|

市场调查报告书

商品编码

1740923

单螺桿挤出机市场机会、成长动力、产业趋势分析及2025-2034年预测Single Screw Extruder Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

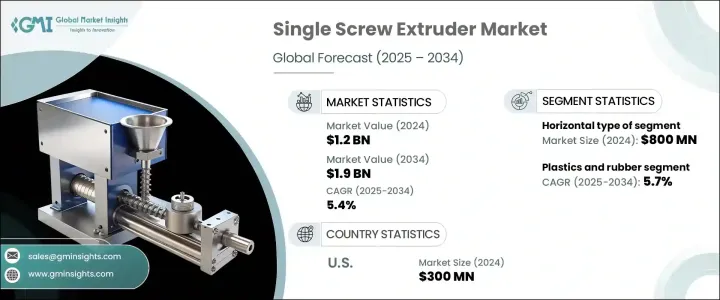

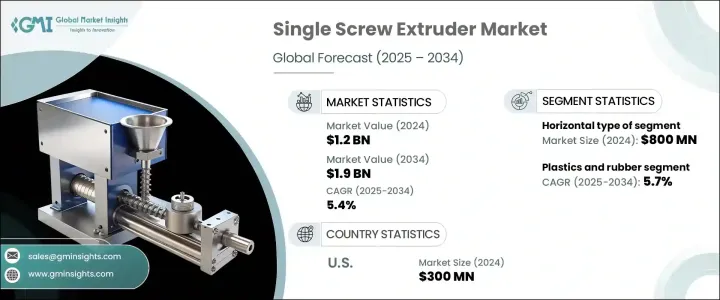

2024年,全球单螺桿挤出机市场规模达12亿美元,预计2034年将以5.4%的复合年增长率成长,达到19亿美元。这主要得益于塑胶製品需求的不断增长、技术创新以及食品、製药和製造等行业日益增长的效率提升需求。单螺桿挤出机用于生产各种塑胶製品,包括管材、板材和薄膜。包装和建筑领域塑胶用量的激增进一步刺激了市场需求。此外,自动化、温度控制和设备设计的进步也提高了这些机器的生产效率,使其对製造商的吸引力日益增强。

在食品和製药领域,对加工食品和先进药物传输系统日益增长的需求正在推动市场成长。单螺桿挤出机用于生产零食、谷物和控释片。这些机器的多功能性和高效性使其非常适合各行各业的大规模生产。此外,该技术也广泛应用于橡胶製品製造,因为挤出机能够实现软管和密封件等部件的大量生产。

| 市场范围 | |

|---|---|

| 起始年份 | 2024 |

| 预测年份 | 2025-2034 |

| 起始值 | 12亿美元 |

| 预测值 | 19亿美元 |

| 复合年增长率 | 5.4% |

单螺桿挤出机市场依挤出机类型划分,主要分为垂直和水平两大类。水平挤出机细分市场在 2024 年的价值为 8 亿美元,预计在 2025 年至 2034 年期间的复合年增长率为 5.6%,这得益于水平挤出机的可扩展性,使其适用于塑料、食品和橡胶等行业的大规模生产运营。水平挤出机因其高效处理高产量的能力而备受青睐。另一方面,以紧凑设计着称的垂直挤出机非常适合优先考虑空间优化的小型生产设施。这些挤出机为占地面积有限但仍需要可靠挤出工艺的运作提供了更节省空间的解决方案。

根据行业使用情况,塑胶和橡胶产业在2024年占了44%的份额。预计该产业在2025年至2034年期间的复合年增长率将达到5.7%。该产业对单螺桿挤出机的需求成长主要源自于塑胶回收的加大,以及此类挤出机在可回收材料和橡胶製品生产的应用日益增加。此外,食品饮料产业对单螺桿挤出机的需求也在显着增长,尤其是在生产零食、谷物食品和即食食品方面。随着消费者对加工食品和方便食品的需求不断增长,对高效率、大量挤出设备的需求也随之成长。

2024年,美国单螺桿挤出机市场规模达3亿美元。美国对永续製造和回收的重视是推动这一成长的关键因素,因为单螺桿挤出机通常用于加工再生塑胶和橡胶材料。技术创新和製造业自动化程度的提高,正在扩大这些挤出机在食品、饮料和製药等各个领域的应用。此外,对更高品质、更具成本效益产品的持续需求也推动了这些产业市场的成长。

市场的主要参与者包括 American Extruded International、Bausano & Figli、Extrudex、Graham Engineering 和 Milacron 等。为了提升市场地位,单螺桿挤出机市场的公司正专注于产品创新,尤其是在自动化和能源效率方面。他们还透过可客製化的解决方案扩展产品线,以满足食品和製药等特定行业的需求。与研究机构和其他行业领导者建立的策略合作伙伴关係促进了先进技术的开发,而对永续生产实践的投资则提升了其在重视环境责任的市场中的吸引力。

目录

第一章:方法论与范围

第二章:执行摘要

第三章:行业洞察

- 产业生态系统分析

- 影响价值链的因素

- 利润率分析

- 中断

- 未来展望

- 製造商

- 经销商

- 川普政府关税分析

- 对贸易的影响

- 贸易量中断

- 报復措施

- 对产业的影响

- 供给侧影响(原料)

- 主要材料价格波动

- 供应链重组

- 生产成本影响

- 需求面影响(售价)

- 价格传导至终端市场

- 市占率动态

- 消费者反应模式

- 供给侧影响(原料)

- 受影响的主要公司

- 策略产业反应

- 供应链重组

- 定价和产品策略

- 政策参与

- 展望与未来考虑

- 对贸易的影响

- 供应商格局

- 技术格局

- 重要新闻和倡议

- 监管格局

- 衝击力

- 成长动力

- 塑胶製品需求不断成长

- 扩大在食品、製药和工业领域的应用

- 产业陷阱与挑战

- 来自双螺桿挤出机的竞争

- 先进技术的高初始投资

- 成长动力

- 成长潜力分析

- 波特的分析

- PESTEL分析

第四章:竞争格局

- 介绍

- 公司市占率分析

- 竞争定位矩阵

- 战略展望矩阵

第五章:市场估计与预测:依类型,2021-2034

- 主要趋势

- 直立式

- 水平

第六章:市场估计与预测:依营运模式,2021-2034 年

- 主要趋势

- 半自动

- 全自动

第七章:市场估计与预测:依产量,2021-2034

- 主要趋势

- 高达200公斤/小时

- 200至400公斤/小时

- 400至600公斤/小时

- 600公斤/小时以上

第 8 章:市场估计与预测:按应用,2021 年至 2034 年

- 主要趋势

- 管材挤出

- 片材挤出

- 型材挤压

- 其他(改性复合等)

第九章:市场估计与预测:依最终用途产业,2021-2034 年

- 主要趋势

- 食品和饮料

- 塑胶和橡胶

- 化工

- 製药

- 其他(矿物和不织布行业等)

第 10 章:市场估计与预测:按配销通路,2021-2034 年

- 主要趋势

- 直销

- 间接销售

第 11 章:市场估计与预测:按地区,2021 年至 2034 年

- 主要趋势

- 北美洲

- 我们

- 加拿大

- 欧洲

- 英国

- 德国

- 法国

- 义大利

- 西班牙

- 俄罗斯

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 澳洲

- 拉丁美洲

- 巴西

- 墨西哥

- MEA

- 阿联酋

- 沙乌地阿拉伯

- 南非

第十二章:公司简介

- American Extrusion International

- B&P Littleford

- Bausano & Figli

- BC Extrusion

- Boston Matthews

- Breyer

- Buhler

- Coperion

- CPM

- Extrudex

- Graham Engineering

- HMG Extrusion Equipment

- Milacron

- R&B Plastics Machinery

- USEON

The Global Single Screw Extruder Market was valued at USD 1.2 billion in 2024 and is estimated to grow at a CAGR of 5.4% to reach USD 1.9 billion by 2034, driven by increasing demand for plastic products, technological innovations, and the growing need for efficiency improvements across industries such as food, pharmaceuticals, and manufacturing. Single screw extruders are used to create a variety of plastic products, including pipes, sheets, and films. The surge in plastic use for packaging and construction has further fueled the market demand. Additionally, advancements in automation, temperature control, and equipment design are enhancing the productivity of these machines, making them increasingly attractive to manufacturers.

In the food and pharmaceutical sectors, the rising demand for processed food and advanced drug delivery systems is contributing to the market's growth. Single screw extruders are used to produce snacks, cereals, and controlled-release tablets. The versatility and efficiency of these machines make them well-suited for large-scale production in various industries. Furthermore, the technology is widely used in the manufacturing of rubber products, as the extruders enable high-volume production of components such as hoses and seals.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $1.2 Billion |

| Forecast Value | $1.9 Billion |

| CAGR | 5.4% |

The single screw extruder market is divided based on the type of extruder, with the two main segments being vertical and horizontal. The horizontal extruder segment, valued at USD 800 million in 2024, is anticipated to grow at a CAGR of 5.6% from 2025 to 2034 due to the scalability of horizontal extruders, which makes them suitable for large-scale production operations across industries such as plastics, food, and rubber. Horizontal extruders are particularly favored for their ability to handle high production efficiently. On the other hand, vertical extruders, known for their compact design, are well-suited for smaller production facilities where space optimization is a priority. These extruders provide a more space-efficient solution for operations with limited floor space but still require reliable extrusion processes.

Based on industry usage, the plastics and rubber segment held a 44% share in 2024. This segment is expected to grow at a CAGR of 5.7% between 2025 and 2034. The demand for single screw extruders in this segment is being driven by increasing efforts toward plastic recycling and the rising use of these extruders in the production of recyclable materials and rubber products. Additionally, the food and beverage sector is also significantly expanding the demand for single screw extruders, particularly to produce snacks, cereals, and ready-to-eat meals. As consumer demand for processed and convenience foods rises, the need for efficient, high-volume extruding equipment increases.

United States Single Screw Extruder Market was valued at USD 300 million in 2024. The country's emphasis on sustainable manufacturing and recycling is a key driver of this growth, as single screw extruders are commonly used to process recycled plastics and rubber materials. Technological innovations and increased automation in manufacturing are expanding the use of these extruders in various sectors, including food, beverage, and pharmaceuticals. Furthermore, the continuous demand for higher quality and more cost-effective products propels the market's growth in these industries.

Key players in the market include American Extrusion International, Bausano & Figli, Extrudex, Graham Engineering, and Milacron, among others. To enhance their market position, companies in the single screw extruder market are focusing on product innovation, particularly through automation and energy efficiency. They are also expanding their offerings with customizable solutions that cater to specific industry needs, such as food and pharmaceuticals. Strategic partnerships with research institutions and other industry leaders are allowing for the development of advanced technologies, while investments in sustainable manufacturing practices are increasing their appeal in markets that prioritize environmental responsibility.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope & definitions

- 1.2 Base estimates & calculations

- 1.3 Forecast calculations.

- 1.4 Data sources

- 1.4.1 Primary

- 1.4.2 Secondary

- 1.4.2.1 Paid sources

- 1.4.2.2 Public sources

Chapter 2 Executive Summary

- 2.1 Industry synopsis, 2021-2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Factor affecting the value chain

- 3.1.2 Profit margin analysis

- 3.1.3 Disruptions

- 3.1.4 Future outlook

- 3.1.5 Manufacturers

- 3.1.6 Distributors

- 3.2 Trump administration tariffs analysis

- 3.2.1 Impact on trade

- 3.2.1.1 Trade volume disruptions

- 3.2.1.2 Retaliatory measures

- 3.2.2 Impact on the industry

- 3.2.2.1 Supply-side impact (raw materials)

- 3.2.2.1.1 Price volatility in key materials

- 3.2.2.1.2 Supply chain restructuring

- 3.2.2.1.3 Production cost implications

- 3.2.2.2 Demand-side impact (selling price)

- 3.2.2.2.1 Price transmission to end markets

- 3.2.2.2.2 Market share dynamics

- 3.2.2.2.3 Consumer response patterns

- 3.2.2.1 Supply-side impact (raw materials)

- 3.2.3 Key companies impacted

- 3.2.4 Strategic industry responses

- 3.2.4.1 Supply chain reconfiguration

- 3.2.4.2 Pricing and product strategies

- 3.2.4.3 Policy engagement

- 3.2.5 Outlook and future considerations

- 3.2.1 Impact on trade

- 3.3 Supplier landscape

- 3.4 Technological Landscape

- 3.5 Key news & initiatives

- 3.6 Regulatory landscape

- 3.7 Impact forces

- 3.7.1 Growth drivers

- 3.7.1.1 Rising demand for plastic products

- 3.7.1.2 Expanding applications in food, pharmaceuticals, and industrial sectors

- 3.7.2 Industry pitfalls & challenges

- 3.7.2.1 Competition from twin screw extruders

- 3.7.2.2 High initial investment in advanced technologies

- 3.7.1 Growth drivers

- 3.8 Growth potential analysis

- 3.9 Porter's analysis

- 3.10 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.3 Competitive positioning matrix

- 4.4 Strategic outlook matrix

Chapter 5 Market Estimates & Forecast, By Type, 2021-2034 (USD Billion) (Thousand Units)

- 5.1 Key trends

- 5.2 Vertical type

- 5.3 Horizontal type

Chapter 6 Market Estimates & Forecast, By Mode of Operation, 2021-2034 (USD Billion) (Thousand Units)

- 6.1 Key trends

- 6.2 Semi-automatic

- 6.3 Fully automatic

Chapter 7 Market Estimates & Forecast, By Output Capacity, 2021-2034 (USD Billion) (Thousand Units)

- 7.1 Key trends

- 7.2 Up to 200 Kg/hr

- 7.3 200 to 400 Kg/hr

- 7.4 400 to 600 Kg/hr

- 7.5 Above 600 Kg/hr

Chapter 8 Market Estimates & Forecast, By Application, 2021-2034 (USD Billion) (Thousand Units)

- 8.1 Key trends

- 8.2 Pipe extrusion

- 8.3 Sheet extrusion

- 8.4 Profile extrusion

- 8.5 Others (modified compounding etc.)

Chapter 9 Market Estimates & Forecast, By End Use Industry, 2021-2034 (USD Billion) (Thousand Units)

- 9.1 Key trends

- 9.2 Food and beverages

- 9.3 Plastics and rubber

- 9.4 Chemical industry

- 9.5 Pharmaceutical

- 9.6 Others (minerals and nonwovens industry etc.)

Chapter 10 Market Estimates & Forecast, By Distribution Channel, 2021-2034 (USD Billion) (Thousand Units)

- 10.1 Key trends

- 10.2 Direct sales

- 10.3 Indirect sales

Chapter 11 Market Estimates & Forecast, By Region, 2021-2034 (USD Billion) (Thousand Units)

- 11.1 Key trends

- 11.2 North America

- 11.2.1 U.S.

- 11.2.2 Canada

- 11.3 Europe

- 11.3.1 UK

- 11.3.2 Germany

- 11.3.3 France

- 11.3.4 Italy

- 11.3.5 Spain

- 11.3.6 Russia

- 11.4 Asia Pacific

- 11.4.1 China

- 11.4.2 India

- 11.4.3 Japan

- 11.4.4 South Korea

- 11.4.5 Australia

- 11.5 Latin America

- 11.5.1 Brazil

- 11.5.2 Mexico

- 11.6 MEA

- 11.6.1 UAE

- 11.6.2 Saudi Arabia

- 11.6.3 South Africa

Chapter 12 Company Profiles

- 12.1 American Extrusion International

- 12.2 B&P Littleford

- 12.3 Bausano & Figli

- 12.4 BC Extrusion

- 12.5 Boston Matthews

- 12.6 Breyer

- 12.7 Buhler

- 12.8 Coperion

- 12.9 CPM

- 12.10 Extrudex

- 12.11 Graham Engineering

- 12.12 HMG Extrusion Equipment

- 12.13 Milacron

- 12.14 R&B Plastics Machinery

- 12.15 USEON