|

市场调查报告书

商品编码

1766215

热成型灌装封口机市场机会、成长动力、产业趋势分析及 2025 - 2034 年预测Thermoform Form-Fill-Seal Machine Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

2024年,全球热成型-填充-封口机市场规模达8.083亿美元,预计2034年将以3.7%的复合年增长率成长,达到11.6亿美元。这一增长主要源于全球消费的成长以及向永续性和环保製造的迫切转变。随着塑胶废弃物法规的不断完善,这些机器现在被设计用于处理可回收和可生物降解的材料。企业正在投资下一代设备,不仅是为了遵守环境政策,也是为了满足消费者对永续包装日益增长的偏好。循环经济实践和智慧工厂计画的推动,正在推动创新自动化包装技术的采用。

在製药、食品和消费品等行业,热成型-填充-封口机的应用日益广泛,以满足人们对更高安全性、防篡改和更长保质期的需求。在工业 4.0 标准下,感测器与物联网系统整合以实现预测性维护和流程优化的势头日益强劲。这项变革正在重塑全球包装生产线,使机器更加高效,能够适应各种材料和产品类型,同时支持经济高效且环保的营运。

| 市场范围 | |

|---|---|

| 起始年份 | 2024 |

| 预测年份 | 2025-2034 |

| 起始值 | 8.083亿美元 |

| 预测值 | 11.6亿美元 |

| 复合年增长率 | 3.7% |

2024年,自动热成型-填充-封口机市场规模达5.092亿美元,预计2025年至2034年期间的复合年增长率将达到4.5%。自动化机型因其能够满足日益增长的快速、可靠和可持续包装需求而被广泛采用。消除人工操作可降低人工成本,增强一致性,并提高生产线的产量。这些机器配备了先进的介面,例如即时追踪、可程式逻辑控制器 (PLC) 和直觉的触控萤幕控制,从而改善了用户体验并提升了营运效率。它们能够适应多种规格和基材,适用于各行业日益广泛的应用。

2024年,袋装和袋式包装占据全球市场主导地位,占39.1%的份额,预计到2034年将达到4.766亿美元。方便食品和健康包装商品的日益普及,也推动了安全卫生包装解决方案的需求。如今,成型-填充-密封系统具备气调密封功能,可确保新鲜度并延长保质期。这些系统也在不断发展,以支持使用可堆肥和环保材料。随着製造商寻求防篡改和防污染的解决方案,优先考虑食品安全和包装完整性的法规持续推动这一领域的创新。

2024年,美国热成型-灌装-封口机市场规模达1.147亿美元,预计2034年的复合年增长率为3.9%。美国市场的成长与消费品、医疗保健以及食品饮料产业对软包装解决方案和永续实践的广泛采用密切相关。对环保替代品的需求日益增长,也促使企业采用更新、更节能的技术升级包装生产线。

热成型-灌装-封口机市场的领导者包括 DS Smith、Anchor Packaging, Inc.、Huhtamaki Oyj、ProMach、Amcor PLC、Winpak Ltd.、Bosch Packaging Technology、Placon Corporation、Barry-Wehmiller Group、Paccor Packaging Corporation、Sealed Air Corporation、Syngonam、Barry-Wehmiller Group、Paccor Packaging Corporation、Sealed Air Corporation、Syngonco、Barry-Wehmiller Group、Paccor Packaging Corporation、Sealed Air Corporation、Syngonam、Paccor Pack为了巩固其在全球热成型-填充-封口机市场的地位,各公司正专注于整合智慧自动化功能和数位监控工具,以提高机器可靠性并减少停机时间。

许多公司正在投资研发,以支援可回收和可生物降解材料的加工,从而符合不断变化的环境法规。透过融入灵活的设计功能,这些製造商正在製造相容于各种包装形式和基材的机器。他们正在与原材料供应商和原始设备製造商建立策略合作伙伴关係,以增强供应链能力和产品创新。一些公司正在透过设立区域服务中心和技术支援中心来扩大其地域覆盖范围,以便更好地服务本地市场并缩短交货时间。

目录

第一章:方法论与范围

第二章:执行摘要

第三章:行业洞察

- 产业生态系统分析

- 供应商格局

- 利润率

- 每个阶段的增值

- 影响价值链的因素

- 产业衝击力

- 成长动力

- 产业陷阱与挑战

- 机会

- 成长潜力分析

- 未来市场趋势

- 技术和创新格局

- 当前的技术趋势

- 新兴技术

- 价格趋势

- 按地区

- 按机器类型

- 监管格局

- 标准和合规要求

- 区域监理框架

- 认证标准

- 波特的分析

- PESTEL分析

第四章:竞争格局

- 介绍

- 公司市占率分析

- 按地区

- 北美洲

- 欧洲

- 亚太地区

- 按地区

- 公司矩阵分析

- 主要市场参与者的竞争分析

- 竞争定位矩阵

- 关键进展

- 併购

- 伙伴关係与合作

- 新产品发布

- 扩张计划

第五章:市场估计与预测:依技术分类,2021 - 2034 年

- 主要趋势

- 手动的

- 半自动

- 全自动

第六章:市场估计与预测:依包装类型,2021 - 2034 年

- 主要趋势

- 包包和小袋

- 杯子和托盘

- 瓶子

- 小袋

- 纸箱

- 其他的

第七章:市场估计与预测:按最终用途产业,2021 - 2034 年

- 主要趋势

- 食品和饮料

- 製药

- 化妆品和个人护理

- 化学品

- 其他的

第八章:市场估计与预测:按材料类型,2021 - 2034 年

- 主要趋势

- 塑胶

- 纸

- 铝箔

- 多层薄膜

- 可生物降解材料

- 其他的

第九章:市场估计与预测:按配销通路,2021 - 2034 年

- 主要趋势

- 直接的

- 间接

第十章:市场估计与预测:按地区,2021 - 2034 年

- 主要趋势

- 北美洲

- 我们

- 加拿大

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 澳洲

- 拉丁美洲

- 巴西

- 墨西哥

- MEA

- 沙乌地阿拉伯

- 阿联酋

- 南非

第 11 章:公司简介

- Amcor PLC

- Anchor Packaging, Inc.

- Barry-Wehmiller Group

- Bosch Packaging Technology

- Coesia Group

- DS Smith

- Huhtamaki Oyj

- Mondi Group

- Paccor Packaging Corporation

- Placon Corporation

- ProMach

- Sealed Air Corporation

- Sonoco Products Company

- Syntegon

- Winpak Ltd.

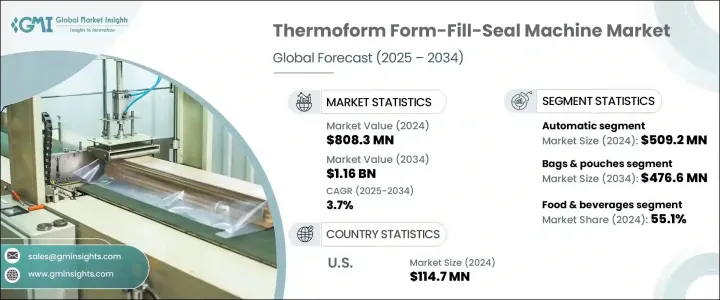

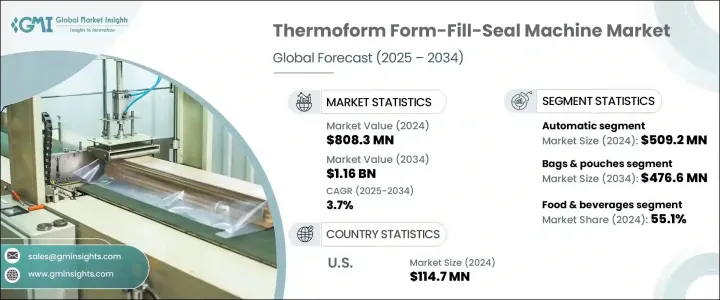

The Global Thermoform Form-Fill-Seal Machine Market was valued at USD 808.3 million in 2024 and is estimated to grow at a CAGR of 3.7% to reach USD 1.16 billion by 2034. This growth is fueled by rising global consumption and the urgent shift toward sustainability and eco-conscious manufacturing. With evolving plastic waste regulations, these machines are now designed to handle recyclable and biodegradable materials. Businesses are investing in next-generation equipment not only to stay compliant with environmental policies but also to align with growing consumer preferences for sustainable packaging. The push toward circular economy practices and smart factory initiatives is encouraging the adoption of innovative, automated packaging technologies.

In industries such as pharmaceuticals, food, and consumer goods, thermoform form-fill-seal machines are increasingly used to meet demands for improved safety, tamper resistance, and longer shelf life. The integration of sensors and IoT-enabled systems for predictive maintenance and process optimization is gaining momentum under Industry 4.0 standards. This evolution is reshaping packaging lines globally, making machines more efficient and adaptive to a wide variety of materials and product types while supporting cost-effective and environmentally friendly operations.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $808.3 million |

| Forecast Value | $1.16 billion |

| CAGR | 3.7% |

In 2024, the automatic thermoform form-fill-seal machine segment recorded USD 509.2 million and is expected to grow at a CAGR of 4.5% between 2025 and 2034. Automatic models are being widely adopted due to their ability to meet rising demands for fast, reliable, and sustainable packaging. The elimination of manual tasks reduces labor costs, enhances consistency, and increases throughput across manufacturing lines. These machines are equipped with advanced interfaces like real-time tracking, programmable logic controllers (PLCs), and intuitive touchscreen controls, which improve user experience and boost operational efficiency. Their adaptability to multiple formats and substrates makes them suitable for an expanding range of applications across sectors.

The bags and pouches packaging format led the global market in 2024, securing a 39.1% share and is forecasted to reach USD 476.6 million by 2034. The growing popularity of convenience foods and health-focused packaged goods is increasing demand for secure and hygienic packaging solutions. Form-fill-seal systems now offer controlled atmosphere sealing capabilities, ensuring freshness and extending shelf life. They are also evolving to support the use of compostable and environmentally safe materials. Regulations that prioritize food safety and packaging integrity continue to drive innovation in this category, as manufacturers seek tamper-proof and contamination-resistant solutions.

United States Thermoform Form-Fill-Seal Machine Market generated USD 114.7 million in 2024, with an anticipated CAGR of 3.9% through 2034. Growth in the U.S. is closely linked to expanding adoption of flexible packaging solutions and sustainable practices across the consumer goods, healthcare, and food and beverage sectors. Increasing demand for eco-friendly alternatives is also pushing companies to upgrade packaging lines with newer, more energy-efficient technologies.

Leading players in the Thermoform Form-Fill-Seal Machine Market include DS Smith, Anchor Packaging, Inc., Huhtamaki Oyj, ProMach, Amcor PLC, Winpak Ltd., Bosch Packaging Technology, Placon Corporation, Barry-Wehmiller Group, Paccor Packaging Corporation, Sealed Air Corporation, Syntegon, Mondi Group, Sonoco Products Company, and Coesia Group. To strengthen their position in the global thermoform form-fill-seal machine market, companies are focusing on integrating smart automation features and digital monitoring tools that enhance machine reliability and reduce operational downtime.

Many are investing in research and development to support the processing of recyclable and biodegradable materials in compliance with evolving environmental regulations. By incorporating flexible design features, these manufacturers are making machines compatible with various packaging formats and substrates. Strategic partnerships with raw material suppliers and OEMs are being formed to enhance supply chain capabilities and product innovation. Some are expanding their geographic presence by setting up regional service centers and technical support hubs to better serve localized markets and reduce lead times.

Table of Contents

Chapter 1 Methodology and Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Machine type

- 2.2.3 End use industry

- 2.2.4 Packaging type

- 2.2.5 Material type

- 2.2.6 Distribution channel

- 2.3 CXO perspectives: Strategic imperatives

- 2.3.1 Key decision points for industry executives

- 2.3.2 Critical success factors for market players

- 2.4 Future Outlook and Strategic Recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.2 Industry pitfalls & challenges

- 3.2.3 Opportunities

- 3.3 Growth potential analysis

- 3.4 Future market trends

- 3.5 Technology and Innovation landscape

- 3.5.1 Current technological trends

- 3.5.2 Emerging technologies

- 3.6 Price trends

- 3.6.1 By region

- 3.6.2 By machine type

- 3.7 Regulatory landscape

- 3.7.1 standards and compliance requirements

- 3.7.2 Regional regulatory frameworks

- 3.7.3 Certification standards

- 3.8 Porter's analysis

- 3.9 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New product launches

- 4.6.4 Expansion plans

Chapter 5 Market Estimates & Forecast, By Technology, 2021 - 2034, (USD Million)(Thousand Units)

- 5.1 Key trends

- 5.2 Manual

- 5.3 Semi-automatic

- 5.4 Fully automatic

Chapter 6 Market Estimates & Forecast, By Packaging Type, 2021 - 2034, (USD Million)(Thousand Units)

- 6.1 Key trends

- 6.2 Bags & pouches

- 6.3 Cups & trays

- 6.4 Bottles

- 6.5 Sachets

- 6.6 Cartons

- 6.7 Others

Chapter 7 Market Estimates & Forecast, By End Use Industry, 2021 - 2034, (USD Million)(Thousand Units)

- 7.1 Key trends

- 7.2 Food & beverages

- 7.3 Pharmaceuticals

- 7.4 Cosmetics & personal care

- 7.5 Chemicals

- 7.6 Others

Chapter 8 Market Estimates & Forecast, By Material Type, 2021 - 2034, (USD Million)(Thousand Units)

- 8.1 Key trends

- 8.2 Plastic

- 8.3 Paper

- 8.4 Aluminum foil

- 8.5 Multi-layer films

- 8.6 Biodegradable materials

- 8.7 Others

Chapter 9 Market Estimates & Forecast, By Distribution Channel, 2021 - 2034, (USD Million)(Thousand Units)

- 9.1 Key trends

- 9.2 Direct

- 9.3 Indirect

Chapter 10 Market Estimates & Forecast, By Region, 2021 - 2034, (USD Million)(Thousand Units)

- 10.1 Key trends

- 10.2 North America

- 10.2.1 U.S.

- 10.2.2 Canada

- 10.3 Europe

- 10.3.1 Germany

- 10.3.2 UK

- 10.3.3 France

- 10.3.4 Italy

- 10.3.5 Spain

- 10.4 Asia Pacific

- 10.4.1 China

- 10.4.2 India

- 10.4.3 Japan

- 10.4.4 South Korea

- 10.4.5 Australia

- 10.5 Latin America

- 10.5.1 Brazil

- 10.5.2 Mexico

- 10.6 MEA

- 10.6.1 Saudi Arabia

- 10.6.2 UAE

- 10.6.3 South Africa

Chapter 11 Company Profiles

- 11.1 Amcor PLC

- 11.2 Anchor Packaging, Inc.

- 11.3 Barry-Wehmiller Group

- 11.4 Bosch Packaging Technology

- 11.5 Coesia Group

- 11.6 DS Smith

- 11.7 Huhtamaki Oyj

- 11.8 Mondi Group

- 11.9 Paccor Packaging Corporation

- 11.10 Placon Corporation

- 11.11 ProMach

- 11.12 Sealed Air Corporation

- 11.13 Sonoco Products Company

- 11.14 Syntegon

- 11.15 Winpak Ltd.