|

市场调查报告书

商品编码

1755224

化工高温工业锅炉市场机会、成长动力、产业趋势分析及2025-2034年预测Chemical High Temperature Industrial Boiler Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

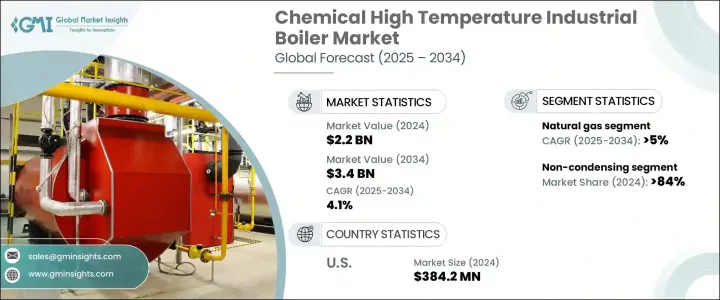

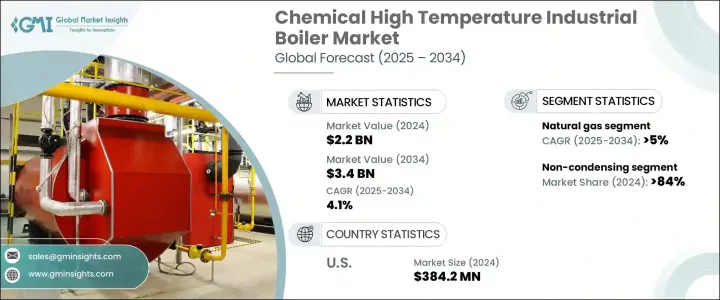

2024年,全球工高温工业锅炉市场规模达22亿美元,预计到2034年将以4.1%的复合年增长率成长,达到34亿美元。这主要得益于快速城镇化推动发展中经济体各产业对先进供热技术的需求不断增长。化学合成、聚合和蒸馏等化学生产过程的复杂性和规模日益扩大,推动了对高效高温蒸汽系统的需求。

此外,采用物联网和自动化技术可以增强即时监控、维护预测和效能最佳化,从而提高锅炉的效率。这项转变对于提高能源效率、最大限度地减少停机时间和遵守严格的排放标准至关重要。在化工厂中,采用先进技术改造现有锅炉正变得越来越普遍,这不仅延长了锅炉的使用寿命,还确保了锅炉符合最新法规。然而,全球贸易中断,尤其是川普总统任期内对进口零件征收的关税,可能会影响国际贸易动态和营运成本,导致製造业长期转移到国内。

| 市场范围 | |

|---|---|

| 起始年份 | 2024 |

| 预测年份 | 2025-2034 |

| 起始值 | 22亿美元 |

| 预测值 | 34亿美元 |

| 复合年增长率 | 4.1% |

在化工高温工业锅炉市场中,天然气驱动部分有望实现显着增长,预计到2034年复合年增长率将达到5%,这得益于天然气基础设施的持续扩张以及各行业对能源安全的日益重视。随着对清洁能源的需求日益增长,天然气被认为比煤炭或石油更环保,进一步推动了这个市场转变。此外,天然气锅炉还具有许多优势,包括更低的排放和更高的燃油效率,使其成为那些致力于遵守更严格环境法规的行业的理想选择。

至2034年,冷凝锅炉市场将以4%的复合年增长率成长。这类锅炉因其卓越的能源效率而越来越受欢迎。冷凝技术能够捕获并再利用废气中的热量,不仅降低了能耗,也减少了温室气体排放。随着人们对环境问题的日益关注以及对更环保技术的追求,各行各业纷纷采用冷凝锅炉,以符合更严格的排放控制标准并降低营运成本。

到2024年,美国化工高温工业锅炉市场价值将达到3.842亿美元,这得益于其持续推进的现有基础设施现代化和老旧锅炉系统的更新换代。美国市场受到了有关能源效率和排放控制的新法规和修订法规的支持,这些法规促使化工厂和其他工业运营商投资先进的锅炉技术。政府对永续发展的日益重视以及企业满足环保标准的需求是推动这一成长的关键驱动力。

在这个市场上营运的公司包括 Babcock & Wilcox Enterprises、Bharat Heavy Electricals、Clayton Industries、Cleaver-Brooks、Cochran、Doosan Heavy Industries & Construction、FERROLI、Fonderie Sime、FONDITAL、Forbes Marshall、GE Vernova、Groupe Atlantic、Hok、FONDITAL、Forbes Marshall、GE Vernova、Groupe Atlantic、Hoval、Hurman、Iilman、Itilla. Group、三菱重工、Miura America、Rentech Boilers、Robert Bosch、西门子、Sofinter、The Fulton Companies、Thermax、Victory Energy Operations、Viessmann 和 Walchandnagar Industries。化工高温工业锅炉市场的关键策略包括广泛的研发投资,以整合物联网和人工智慧等创新技术,从而提高营运效能并降低维护成本。此外,公司正致力于以节能解决方案改造旧设备,确保符合更严格的环境和排放标准。

目录

第一章:方法论与范围

第二章:执行摘要

第三章:行业洞察

- 产业生态系统分析

- 川普政府关税分析

- 对贸易的影响

- 贸易量中断

- 报復措施

- 对产业的影响

- 供应方影响(原料)

- 主要材料价格波动

- 供应链重组

- 生产成本影响

- 需求面影响(售价)

- 价格传导至终端市场

- 市占率动态

- 消费者反应模式

- 供应方影响(原料)

- 受影响的主要公司

- 策略产业反应

- 供应链重组

- 定价和产品策略

- 政策参与

- 展望与未来考虑

- 对贸易的影响

- 监管格局

- 产业衝击力

- 成长动力

- 产业陷阱与挑战

- 成长潜力分析

- 波特的分析

- PESTEL分析

第四章:竞争格局

- 介绍

- 公司市占率分析

- 战略仪表板

- 策略倡议

- 竞争基准测试

- 创新与永续发展格局

第五章:市场规模及预测:依温度,2021 - 2034 年

- 主要趋势

- 180°F - 200°F

- > 200°F - 220°F

- > 220°F - 240°F

- > 240°F

第六章:市场规模及预测:依产品,2021 - 2034

- 主要趋势

- 火管

- 水管

第七章:市场规模及预测:依产能,2021 - 2034

- 主要趋势

- < 10 百万英热单位/小时

- 10 - 25 百万英热单位/小时

- 25 - 50 百万英热单位/小时

- 50 - 75 百万英热单位/小时

- 75 - 100 百万英热单位/小时

- 100 - 175 百万英热单位/小时

- 175 - 250 百万英热单位/小时

- > 250 百万英热单位/小时

第八章:市场规模及预测:依燃料,2021 - 2034

- 主要趋势

- 天然气

- 油

- 煤炭

- 其他的

第九章:市场规模及预测:依技术分类,2021 - 2034 年

- 主要趋势

- 冷凝

- 无凝结

第 10 章:市场规模与预测:按地区,2021 年至 2034 年

- 主要趋势

- 北美洲

- 我们

- 加拿大

- 墨西哥

- 欧洲

- 法国

- 英国

- 波兰

- 义大利

- 西班牙

- 奥地利

- 德国

- 瑞典

- 俄罗斯

- 亚太地区

- 中国

- 印度

- 菲律宾

- 日本

- 韩国

- 澳洲

- 印尼

- 中东和非洲

- 沙乌地阿拉伯

- 伊朗

- 阿联酋

- 奈及利亚

- 南非

- 拉丁美洲

- 阿根廷

- 智利

- 巴西

第 11 章:公司简介

- Babcock and Wilcox Enterprises

- Bharat Heavy Electricals

- Clayton Industries

- Cleaver-Brooks

- Cochran

- Doosan Heavy Industries & Construction

- FERROLI

- Fonderie Sime

- FONDITAL

- Forbes Marshall

- GE Vernova

- Groupe Atlantic

- Hoval

- Hurst Boiler and Welding

- IHI Corporation

- John Cockerill

- John Wood Group

- Mitsubishi Heavy Industries

- Miura America

- Rentech Boilers

- Robert Bosch

- Siemens

- Sofinter

- The Fulton Companies

- Thermax

- Victory Energy Operations

- Viessmann

- Walchandnagar Industries

The Global Chemical High Temperature Industrial Boiler Market was valued at USD 2.2 billion in 2024 and is estimated to grow at a CAGR of 4.1% to reach USD 3.4 billion by 2034, driven by the rising demand for advanced heating technologies in in industries across developing economies, fueled by rapid urbanization. The increasing complexity and scale of chemical production processes, including chemical synthesis, polymerization, and distillation, propel the need for efficient, high-temperature steam systems.

Furthermore, adopting IoT and automation technologies enhances real-time monitoring, maintenance predictions, and performance optimization, making these boilers increasingly efficient. This shift is critical for improving energy efficiency, minimizing downtime, and complying with strict emissions standards. Retrofitting existing boilers with advanced technologies is becoming common among chemical plants, extending boiler lifespans and ensuring compliance with updated regulations. However, global trade disruptions, particularly tariffs on imported components during the Trump presidency, could impact international trade dynamics and operational costs, creating a shift toward domestic manufacturing in the long term.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $2.2 Billion |

| Forecast Value | $3.4 Billion |

| CAGR | 4.1% |

The natural gas-powered segment of the chemical high-temperature industrial boiler market is poised for significant growth, with an anticipated CAGR of 5% by 2034 fueled by the continuous expansion of natural gas infrastructure and a heightened focus on energy security across industries. The increasing demand for cleaner energy sources, natural gas is considered more environmentally friendly than coal or oil, further supports this market shift. Additionally, natural gas boilers offer several advantages, including lower emissions and better fuel efficiency, making them an attractive choice for industries aiming to comply with stricter environmental regulations.

The condensing boilers segment will grow at a 4% CAGR by 2034. These boilers are becoming increasingly popular due to their superior energy efficiency. Condensing technology enables the capture and reuse of heat from exhaust gases, which not only reduces energy consumption but lowers greenhouse gas emissions. With growing environmental concerns and the push for greener technologies, industries are adopting condensing boilers to comply with more stringent emission control standards and to reduce operational costs.

United States Chemical High Temperature Industrial Boiler Market was valued at USD 384.2 million by 2024 attributed to the ongoing efforts toward modernizing existing infrastructure and replacing outdated boiler systems. The U.S. market has been supported by new and revised regulations concerning energy efficiency and emission controls, which have prompted chemical plants and other industrial operators to invest in advanced boiler technologies. The government's increasing focus on sustainability and the need for businesses to meet environmental standards are key drivers of this growth.

Companies operating in this market include Babcock & Wilcox Enterprises, Bharat Heavy Electricals, Clayton Industries, Cleaver-Brooks, Cochran, Doosan Heavy Industries & Construction, FERROLI, Fonderie Sime, FONDITAL, Forbes Marshall, GE Vernova, Groupe Atlantic, Hoval, Hurst Boiler and Welding, IHI Corporation, John Cockerill, John Wood Group, Mitsubishi Heavy Industries, Miura America, Rentech Boilers, Robert Bosch, Siemens, Sofinter, The Fulton Companies, Thermax, Victory Energy Operations, Viessmann, and Walchandnagar Industries. Key strategies in the chemical high-temperature industrial boiler market include extensive R&D investment to integrate innovative technologies, such as IoT and AI, which improve operational performance and reduce maintenance costs. Additionally, companies are focusing on retrofitting older units with energy-efficient solutions, ensuring compliance with stricter environmental and emissions standards.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Research design

- 1.2 Market estimates & forecast parameters

- 1.3 Forecast calculation

- 1.4 Data sources

- 1.4.1 Primary

- 1.4.2 Secondary

- 1.4.2.1 Paid

- 1.4.2.2 Public

- 1.5 Market definitions

Chapter 2 Executive Summary

- 2.1 Industry synopsis, 2021 - 2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.2 Trump administration tariffs analysis

- 3.2.1 Impact on trade

- 3.2.1.1 Trade volume disruptions

- 3.2.1.2 Retaliatory measures

- 3.2.2 Impact on the industry

- 3.2.2.1 Supply-side impact (raw materials)

- 3.2.2.1.1 Price volatility in key materials

- 3.2.2.1.2 Supply chain restructuring

- 3.2.2.1.3 Production cost implications

- 3.2.2.2 Demand-side impact (selling price)

- 3.2.2.2.1 Price transmission to end markets

- 3.2.2.2.2 Market share dynamics

- 3.2.2.2.3 Consumer response patterns

- 3.2.2.1 Supply-side impact (raw materials)

- 3.2.3 Key companies impacted

- 3.2.4 Strategic industry responses

- 3.2.4.1 Supply chain reconfiguration

- 3.2.4.2 Pricing and product strategies

- 3.2.4.3 Policy engagement

- 3.2.5 Outlook and future considerations

- 3.2.1 Impact on trade

- 3.3 Regulatory landscape

- 3.4 Industry impact forces

- 3.4.1 Growth drivers

- 3.4.2 Industry pitfalls & challenges

- 3.5 Growth potential analysis

- 3.6 Porter's analysis

- 3.6.1 Bargaining power of suppliers

- 3.6.2 Bargaining power of buyers

- 3.6.3 Threat of new entrants

- 3.6.4 Threat of substitutes

- 3.7 PESTEL analysis

Chapter 4 Competitive Landscape, 2025

- 4.1 Introduction

- 4.2 Company market share analysis, 2024

- 4.3 Strategic dashboard

- 4.4 Strategic initiatives

- 4.5 Competitive benchmarking

- 4.6 Innovation & sustainability landscape

Chapter 5 Market Size and Forecast, By Temperature, 2021 - 2034 (USD Million, MMBTU/hr & Units)

- 5.1 Key trends

- 5.2 180°F - 200°F

- 5.3 > 200°F - 220°F

- 5.4 > 220°F - 240°F

- 5.5 > 240°F

Chapter 6 Market Size and Forecast, By Product, 2021 - 2034 (USD Million, MMBTU/hr & Units)

- 6.1 Key trends

- 6.2 Fire-tube

- 6.3 Water-tube

Chapter 7 Market Size and Forecast, By Capacity, 2021 - 2034 (USD Million, MMBTU/hr & Units)

- 7.1 Key trends

- 7.2 < 10 MMBTU/hr

- 7.3 10 - 25 MMBTU/hr

- 7.4 25 - 50 MMBTU/hr

- 7.5 50 - 75 MMBTU/hr

- 7.6 75 - 100 MMBTU/hr

- 7.7 100 - 175 MMBTU/hr

- 7.8 175 - 250 MMBTU/hr

- 7.9 > 250 MMBTU/hr

Chapter 8 Market Size and Forecast, By Fuel, 2021 - 2034 (USD Million, MMBTU/hr & Units)

- 8.1 Key trends

- 8.2 Natural gas

- 8.3 Oil

- 8.4 Coal

- 8.5 Others

Chapter 9 Market Size and Forecast, By Technology, 2021 - 2034 (USD Million, MMBTU/hr & Units)

- 9.1 Key trends

- 9.2 Condensing

- 9.3 Non-condensing

Chapter 10 Market Size and Forecast, By Region, 2021 - 2034 (USD Million, MMBTU/hr & Units)

- 10.1 Key trends

- 10.2 North America

- 10.2.1 U.S.

- 10.2.2 Canada

- 10.2.3 Mexico

- 10.3 Europe

- 10.3.1 France

- 10.3.2 UK

- 10.3.3 Poland

- 10.3.4 Italy

- 10.3.5 Spain

- 10.3.6 Austria

- 10.3.7 Germany

- 10.3.8 Sweden

- 10.3.9 Russia

- 10.4 Asia Pacific

- 10.4.1 China

- 10.4.2 India

- 10.4.3 Philippines

- 10.4.4 Japan

- 10.4.5 South Korea

- 10.4.6 Australia

- 10.4.7 Indonesia

- 10.5 Middle East & Africa

- 10.5.1 Saudi Arabia

- 10.5.2 Iran

- 10.5.3 UAE

- 10.5.4 Nigeria

- 10.5.5 South Africa

- 10.6 Latin America

- 10.6.1 Argentina

- 10.6.2 Chile

- 10.6.3 Brazil

Chapter 11 Company Profiles

- 11.1 Babcock and Wilcox Enterprises

- 11.2 Bharat Heavy Electricals

- 11.3 Clayton Industries

- 11.4 Cleaver-Brooks

- 11.5 Cochran

- 11.6 Doosan Heavy Industries & Construction

- 11.7 FERROLI

- 11.8 Fonderie Sime

- 11.9 FONDITAL

- 11.10 Forbes Marshall

- 11.11 GE Vernova

- 11.12 Groupe Atlantic

- 11.13 Hoval

- 11.14 Hurst Boiler and Welding

- 11.15 IHI Corporation

- 11.16 John Cockerill

- 11.17 John Wood Group

- 11.18 Mitsubishi Heavy Industries

- 11.19 Miura America

- 11.20 Rentech Boilers

- 11.21 Robert Bosch

- 11.22 Siemens

- 11.23 Sofinter

- 11.24 The Fulton Companies

- 11.25 Thermax

- 11.26 Victory Energy Operations

- 11.27 Viessmann

- 11.28 Walchandnagar Industries