|

市场调查报告书

商品编码

1822637

光学分选机市场机会、成长动力、产业趋势分析及 2025 - 2034 年预测Optical Sorter Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

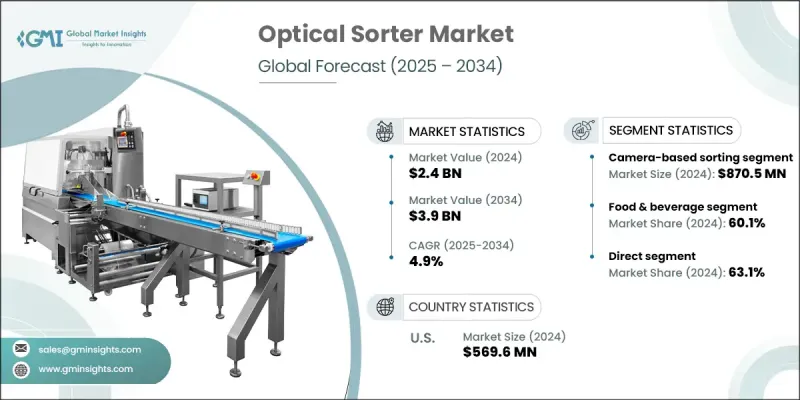

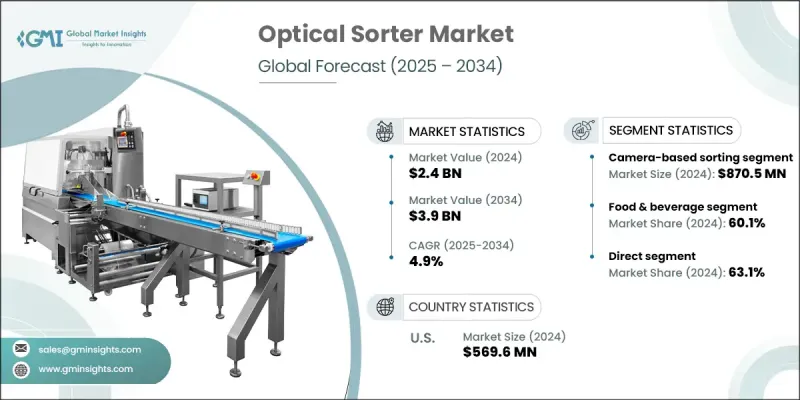

2024 年全球光学分选机市场价值为 24 亿美元,预计到 2034 年将以 4.9% 的复合年增长率成长至 39 亿美元。

蓬勃发展的包装食品产业推动了自动化分类解决方案需求的不断增长,尤其是在快速成长的经济体中。随着加工食品消费量的激增,製造商面临越来越大的满足卫生、安全和品质标准的压力。随着全球人口预测的成长,企业现在面临着高效扩大食品生产规模的巨大压力,这使得光学分类技术成为创新和合规的重中之重。这些系统不再是可有可无的升级,而是在人工检测无法满足需求的高产量设施中不可或缺的。

| 市场范围 | |

|---|---|

| 起始年份 | 2024 |

| 预测年份 | 2025-2034 |

| 起始值 | 24亿美元 |

| 预测值 | 39亿美元 |

| 复合年增长率 | 4.9% |

光学分选技术能够高速、非接触式地侦测并剔除瑕疵产品、污染物和不合格品。这些解决方案不仅符合严格的食品安全法规,还能提高营运吞吐量。不断发展的永续发展目标也影响着产业成长,因为光学分选机在循环经济(包括减少废弃物和资源回收)中发挥关键作用。如今,先进的机器整合了近红外线、高光谱感测器、X射线视觉和人工智慧成像技术,能够根据结构、形状、颜色和化学成分对材料进行精确分选。这些创新正在食品、回收和製药等各行各业中不断增强其重要性。

基于摄影机的分选机在2024年创造了8.705亿美元的市场规模,预计到2034年将以4.6%的复合年增长率成长。由于其成本效益、易于整合和技术灵活性,该细分市场正在迅速扩张。这些系统使用高影格速率的RGB和单色摄像头,可以检测产品特征的细微变化。它们能够处理从新鲜农产品到工业零件的各种产品,使其具有高度的适应性。解析度、边缘运算和板载AI的最新进展正在提高检测率、提高即时准确性并最大限度地减少误判。

食品饮料产业在2024年占了60.1%的市场份额,预计在2025年至2034年期间的复合年增长率将达到4.7%。消费者对品质、清洁度和透明度的期望不断提高,促使加工商投资高效的光学分选机。监管机构日益严格的审查,加上消费者对食品安全和可追溯性的要求,使得这些系统变得至关重要。即时缺陷检测和精准剔除有助于生产商保持一致的产品质量,最大限度地减少召回,并建立品牌信任。

2024年,美国光学分选机市场规模达5.696亿美元,预计2034年将以5.2%的复合年增长率成长。食品加工、回收和製药业的强劲成长推动了这一成长。各机构严格的监管标准要求技术能够提供一流的卫生、精度和可追溯性。随着人们对永续性、减少浪费和自动化的认识不断提高,美国各工业领域对尖端分选设备的需求也不断增长。

影响全球光学分选机市场的关键公司包括 Buhler、Raytec Vision、TOMRA、STEINERT、SATAKE、Allgaier、CP Manufacturing、Cimbria Heid、Angelon、SORTEX、Pellenc ST、GREEFA、NEWTEC、Sesotec 和 NRT (National Recovery Technologies)。光学分选机市场的领导者正在大力投资人工智慧技术和智慧感测器,以提高分选精度并减少处理错误。许多公司正在整合高光谱成像和深度学习演算法来处理各种材料的复杂分选需求。各公司正在扩展其产品组合,以提供可同时满足食品和非食品行业的多应用系统。与自动化供应商的合作有助于简化工厂运作并增强机器互通性。关键公司也透过合资企业和服务伙伴关係扩大其在高成长地区的业务。

目录

第一章:方法论与范围

第 2 章:执行摘要

第三章:行业洞察

- 产业生态系统分析

- 供应商格局

- 利润率

- 每个阶段的增值

- 影响价值链的因素

- 产业衝击力

- 成长动力

- 食品饮料业的扩张

- 回收和废弃物管理需求不断增长

- 技术进步

- 产业陷阱与挑战

- 资本投资成本高

- 在成本敏感的市场中采用有限

- 成长动力

- 成长潜力分析

- 未来市场趋势

- 技术和创新格局

- 当前的技术趋势

- 新兴技术

- 价格趋势

- 按地区

- 按类型

- 监管格局

- 标准和合规性要求

- 区域监理框架

- 认证标准

- 波特的分析

- PESTEL分析

第四章:竞争格局

- 介绍

- 公司市占率分析

- 按地区

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- 中东和非洲

- 按地区

- 公司矩阵分析

- 主要市场参与者的竞争分析

- 竞争定位矩阵

- 关键进展

- 併购

- 伙伴关係与合作

- 新产品发布

- 扩张计划

第五章:市场估计与预测:按类型,2021 - 2034

- 主要趋势

- 基于摄影机的分类

- 雷射分选

- NIR(近红外线)分选

- 高光谱成像

- X射线分选

- 组合/混合系统

第六章:市场估计与预测:依平台,2021 - 2034

- 主要趋势

- 自由落体

- 腰带

- 车道

- 杂交种

- ADR 系统

- 机械平地机

第七章:市场估计与预测:按应用,2021 - 2034

- 主要趋势

- 食品和饮料

- 回收利用

- 製药

- 其他的

第 8 章:市场估计与预测:按配销通路,2021 年至 2034 年

- 主要趋势

- 直接的

- 间接

第九章:市场估计与预测:按地区,2021 - 2034

- 主要趋势

- 北美洲

- 我们

- 加拿大

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 澳洲

- 印尼

- 马来西亚

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- 多边环境协定

- 沙乌地阿拉伯

- 阿联酋

- 南非

第十章:公司简介

- Allgaier

- Buhler

- Cimbria Heid

- CP Manufacturing

- GREEFA

- NRT (National Recovery Technologies)

- NEWTEC

- Pellenc ST

- Raytec Vision

- SATAKE

- Sesotec

- SORTEX

- STEINERT

- TOMRA

- Angelon

The Global Optical Sorter Market was valued at USD 2.4 billion in 2024 and is estimated to grow at a CAGR of 4.9% to reach USD 3.9 billion by 2034.

The accelerating demand for automated sorting solutions, especially in fast-growing economies, is driven by a booming packaged goods sector. As consumption of processed food surges, manufacturers are under mounting pressure to meet hygiene, safety, and quality standards. With rising global population projections, organizations now face intense pressure to scale food production efficiently, placing optical sorting at the forefront of innovation and compliance. These systems are no longer an optional upgrade-they're a necessity in high-output facilities where manual inspection fails to meet demand.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $2.4 Billion |

| Forecast Value | $3.9 Billion |

| CAGR | 4.9% |

Optical sorting technology enables high-speed, contactless detection and removal of defective products, contaminants, and non-conforming items. These solutions support rigorous food safety regulations while increasing operational throughput. Evolving sustainability goals are also influencing growth, as optical sorters play a key role in circular economy efforts, including waste reduction and resource recovery. Advanced machines now integrate near-infrared, hyperspectral sensors, X-ray vision, and AI-powered imaging to accurately sort materials by structure, shape, color, and chemical composition. These innovations are reinforcing their relevance across a diverse range of industries-from food to recycling to pharmaceuticals.

The camera-based sorters generated USD 870.5 million in 2024 and are projected to grow at a CAGR of 4.6% through 2034. This segment is expanding rapidly due to its cost-efficiency, ease of integration, and technological flexibility. Using RGB and monochrome cameras at high frame rates, these systems can detect minute variations in product features. Their ability to process everything from fresh produce to industrial parts makes them highly adaptable. Recent improvements in resolution, edge computing, and onboard AI are sharpening detection rates, improving real-time accuracy, and minimizing false rejects.

The food & beverage industry segment held a 60.1% share in 2024 and is forecast to grow at a CAGR of 4.7% between 2025 and 2034. Rising consumer expectations for quality, cleanliness, and transparency are pushing processors to invest in high-efficiency optical sorters. Increasing scrutiny from regulatory bodies, combined with consumer demands for food safety and traceability, has made these systems essential. Real-time defect detection and precision removal help producers maintain consistent product quality, minimize recalls, and build brand trust.

United States Optical Sorter Market was valued at USD 569.6 million in 2024 and is expected to grow at a CAGR of 5.2% through 2034. Strong growth in food processing, recycling, and pharmaceutical manufacturing is driving this expansion. High regulatory standards from agencies require technologies to deliver top-tier hygiene, precision, and traceability. Growing awareness of sustainability, waste reduction, and automation is accelerating the demand for cutting-edge sorting equipment across the country's industrial sectors.

Key companies shaping the Global Optical Sorter Market include Buhler, Raytec Vision, TOMRA, STEINERT, SATAKE, Allgaier, CP Manufacturing, Cimbria Heid, Angelon, SORTEX, Pellenc ST, GREEFA, NEWTEC, Sesotec, and NRT (National Recovery Technologies). Leading players in the optical sorter market are investing heavily in AI-driven technologies and smart sensors to boost sorting accuracy and reduce processing errors. Many are integrating hyperspectral imaging and deep learning algorithms to handle complex sorting needs across various materials. Companies are expanding their portfolios to offer multi-application systems that cater to both food and non-food sectors. Collaborations with automation providers help streamline plant operations and enhance machine interoperability. Key firms are also scaling their presence in high-growth regions through joint ventures and service partnerships.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Type

- 2.2.3 Platform

- 2.2.4 Application

- 2.2.5 Distribution channel

- 2.3 CXO perspectives: strategic imperatives

- 2.3.1 Key decision points for industry executives

- 2.3.2 Critical success factors for market players

- 2.4 Future outlook and strategic recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Expansion of the food & beverage industry

- 3.2.1.2 Raising demand in recycling & waste management

- 3.2.1.3 Technological advancements

- 3.2.2 Industry pitfalls & challenges

- 3.2.2.1 High capital investment costs

- 3.2.2.2 Limited adoption in cost-sensitive markets

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Future market trends

- 3.5 Technology and innovation landscape

- 3.5.1 Current technological trends

- 3.5.2 Emerging technologies

- 3.6 Price trends

- 3.6.1 By region

- 3.6.2 By type

- 3.7 Regulatory landscape

- 3.7.1 Standards and compliance requirements

- 3.7.2 Regional regulatory frameworks

- 3.7.3 Certification standards

- 3.8 Porter's analysis

- 3.9 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By Region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 Latin America

- 4.2.1.5 Middle East & Africa

- 4.2.1 By Region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New product launches

- 4.6.4 Expansion Plans

Chapter 5 Market Estimates & Forecast, By Type, 2021 - 2034, (USD Million) (Thousand Units)

- 5.1 Key trends

- 5.2 Camera-based sorting

- 5.3 Laser-based sorting

- 5.4 NIR (near-infrared) sorting

- 5.5 Hyperspectral imaging

- 5.6 X-ray sorting

- 5.7 Combined/Hybrid systems

Chapter 6 Market Estimates & Forecast, By Platform, 2021 - 2034, (USD Million) (Thousand Units)

- 6.1 Key trends

- 6.2 Freefall

- 6.3 Belt

- 6.4 Lane

- 6.5 Hybrid

- 6.6 ADR systems

- 6.7 Mechanical graders

Chapter 7 Market Estimates & Forecast, By Application, 2021 - 2034, (USD Million) (Thousand Units)

- 7.1 Key trends

- 7.2 Food & beverage

- 7.3 Recycling

- 7.4 Pharmaceuticals

- 7.5 Others

Chapter 8 Market Estimates & Forecast, By Distribution Channel, 2021 - 2034, (USD Million) (Thousand Units)

- 8.1 Key trends

- 8.2 Direct

- 8.3 Indirect

Chapter 9 Market Estimates & Forecast, By Region, 2021 - 2034, (USD Million) (Thousand Units)

- 9.1 Key trends

- 9.2 North America

- 9.2.1 U.S.

- 9.2.2 Canada

- 9.3 Europe

- 9.3.1 Germany

- 9.3.2 UK

- 9.3.3 France

- 9.3.4 Italy

- 9.3.5 Spain

- 9.4 Asia Pacific

- 9.4.1 China

- 9.4.2 India

- 9.4.3 Japan

- 9.4.4 South Korea

- 9.4.5 Australia

- 9.4.6 Indonesia

- 9.4.7 Malaysia

- 9.5 Latin America

- 9.5.1 Brazil

- 9.5.2 Mexico

- 9.5.3 Argentina

- 9.6 MEA

- 9.6.1 Saudi Arabia

- 9.6.2 UAE

- 9.6.3 South Africa

Chapter 10 Company Profiles

- 10.1 Allgaier

- 10.2 Buhler

- 10.3 Cimbria Heid

- 10.4 CP Manufacturing

- 10.5 GREEFA

- 10.6 NRT (National Recovery Technologies)

- 10.7 NEWTEC

- 10.8 Pellenc ST

- 10.9 Raytec Vision

- 10.10 SATAKE

- 10.11 Sesotec

- 10.12 SORTEX

- 10.13 STEINERT

- 10.14 TOMRA

- 10.15 Angelon