|

市场调查报告书

商品编码

1721477

生物相容性 3D 列印材料市场机会、成长动力、产业趋势分析及 2025 - 2034 年预测Biocompatible 3D Printing Materials Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

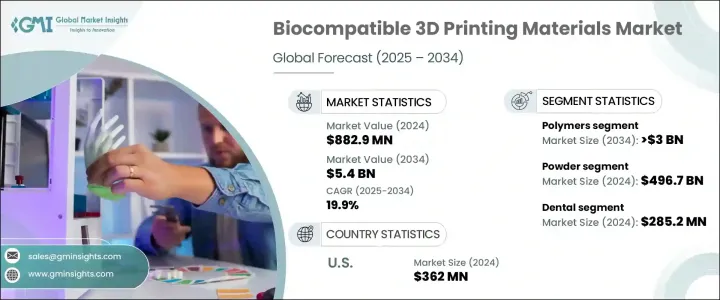

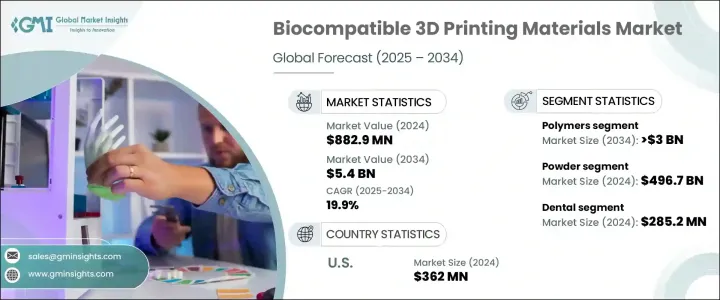

2024 年全球生物相容性 3D 列印材料市场价值为 8.829 亿美元,预计到 2034 年将以 19.9% 的复合年增长率成长,达到 54 亿美元。这一成长轨迹反映了对具有高精度、高性能和患者相容性的下一代医疗材料日益增长的需求。对先进医疗干预的需求日益增长,尤其是老龄化人口,推动了 3D 列印材料在各种医疗保健应用中的应用。随着全球医疗保健系统转向以患者为中心的方法,使用生物相容性 3D 列印材料对于提供客製化、高效和微创的医疗解决方案变得至关重要。除了骨科和义肢之外,这些材料在牙科护理、手术器械、组织支架和再生医学领域也得到了广泛的关注。这些材料能够支持复杂的几何形状、改善手术效果并缩短恢復时间,使其成为现代医疗製造中必不可少的组成部分。随着有利的监管政策、不断增长的研发投资以及个人化医疗意识的不断提高,已开发经济体和新兴经济体的市场继续呈现强劲发展势头。

市场的成长也主要归因于积层製造技术的快速进步,包括选择性雷射烧结 (SLS)、立体光刻 (SLA) 和直接金属雷射烧结 (DMLS)。这些技术能够生产符合个别解剖要求的高精度、生物相容性的医疗零件。材料创新进一步促进了市场扩张,高性能金属合金、聚合物和生物墨水的发展提高了印刷生物医学产品的可靠性、耐用性和相容性。这些突破对于创造具有更高性能和更低併发症发生率的功能性植入物、义肢和手术工具尤其重要。

| 市场范围 | |

|---|---|

| 起始年份 | 2024 |

| 预测年份 | 2025-2034 |

| 起始值 | 8.829亿美元 |

| 预测值 | 54亿美元 |

| 复合年增长率 | 19.9% |

市场分为聚合物、金属和其他材料类型,其中聚合物类别预计将引领未来成长。预计到 2034 年该领域规模将达到 30 亿美元,复合年增长率为 19.9%。在针对特定患者的植入物、牙齿修復体和义肢的生产中,对客製化 3D 列印聚合物的需求不断增长。聚醚醚酮 (PEEK)、聚乳酸 (PLA) 和生物可吸收聚合物等先进材料因其卓越的强度、生物相容性以及对复杂医疗要求的适应性而越来越受到青睐。

2024 年牙科行业的产值达到 2.852 亿美元,并且由于牙齿脱落、牙周病和龋齿等疾病的患病率不断上升而稳步增长。 SLA、数位光处理 (DLP) 和 SLS 等技术大大提高了牙齿修復的精确度、强度和贴合度,从而推动了牙科专业人士和患者的需求。

2024 年,美国生物相容性 3D 列印材料市场价值为 3.62 亿美元,由于老龄化人口患牙科和骨科疾病的风险增加,该市场正在经历显着增长。快速製造客製化义肢和植入物的能力加速了全国医疗机构采用 3D 列印技术。

全球市场的主要参与者包括 Stratasys、3D Systems、GE Additive、Formlabs、Materialise、Renishaw、Royal DSM、Arkema、Solvay、Cellink、Concept Laser、EOS、Evonik Industries、EnvisionTEC 和 Hoganas。这些公司正在积极投资先进的高性能材料,以提高生物相容性和应用精度。与医疗保健提供者和研究机构的策略合作有助于扩大 3D 列印的临床实用性。此外,持续的产品开发专注于创新、针对特定条件的解决方案,使市场领导者能够增强其全球影响力和竞争地位。

目录

第一章:方法论与范围

第二章:执行摘要

第三章:行业洞察

- 产业生态系统分析

- 产业衝击力

- 成长动力

- 医疗保健产业对生物相容性3D列印的需求日益增长

- 3D列印材料的技术进步

- 个人化医疗日益普及

- 产业陷阱与挑战

- 生物相容性3D列印材料成本高

- 严格的监管要求

- 成长动力

- 成长潜力分析

- 监管格局

- 技术格局

- 未来市场趋势

- 差距分析

- 波特的分析

- PESTEL分析

第四章:竞争格局

- 介绍

- 公司市占率分析

- 公司矩阵分析

- 主要市场参与者的竞争分析

- 竞争定位矩阵

- 策略仪表板

第五章:市场估计与预测:按材料类型,2021 - 2034 年

- 主要趋势

- 聚合物

- 金属

- 其他材料类型

第六章:市场估计与预测:依形式,2021 - 2034 年

- 主要趋势

- 粉末

- 液体

- 其他形式

第七章:市场估计与预测:按应用,2021 - 2034 年

- 主要趋势

- 牙科

- 药物输送系统

- 手术器械及植入物

- 组织工程

- 心血管

- 骨科

- 其他应用

第八章:市场估计与预测:按地区,2021 - 2034 年

- 主要趋势

- 北美洲

- 我们

- 加拿大

- 欧洲

- 德国

- 英国

- 法国

- 西班牙

- 义大利

- 荷兰

- 亚太地区

- 中国

- 日本

- 印度

- 澳洲

- 韩国

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- 中东和非洲

- 南非

- 沙乌地阿拉伯

- 阿联酋

第九章:公司简介

- Arkema

- BIO INX

- Cellink

- EnvisionTEC

- EOS

- Evonik Industries

- Formlabs

- GE Additive

- Hoganas

- Materialise

- Renishaw

- Royal DSM

- Solvay

- Stratasys

- 3D Systems

The Global Biocompatible 3D Printing Materials Market was valued at USD 882.9 million in 2024 and is estimated to grow at a CAGR of 19.9% to reach USD 5.4 billion by 2034. This growth trajectory reflects the rising demand for next-generation medical materials that offer high levels of precision, performance, and patient compatibility. The increasing need for advanced medical interventions, particularly among the aging population, is fueling the adoption of 3D-printed materials across a variety of healthcare applications. As global healthcare systems pivot toward more patient-centric approaches, the use of biocompatible 3D printing materials is becoming critical in delivering customized, efficient, and minimally invasive medical solutions. In addition to orthopedics and prosthetics, the materials are gaining widespread traction in dental care, surgical tools, tissue scaffolds, and regenerative medicine. The ability of these materials to support complex geometries, enhance surgical outcomes, and reduce recovery times positions them as essential components in modern medical manufacturing. With favorable regulatory policies, growing R&D investments, and expanding awareness about personalized healthcare, the market continues to experience substantial momentum across both developed and emerging economies.

The market's growth is also largely attributed to rapid advancements in additive manufacturing techniques, including Selective Laser Sintering (SLS), Stereolithography (SLA), and Direct Metal Laser Sintering (DMLS). These technologies enable the production of highly accurate and biocompatible medical components that align with individual anatomical requirements. Material innovations further contribute to market expansion, with the development of high-performance metal alloys, polymers, and bioinks improving the reliability, durability, and compatibility of printed biomedical products. These breakthroughs are particularly relevant in creating functional implants, prosthetics, and surgical tools that offer improved performance and reduced complication rates.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $882.9 Million |

| Forecast Value | $5.4 Billion |

| CAGR | 19.9% |

The market is segmented into polymers, metals, and other material types, with the polymers category expected to lead future growth. This segment is projected to reach USD 3 billion by 2034, growing at a CAGR of 19.9%. The rising demand for customized 3D-printed polymers is evident in the production of patient-specific implants, dental restorations, and prosthetic devices. Advanced materials such as Polyether Ether Ketone (PEEK), Polylactic Acid (PLA), and bioresorbable polymers are gaining ground due to their superior strength, biocompatibility, and adaptability to complex medical requirements.

The dental sector accounted for USD 285.2 million in 2024 and is expanding steadily, driven by the increasing prevalence of conditions like tooth loss, periodontal diseases, and dental caries. Technologies such as SLA, Digital Light Processing (DLP), and SLS have dramatically improved the precision, strength, and fit of dental restorations, boosting demand among dental professionals and patients alike.

The U.S. Biocompatible 3D Printing Materials Market was valued at USD 362 million in 2024 and is experiencing significant growth due to the aging population's heightened risk of dental and orthopedic issues. The ability to rapidly manufacture tailored prosthetics and implants has accelerated the adoption of 3D printing in medical facilities across the country.

Key players in the global market include Stratasys, 3D Systems, GE Additive, Formlabs, Materialise, Renishaw, Royal DSM, Arkema, Solvay, Cellink, Concept Laser, EOS, Evonik Industries, EnvisionTEC, and Hoganas. These companies are actively investing in advanced, high-performance materials to improve biocompatibility and application precision. Strategic collaborations with healthcare providers and research organizations are helping to expand the clinical utility of 3D printing. Moreover, ongoing product development focused on innovative, condition-specific solutions is allowing market leaders to enhance their global footprint and competitive positioning.

Table of Contents

Chapter 1 Methodology and Scope

- 1.1 Market scope and definitions

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Base estimates and calculations

- 1.3.1 Base year calculation

- 1.3.2 Key trends for market estimation

- 1.4 Forecast model

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.5.2 Data mining sources

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Increasing demand of biocompatible 3D printing in healthcare industry

- 3.2.1.2 Technological advancements in 3D printing materials

- 3.2.1.3 Growing adoption of personalized medicine

- 3.2.2 Industry pitfalls and challenges

- 3.2.2.1 High cost of biocompatible 3D printing materials

- 3.2.2.2 Stringent regulatory requirements

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.5 Technology landscape

- 3.6 Future market trends

- 3.7 Gap analysis

- 3.8 Porter's analysis

- 3.9 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Strategy dashboard

Chapter 5 Market Estimates and Forecast, By Material Type, 2021 - 2034 ($ Mn)

- 5.1 Key trends

- 5.2 Polymers

- 5.3 Metals

- 5.4 Other material types

Chapter 6 Market Estimates and Forecast, By Form, 2021 - 2034 ($ Mn)

- 6.1 Key trends

- 6.2 Powder

- 6.3 Liquid

- 6.4 Other forms

Chapter 7 Market Estimates and Forecast, By Application, 2021 - 2034 ($ Mn)

- 7.1 Key trends

- 7.2 Dental

- 7.3 Drug delivery systems

- 7.4 Surgical tools and implants

- 7.5 Tissue engineering

- 7.6 Cardiovascular

- 7.7 Orthopedic

- 7.8 Other applications

Chapter 8 Market Estimates and Forecast, By Region, 2021 - 2034 ($ Mn)

- 8.1 Key trends

- 8.2 North America

- 8.2.1 U.S.

- 8.2.2 Canada

- 8.3 Europe

- 8.3.1 Germany

- 8.3.2 UK

- 8.3.3 France

- 8.3.4 Spain

- 8.3.5 Italy

- 8.3.6 Netherlands

- 8.4 Asia Pacific

- 8.4.1 China

- 8.4.2 Japan

- 8.4.3 India

- 8.4.4 Australia

- 8.4.5 South Korea

- 8.5 Latin America

- 8.5.1 Brazil

- 8.5.2 Mexico

- 8.5.3 Argentina

- 8.6 Middle East and Africa

- 8.6.1 South Africa

- 8.6.2 Saudi Arabia

- 8.6.3 UAE

Chapter 9 Company Profiles

- 9.1 Arkema

- 9.2 BIO INX

- 9.3 Cellink

- 9.4 EnvisionTEC

- 9.5 EOS

- 9.6 Evonik Industries

- 9.7 Formlabs

- 9.8 GE Additive

- 9.9 Hoganas

- 9.10 Materialise

- 9.11 Renishaw

- 9.12 Royal DSM

- 9.13 Solvay

- 9.14 Stratasys

- 9.15 3D Systems