|

市场调查报告书

商品编码

1833422

防静电泡棉包装市场机会、成长动力、产业趋势分析及2025-2034年预测Anti-Static Foam Packaging Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

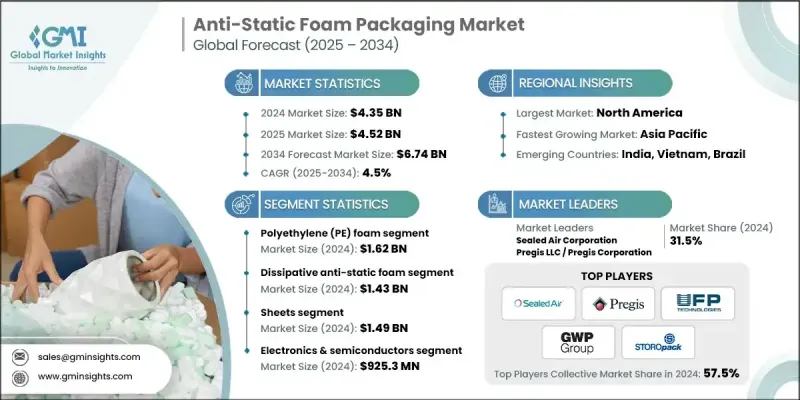

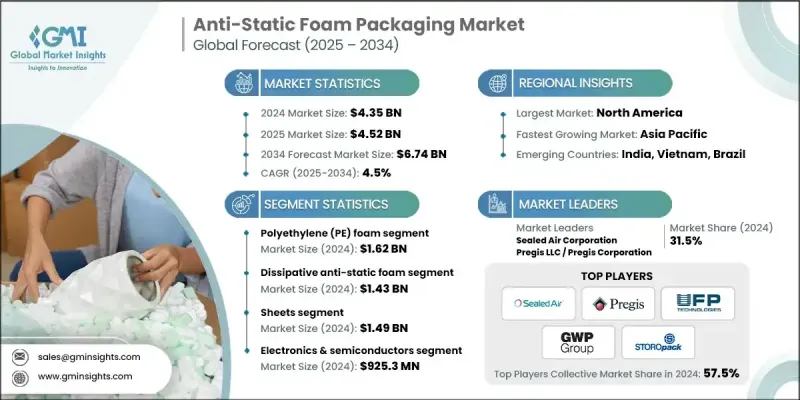

2024 年全球防静电泡棉包装市场价值为 43.5 亿美元,预计到 2034 年将以 4.5% 的复合年增长率成长至 67.4 亿美元。

半导体、电路板和消费性电子产品等敏感电子设备的成长推动了对防静电泡沫包装的需求,以防止在储存和运输过程中因静电放电而造成的损坏。

| 市场范围 | |

|---|---|

| 起始年份 | 2024 |

| 预测年份 | 2025-2034 |

| 起始值 | 43.5亿美元 |

| 预测值 | 67.4亿美元 |

| 复合年增长率 | 4.5% |

聚乙烯(PE)泡沫的采用率不断上升

聚乙烯 (PE) 泡棉凭藉其轻质特性、缓衝性能和优异的抗静电性能,在 2024 年占据了显着的市场份额。 PE 泡棉广泛用于保护精密电子元件,其设计和应用灵活性高,适用于客製化插件、托盘和包装。随着对经济高效的防护材料的需求不断增长,该领域在製造商和供应商中持续成长。

床单需求不断成长

板材细分市场在2024年实现了可持续的市场份额,这得益于其多功能性和易于自订的特性。这些板材非常适合切割成各种工业和消费应用中的插件、隔板和保护层。此细分市场受益于仓储、运输和组装环节日益增长的需求,在这些环节中,防止零件静电积聚至关重要。

电子和半导体产业将获得发展动力

到2034年,电子和半导体领域将保持显着成长,这得益于防止静电放电损坏微晶片、处理器和印刷电路板等高灵敏度设备的需求。随着技术变得越来越紧凑和性能越来越高,包装精度和保护变得比以往任何时候都更加重要。服务于该领域的公司正在开发具有更严格静电控制规范的泡沫解决方案,并整合无尘室包装、配套和合规性测试等增值服务,以支援半导体製造和物流的品质保证。

北美将成为推动力地区

由于其强大的电子製造生态系统和完善的物流基础设施,北美防静电泡沫包装市场在2024年保持持续成长。该地区拥有多家关键企业,是包装技术创新的中心。监管部门对产品安全的重视,加上敏感电子产品的高价值出口,将持续推动市场成长。

防静电泡棉包装市场的主要参与者有 Kaneka Corporation、Foam Fabricators, Inc.、GWP Group Limited、Antistat、Pregis Corporation、UFP Technologies, Inc.、Conductive Containers, Inc. (CCI)、Flexipol Foams Pvt. Ltd.、Storoion Hans Reichenecker Gth、Richenecker NVS、Rectic. AB、BASF SE、Polymer Packaging Inc.、Tekni-Plex, Inc.、Protective Packaging Corporation、Sonoco Products Company 和 ACH Foam Technologies。

为了巩固其在防静电泡棉包装市场的地位,各公司正采取以创新、永续性和以客户为中心的服务为中心的策略。许多公司正在投资环保材料和可回收泡沫,以满足日益增长的环保需求。其他公司则透过精密切割技术和模组化包装系统来增强产品客製化。与电子产品製造商和物流供应商的策略合作有助于简化供应链并确保长期合约的签订。

目录

第一章:方法论与范围

第二章:执行摘要

第三章:行业洞察

- 产业生态系统分析

- 供应商概况

- 利润率

- 成本结构

- 每个阶段的增值

- 影响价值链的因素

- 中断

- 产业衝击力

- 成长动力

- 电子和半导体製造业蓬勃发展

- 全球电子产品电子商务的兴起

- 汽车电子产品的扩展和电动车的普及

- 微型化、ESD敏感元件的激增

- 航太、国防和医疗器材包装的应用

- 产业陷阱与挑战

- 生产和材料成本高

- 环境问题和回收限制

- 市场机会

- 新兴地区半导体工厂的扩张

- 人工智慧和机器学习在光刻製程控制中的集成

- 高数值孔径EUV技术的发展

- 对先进封装和 3D IC 的需求不断增长

- 成长动力

- 成长潜力分析

- 监管格局

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- 中东和非洲

- 波特的分析

- PESTEL分析

- 技术和创新格局

- 当前的技术趋势

- 新兴技术

- 价格趋势

- 按地区

- 按产品

- 定价策略

- 新兴商业模式

- 合规性要求

- 永续性措施

- 消费者情绪分析

- 专利和智慧财产权分析

- 地缘政治与贸易动态

第四章:竞争格局

- 公司简介 市占率分析

- 公司市占率分析

- 按地区

- 北美洲

- 欧洲

- 亚太地区

- 市场集中度分析

- 关键参与者的竞争基准化分析

- 财务绩效比较

- 收入

- 利润率

- 研发

- 产品组合比较

- 产品范围广度

- 科技

- 创新

- 地理分布比较

- 全球足迹分析

- 服务网路覆盖

- 各地区市场渗透率

- 竞争定位矩阵

- 领导者

- 挑战者

- 追踪者

- 利基市场参与者

- 战略展望矩阵

- 财务绩效比较

- 2021-2024 年关键发展

- 併购

- 伙伴关係与合作

- 技术进步

- 扩张和投资策略

- 永续发展倡议

- 数位转型计划

- 新兴/新创企业竞争对手格局

第五章:市场估计与预测:依材料类型,2021 - 2034 年

- 聚乙烯(PE)泡沫

- 聚氨酯(PU)泡沫

- 聚丙烯(PP)泡沫

- 其他材质(例如 PVC、ESD 波纹泡棉)

第六章:市场估计与预测:依产品类型,2021-2034 年

- 导电防静电泡沫

- 耗散防静电泡沫

- 屏蔽防静电泡沫

- 静电中性泡沫

第七章:市场估计与预测:依形式,2021 - 2034

- 工作表

- 麵包捲

- 包包和小袋

- 插入件和托盘

- 客製化形状(模切、模压)

第 8 章:市场估计与预测:按最终用途产业,2021-2034 年

- 电子与半导体

- 汽车

- 消费性电器

- 航太与国防

- 医疗保健和医疗器械

- 工业设备

- 其他(例如电信、再生能源)

第九章:市场估计与预测:按地区,2021 - 2034

- 主要趋势

- 北美洲

- 我们

- 加拿大

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 荷兰

- 鱼子

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 澳洲

- 亚太区

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- 罗拉塔姆

- 中东和非洲

- 阿联酋

- 沙乌地阿拉伯

- 南非

- 罗马

第十章:公司简介

- Sealed Air Corporation

- Pregis Corporation

- Sonoco Products Company

- Storopack Hans Reichenecker GmbH

- Conductive Containers, Inc. (CCI)

- Antistat

- Nefab AB

- Polymer Packaging Inc.

- ACH Foam Technologies

- Foam Fabricators, Inc.

- BASF SE

- Dow Chemical Company

- Kaneka Corporation

- Recticel NV

- Tekni-Plex, Inc.

- DS Smith Plc

- UFP Technologies, Inc.

- GWP Group Limited

- Protective Packaging Corporation

- Flexipol Foams Pvt. Ltd.

The Global Anti-Static Foam Packaging Market was valued at USD 4.35 billion in 2024 and is estimated to grow at a CAGR of 4.5% to reach USD 6.74 billion by 2034.

The growth of sensitive electronic devices such as semiconductors, circuit boards, and consumer electronics drives the need for anti-static foam packaging to prevent damage from electrostatic discharge during storage and transportation.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $4.35 Billion |

| Forecast Value | $6.74 Billion |

| CAGR | 4.5% |

Rising Adoption of Polyethylene (PE) Foam

The polyethylene (PE) foam segment held a notable share in 2024, owing to its lightweight nature, cushioning ability, and excellent resistance to static discharge. Widely used for protecting delicate electronic components, PE foam provides flexibility in both design and application, making it suitable for custom inserts, trays, and wraps. With a growing demand for cost-effective protective materials, this segment continues to gain momentum among manufacturers and suppliers.

Increasing Demand for Sheets

The sheets segment generated a sustainable share in 2024, backed by its versatility and ease of customization. These sheets are ideal for cutting into inserts, dividers, and protective layers used in various industrial and consumer applications. The segment benefits from rising demand across warehousing, shipping, and assembly operations where component protection against static buildup is critical.

Electronics & Semiconductors to Gain Traction

The electronics and semiconductors segment will grow at a significant rate through 2034, driven by the need to prevent electrostatic discharge damage to highly sensitive devices like microchips, processors, and PCBs. As technology becomes more compact and performance-intensive, packaging precision and protection have become more critical than ever. Companies serving this segment are developing foam solutions with tighter static control specifications and integrating value-added services such as cleanroom packaging, kitting, and compliance testing to support quality assurance in semiconductor manufacturing and logistics.

North America to Emerge as a Propelling Region

North America anti-static foam packaging market held sustained growth in 2024, owing to its robust electronics manufacturing ecosystem and well-established logistics infrastructure. The region is home to several key players and serves as a hub for innovation in packaging technology. Regulatory focus on product safety, coupled with high-value exports of sensitive electronics, continues to fuel market growth.

Major players in the anti-static foam packaging market are Kaneka Corporation, Foam Fabricators, Inc., GWP Group Limited, Antistat, Pregis Corporation, UFP Technologies, Inc., Conductive Containers, Inc. (CCI), Flexipol Foams Pvt. Ltd., Storopack Hans Reichenecker GmbH, Recticel NV, DS Smith Plc, Dow Chemical Company, Sealed Air Corporation, Nefab AB, BASF SE, Polymer Packaging Inc., Tekni-Plex, Inc., Protective Packaging Corporation, Sonoco Products Company, and ACH Foam Technologies.

To strengthen their position in the anti-static foam packaging market, companies are adopting strategies centered around innovation, sustainability, and customer-centric service. Many are investing in eco-friendly materials and recyclable foams to meet growing environmental expectations. Others are enhancing product customization through precision cutting technologies and modular packaging systems. Strategic collaborations with electronics manufacturers and logistics providers help streamline supply chains and secure recurring contracts.

Table of Contents

Chapter 1 Methodology and Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 360° synopsis

- 2.2 Key market trends

- 2.2.1. Material Type

- 2.2.2 Product Type

- 2.2.3 Form

- 2.2.4 End use Industry

- 2.2.5 North America

- 2.2.6 Europe

- 2.2.7 Asia Pacific

- 2.2.8 Latin America

- 2.2.9 Middle East & Africa

- 2.3 TAM Analysis, 2025-2034 (USD Million)

- 2.4 CXO perspective: Strategic imperatives

- 2.5 Executive decision points

- 2.6 Critical Success Factors

- 2.7 Future Outlook and Strategic Recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier Landscape

- 3.1.2 Profit Margin

- 3.1.3 Cost structure

- 3.1.4 Value addition at each stage

- 3.1.5 Factor affecting the value chain

- 3.1.6 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Boom in electronics and semiconductor manufacturing

- 3.2.1.2 Rise in global e-commerce for electronics

- 3.2.1.3 Expansion of automotive electronics and ev adoption

- 3.2.1.4 Proliferation of miniaturized, ESD-sensitive components

- 3.2.1.5 Adoption in aerospace, defense, and medical device packaging

- 3.2.2 Industry pitfalls and challenges

- 3.2.2.1 High Production and Material Costs

- 3.2.2.2 Environmental Concerns and Recycling Limitations

- 3.2.3 Market Opportunities

- 3.2.3.1 Expansion of semiconductor fabs in emerging regions

- 3.2.3.2 Integration of AI and machine learning in lithography process control

- 3.2.3.3 Development of High-NA EUV technology

- 3.2.3.4 Growing demand for advanced packaging and 3D ICs

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.4.1 North America

- 3.4.2 Europe

- 3.4.3 Asia Pacific

- 3.4.4 Latin America

- 3.4.5 Middle East & Africa

- 3.5 Porter’s analysis

- 3.6 PESTEL analysis

- 3.7 Technological and Innovation landscape

- 3.7.1 Current technological trends

- 3.7.2 Emerging technologies

- 3.8 Price Trends

- 3.8.1 By region

- 3.8.2 By product

- 3.9 Pricing strategies

- 3.10 Emerging business models

- 3.11 Compliance requirements

- 3.12 Sustainability measures

- 3.13 Consumer sentiment analysis

- 3.14 Patent and IP analysis

- 3.15 Geopolitical and trade dynamics

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction Company market share analysis

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1. North America

- 4.2.2. Europe

- 4.2.3. Asia Pacific

- 4.2.2 Market concentration analysis

- 4.3 Competitive Benchmarking of key Players

- 4.3.1 Financial Performance Comparison

- 4.3.1.1. Revenue

- 4.3.1.2. Profit Margin

- 4.3.1.3. R&D

- 4.3.2 Product Portfolio Comparison

- 4.3.2.1. Product Range Breadth

- 4.3.2.2. Technology

- 4.3.2.3. Innovation

- 4.3.3 Geographic Presence Comparison

- 4.3.3.1. Global Footprint Analysis

- 4.3.3.2. Service Network Coverage

- 4.3.3.3. Market Penetration by Region

- 4.3.4 Competitive Positioning Matrix

- 4.3.4.1. Leaders

- 4.3.4.2. Challengers

- 4.3.4.3. Followers

- 4.3.4.4. Niche Players

- 4.3.5 Strategic outlook matrix

- 4.3.1 Financial Performance Comparison

- 4.4 Key developments, 2021-2024

- 4.4.1 Mergers and Acquisitions

- 4.4.2 Partnerships and Collaborations

- 4.4.3 Technological Advancements

- 4.4.4 Expansion and Investment Strategies

- 4.4.5 Sustainability Initiatives

- 4.4.6 Digital Transformation Initiatives

- 4.5 Emerging/ Startup Competitors Landscape

Chapter 5 Market Estimates & Forecast, By Material Type, 2021 - 2034 (USD Million)

- 5.1 Polyethylene (PE) Foam

- 5.2 Polyurethane (PU) Foam

- 5.3 Polypropylene (PP) Foam

- 5.4 Other Materials (e.g., PVC, ESD corrugated foam)

Chapter 6 Market estimates & forecast, By Product Type, 2021 - 2034 (USD Million)

- 6.1 Conductive Anti-Static Foam

- 6.2 Dissipative Anti-Static Foam

- 6.3 Shielding Anti-Static Foam

- 6.4 Static-Neutral Foam

Chapter 7 Market estimates & forecast, By Form, 2021 - 2034 (USD Million)

- 7.1 Sheets

- 7.2 Rolls

- 7.3 Bags & Pouches

- 7.4 Inserts & Trays

- 7.5 Custom Shapes (Die-cut, Molded)

Chapter 8 Market estimates & forecast, By End use Industry, 2021-2034 (USD Million)

- 8.1 Electronics & Semiconductors

- 8.2 Automotive

- 8.3 Consumer Appliances

- 8.4 Aerospace & Defense

- 8.5 Healthcare & Medical Devices

- 8.6 Industrial Equipment

- 8.7 Others (e.g., telecom, renewable energy)

Chapter 9 Market Estimates and Forecast, By Region, 2021 - 2034 (USD Million)

- 9.1 Key trends

- 9.2 North America

- 9.2.1 U.S.

- 9.2.2 Canada

- 9.3 Europe

- 9.3.1 Germany

- 9.3.2 U.K.

- 9.3.3 France

- 9.3.4 Italy

- 9.3.5 Spain

- 9.3.6 Netherlands

- 9.3.7 ROE

- 9.4 Asia Pacific

- 9.4.1 China

- 9.4.2 India

- 9.4.3 Japan

- 9.4.4 South Korea

- 9.4.5 Australia

- 9.4.6 RoAPAC

- 9.5 Latin America

- 9.5.1 Brazil

- 9.5.2 Mexico

- 9.5.3 Argentina

- 9.5.4 RoLATAM

- 9.6 Middle East & Africa

- 9.6.1 UAE

- 9.6.2 Saudi Arabia

- 9.6.3 South Africa

- 9.6.4 RoMEA

Chapter 10 Company Profile

- 10.1 Sealed Air Corporation

- 10.2 Pregis Corporation

- 10.3 Sonoco Products Company

- 10.4 Storopack Hans Reichenecker GmbH

- 10.5 Conductive Containers, Inc. (CCI)

- 10.6 Antistat

- 10.7 Nefab AB

- 10.8 Polymer Packaging Inc.

- 10.9 ACH Foam Technologies

- 10.10 Foam Fabricators, Inc.

- 10.11 BASF SE

- 10.12 Dow Chemical Company

- 10.13 Kaneka Corporation

- 10.14 Recticel NV

- 10.15 Tekni-Plex, Inc.

- 10.16 DS Smith Plc

- 10.17 UFP Technologies, Inc.

- 10.18 GWP Group Limited

- 10.19 Protective Packaging Corporation

- 10.20 Flexipol Foams Pvt. Ltd.