|

市场调查报告书

商品编码

1766234

模组化机器平台市场机会、成长动力、产业趋势分析及 2025 - 2034 年预测Modular Machine Platforms Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

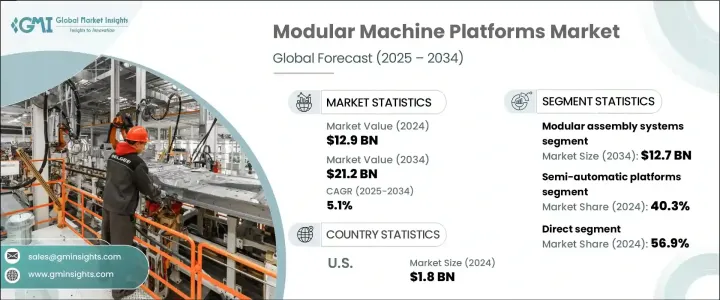

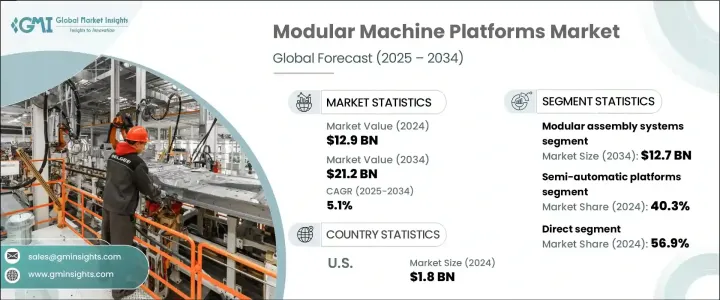

2024年,全球模组化机械平台市场规模达1,29亿美元,预计到2034年将以5.1%的复合年增长率成长,达到212亿美元。由于现代製造业对可客製化、可扩展和可重构机械的需求日益增长,该市场正在迅速扩张。模组化机械平台能够更快地适应产品设计变更和大量生产需求,无需大量停机或重新装配,从而简化生产流程。这些解决方案对于电子、消费品和工业机械等行业的製造商至关重要,因为它们需要跟上不断变化的客户需求和大规模客製化趋势。

随着越来越多的产业优先考虑精实流程和即时工作流程,模组化解决方案正成为实现生产力和成本效益目标不可或缺的一部分。这些平台也支援工业 4.0 的目标,帮助製造商整合智慧系统并提高自动化程度,而无需进行全面检修。在强大的工业自动化生态系统和日益增长的生产敏捷性压力的支持下,北美、欧洲和亚太地区继续推动全球采用模组化解决方案。

| 市场范围 | |

|---|---|

| 起始年份 | 2024 |

| 预测年份 | 2025-2034 |

| 起始值 | 129亿美元 |

| 预测值 | 212亿美元 |

| 复合年增长率 | 5.1% |

模组化组装系统细分市场在2024年创造了82亿美元的产值,预计到2034年将成长至127亿美元。这些系统因其能够使用模组化、可互换的单元快速适应不同类型和尺寸的产品而备受推崇。其可扩展性有助于减少代价高昂的停机时间,并最大限度地减少重新设计的需求,使其在快速发展的行业中特别有效。模组化组装系统的受欢迎程度与精益製造计划和注重效率的生产模式密切相关,这些模式旨在减少浪费并缩短响应时间。

半自动平台细分市场在2024年占据了40.3%的市场份额,预计到2034年将以4.5%的复合年增长率成长。这些平台将人工输入与机械化功能相结合,为需要人工监督品质敏感或客製化生产任务的製造商提供了平衡的解决方案。与全自动系统相比,它们的吸引力在于前期投资更低,同时显着提高了产量和一致性。这些系统也对劳动力技能和可用性适中的地区具有吸引力,在手动操作和全自动化之间提供了理想的中间地带。

2024年,美国模组化机械平台市场规模达18亿美元,预计2034年复合年增长率将达5.7%。美国凭藉其高度先进的自动化基础设施,以及航太、汽车和高科技製造等工业领域的旺盛需求,在北美地区保持领先地位。美国持续致力于製造业回流和智慧製造理念的采用,这有利于加速部署旨在实现弹性生产的模组化系统。在研发投入庞大和工业数位化不断发展的推动下,北美将继续成为早期技术应用的中心。

模组化机械平台产业的主要领导者包括ABB有限公司、倍福自动化、三菱电机、ATS自动化、博世力士乐、西门子股份公司、贝加莱工业自动化、史陶比尔国际股份公司、安川电机株式会社、库卡股份公司、雄克有限公司、FlexLink系统公司、罗克韦尔自动化、费斯托股份公司和优机器人傲。为了巩固市场地位,各大公司正致力于将物联网、人工智慧和资料分析等数位技术整合到模组化系统中,以提升功能和效能。他们还在扩展产品组合,提供即插即用的模组化单元,以实现快速配置,并最大程度地减少系统升级期间的中断。

目录

第一章:方法论与范围

第二章:执行摘要

第三章:行业洞察

- 产业生态系统分析

- 供应商格局

- 利润率

- 每个阶段的增值

- 影响价值链的因素

- 中断

- 产业衝击力

- 成长动力

- 产业陷阱与挑战

- 机会

- 成长潜力分析

- 未来市场趋势

- 技术和创新格局

- 当前的技术趋势

- 新兴技术

- 价格趋势

- 按地区

- 依产品类型

- 监理框架

- 标准和认证

- 环境法规

- 进出口法规

- 贸易统计数据

- 主要进口国

- 主要出口国

- 波特五力分析

- PESTEL分析

第四章:竞争格局

- 介绍

- 公司市占率分析

- 按地区

- 公司矩阵分析

- 主要市场参与者的竞争分析

- 竞争定位矩阵

- 关键进展

- 併购

- 伙伴关係与合作

- 新产品发布

- 扩张计划

第五章:市场估计与预测:依产品类型,2021 - 2034 年

- 主要趋势

- 模组化组装系统

- 模组化机器人平台

- 模组化CNC工具机

- 模组化包装机

- 其他的

第六章:市场估计与预测:依模组化水平,2021 - 2034 年

- 主要趋势

- 固定模组化平台

- 灵活的模组化平台

- 可重构机器系统(RMS)

第七章:市场估计与预测:按运营,2021 - 2034 年

- 主要趋势

- 手动模组化平台

- 半自动平台

- 全自动平台

第八章:市场估计与预测:按应用,2021 - 2034 年

- 主要趋势

- 集会

- 物料处理

- 检查和测试

- 加工

- 包装

- 其他的

第九章:市场估计与预测:依最终用途,2021 - 2034 年

- 主要趋势

- 汽车

- 电子和半导体

- 食品和饮料

- 製药

- 消费品

- 航太和国防

- 物流和仓储

- 其他(纺织、印刷等)

第 10 章:市场估计与预测:按配销通路,2021 年至 2034 年

- 主要趋势

- 直接的

- 间接

第 11 章:市场估计与预测:按地区,2021 年至 2034 年

- 主要趋势

- 北美洲

- 我们

- 加拿大

- 欧洲

- 英国

- 德国

- 法国

- 义大利

- 西班牙

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 澳洲

- 拉丁美洲

- 巴西

- 墨西哥

- MEA

- 南非

- 阿联酋

- 沙乌地阿拉伯

第十二章:公司简介

- ABB Ltd.

- ATS Automation

- B&R Industrial Automation

- Beckhoff Automation

- Bosch Rexroth

- Festo AG & Co. KG

- FlexLink Systems

- KUKA AG

- Mitsubishi Electric

- Rockwell Automation

- Schunk GmbH

- Siemens AG

- Staubli International AG

- Universal Robots

- Yaskawa Electric Corporation

The Global Modular Machine Platforms Market was valued at USD 12.9 billion in 2024 and is estimated to grow at a CAGR of 5.1% to reach USD 21.2 billion by 2034. This market is expanding rapidly due to the increasing demand for customizable, scalable, and reconfigurable machinery across modern manufacturing sectors. Modular machine platforms offer companies the ability to streamline production by allowing faster adaptation to product design changes and batch production needs without significant downtime or retooling. These solutions are vital for manufacturers in sectors like electronics, consumer goods, and industrial machinery that need to keep pace with evolving customer demands and mass customization trends.

As more industries prioritize lean processes and just-in-time workflows, modular solutions are becoming integral to achieving productivity and cost-efficiency goals. These platforms also support the goals of Industry 4.0, helping manufacturers integrate smart systems and increase automation without committing to full overhauls. North America, Europe, and Asia-Pacific continue to drive global adoption, supported by strong industrial automation ecosystems and increasing pressure to improve production agility.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $12.9 Billion |

| Forecast Value | $21.2 Billion |

| CAGR | 5.1% |

The modular assembly systems segment generated USD 8.2 billion in 2024 and is forecasted to grow to USD 12.7 billion by 2034. These systems are highly valued for their ability to adapt quickly to different product types and sizes using modular, interchangeable units. Their scalable nature helps reduce costly downtimes and minimizes the need for reengineering, making them particularly effective in fast-moving sectors. Their popularity is closely linked to lean manufacturing initiatives and efficiency-focused production models aimed at reducing waste and improving response times.

The semi-automatic platforms segment captured 40.3% share in 2024 and is projected to grow at a CAGR of 4.5% through 2034. These platforms combine human input with mechanized functions, creating a balanced solution for manufacturers who require manual oversight for quality-sensitive or custom production tasks. Their appeal lies in lower upfront investment compared to fully automated systems while offering significant improvements in output and consistency. These systems also appeal to regions where labor skills and availability are moderate, offering an ideal middle ground between manual work and full automation.

United States Modular Machine Platforms Market was worth USD 1.8 billion in 2024 and is expected to register a CAGR of 5.7% through 2034. The U.S. maintains its leadership in the North American region due to its highly advanced automation infrastructure and high demand from industrial sectors like aerospace, automotive, and high-tech manufacturing. The country's ongoing commitment to reshoring and adopting smart manufacturing principles supports the accelerated deployment of modular systems designed to enable flexible production. North America continues to serve as a hub for early technology adoption, driven by significant investment in R&D and growing industrial digitization.

Key players leading the Modular Machine Platforms Industry include ABB Ltd., Beckhoff Automation, Mitsubishi Electric, ATS Automation, Bosch Rexroth, Siemens AG, B&R Industrial Automation, Staubli International AG, Yaskawa Electric Corporation, KUKA AG, Schunk GmbH, FlexLink Systems, Rockwell Automation, Festo AG & Co. KG, and Universal Robots. To reinforce their market position, major companies are focusing on integrating digital technologies such as IoT, AI, and data analytics into modular systems to improve functionality and performance. They are also expanding their product portfolios to offer plug-and-play modular units that allow rapid configuration and minimal disruption during system upgrades.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Product type

- 2.2.3 Modularity level

- 2.2.4 Operation

- 2.2.5 Application

- 2.2.6 End use

- 2.2.7 Distribution channel

- 2.3 CXO perspectives: Strategic imperatives

- 2.3.1 Key decision points for industry executives

- 2.3.2 Critical success factors for market players

- 2.4 Future Outlook and Strategic Recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.1.5 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.2 Industry pitfalls & challenges

- 3.2.3 Opportunities

- 3.3 Growth potential analysis

- 3.4 Future market trends

- 3.5 Technology and Innovation landscape

- 3.5.1 Current technological trends

- 3.5.2 Emerging technologies

- 3.6 Price trends

- 3.6.1 By region

- 3.6.2 By product type

- 3.7 Regulatory framework

- 3.7.1 Standards and certifications

- 3.7.2 Environmental regulations

- 3.7.3 Import export regulations

- 3.8 Trade statistics

- 3.8.1 Major importing countries

- 3.8.2 Major exporting countries

- 3.9 Porter's five forces analysis

- 3.10 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 Latin America

- 4.2.1.5 Middle East and Africa

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New product launches

- 4.6.4 Expansion plans

Chapter 5 Market Estimates & Forecast, By Product type, 2021 - 2034 (USD Billion) (Thousand Units)

- 5.1 Key trends

- 5.2 Modular assembly systems

- 5.3 Modular robotics platforms

- 5.4 Modular CNC machines

- 5.5 Modular packaging machines

- 5.6 Others

Chapter 6 Market Estimates & Forecast, By Modularity level, 2021 - 2034 (USD Billion) (Thousand Units)

- 6.1 Key trends

- 6.2 Fixed modular platforms

- 6.3 Flexible modular platforms

- 6.4 Reconfigurable machine systems (RMS)

Chapter 7 Market Estimates & Forecast, By Operation, 2021 - 2034 (USD Billion) (Thousand Units)

- 7.1 Key trends

- 7.2 Manual modular platforms

- 7.3 Semi-automatic platforms

- 7.4 Fully automatic platforms

Chapter 8 Market Estimates & Forecast, By Application, 2021 - 2034 (USD Billion) (Thousand Units)

- 8.1 Key trends

- 8.2 Assembly

- 8.3 Material handling

- 8.4 Inspection & testing

- 8.5 Machining

- 8.6 Packaging

- 8.7 Others

Chapter 9 Market Estimates & Forecast, By End Use, 2021 - 2034 (USD Billion) (Thousand Units)

- 9.1 Key trends

- 9.2 Automotive

- 9.3 Electronics and semiconductors

- 9.4 Food and beverage

- 9.5 Pharmaceuticals

- 9.6 Consumer goods

- 9.7 Aerospace and defense

- 9.8 Logistics and warehousing

- 9.9 Others (textile, printing, etc.)

Chapter 10 Market Estimates & Forecast, By Distribution Channel, 2021 - 2034 (USD Billion) (Thousand Units)

- 10.1 Key trends

- 10.2 Direct

- 10.3 Indirect

Chapter 11 Market Estimates & Forecast, By Region, 2021 - 2034 (USD Billion) (Thousand Units)

- 11.1 Key trends

- 11.2 North America

- 11.2.1 U.S.

- 11.2.2 Canada

- 11.3 Europe

- 11.3.1 UK

- 11.3.2 Germany

- 11.3.3 France

- 11.3.4 Italy

- 11.3.5 Spain

- 11.4 Asia Pacific

- 11.4.1 China

- 11.4.2 India

- 11.4.3 Japan

- 11.4.4 South Korea

- 11.4.5 Australia

- 11.5 Latin America

- 11.5.1 Brazil

- 11.5.2 Mexico

- 11.6 MEA

- 11.6.1 South Africa

- 11.6.2 UAE

- 11.6.3 Saudi Arabia

Chapter 12 Company Profiles

- 12.1 ABB Ltd.

- 12.2 ATS Automation

- 12.3 B&R Industrial Automation

- 12.4 Beckhoff Automation

- 12.5 Bosch Rexroth

- 12.6 Festo AG & Co. KG

- 12.7 FlexLink Systems

- 12.8 KUKA AG

- 12.9 Mitsubishi Electric

- 12.10 Rockwell Automation

- 12.11 Schunk GmbH

- 12.12 Siemens AG

- 12.13 Staubli International AG

- 12.14 Universal Robots

- 12.15 Yaskawa Electric Corporation