicating extreme launch, flight, or transport conditions. Furthermore, AI-driven software can now automatically adjust test parameters in real-time based on sensor feedback, reducing test time and improving accuracy. As defense R&D moves toward more agile and accelerated development cycles, technology-enhanced vibration test systems are emerging as essential enablers of reliability assurance, structural certification, and system resilience in increasingly dynamic military environments.

Key Drivers in Vibration Test Equipment Market:

Several strategic and operational factors are propelling the demand for advanced vibration test equipment within global defense sectors. Chief among them is the growing complexity and performance demands of modern defense systems, many of which include compact electronic assemblies, high-precision guidance units, and modular structural elements-all of which must endure unpredictable environmental and mechanical stressors. As militaries pursue lighter, more agile, and electronically integrated systems, ensuring these components maintain functional integrity under vibration is not optional-it is mandatory. Another significant driver is the ongoing global push for defense system modernization and platform interoperability, particularly as countries phase out legacy platforms in favor of next-generation vehicles, missiles, and aircraft that require new testing protocols. In addition, increasing investments in hypersonic weapons, reusable space systems, and unmanned combat aerial vehicles (UCAVs) have introduced new vibration test parameters involving high-speed transit, atmospheric re-entry, and extreme thermal variation-conditions that place unparalleled mechanical stress on sensitive subsystems. Government defense contracts also increasingly specify stricter compliance with environmental test standards, which necessitates the use of highly capable and certifiable vibration test solutions. Finally, the defense industry's growing emphasis on extending asset lifecycles-through structural health monitoring and predictive maintenance-relies heavily on test equipment that can simulate operational wear and assess material fatigue before critical failure occurs. Collectively, these drivers are transforming vibration testing from a routine verification process to a strategic function within defense systems engineering and lifecycle management.

Regional Trends in Vibration Test Equipment Market:

The adoption and development of vibration test equipment in the defense sector varies across global regions, reflecting distinct national priorities, defense procurement strategies, and industrial capabilities. In North America, particularly the United States, defense agencies and prime contractors maintain some of the world's most sophisticated test facilities, supporting development of aircraft like the F-35, missile systems under the Missile Defense Agency, and space programs led by the U.S. Space Force. These facilities invest in cutting-edge vibration simulation infrastructure, often paired with climate chambers and EMI/EMC labs, to deliver comprehensive qualification processes. Canada also maintains an active role, especially in testing for NATO-interoperable systems and cold-weather stress applications. In Europe, countries like Germany, France, and the UK are investing heavily in vibration testing capabilities for joint defense programs like the Future Combat Air System (FCAS) and Tempest, while also supporting dual-use technologies for both military and civil aviation. European defense firms often collaborate with academic institutions and testing consortia, creating innovation clusters that advance vibration simulation methods and standards compliance. In the Asia-Pacific region, China and India are rapidly expanding their defense manufacturing bases and associated testing infrastructure. China, in particular, is building large-scale vibration and shock testing complexes to support the development of indigenous fighter aircraft, long-range missile systems, and space assets. India, through DRDO and ISRO, is enhancing its vibration test capabilities as it pushes toward strategic autonomy in defense production. Japan and South Korea, while smaller in defense output, lead in high-precision vibration systems used for naval and aerospace component qualification. In the Middle East, especially in countries like the UAE and Saudi Arabia, there is growing investment in establishing in-country test facilities as part of defense localization efforts. These regional trends suggest that while North America and Europe maintain leadership in vibration testing technology, Asia-Pacific and the Middle East are rapidly scaling up their capabilities to meet domestic manufacturing and strategic independence goals.

Key Vibration Test Equipment Program:

The impending deployment of the U.S. Army's Long-Range Hypersonic Weapon (LRHW), officially named "Dark Eagle," signals a significant shift in the dynamics of modern warfare. Expected to enter service by the end of fiscal year 2025, Dark Eagle marks the United States' official entry into the hypersonic missile arena-an area currently led by China and Russia. This development holds far-reaching implications for both U.S. military capabilities and the broader global strategic balance and deterrence posture.

Table of Contents

Global vibration test equipment Market - Table of Contents

Global vibration test equipment Market Report Definition

Global vibration test equipment Market Segmentation

By Region

By Type

By Equipment Type

By Application

Global vibration test equipment Market Analysis for next 10 Years

The 10-year Global vibration test equipment market analysis would give a detailed overview of Global vibration test equipment market growth, changing dynamics, technology adoption overviews and the overall market attractiveness is covered in this chapter.

Market Technologies of Global vibration test equipment Market

This segment covers the top 10 technologies that is expected to impact this market and the possible implications these technologies would have on the overall market.

Global vibration test equipment Market Forecast

The 10-year Global vibration test equipment market forecast of this market is covered in detailed across the segments which are mentioned above.

Regional Global vibration test equipment Market Trends & Forecast

The regional Global vibration test equipment market trends, drivers, restraints and Challenges of this market, the Political, Economic, Social and Technology aspects are covered in this segment. The market forecast and scenario analysis across regions are also covered in detailed in this segment. The last part of the regional analysis includes profiling of the key companies, supplier landscape and company benchmarking. The current market size is estimated based on the normal scenario.

North America

Drivers, Restraints and Challenges

PEST

Market Forecast & Scenario Analysis

Key Companies

Supplier Tier Landscape

Company Benchmarking

Europe

Middle East

APAC

South America

Country Analysis of Global vibration test equipment Market

This chapter deals with the key defense programs in this market, it also covers the latest news and patents which have been filed in this market. Country level 10 year market forecast and scenario analysis are also covered in this chapter.

US

Defense Programs

Latest News

Patents

Current levels of technology maturation in this market

Market Forecast & Scenario Analysis

Canada

Italy

France

Germany

Netherlands

Belgium

Spain

Sweden

Greece

Australia

South Africa

India

China

Russia

South Korea

Japan

Malaysia

Singapore

Brazil

Opportunity Matrix for Global vibration test equipment Market

The opportunity matrix helps the readers understand the high opportunity segments in this market.

Expert Opinions on Global vibration test equipment Market Report

Hear from our experts their opinion of the possible analysis for this market.

Conclusions

About Aviation and Defense Market Reports

List of Tables

- Table 1: 10 Year Market Outlook, 2025-2035

- Table 2: Drivers, Impact Analysis, North America

- Table 3: Restraints, Impact Analysis, North America

- Table 4: Challenges, Impact Analysis, North America

- Table 5: Drivers, Impact Analysis, Europe

- Table 6: Restraints, Impact Analysis, Europe

- Table 7: Challenges, Impact Analysis, Europe

- Table 8: Drivers, Impact Analysis, Middle East

- Table 9: Restraints, Impact Analysis, Middle East

- Table 10: Challenges, Impact Analysis, Middle East

- Table 11: Drivers, Impact Analysis, APAC

- Table 12: Restraints, Impact Analysis, APAC

- Table 13: Challenges, Impact Analysis, APAC

- Table 14: Drivers, Impact Analysis, South America

- Table 15: Restraints, Impact Analysis, South America

- Table 16: Challenges, Impact Analysis, South America

- Table 17: Scenario Analysis, Scenario 1, By Region, 2025-2035

- Table 18: Scenario Analysis, Scenario 1, By Type, 2025-2035

- Table 19: Scenario Analysis, Scenario 1, By Application, 2025-2035

- Table 20: Scenario Analysis, Scenario 1, By Equipment Type, 2025-2035

- Table 21: Scenario Analysis, Scenario 2, By Region, 2025-2035

- Table 22: Scenario Analysis, Scenario 2, By Type, 2025-2035

- Table 23: Scenario Analysis, Scenario 2, By Application, 2025-2035

- Table 24: Scenario Analysis, Scenario 2, By Equipment Type, 2025-2035

List of Figures

- Figure 1: Global Vibration Test Equipment Market Forecast, 2025-2035

- Figure 2: Global Vibration Test Equipment Market Forecast, By Region, 2025-2035

- Figure 3: Global Vibration Test Equipment Market Forecast, By Type, 2025-2035

- Figure 4: Global Vibration Test Equipment Market Forecast, By Application, 2025-2035

- Figure 5: Global Vibration Test Equipment Market Forecast, By Equipment Type, 2025-2035

- Figure 6: North America, Vibration Test Equipment Market, Market Forecast, 2025-2035

- Figure 7: Europe, Vibration Test Equipment Market, Market Forecast, 2025-2035

- Figure 8: Middle East, Vibration Test Equipment Market, Market Forecast, 2025-2035

- Figure 9: APAC, Vibration Test Equipment Market, Market Forecast, 2025-2035

- Figure 10: South America, Vibration Test Equipment Market, Market Forecast, 2025-2035

- Figure 11: United States, Vibration Test Equipment Market, Technology Maturation, 2025-2035

- Figure 12: United States, Vibration Test Equipment Market, Market Forecast, 2025-2035

- Figure 13: Canada, Vibration Test Equipment Market, Technology Maturation, 2025-2035

- Figure 14: Canada, Vibration Test Equipment Market, Market Forecast, 2025-2035

- Figure 15: Italy, Vibration Test Equipment Market, Technology Maturation, 2025-2035

- Figure 16: Italy, Vibration Test Equipment Market, Market Forecast, 2025-2035

- Figure 17: France, Vibration Test Equipment Market, Technology Maturation, 2025-2035

- Figure 18: France, Vibration Test Equipment Market, Market Forecast, 2025-2035

- Figure 19: Germany, Vibration Test Equipment Market, Technology Maturation, 2025-2035

- Figure 20: Germany, Vibration Test Equipment Market, Market Forecast, 2025-2035

- Figure 21: Netherlands, Vibration Test Equipment Market, Technology Maturation, 2025-2035

- Figure 22: Netherlands, Vibration Test Equipment Market, Market Forecast, 2025-2035

- Figure 23: Belgium, Vibration Test Equipment Market, Technology Maturation, 2025-2035

- Figure 24: Belgium, Vibration Test Equipment Market, Market Forecast, 2025-2035

- Figure 25: Spain, Vibration Test Equipment Market, Technology Maturation, 2025-2035

- Figure 26: Spain, Vibration Test Equipment Market, Market Forecast, 2025-2035

- Figure 27: Sweden, Vibration Test Equipment Market, Technology Maturation, 2025-2035

- Figure 28: Sweden, Vibration Test Equipment Market, Market Forecast, 2025-2035

- Figure 29: Brazil, Vibration Test Equipment Market, Technology Maturation, 2025-2035

- Figure 30: Brazil, Vibration Test Equipment Market, Market Forecast, 2025-2035

- Figure 31: Australia, Vibration Test Equipment Market, Technology Maturation, 2025-2035

- Figure 32: Australia, Vibration Test Equipment Market, Market Forecast, 2025-2035

- Figure 33: India, Vibration Test Equipment Market, Technology Maturation, 2025-2035

- Figure 34: India, Vibration Test Equipment Market, Market Forecast, 2025-2035

- Figure 35: China, Vibration Test Equipment Market, Technology Maturation, 2025-2035

- Figure 36: China, Vibration Test Equipment Market, Market Forecast, 2025-2035

- Figure 37: Saudi Arabia, Vibration Test Equipment Market, Technology Maturation, 2025-2035

- Figure 38: Saudi Arabia, Vibration Test Equipment Market, Market Forecast, 2025-2035

- Figure 39: South Korea, Vibration Test Equipment Market, Technology Maturation, 2025-2035

- Figure 40: South Korea, Vibration Test Equipment Market, Market Forecast, 2025-2035

- Figure 41: Japan, Vibration Test Equipment Market, Technology Maturation, 2025-2035

- Figure 42: Japan, Vibration Test Equipment Market, Market Forecast, 2025-2035

- Figure 43: Malaysia, Vibration Test Equipment Market, Technology Maturation, 2025-2035

- Figure 44: Malaysia, Vibration Test Equipment Market, Market Forecast, 2025-2035

- Figure 45: Singapore, Vibration Test Equipment Market, Technology Maturation, 2025-2035

- Figure 46: Singapore, Vibration Test Equipment Market, Market Forecast, 2025-2035

- Figure 47: United Kingdom, Vibration Test Equipment Market, Technology Maturation, 2025-2035

- Figure 48: United Kingdom, Vibration Test Equipment Market, Market Forecast, 2025-2035

- Figure 49: Opportunity Analysis, Vibration Test Equipment Market, By Region (Cumulative Market), 2025-2035

- Figure 50: Opportunity Analysis, Vibration Test Equipment Market, By Region (CAGR), 2025-2035

- Figure 51: Opportunity Analysis, Vibration Test Equipment Market, By Type (Cumulative Market), 2025-2035

- Figure 52: Opportunity Analysis, Vibration Test Equipment Market, By Type (CAGR), 2025-2035

- Figure 53: Opportunity Analysis, Vibration Test Equipment Market, By Application (Cumulative Market), 2025-2035

- Figure 54: Opportunity Analysis, Vibration Test Equipment Market, By Application (CAGR), 2025-2035

- Figure 55: Opportunity Analysis, Vibration Test Equipment Market, By Equipment Type (Cumulative Market), 2025-2035

- Figure 56: Opportunity Analysis, Vibration Test Equipment Market, By Equipment Type (CAGR), 2025-2035

- Figure 57: Scenario Analysis, Vibration Test Equipment Market, Cumulative Market, 2025-2035

- Figure 58: Scenario Analysis, Vibration Test Equipment Market, Global Market, 2025-2035

- Figure 59: Scenario 1, Vibration Test Equipment Market, Total Market, 2025-2035

- Figure 60: Scenario 1, Vibration Test Equipment Market, By Region, 2025-2035

- Figure 61: Scenario 1, Vibration Test Equipment Market, By Type, 2025-2035

- Figure 62: Scenario 1, Vibration Test Equipment Market, By Application, 2025-2035

- Figure 63: Scenario 1, Vibration Test Equipment Market, By Equipment Type, 2025-2035

- Figure 64: Scenario 2, Vibration Test Equipment Market, Total Market, 2025-2035

- Figure 65: Scenario 2, Vibration Test Equipment Market, By Region, 2025-2035

- Figure 66: Scenario 2, Vibration Test Equipment Market, By Type, 2025-2035

- Figure 67: Scenario 2, Vibration Test Equipment Market, By Application, 2025-2035

- Figure 68: Scenario 2, Vibration Test Equipment Market, By Equipment Type, 2025-2035

- Figure 69: Company Benchmark, Vibration Test Equipment Market, 2025-2035