|

市场调查报告书

商品编码

1740763

工业缝纫机市场机会、成长动力、产业趋势分析及2025-2034年预测Industrial Sewing Machine Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

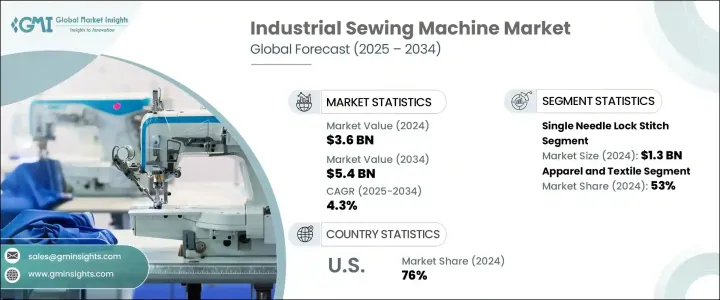

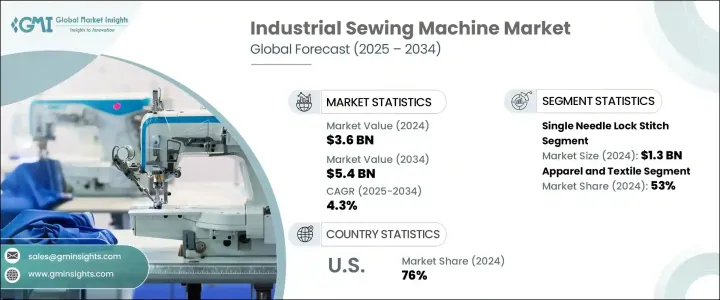

2024年,全球工业缝纫机市场规模达36亿美元,预计到2034年将以4.3%的复合年增长率成长,达到54亿美元。这一增长主要源于全球对服装和纺织品日益增长的需求,而人口增长、城镇化和消费者偏好的不断变化又推动了这一需求。工业缝纫机在支援大批量纺织服装生产方面发挥关键作用,对于追求速度、精确度和效率的製造商而言,它至关重要。机器人、物联网连接和自动化等先进技术的整合显着提高了营运产出,减少了对劳动力的依赖,并改善了製造环境中的品质控制。随着新兴经济体企业持续工业化,对更先进缝纫系统的需求也日益增长。时尚潮流的快速变化、快时尚的兴起以及对可扩展生产的需求,进一步加剧了对先进缝纫设备的需求。如今,工业缝纫机已超越了基本功能,并配备了智慧系统,有助于简化生产流程、减少停机时间并提高缝纫一致性,最终提升全球製造商的获利能力。

市场上的机器类型多种多样,以满足不同的应用需求。主要类别包括双针锁式线迹、锯齿形线迹、单针锁式线迹、包缝、平缝以及其他专用系统。其中,单针锁式线迹细分市场在2024年占据主导地位,贡献了超过13亿美元的收入。预测显示,到2034年,该细分市场的复合年增长率将达到4.8%左右。这类机器在服装製造业中尤其受到重视,因为它在轻质和标准布料上进行直线缝纫时,可靠性和简便性都很高。目前,该细分市场的创新包括自动穿线、先进的马达功能和数位张力控制等功能,这些功能简化了操作,减轻了操作员的疲劳,同时确保了线蹟的均匀性。

| 市场范围 | |

|---|---|

| 起始年份 | 2024 |

| 预测年份 | 2025-2034 |

| 起始值 | 36亿美元 |

| 预测值 | 54亿美元 |

| 复合年增长率 | 4.3% |

从产业应用角度来看,市场分为服装和纺织品、汽车、家具和室内装潢、皮革製品以及其他工业领域。服装和纺织品类别在2024年占据主导地位,占总市场份额的53%以上。随着对能够快速、精确地执行多种功能的高输出机器的需求不断增长,这一细分市场将继续增长。自动剪线、可编程针迹图案和基于感测器的调整等增强功能越来越多地被应用于服务于该行业的机器中,从而提高了生产效率并降低了误差幅度。

就销售通路而言,市场分为直接销售和间接销售。 2024年,由于对客製化解决方案和全面售后服务的需求日益增长,直接销售将引领分销格局。製造商青睐这一管道,因为它有助于建立长期的业务关係,确保重复订单,并更深入地了解客户需求。透过直接接触,公司还可以提供培训、维护和安装支援——这些对大型工业客户至关重要。

儘管如此,间接销售管道对于市场扩张仍然至关重要,尤其是在触达中小型企业方面。经销商在提供完整的产品系列、库存解决方案和本地化技术支援方面发挥关键作用。线上平台也已成为分销组合的重要组成部分,提供便利的服务、价格竞争力以及更丰富的机器选择。这种转变显着影响了寻求灵活、经济实惠方案的小型企业的采购决策。

从区域来看,北美在全球市场格局中扮演着重要角色。 2024年,美国占据该地区约76%的市场份额,创造了近7.6亿美元的收入。强大的技术基础设施、蓬勃发展的电商活动以及汽车和家具行业日益增长的生产需求等因素共同促成了北美的主导地位。美国纺织业也正在经历復苏,这得益于其对生产回流和永续生产方式的重视。这些发展趋势正在推动对先进工业缝纫解决方案的投资。

市场竞争仍维持中等集中度,领导企业合计市占率介于15%至20%之间。这些关键企业持续透过策略性收购、合作和设施升级进行扩张,以丰富产品线,拓展新的客户群,并保持竞争优势。

目录

第一章:方法论与范围

第二章:执行摘要

第三章:行业洞察

- 产业生态系统分析

- 影响价值链的因素。

- 利润率分析。

- 中断

- 未来展望

- 製成品

- 经销商

- 川普政府关税分析

- 对贸易的影响

- 贸易量中断

- 报復措施

- 对产业的影响

- 供给侧影响(原料)

- 主要材料价格波动

- 供应链重组

- 生产成本影响

- 需求面影响(售价)

- 价格传导至终端市场

- 市占率动态

- 消费者反应模式

- 受影响的主要公司

- 策略产业反应

- 供应链重组

- 定价和产品策略

- 政策参与

- 展望与未来考虑

- 对贸易的影响

- 供应商格局

- 重要新闻和倡议

- 监管格局

- 衝击力

- 成长动力

- 服装和纺织品需求不断增长

- 新兴经济体的工业成长

- 产业陷阱与挑战

- 初始成本高

- 来自低成本製造商的激烈竞争

- 成长动力

- 成长潜力分析

- 波特的分析

- PESTEL分析

第四章:竞争格局

- 介绍

- 公司市占率分析

- 竞争定位矩阵

- 战略展望矩阵

第五章:市场估计与预测:按机器类型,2021 - 2034 年

- 主要趋势

- 单针锁式线迹

- 双针锁式线迹

- 锯齿形缝线

- 包包缝纫

- 平缝纫

- 其他(套结机、臂式送料机等)

第六章:市场估计与预测:依营运模式,2021 年至 2034 年

- 主要趋势

- 手动的

- 半自动

- 全自动

第七章:市场估计与预测:按速度,2021 - 2034 年

- 主要趋势

- 高达 1000 spm

- 1000 至 2000 spm

- 2000 至 4000 spm

- 4000 spm以上

第八章:市场估计与预测:按线轴类型,2021 - 2034 年

- 主要趋势

- 大线轴

- 小线轴

第九章:市场估计与预测:按应用,2021 - 2034 年

- 主要趋势

- 服饰

- 非服装

- 鞋

- 包包

- 室内装潢

- 其他(绷带、敷料等)

第 10 章:市场估计与预测:按最终用途产业,2021 年至 2034 年

- 主要趋势

- 服装和纺织品

- 汽车

- 室内装潢和家具

- 皮革製品

- 其他(製鞋业、包装业等)

第 11 章:市场估计与预测:按配销通路,2021 年至 2034 年

- 主要趋势

- 直销

- 间接销售

第 12 章:市场估计与预测:按地区,2021 年至 2034 年

- 主要趋势

- 北美洲

- 我们

- 加拿大

- 欧洲

- 英国

- 德国

- 法国

- 义大利

- 西班牙

- 俄罗斯

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 澳洲

- 拉丁美洲

- 巴西

- 墨西哥

- MEA

- 阿联酋

- 沙乌地阿拉伯

- 南非

第十三章:公司简介

- AMF Reece

- Brother

- Consew

- Dohle

- Jack

- Juki

- Kansai Special

- Merrow

- Miller Weldmaster

- Pegasus

- Seiko Industries

- Singer

- Usha International

- Vetron Typical

- Yamato

The Global Industrial Sewing Machine Market was valued at USD 3.6 billion in 2024 and is estimated to grow at a CAGR of 4.3% to reach USD 5.4 billion by 2034. This expansion is largely driven by increasing global demand for apparel and textiles, propelled by population growth, urbanization, and evolving consumer preferences. Industrial sewing machines play a critical role in supporting high-volume textile and garment production, making them essential for manufacturers aiming for speed, precision, and efficiency. The integration of advanced technologies like robotics, IoT connectivity, and automation has significantly enhanced operational output, reduced labor dependency, and improved quality control in manufacturing environments. As businesses across emerging economies continue to industrialize, the demand for more sophisticated sewing systems continues to grow. Rapid shifts in fashion trends, the rise of fast fashion, and the need for scalable production have further intensified the need for advanced sewing equipment. Industrial sewing machines now go beyond basic functions and are developed to include intelligent systems that help streamline production, reduce downtime, and improve stitching consistency, ultimately boosting profitability for manufacturers globally.

Within the market, machine types vary to serve diverse applications. Key categories include double needle lock stitch, zigzag stitching, single needle lock stitch, overlock sewing, flatlock sewing, and other specialized systems. Among these, the single needle lock stitch segment led the category in 2024, contributing over USD 1.3 billion in revenue. Forecasts suggest this segment will witness a CAGR of around 4.8% through 2034. This machine type is particularly valued in garment manufacturing for its reliability and simplicity in performing straight-line stitching on lightweight and standard fabrics. Innovations in this segment now include features like automatic threading, advanced motor functions, and digital tension control, which simplify tasks and reduce fatigue for operators while ensuring stitch uniformity.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $3.6 Billion |

| Forecast Value | $5.4 Billion |

| CAGR | 4.3% |

From an industry application perspective, the market is divided into apparel and textiles, automotive, furniture and upholstery, leather goods, and other industrial sectors. The apparel and textile category held the dominant position in 2024, accounting for more than 53% of the total market share. This segment continues to grow as demand rises for high-output machines that can perform multiple functions with speed and precision. Enhanced features such as automatic thread trimming, programmable stitch patterns, and sensor-based adjustments are increasingly incorporated into machines serving this industry, leading to higher productivity and lower error margins.

Regarding sales channels, the market is split into direct and indirect sales. In 2024, direct sales led the distribution landscape, fueled by the growing need for tailor-made solutions and comprehensive after-sales services. Manufacturers prefer this channel as it helps in forging long-lasting business relationships, ensuring repeat orders, and enabling a deeper understanding of client requirements. Through direct engagement, companies can also offer training, maintenance, and installation support-factors critical for large-scale industrial clients.

Nevertheless, indirect sales channels remain crucial for market expansion, particularly in reaching small to mid-sized enterprises. Distributors play a key role in delivering complete product ranges, inventory solutions, and localized technical assistance. Online platforms have also become an important part of the distribution mix, offering convenience, price competitiveness, and easy access to a wider selection of machines. This shift has notably impacted purchasing decisions for small businesses seeking flexible, budget-friendly options.

Regionally, North America plays a prominent role in global market dynamics, with the United States commanding approximately 76% of the region's market in 2024 and generating close to USD 760 million in revenue. Factors such as strong technological infrastructure, rising e-commerce activities, and growing production needs in the automotive and furniture sectors have contributed to this dominance. The U.S. textile industry is also witnessing a revival driven by a focus on reshoring production and adopting sustainable practices. These developments are fueling investments in advanced industrial sewing solutions.

Market competition remains moderately concentrated, with leading companies collectively holding a market share between 15% and 20%. These key players continue to expand through strategic acquisitions, collaborations, and facility upgrades to diversify their offerings, access new customer segments, and maintain competitive advantage.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope & definitions

- 1.2 Base estimates & calculations

- 1.3 Forecast calculations.

- 1.4 Data sources

- 1.4.1 Primary

- 1.4.2 Secondary

- 1.4.2.1 Paid sources

- 1.4.2.2 Public sources

Chapter 2 Executive Summary

- 2.1 Industry synopsis, 2021 - 2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Factor affecting the value chain.

- 3.1.2 Profit margin analysis.

- 3.1.3 Disruptions

- 3.1.4 Future outlook

- 3.1.5 Manufactures

- 3.1.6 Distributors

- 3.2 Trump administration tariffs analysis

- 3.2.1 Impact on trade

- 3.2.1.1 Trade volume disruptions

- 3.2.1.2 Retaliatory measures

- 3.2.2 Impact on the industry

- 3.2.2.1 Supply-side impact (raw materials)

- 3.2.2.2 Price volatility in key materials

- 3.2.2.3 Supply chain restructuring

- 3.2.2.4 Production cost implications

- 3.2.2.5 Demand-side impact (selling price)

- 3.2.2.6 Price transmission to end markets

- 3.2.2.7 Market share dynamics

- 3.2.2.8 Consumer response patterns

- 3.2.3 Key companies impacted

- 3.2.4 Strategic industry responses

- 3.2.4.1 Supply chain reconfiguration

- 3.2.4.2 Pricing and product strategies

- 3.2.4.3 Policy engagement

- 3.2.5 Outlook and future considerations

- 3.2.1 Impact on trade

- 3.3 Supplier landscape

- 3.4 Key news & initiatives

- 3.5 Regulatory landscape

- 3.6 Impact forces

- 3.6.1 Growth drivers

- 3.6.1.1 Rising demand for apparel and textiles

- 3.6.1.2 Industrial growth in emerging economies

- 3.6.2 Industry pitfalls & challenges

- 3.6.2.1 High initial costs

- 3.6.2.2 Intense competition from low-cost manufacturers

- 3.6.1 Growth drivers

- 3.7 Growth potential analysis

- 3.8 Porter's analysis

- 3.9 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.3 Competitive positioning matrix

- 4.4 Strategic outlook matrix

Chapter 5 Market Estimates & Forecast, By Machine Type, 2021 - 2034 (USD Billion) (Thousand Units)

- 5.1 Key trends

- 5.2 Single needle lock stitch

- 5.3 Double needle lock stitch

- 5.4 Zigzag stitching

- 5.5 Overlock sewing

- 5.6 Flatlock sewing

- 5.7 Others (bartack machine, feed off the arm etc.)

Chapter 6 Market Estimates & Forecast, By Mode of Operation, 2021 - 2034 (USD Billion) (Thousand Units)

- 6.1 Key trends

- 6.2 Manual

- 6.3 Semi-automatic

- 6.4 Fully automatic

Chapter 7 Market Estimates & Forecast, By Speed, 2021 - 2034 (USD Billion) (Thousand Units)

- 7.1 Key trends

- 7.2 Up to 1000 spm

- 7.3 1000 to 2000 spm

- 7.4 2000 to 4000 spm

- 7.5 Above 4000 spm

Chapter 8 Market Estimates & Forecast, By Bobbin Type, 2021 - 2034 (USD Billion) (Thousand Units)

- 8.1 Key trends

- 8.2 Large bobbin

- 8.3 Small bobbin

Chapter 9 Market Estimates & Forecast, By Application, 2021 - 2034 (USD Billion) (Thousand Units)

- 9.1 Key trends

- 9.2 Apparel

- 9.3 Non-apparel

- 9.3.1 Shoes

- 9.3.2 Bags

- 9.3.3 Upholstery

- 9.3.4 Others (bandages and dressings etc.)

Chapter 10 Market Estimates & Forecast, By End Use Industry, 2021 - 2034 (USD Billion) (Thousand Units)

- 10.1 Key trends

- 10.2 Apparel and textile

- 10.3 Automotive

- 10.4 Upholstery and furniture

- 10.5 Leather goods

- 10.6 Others (footwear industry, packaging etc.)

Chapter 11 Market Estimates & Forecast, By Distribution Channel, 2021 - 2034 (USD Billion) (Thousand Units)

- 11.1 Key trends

- 11.2 Direct sales

- 11.3 Indirect sales

Chapter 12 Market Estimates & Forecast, By Region, 2021 - 2034 (USD Billion) (Thousand Units)

- 12.1 Key trends

- 12.2 North America

- 12.2.1 U.S.

- 12.2.2 Canada

- 12.3 Europe

- 12.3.1 UK

- 12.3.2 Germany

- 12.3.3 France

- 12.3.4 Italy

- 12.3.5 Spain

- 12.3.6 Russia

- 12.4 Asia Pacific

- 12.4.1 China

- 12.4.2 India

- 12.4.3 Japan

- 12.4.4 South Korea

- 12.4.5 Australia

- 12.5 Latin America

- 12.5.1 Brazil

- 12.5.2 Mexico

- 12.6 MEA

- 12.6.1 UAE

- 12.6.2 Saudi Arabia

- 12.6.3 South Africa

Chapter 13 Company Profiles

- 13.1 AMF Reece

- 13.2 Brother

- 13.3 Consew

- 13.4 Dohle

- 13.5 Jack

- 13.6 Juki

- 13.7 Kansai Special

- 13.8 Merrow

- 13.9 Miller Weldmaster

- 13.10 Pegasus

- 13.11 Seiko Industries

- 13.12 Singer

- 13.13 Usha International

- 13.14 Vetron Typical

- 13.15 Yamato