|

市场调查报告书

商品编码

1871234

自修復黏合剂市场机会、成长驱动因素、产业趋势分析及预测(2025-2034年)Self-healing Adhesives Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

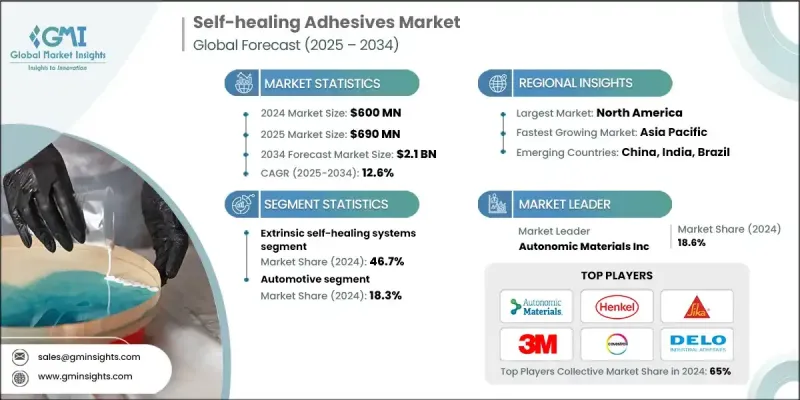

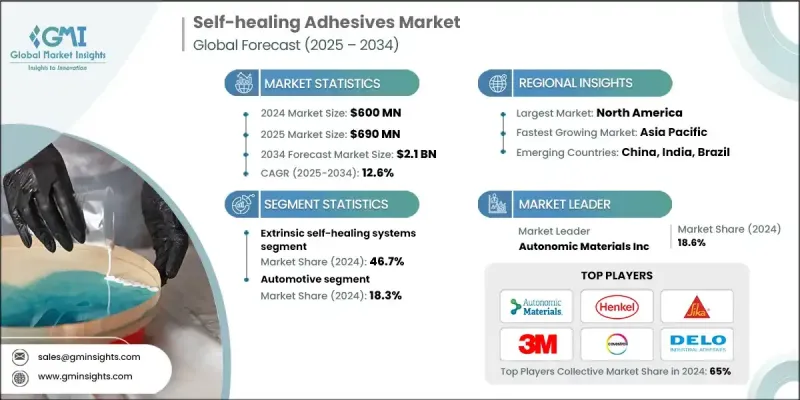

2024 年全球自修復黏合剂市场价值为 6 亿美元,预计到 2034 年将以 12.6% 的复合年增长率增长至 21 亿美元。

建筑、汽车和电子产业对高性能、高耐用性黏接解决方案的需求不断增长,推动了市场的强劲成长。降低维护成本、延长产品寿命的日益重视也进一步促进了自修復黏合剂的应用。随着各行业对能够自动修復损伤和恢復结构的材料的日益需求,自修復黏合剂在整体市场扩张中贡献了近7%的份额。这项技术在航太应用中尤其关键,因为维持结构完整性和复合材料修復效率至关重要。然而,人们对长期性能可靠性的担忧以及有限的现场资料阻碍了其更广泛的应用。诸如修復剂容量受限以及机械应力下不可逆的修復过程等技术挑战也延缓了商业化进程。持续的研究创新已开始透过改进修復动力学、机械恢復和重复性来解决这些障碍。先进奈米材料的整合实现了数分钟内的快速强度恢復,标誌着新一代自修復黏合剂性能的显着提升。

| 市场范围 | |

|---|---|

| 起始年份 | 2024 |

| 预测年份 | 2025-2034 |

| 起始值 | 6亿美元 |

| 预测值 | 21亿美元 |

| 复合年增长率 | 12.6% |

2024年,固有自修復系统市占率达到31.7%,预计将以13.9%的复合年增长率成长。利用动态共价键和超分子键结机制的可逆化学技术日益受到青睐,正在重塑产品开发格局。这些系统无需外部修復剂,即可实现连续、可重复的修復循环,且不会损害材料完整性。分子设计和化学技术的进步显着拓宽了工作温度范围,并提升了整体修復性能。由于其製造流程简单,且适用于各种需要持续机械修復的工业应用,製造商正越来越多地采用这种方法。

2024年,建筑和基础设施应用领域占据18%的市场份额,预计到2034年将以9.3%的复合年增长率成长。该领域反映了成熟的应用趋势,这主要得益于自修復材料在防风雨、结构加强和裂缝修復方面的应用。持续的基础设施现代化以及人们对全生命週期成本效益意识的提高,不断增强了市场需求。自修復混凝土添加剂和黏合剂在桥樑、隧道等关键基础设施中的日益广泛应用,凸显了该技术在维护结构安全性和韧性方面的长期价值。

2024年美国自修復黏合剂市场规模为1.872亿美元,预计到2034年将达到6.674亿美元。美国在北美市场占据主导地位,这主要得益于航太製造商对先进复合材料修復技术的强劲需求。汽车原始设备製造商(OEM)也是重要的市场贡献者,他们在电动车的电池组装和热管理方面广泛采用自修復黏合剂。不断扩展的电动车生态系统以及领先汽车製造商的电气化努力持续推动创新。此外,电子产业也见证了主要科技品牌对柔性穿戴装置黏合剂需求的不断增长,这反映了强劲的国内消费和研发活动。

全球自修復胶合剂市场的主要企业包括西卡(Sika)、3M公司、汉高股份及两合公司(Henkel AG & Co. KGaA)、科思创股份公司(Covestro AG)、Autonomic Materials Inc.和德乐工业胶合剂公司(DELO Industrial Adhesives)。这些市场领导者正积极推行策略倡议,以提升竞争力并巩固其全球布局。各企业大力投资研发,致力于开发具有更高修復效率、更强重复性和更优异耐环境性能的配方。与科研机构和材料科学公司的策略合作,推动了聚合物化学和奈米技术融合的进步。此外,製造商也专注于扩大产能,并拓展应用领域,涵盖建筑、航太和电子等产业。

目录

第一章:方法论与范围

第二章:执行概要

第三章:行业洞察

- 产业生态系分析

- 供应商格局

- 利润率

- 每个阶段的价值增加

- 影响价值链的因素

- 中断

- 产业影响因素

- 成长驱动因素

- 产业陷阱与挑战

- 市场机会

- 成长潜力分析

- 监管环境

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- 中东和非洲

- 波特的分析

- PESTEL 分析

- 价格趋势

- 按地区

- 未来市场趋势

- 技术与创新格局

- 当前技术趋势

- 新兴技术

- 专利格局

- 贸易统计(HS编码)(註:仅提供重点国家的贸易统计资料)

- 主要进口国

- 主要出口国

- 永续性和环境方面

- 永续实践

- 减少废弃物策略

- 生产中的能源效率

- 环保倡议

- 碳足迹考量

第四章:竞争格局

- 介绍

- 公司市占率分析

- 按地区

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- 中东和非洲

- 按地区

- 公司矩阵分析

- 主要市场参与者的竞争分析

- 竞争定位矩阵

- 关键进展

- 併购

- 合作伙伴关係与合作

- 新产品发布

- 扩张计划

第五章:市场规模及预测:依治疗机制划分,2021-2034年

- 主要趋势

- 内在自癒系统

- 外在自癒系统

- 混合型自癒系统

第六章:市场规模及预测:依应用领域划分,2021-2034年

- 主要趋势

- 航太与国防

- 复合材料修復系统

- 保护涂层

- 汽车

- 电动汽车电池密封和热管理

- 结构黏合与车身组装

- 电子元件保护

- 电子与半导体

- 装置组装与封装

- 热界面材料

- 柔性电子产品和穿戴式设备

- 建筑与基础设施

- 结构修復系统

- 防风雨和密封

- 维护与翻新

- 医疗器材

- 海洋与近海

- 其他的

第七章:市场规模及预测:依材料类型划分,2021-2034年

- 主要趋势

- 环氧树脂基体系

- 聚氨酯基体系

- 硅基系统

- 丙烯酸基系统

- 生物基系统

第八章:市场规模及预测:依地区划分,2021-2034年

- 主要趋势

- 北美洲

- 我们

- 加拿大

- 欧洲

- 英国

- 德国

- 法国

- 义大利

- 西班牙

- 欧洲其他地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 澳洲

- 亚太其他地区

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- 拉丁美洲其他地区

- 中东和非洲

- 南非

- 沙乌地阿拉伯

- 阿联酋

- 中东和非洲其他地区

第九章:公司简介

- Autonomic Materials

- Henkel AG

- 3M Company

- DowDuPont

- Arkema Group

- Covestro AG

- DELO Industrial Adhesives

- Fraunhofer

- HB Fuller Company

- Lohmann-koester GmbH

- Sika

- WACKER Chemie

- WEICON GmbH

The Global Self-healing Adhesives Market was valued at USD 600 million in 2024 and is estimated to grow at a CAGR of 12.6% to reach USD 2.1 Billion by 2034.

Rising demand for high-performance and durable bonding solutions across the construction, automotive, and electronics sectors is driving strong market growth. The growing focus on reducing maintenance expenses while extending product lifespan is further encouraging adoption. Self-healing adhesives contribute nearly 7% to overall market expansion, as industries increasingly seek materials capable of automatic damage repair and structural recovery. The technology is particularly critical in aerospace applications where maintaining structural integrity and composite repair efficiency is essential. However, concerns surrounding long-term performance reliability and limited field data have hindered broader adoption. Technical challenges such as restricted healing agent capacity and irreversible repair processes under mechanical stress have also slowed commercialization. Ongoing research innovations have started to address these barriers by improving healing kinetics, mechanical recovery, and repeatability. The integration of advanced nanomaterials has enabled rapid strength recovery within minutes, marking a significant leap in the performance of next-generation self-healing adhesives.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $600 Million |

| Forecast Value | $2.1 Billion |

| CAGR | 12.6% |

The intrinsic self-healing systems segment held 31.7% share in 2024 and is forecast to grow at a CAGR of 13.9%. The growing preference for reversible chemistry-based technologies that utilize dynamic covalent and supramolecular bonding mechanisms is reshaping product development. These systems eliminate the need for external healing agents and enable continuous, repeatable repair cycles without compromising material integrity. The advancement in molecular design and chemistry has significantly expanded operating temperature ranges and enhanced overall healing performance. Manufacturers are increasingly adopting this approach due to its manufacturing simplicity and suitability for various industrial applications requiring consistent mechanical recovery.

The construction and infrastructure applications segment held 18% share in 2024 and is expected to grow at a 9.3% CAGR through 2034. This segment reflects a mature adoption trend driven by self-healing materials for weatherproofing, structural reinforcement, and crack mitigation. Ongoing infrastructure modernization, combined with rising awareness about lifecycle cost efficiency, continues to strengthen market demand. The growing application of self-healing concrete additives and bonding agents in critical infrastructure such as bridges and tunnels underscores the technology's long-term value in maintaining structural safety and resilience.

U.S. Self-healing Adhesives Market was valued at USD 187.2 million in 2024 and is estimated to reach USD 667.4 million by 2034. The United States dominates the North American landscape, supported by substantial demand from aerospace manufacturers that require advanced composite repair technologies. Automotive OEMs are also major contributors, with strong adoption of self-healing adhesives for battery assembly and thermal management in electric vehicles. The expanding EV ecosystem, alongside the electrification efforts of leading carmakers, continues to drive innovation. Additionally, the electronics sector is witnessing rising use of flexible and wearable device adhesives from major technology brands, reflecting strong domestic consumption and R&D activity.

Prominent companies operating in the Global Self-healing Adhesives Market include Sika, 3M Company, Henkel AG & Co. KGaA, Covestro AG, Autonomic Materials Inc., and DELO Industrial Adhesives. Leading participants in the Global Self-healing Adhesives Market are pursuing strategic initiatives to enhance competitiveness and strengthen their global footprint. Companies are heavily investing in R&D to develop formulations with improved healing efficiency, repeatability, and environmental resistance. Strategic collaborations with research institutions and material science firms are enabling advancements in polymer chemistry and nanotechnology integration. Manufacturers are also focusing on expanding production capacities and diversifying application portfolios across construction, aerospace, and electronics.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 360° synopsis

- 2.2 Key market trends

- 2.2.1 Healing Mechanism

- 2.2.2 Application

- 2.2.3 Material Base

- 2.3 TAM analysis, 2025-2034

- 2.4 CXO perspectives: Strategic imperatives

- 2.4.1 Executive decision points

- 2.4.2 Critical success factors

- 2.5 Outlook and strategic recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.1.5 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.2 Industry pitfalls and challenges

- 3.2.3 Market opportunities

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.4.1 North America

- 3.4.2 Europe

- 3.4.3 Asia Pacific

- 3.4.4 Latin America

- 3.4.5 Middle East & Africa

- 3.5 Porter's analysis

- 3.6 PESTEL analysis

- 3.6.1 Technology and innovation landscape

- 3.6.2 Current technological trends

- 3.6.3 Emerging technologies

- 3.7 Price trends

- 3.7.1 By region

- 3.8 Future market trends

- 3.9 Technology and innovation landscape

- 3.9.1 Current technological trends

- 3.9.2 Emerging technologies

- 3.10 Patent landscape

- 3.11 Trade statistics (HS code) (Note: the trade statistics will be provided for key countries only)

- 3.11.1 Major importing countries

- 3.11.2 Major exporting countries

- 3.12 Sustainability and environmental aspects

- 3.12.1 Sustainable practices

- 3.12.2 Waste reduction strategies

- 3.12.3 Energy efficiency in production

- 3.12.4 Eco-friendly initiatives

- 3.13 Carbon footprint considerations

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 Latin America

- 4.2.1.5 Middle East & Africa

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New product launches

- 4.6.4 Expansion plans

Chapter 5 Market Size and Forecast, By Healing Mechanism, 2021-2034 (USD Million) (Kilo Tons)

- 5.1 Key trends

- 5.2 Intrinsic self-healing systems

- 5.3 Extrinsic self-healing systems

- 5.4 Hybrid self-healing systems

Chapter 6 Market Size and Forecast, By Application, 2021-2034 (USD Million) (Kilo Tons)

- 6.1 Key trends

- 6.2 Aerospace & defense

- 6.2.1 Composite repair systems

- 6.2.2 Protective coatings

- 6.3 Automotive

- 6.3.1 EV battery sealing & thermal management

- 6.3.2 Structural bonding & body assembly

- 6.3.3 Electronic component protection

- 6.4 Electronics & semiconductors

- 6.4.1 Device assembly & encapsulation

- 6.4.2 Thermal interface materials

- 6.4.3 Flexible electronics & wearables

- 6.5 Construction & infrastructure

- 6.5.1 Structural repair systems

- 6.5.2 Weatherproofing & sealing

- 6.5.3 Maintenance & renovation

- 6.6 Medical devices

- 6.7 Marine & offshore

- 6.8 Others

Chapter 7 Market Size and Forecast, By Material Base, 2021-2034 (USD Million) (Kilo Tons)

- 7.1 Key trends

- 7.2 Epoxy-based systems

- 7.3 Polyurethane-based systems

- 7.4 Silicone-based systems

- 7.5 Acrylic-based systems

- 7.6 Bio-based systems

Chapter 8 Market Size and Forecast, By Region, 2021-2034 (USD Million) (Kilo Tons)

- 8.1 Key trends

- 8.2 North America

- 8.2.1 U.S.

- 8.2.2 Canada

- 8.3 Europe

- 8.3.1 UK

- 8.3.2 Germany

- 8.3.3 France

- 8.3.4 Italy

- 8.3.5 Spain

- 8.3.6 Rest of Europe

- 8.4 Asia Pacific

- 8.4.1 China

- 8.4.2 India

- 8.4.3 Japan

- 8.4.4 South Korea

- 8.4.5 Australia

- 8.4.6 Rest of Asia Pacific

- 8.5 Latin America

- 8.5.1 Brazil

- 8.5.2 Mexico

- 8.5.3 Argentina

- 8.5.4 Rest of Latin America

- 8.6 Middle East & Africa

- 8.6.1 South Africa

- 8.6.2 Saudi Arabia

- 8.6.3 UAE

- 8.6.4 Rest of Middle East & Africa

Chapter 9 Company Profiles

- 9.1 Autonomic Materials

- 9.2 Henkel AG

- 9.3 3M Company

- 9.4 DowDuPont

- 9.5 Arkema Group

- 9.6 Covestro AG

- 9.7 DELO Industrial Adhesives

- 9.8 Fraunhofer

- 9.9 H.B. Fuller Company

- 9.10 Lohmann-koester GmbH

- 9.11 Sika

- 9.12 WACKER Chemie

- 9.13 WEICON GmbH