|

市场调查报告书

商品编码

1708574

三价铬表面处理市场(按系统、应用、最终用途和地区)Trivalent Chromium Finishing Market, By System, By Application, By End-use, By Geography |

||||||

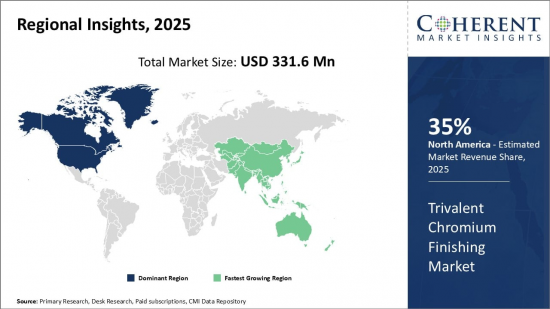

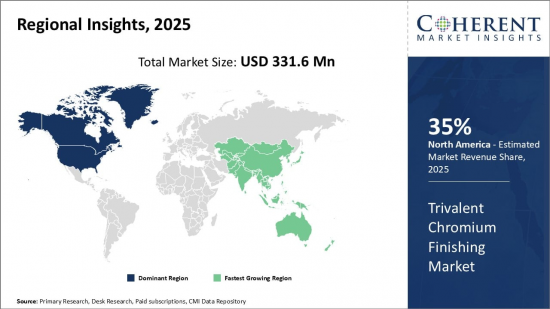

2025 年全球三价铬精加工市场规模估计为 3.316 亿美元,预计到 2032 年将达到 4.513 亿美元,2025 年至 2032 年的复合年增长率为 4.5%。

| 报告范围 | 报告详细信息 | ||

|---|---|---|---|

| 基准年 | 2024 | 2025年的市场规模 | 3.316亿美元 |

| 效能数据 | 2020-2024 | 预测期 | 2025-2032 |

| 预测期间:2025年至2032年的复合年增长率 | 4.50% | 2032年价值预测 | 4.513亿美元 |

三价铬处理是在金属基材表面电镀一层薄薄的铬的製程。镀铬表面为基材提供了耐腐蚀、耐磨和美观的光泽。将金属零件浸入含有三价铬盐的水溶液中,并通入电流,在基材表面沉积一层緻密的铬层。三价铬比传统的六价铬处理方法毒性小,也更环保。它可以保护金属表面免受腐蚀和磨损,并改善各种工业和建筑应用中的外观。众所周知,三价铬涂层具有优异的耐腐蚀性、硬度、耐磨性和耐化学性。近年来,有关六价铬使用的环境法规越来越严格,导致三价铬精加工製程的应用越来越多。电镀技术的进步使得三价铬表面更具装饰性和耐用性。由于全球工业化和製造业活动的不断增加,预计全球三价铬精加工市场在预测期内将大幅成长。

市场动态

三价铬涂层市场受到全球严格的环境法规的推动,这些法规禁止使用致癌性六价铬。欧盟的 REACH 和 UL 标准以及环保署 (EPA) 的倡议正在强制要求过渡到无毒的三价铬涂层,从而推动市场成长。建筑业和汽车业的发展,利用装饰性和功能性镀铬,推动了需求。然而,替代表面治疗方法的可用性可能会限制市场。不限制防腐或操作特性的绿色三价铬处理解决方案的开发为市场扩展提供了机会。

研究的主要特点

本报告对全球三价铬精加工市场进行了详细分析,并给出了预测期(2025-2032)的市场规模和年复合成长率(CAGR%),假设 2024 年为基准年。

它还强调了各个领域的潜在商机,并说明了该市场的有吸引力的投资提案矩阵。

它还提供了有关市场驱动因素、限制因素、机会、新产品发布和核准、市场趋势、区域前景和主要企业采用的竞争策略的重要见解。

全球三价铬精加工市场的主要企业是根据公司亮点、产品系列、关键亮点、性能和策略等参数进行的分析。

主要企业包括 Kakihara Industries Co.、Ronatec C2C, Inc.、MacDermid, Inc.、Atotech、Sarrel Group、Chem Processing, Inc. 等。

本报告的见解将使负责人和企业经营团队能够就未来的产品发布、新兴趋势、市场扩张和行销策略做出明智的决策。

本研究报告针对该产业的各个相关人员,包括投资者、供应商、产品製造商、经销商、新进业者和财务分析师。

可以透过全球三价铬表面处理市场分析中使用的各种策略矩阵来促进相关人员的决策。

目录

第一章 调查目的与前提条件

- 研究目标

- 先决条件

- 简称

第二章 市场展望

- 报告描述

- 市场定义和范围

- 执行摘要

- 一致的机会图(COM)

第三章市场动态、法规与趋势分析

- 市场动态

- 了解日益增长的太空探勘需求

- 太空飞行安全

- 机会

- 影响分析

- 监管情景

- 产品发布/核准

- PEST分析

- 波特分析

- 併购场景

4. 三价铬表面处理市场-冠状病毒(COVID-19)疫情的影响

- COVID-19流行病学

- 供需侧分析

- 对空间医疗市场的影响

5. 三价铬精加工市场(依系统划分),2020 年至 2032 年

- 介绍

- 电镀

- 装饰电镀

- 功能性电镀

- 化学涂层

- 装饰转化膜

- 功能性转化涂层

- 钝化

6. 三价铬涂层市场(按应用)2020 年至 2032 年

- 介绍

- 装饰性的

- 功能

7. 三价铬涂层市场(依最终用途划分),2020 年至 2032 年

- 介绍

- 车

- 石油和天然气

- 航太

- 液压/重型机械

- 其他的

8. 三价铬表面处理市场(按地区),2020 年至 2032 年

- 介绍

- 北美洲

- 拉丁美洲

- 欧洲

- 亚太地区

- 中东

- 非洲

第九章 竞争态势

- Kakihara Industries Co., Ltd.

- Ronatec C2C, Inc.

- MacDermid, Inc.

- Atotech

- Chem Processing, Inc

- Sarrel Group

第 10 章 章节

- 调查方法

- 关于出版商

Global Trivalent Chromium Finishing Market is estimated to be valued at USD 331.6 Mn in 2025 and is expected to reach USD 451.3 Mn by 2032, growing at a compound annual growth rate (CAGR) of 4.5% from 2025 to 2032.

| Report Coverage | Report Details | ||

|---|---|---|---|

| Base Year: | 2024 | Market Size in 2025: | USD 331.6 Mn |

| Historical Data for: | 2020 To 2024 | Forecast Period: | 2025 To 2032 |

| Forecast Period 2025 to 2032 CAGR: | 4.50% | 2032 Value Projection: | USD 451.3 Mn |

Trivalent chromium finishing is the process of electroplating a thin layer of chromium onto the surface of a metal substrate. Chromium plating provides corrosion resistance, wear resistance, and an aesthetically pleasing shine to the substrate. The process involves submerging a metal part in a water-based solution containing trivalent chromium salts and electrical current is applied to deposition a microscopically thin chrome layer on the substrate surface. Trivalent chromium is less toxic and more environmentally friendly than previous hexavalent chromium finishing methods. It protects metal surfaces from corrosion and abrasion and improves appearance in various industrial and architectural applications. Trivalent chromium coatings are known to provide excellent corrosion protection, hardness, wear and chemical resistance properties. Stringent environmental regulations regarding the use of hexavalent chromium have stimulated greater adoption of trivalent chromium finishing processes in recent years. Advancements in plating technologies have improved the decorative appeal and durability of trivalent chromium coatings. The global trivalent chromium finishing market is expected to grow significantly over the forecast period owing to rising industrialization and manufacturing activities worldwide.

Market Dynamics:

The trivalent chromium finishing market is driven by stringent environmental regulations banning the use of carcinogenic hexavalent chromium globally. The EU REACH and UL standards necessitating the shift to non-toxic trivalent chrome plating, along with initiatives by the Environmental Protection Agency (EPA), are boosting market growth. The growing construction and automotive industries utilizing decorative and functional chrome plating are augmenting demand. However, the availability of alternative surface treatment methods can restrain the market. The development of green trivalent chrome plating solutions without restricting corrosion protection or operational properties offers opportunities for market expansion.

Key features of the study:

This report provides in-depth analysis of the global trivalent chromium finishing market, and provides market size (US$ Million) and compound annual growth rate (CAGR%) for the forecast period (2025-2032), considering 2024 as the base year.

It elucidates potential revenue opportunities across different segments and explains attractive investment proposition matrices for this market

This study also provides key insights about market drivers, restraints, opportunities, new product launches or approval, market trends, regional outlook, and competitive strategies adopted by key players

It profiles key players in the global trivalent chromium finishing market based on the following parameters - company highlights, products portfolio, key highlights, financial performance, and strategies

Key companies covered as a part of this study include Kakihara Industries Co., Ltd.; Ronatec C2C, Inc., MacDermid, Inc.; Atotech; Sarrel Group; Chem Processing, Inc.

Insights from this report would allow marketers and the management authorities of the companies to make informed decisions regarding their future product launches, type up-gradation, market expansion, and marketing tactics

The global trivalent chromium finishing market report caters to various stakeholders in this industry including investors, suppliers, product manufacturers, distributors, new entrants, and financial analysts

Stakeholders would have ease in decision-making through various strategy matrices used in analyzing the global trivalent chromium finishing market

Trivalent Chromium Finishing Market Segmentation

- Trivalent Chromium Finishing Market by System

- Plating

- Decorative Plating

- Functional Plating

- Conversion Coatings

- Decorative Conversion Coatings

- Functional Conversion Coatings

- Passivation

- Trivalent Chromium Finishing Market by Application

- Decorative

- Functional

- Trivalent Chromium Finishing Market by End-use

- Automotive

- Oil & Gas

- Aerospace

- Hydraulics & Heavy Machinery

- Others

- Trivalent Chromium Finishing Market by Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

- Company Profiles

- Kakihara Industries Co., Ltd.;

- Ronatec C2C, Inc.,

- MacDermid, Inc.;

- Atotech;

- Sarrel Group;

- Chem Processing, Inc.

Table of Contents

1. Research Objectives and Assumptions

- Research Objectives

- Assumptions

- Abbreviations

2. Market Purview

- Report Description

- Market Definition and Scope

- Executive Summary

- Trivalent Chromium Finishing Market, By System

- Trivalent Chromium Finishing Market, By Application

- Trivalent Chromium Finishing Market, By End-Use

- Trivalent Chromium Finishing Market, By Region

- Coherent Opportunity Map (COM)

3. Market Dynamics, Regulations, and Trends Analysis

- Market Dynamics

- Driver

- Understanding the growing need for space exploration

- Space flight safety

- Restraint

- Opportunities

- Impact Analysis

- Key Highlights

- Regulatory Scenario

- Product Launches/Approvals

- PEST Analysis

- PORTER's Analysis

- Merger and Acquisition Scenario

4. Trivalent Chromium Finishing Market -Impact of Coronavirus (COVID-19) Pandemic

- COVID-19 Epidemiology

- Supply Side and Demand Side Analysis

- Impact Space Medicine Market

5. Trivalent Chromium Finishing Market, By System, 2020-2032, (US$ Mn)

- Introduction

- Market Share Analysis, 2025 and 2032 (%)

- Y-o-Y Growth Analysis, 2021 - 2032

- Segment Trends

- Plating

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, 2020-2032,(US$ Mn)

- Decorative Plating

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, 2020-2032,(US$ Mn)

- Functional Plating

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, 2020-2032,(US$ Mn)

- Conversion Coatings

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, 2020-2032,(US$ Mn)

- Decorative Conversion Coatings

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, 2020-2032,(US$ Mn)

- Functional Conversion Coatings

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, 2020-2032,(US$ Mn)

- Passivation

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, 2020-2032,(US$ Mn)

6. Trivalent Chromium Finishing Market, By Application, 2020-2032, (US$ Mn)

- Introduction

- Market Share Analysis, 2025 and 2032 (%)

- Y-o-Y Growth Analysis, 2021 - 2032

- Segment Trends

- Decorative

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, 2020-2032,(US$ Mn)

- Functional

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, 2020-2032,(US$ Mn)

7. Trivalent Chromium Finishing Market, By End-Use , 2020-2032, (US$ Mn)

- Introduction

- Market Share Analysis, 2025 and 2032 (%)

- Y-o-Y Growth Analysis, 2021 - 2032

- Segment Trends

- Automotive

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, 2020-2032,(US$ Mn)

- Oil & Gas

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, 2020-2032,(US$ Mn)

- Aerospace

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, 2020-2032,(US$ Mn)

- Hydraulics & Heavy Machinery

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, 2020-2032,(US$ Mn)

- Others

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, 2020-2032,(US$ Mn)

8. Trivalent Chromium Finishing Market , By Region, 2020-2032, (US$ Mn)

- Introduction

- Market Share Analysis, By Region, 2025 and 2032 (%)

- Y-o-Y Growth Analysis, For Region 2021 -2032

- Country Trends

- North America

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, By System, 2020-2032,(US$ Mn)

- Market Size and Forecast, and Y-o-Y Growth, By Application, 2020-2032,(US$ Mn)

- Market Size and Forecast, and Y-o-Y Growth, By End Use, 2020-2032,(US$ Mn)

- Market Size and Forecast, and Y-o-Y Growth, By Country, 2020-2032,(US$ Mn)

- U.S.

- Canada

- Latin America

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, By System, 2020-2032,(US$ Mn)

- Market Size and Forecast, and Y-o-Y Growth, By Application, 2020-2032,(US$ Mn)

- Market Size and Forecast, and Y-o-Y Growth, By End Use, 2020-2032 (US$ Mn)

- Market Size and Forecast, and Y-o-Y Growth, By Country, 2020-2032,(US$ Mn)

- Brazil

- Argentina

- Mexico

- Rest of Latin America

- Europe

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, By System, 2020-2032,(US$ Mn)

- Market Size and Forecast, and Y-o-Y Growth, By Application, 2020-2032 (US$ Mn)

- Market Size and Forecast, and Y-o-Y Growth, By End User, 2020-2032,(US$ Mn)

- Market Size and Forecast, and Y-o-Y Growth, By Country, 2020-2032 (US$ Mn)

- Germany

- U.K.

- Spain

- France

- Italy

- Russia

- Rest of Europe

- Asia Pacific

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, By System, 2020-2032,(US$ Mn)

- Market Size and Forecast, and Y-o-Y Growth, By Application, 2020-2032,(US$ Mn)

- Market Size and Forecast, and Y-o-Y Growth, By End Use, 2020-2032,(US$ Mn)

- Market Size and Forecast, and Y-o-Y Growth, By Country, 2020-2032,(US$ Mn)

- China

- India

- Japan

- Australia

- South Korea

- ASEAN

- Rest of Asia Pacific

- Middle East

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, By System, 2020-2032,(US$ Mn)

- Market Size and Forecast, and Y-o-Y Growth, By Application, 2020-2032,(US$ Mn)

- Market Size and Forecast, and Y-o-Y Growth, By End Use, 2020-2032,(US$ Mn)

- Market Size and Forecast, and Y-o-Y Growth, By Country, 2020-2032,(US$ Mn)

- GCC Countries

- Israel

- Rest of Middle East

- Africa

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, By System, 2020-2032,(US$ Mn)

- Market Size and Forecast, and Y-o-Y Growth, By Application, 2020-2032,(US$ Mn)

- Market Size and Forecast, and Y-o-Y Growth, By End Use, 2020-2032,(US$ Mn)

- Market Size and Forecast, and Y-o-Y Growth, By Country/Region, 2020-2032,(US$ Mn)

- South Africa

- North Africa

- Central Africa

9. Competitive Landscape

- Kakihara Industries Co., Ltd.

- Company Highlights

- Product Portfolio

- Key Highlights

- Financial Performance

- Strategies

- Ronatec C2C, Inc.

- Company Highlights

- Product Portfolio

- Key Highlights

- Financial Performance

- Strategies

- MacDermid, Inc.,

- Company Highlights

- Product Portfolio

- Key Highlights

- Financial Performance

- Strategies

- Atotech

- Company Highlights

- Product Portfolio

- Key Highlights

- Financial Performance

- Chem Processing, Inc,

- Company Highlights

- Product Portfolio

- Key Highlights

- Financial Performance

- Strategies

- Sarrel Group,

- Company Highlights

- Product Portfolio

- Key Highlights

- Financial Performance

- Strategies

- Analyst Views

10. Section

- Research Methodology

- About us