|

市场调查报告书

商品编码

1685145

发泡聚丙烯 (EPP) 市场机会、成长动力、产业趋势分析及 2025 - 2034 年预测Expanded Polypropylene (EPP) Foam Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

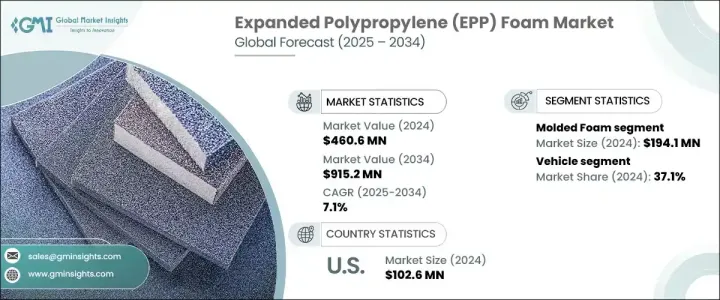

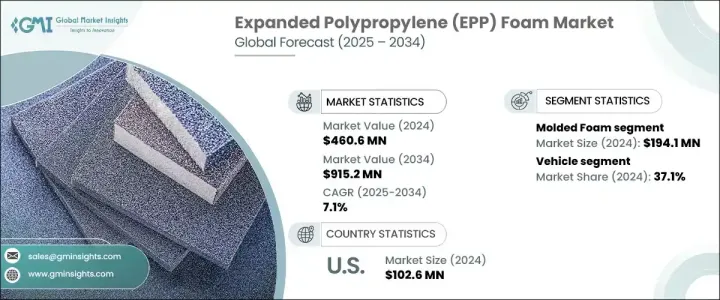

2024 年全球发泡聚丙烯市场规模达到 4.606 亿美元,预计 2025 年至 2034 年期间的复合年增长率为 7.1%。这一成长主要受到汽车、包装、航太和消费品等主要产业需求不断增长的推动。随着企业不断寻求轻质和高性能材料,EPP 泡棉因其出色的缓衝、抗衝击和能量吸收能力而脱颖而出。这些特性使其成为多个领域不可或缺的材料,尤其是在减轻重量和耐用性至关重要的行业。

EPP 泡沫越来越受欢迎,是因为与传统泡沫材料相比,它具有多功能性和优异的性能。它因其高强度重量比、隔热性和可回收性而广受认可,符合全球永续发展的趋势。随着严格的法规鼓励使用环保材料,製造商正在将 EPP 泡沫融入其产品中以满足不断发展的行业标准。此外,製造技术的进步正在提高产品品质、客製化选项和成本效率,进一步推动其采用。

| 市场范围 | |

|---|---|

| 起始年份 | 2024 |

| 预测年份 | 2025-2034 |

| 起始值 | 4.606 亿美元 |

| 预测值 | 9.152亿美元 |

| 复合年增长率 | 7.1% |

按类型细分的市场包括珠状泡棉、模製泡棉、加工泡棉、汽车泡棉等。其中,模塑泡沫在2024年占据主导地位,价值为1.941亿美元。珠状泡棉广泛用于汽车、包装和电子产品,因其减震和绝缘性能而受到重视。人造泡棉以其客製化能力而闻名,可用于需要客製化解决方案的行业,例如医疗设备和保护包装。 EPP 泡沫类型的多样性确保了市场的稳定扩张,满足了行业特定的需求,同时支援向轻质、高性能材料的转变。

市场也按应用程式细分,类别包括车辆、包装、消费品、航太、建筑、体育和休閒等。 2024 年,汽车占据了 37.1% 的市场份额,随着汽车製造商继续优先考虑节能和抗衝击材料,需求预计会增加。在包装方面,EPP泡棉为电子产品、电器和易腐物品等易碎商品提供卓越的保护。电子商务产业的快速扩张进一步加速了其对保护性包装解决方案的需求。航太製造商越来越依赖 EPP 泡沫的抗衝击和隔热性能,而其在消费品中的适应性凸显了其在各个行业中的重要性。

2024 年,美国发泡聚丙烯市场产值达到 1.026 亿美元,未来几年将大幅成长。强大的汽车产业优先考虑轻量化和吸能材料,仍然是这一成长的主要驱动力。此外,蓬勃发展的电子商务产业也推动了对先进保护性包装的需求,以适应消费者购买行为的转变。美国拥有先进的製造设施并且注重创新,进一步巩固了该国在全球 EPP 泡沫市场的领先地位。随着对高性能和永续材料的需求不断增长,EPP 泡沫预计将在多个行业中发挥更大的作用,推动长期市场扩张。

目录

第 1 章:方法论与范围

- 市场范围和定义

- 基础估算与计算

- 预测计算

- 资料来源

- 基本的

- 次要

- 付费来源

- 公共资源

第 2 章:执行摘要

第 3 章:产业洞察

- 产业生态系统分析

- 影响价值链的因素

- 利润率分析

- 中断

- 未来展望

- 製造商

- 经销商

- 供应商概况

- 利润率分析

- 重要新闻及倡议

- 监管格局

- 衝击力

- 成长动力

- 产业陷阱与挑战

- 成长潜力分析

- 波特的分析

- PESTEL 分析

第四章:竞争格局

- 介绍

- 公司市占率分析

- 竞争定位矩阵

- 战略展望矩阵

第 5 章:市场估计与预测:按类型,2021 年至 2034 年

- 主要趋势

- 珠状泡沫

- 模塑泡沫

- 人造泡沫

- 汽车泡棉

- 其他的

第 6 章:市场估计与预测:按应用,2021 年至 2034 年

- 主要趋势

- 车辆

- 包装

- 消费品

- 航太

- 建筑与施工

- 运动与休閒

- 其他的

第 7 章:市场估计与预测:依最终用途,2021 年至 2034 年

- 主要趋势

- 汽车

- 电子产品

- 医疗的

- 包装

- 航太

- 建造

- 其他的

第 8 章:市场估计与预测:按地区,2021 年至 2034 年

- 主要趋势

- 北美洲

- 我们

- 加拿大

- 欧洲

- 英国

- 德国

- 法国

- 义大利

- 西班牙

- 俄罗斯

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 澳洲

- 拉丁美洲

- 巴西

- 墨西哥

- 中东及非洲

- 南非

- 沙乌地阿拉伯

- 阿联酋

第九章:公司简介

- JSP Corporation

- BASF SE

- Kaneka Corporation

- Furukawa Electric Co.

- DS Smith PLC

- Hanwha Corporation

- Sonoco Products Company

- The Woodbridge Group

- Knauf Industries GmbH

- Greiner Holding AG

- Recticel NV

- Armacell International GmbH

- Zotefoams plc

- Swedfoam AB

- FoamPartner AG

The Global Expanded Polypropylene Foam Market reached USD 460.6 million in 2024 and is projected to expand at a CAGR of 7.1% between 2025 and 2034. This growth is largely driven by increasing demand from key industries such as automotive, packaging, aerospace, and consumer goods. As businesses continue to seek lightweight and high-performance materials, EPP foam stands out for its exceptional cushioning, impact resistance, and energy absorption capabilities. These properties make it an indispensable material across multiple sectors, especially in industries where weight reduction and durability are critical.

EPP foam's growing popularity stems from its versatility and superior performance compared to conventional foam materials. It is widely recognized for its high strength-to-weight ratio, thermal insulation, and recyclability, aligning with the global push toward sustainability. With stringent regulations encouraging eco-friendly materials, manufacturers are integrating EPP foam into their products to meet evolving industry standards. Additionally, advancements in manufacturing techniques are enhancing product quality, customization options, and cost-efficiency, further fueling its adoption.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $460.6 Million |

| Forecast Value | $915.2 Million |

| CAGR | 7.1% |

Market segmentation by type includes bead foam, molded foam, fabricated foam, automotive foam, and others. Among these, molded foam dominated in 2024, accounting for USD 194.1 million. Bead foam, widely used in automotive, packaging, and electronics, is valued for its shock-absorbing and insulating properties. Fabricated foam, known for its customization capabilities, serves industries requiring tailored solutions, such as medical devices and protective packaging. The diverse range of EPP foam types ensures a steady market expansion, catering to industry-specific demands while supporting the transition toward lightweight, high-performance materials.

The market is also segmented by application, with categories including vehicles, packaging, consumer goods, aerospace, building and construction, sports and leisure, and others. Vehicles accounted for a substantial 37.1% market share in 2024, with demand expected to rise as automakers continue prioritizing energy-efficient and impact-resistant materials. In packaging, EPP foam provides superior protection for fragile goods such as electronics, appliances, and perishables. The rapid expansion of the e-commerce industry has further accelerated its demand for protective packaging solutions. Aerospace manufacturers increasingly rely on EPP foam for impact resistance and thermal insulation, while its adaptability in consumer goods highlights its importance across various industries.

The U.S. expanded polypropylene foam market generated USD 102.6 million in 2024 and is poised for significant growth in the coming years. A strong automotive industry, prioritizing lightweight and energy-absorbing materials, remains a primary driver of this growth. Additionally, the booming e-commerce sector has fueled the need for advanced protective packaging, aligning with shifting consumer purchasing behaviors. The presence of advanced manufacturing facilities and a focus on innovation in the U.S. further solidify the country's leading position in the global EPP foam market. As demand for high-performance and sustainable materials continues to rise, EPP foam is expected to play an even greater role across multiple industries, driving long-term market expansion.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope & definitions

- 1.2 Base estimates & calculations

- 1.3 Forecast calculations

- 1.4 Data sources

- 1.4.1 Primary

- 1.4.2 Secondary

- 1.4.2.1 Paid sources

- 1.4.2.2 Public sources

Chapter 2 Executive Summary

- 2.1 Industry synopsis, 2021-2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Factor affecting the value chain

- 3.1.2 Profit margin analysis

- 3.1.3 Disruptions

- 3.1.4 Future outlook

- 3.1.5 Manufacturers

- 3.1.6 Distributors

- 3.2 Supplier landscape

- 3.3 Profit margin analysis

- 3.4 Key news & initiatives

- 3.5 Regulatory landscape

- 3.6 Impact forces

- 3.6.1 Growth drivers

- 3.6.2 Industry pitfalls & challenges

- 3.7 Growth potential analysis

- 3.8 Porter’s analysis

- 3.9 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.3 Competitive positioning matrix

- 4.4 Strategic outlook matrix

Chapter 5 Market Estimates & Forecast, By Type, 2021-2034 (USD Million) (Kilo Tons)

- 5.1 Key trends

- 5.2 Bead foam

- 5.3 Molded foam

- 5.4 Fabricated foam

- 5.5 Automotive foam

- 5.6 Others

Chapter 6 Market Estimates & Forecast, By Application, 2021-2034 (USD Million) (Kilo Tons)

- 6.1 Key trends

- 6.2 Vehicle

- 6.3 Packaging

- 6.4 Consumer goods

- 6.5 Aerospace

- 6.6 Building & construction

- 6.7 Sports & leisure

- 6.8 Others

Chapter 7 Market Estimates & Forecast, By End Use, 2021-2034 (USD Million) (Kilo Tons)

- 7.1 Key trends

- 7.2 Automotive

- 7.3 Electronics

- 7.4 Medical

- 7.5 Packaging

- 7.6 Aerospace

- 7.7 Construction

- 7.8 Others

Chapter 8 Market Estimates & Forecast, By Region, 2021-2034 (USD Million) (Kilo Tons)

- 8.1 Key trends

- 8.2 North America

- 8.2.1 U.S.

- 8.2.2 Canada

- 8.3 Europe

- 8.3.1 UK

- 8.3.2 Germany

- 8.3.3 France

- 8.3.4 Italy

- 8.3.5 Spain

- 8.3.6 Russia

- 8.4 Asia Pacific

- 8.4.1 China

- 8.4.2 India

- 8.4.3 Japan

- 8.4.4 South Korea

- 8.4.5 Australia

- 8.5 Latin America

- 8.5.1 Brazil

- 8.5.2 Mexico

- 8.6 MEA

- 8.6.1 South Africa

- 8.6.2 Saudi Arabia

- 8.6.3 UAE

Chapter 9 Company Profiles

- 9.1 JSP Corporation

- 9.2 BASF SE

- 9.3 Kaneka Corporation

- 9.4 Furukawa Electric Co.

- 9.5 DS Smith PLC

- 9.6 Hanwha Corporation

- 9.7 Sonoco Products Company

- 9.8 The Woodbridge Group

- 9.9 Knauf Industries GmbH

- 9.10 Greiner Holding AG

- 9.11 Recticel NV

- 9.12 Armacell International GmbH

- 9.13 Zotefoams plc

- 9.14 Swedfoam AB

- 9.15 FoamPartner AG