|

市场调查报告书

商品编码

1876818

再生碳纤维市场机会、成长驱动因素、产业趋势分析及预测(2025-2034年)Recycled Carbon Fiber Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

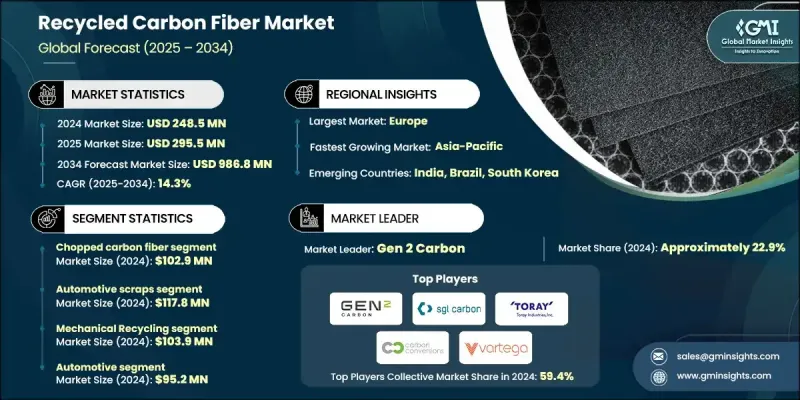

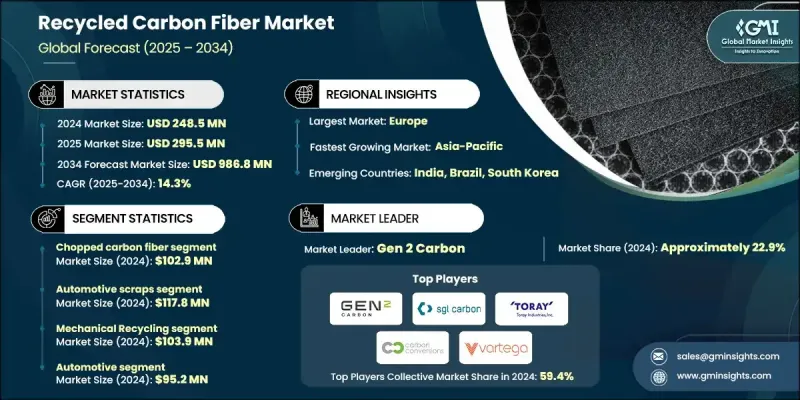

2024 年全球再生碳纤维市场价值为 2.485 亿美元,预计到 2034 年将以 14.3% 的复合年增长率增长至 9.868 亿美元。

市场成长的驱动力在于人们日益重视减少原生碳纤维生产对环境的影响,这促使原始设备製造商(OEM)将再生碳纤维(rCF)应用于电动车零件和轻量化汽车内装。 Vartega 和 ELG Carbon Fibre 等公司已扩大产能以满足不断增长的需求。政府支持的研究项目,尤其是在交通运输领域,正在推广 rCF 的应用,以提高车辆效率并降低排放。热解和溶剂分解技术的进步使得更长的纤维束成为可能,使其在结构应用方面更具可行性。航太和汽车产业正在扩大 rCF 在内饰、塑胶增强材料和底盘部件中的应用。中国也加大了投入,建立了回收中心来处理风力涡轮机叶片和复合材料废弃物。循环经济政策和更清洁的复合材料加工技术为从利基应用到可规模化商业化生产的转变提供了支持。纤维回收技术的创新,包括低温热解和化学溶剂分解,正在提高纤维的长度和强度。 Vartega 和 Carbon Conversions 等公司生产的再生碳纤维 (rCF) 品质接近原生材料,适用于热塑性塑料和片状模塑料,可应用于对錶面光洁度和性能要求极高的高性能消费电子产品和体育用品领域。

| 市场范围 | |

|---|---|

| 起始年份 | 2024 |

| 预测年份 | 2025-2034 |

| 起始值 | 2.485亿美元 |

| 预测值 | 9.868亿美元 |

| 复合年增长率 | 14.3% |

2024年,短切碳纤维市场规模为1.029亿美元,预计到2034年将以13.1%的复合年增长率成长。短切和研磨后的再生碳纤维(rCF)因其易于与热塑性塑料和树脂混合而被广泛应用,尤其是在汽车和电子製造领域。这些纤维的注塑成型过程实现了轻量化零件的大规模生产,而纤维尺寸的一致性是原始设备製造商(OEM)的重点。

2024年,以汽车废弃物为基础的再生碳纤维(rCF)市值达1.178亿美元,预计2025年至2034年复合年增长率将达到17%。电动车的蓬勃发展和日益严格的垃圾掩埋法规加速了汽车和工业废弃物数量的成长,推动了这个细分市场的发展。破碎的碳纤维增强复合材料(CFRP)废料越来越多地被加工成短切和研磨纤维,用于注塑成型。风力涡轮机叶片的回收利用在欧洲也日益普及,目前正在试验采用先进方法从混合来源中回收材料。

2024年美国再生碳纤维市场规模为5,850万美元,预计2034年将以14.4%的复合年增长率成长。轻量化措施、电动车普及率的提高以及对垃圾掩埋场废弃物的监管压力是推动市场需求成长的主要因素。 Carbon Conversions和Vartega等公司已与美国本土汽车製造商建立了合作关係,而美国能源部也支持汽车产业再生碳纤维回收技术的创新。随着汽车製造商越来越多地采用循环製造模式,美国本土的工业回收中心为扩大生产规模提供了机会。

全球再生碳纤维市场的主要参与者包括Vartega、Gen 2 Carbon、东丽株式会社、Carbon Conversions和SGL Carbon。为了巩固市场地位,再生碳纤维产业的企业正大力投资研发,以提高纤维回收率、维持结构完整性并提升再生碳纤维(rCF)的品质。与汽车和航太设备製造商(OEM)建立策略合作伙伴关係,使企业能够获得长期供应合约并扩大生产规模。此外,企业也正在扩大全球产能以满足不断增长的需求,并采用循环经济实践来吸引具有环保意识的客户。热解、溶剂解和低温加工等技术的创新确保了纤维接近原生纤维的质量,使其能够进入消费性电子产品和运动器材等高价值应用领域。

目录

第一章:方法论

- 市场范围和定义

- 研究设计

- 研究方法

- 资料收集方法

- 资料探勘来源

- 全球的

- 地区/国家

- 基准估算和计算

- 基准年计算

- 市场估算的关键趋势

- 初步研究和验证

- 原始资料

- 预测模型

- 研究假设和局限性

第二章:执行概要

第三章:行业洞察

- 产业生态系分析

- 供应商格局

- 利润率

- 每个阶段的价值增加

- 影响价值链的因素

- 中断

- 产业影响因素

- 成长驱动因素

- 产业陷阱与挑战

- 市场机会

- 成长潜力分析

- 监管环境

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- 中东和非洲

- 波特的分析

- PESTEL 分析

- 价格趋势

- 按地区

- 未来市场趋势

- 技术与创新格局

- 当前技术趋势

- 新兴技术

- 专利格局

- 贸易统计(註:仅提供重点国家的贸易统计)

- 主要进口国

- 主要出口国

- 永续性和环境方面

- 永续实践

- 减少废弃物策略

- 生产中的能源效率

- 环保倡议

- 碳足迹考量

第四章:竞争格局

- 介绍

- 公司市占率分析

- 按地区

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- MEA

- 按地区

- 公司矩阵分析

- 主要市场参与者的竞争分析

- 竞争定位矩阵

- 关键进展

- 併购

- 合作伙伴关係与合作

- 新产品发布

- 扩张计划

第五章:市场估算与预测:依产品类型划分,2025-2034年

- 短切碳纤维

- 铣削碳纤维

- 碳纤维垫

- 其他的

第六章:市场估算与预测:依来源划分,2025-2034年

- 主要趋势

- 汽车废料

- 航太废料

- 其他

第七章:市场估算与预测:依回收方式划分,2025-2034年

- 主要趋势

- 机械回收

- 化学回收

- 热解

- 溶剂分解

- 其他的

第八章:市场估算与预测:依最终用途划分,2025-2034年

- 主要趋势

- 航太与国防

- 汽车

- 风能

- 运动与休閒

- 建造

- 电子

- 其他的

第九章:市场估计与预测:依地区划分,2025-2034年

- 主要趋势

- 北美洲

- 我们

- 加拿大

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 欧洲其他地区

- 亚太地区

- 中国

- 印度

- 日本

- 澳洲

- 韩国

- 亚太其他地区

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- 拉丁美洲其他地区

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 阿联酋

- 中东和非洲其他地区

第十章:公司简介

- Gen 2 Carbon

- Carbon Conversions

- Vartega

- SGL Carbon

- Toray Industries

- Mitsubishi Chemical

- Procotex Corporation

- Shocker Composites

- Carbon Fiber Recycling

- CFK Valley Stade

- Zoltek (Toray Group)

- Karborek

- Alpha Recyclage

- Sigmatex

- Carbon Clean Tech

- Recycled Carbon Fiber Ltd

- Composite Recycling Ltd

- Adherent Technologies

- Carbon Fiber Remanufacturing

- Fiberline Composites

The Global Recycled Carbon Fiber Market was valued at USD 248.5 million in 2024 and is estimated to grow at a CAGR of 14.3% to reach USD 986.8 million by 2034.

Market growth is fueled by the increasing push to reduce the environmental impact of primary carbon fiber production, prompting Original Equipment Manufacturers to integrate rCF in electric vehicle components and lightweight automotive interiors. Companies such as Vartega and ELG Carbon Fibre have expanded their production capacities to meet growing demand. Government-backed research initiatives, particularly in the transportation sector, are promoting rCF for enhanced vehicle efficiency and lower emissions. Advances in pyrolysis and solvolysis are enabling longer fiber strands, making structural applications more feasible. Aerospace and automotive industries are scaling the use of rCF in interiors, plastic reinforcements, and underbody components. China has also intensified efforts, developing recycling hubs to manage wind turbine blades and composite waste. The transition from niche applications to scalable commercial production is supported by circular economy policies and cleaner composite processing technologies. Innovations in fiber recovery, including low-temperature pyrolysis and chemical solvolysis, are enhancing fiber length and strength. Companies such as Vartega and Carbon Conversions are producing rCF with near-virgin quality suitable for thermoplastics and sheet molding compounds, enabling applications in high-performance consumer electronics and sporting goods where finish and performance are critical.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $248.5 Million |

| Forecast Value | $986.8 Million |

| CAGR | 14.3% |

The chopped carbon fiber segment was valued at USD 102.9 million in 2024 and is expected to grow at a CAGR of 13.1% through 2034. Chopped and milled rCF is widely used due to its ease of integration with thermoplastics and resins, particularly in automotive and electronics manufacturing. Injection molding of these fibers has enabled mass production of lightweight components, with consistent fiber sizing being a key focus for OEMs.

The automotive scrap-based rCF was valued at USD 117.8 million in 2024, with a projected CAGR of 17% from 2025 to 2034. Rising volumes of automotive and industrial waste, accelerated by the electric vehicle boom and stricter landfill regulations, are driving this segment. Shredded CFRP waste is increasingly processed into chopped and milled fibers for injection molding applications. Wind turbine blade recycling is also gaining traction in Europe, with advanced methods being piloted to recover materials from mixed sources.

U.S. Recycled Carbon Fiber Market was valued at USD 58.5 million in 2024 and is expected to grow at a CAGR of 14.4% through 2034. Demand is driven by lightweighting initiatives, increased EV adoption, and regulatory pressure on landfill waste. Companies like Carbon Conversions and Vartega have partnered with domestic automakers, while the Department of Energy supports innovation in automotive-focused recycling. U.S.-based industrial recycling hubs offer opportunities to scale production as OEMs increasingly adopt circular manufacturing practices.

Key players in the Global Recycled Carbon Fiber Market include Vartega, Gen 2 Carbon, Toray Industries, Carbon Conversions, and SGL Carbon. To strengthen their foothold, companies in the recycled carbon fiber sector are investing heavily in research and development to improve fiber recovery, maintain structural integrity, and enhance the quality of rCF. Strategic partnerships with automotive and aerospace OEMs allow firms to secure long-term supply contracts and scale production. Firms are also expanding their global production capacity to meet rising demand and adopting circular economy practices to attract environmentally conscious clients. Technological innovation in pyrolysis, solvolysis, and low-temperature processing ensures near-virgin quality fibers, enabling entry into high-value applications like consumer electronics and sports equipment.

Table of Contents

Chapter 1 Methodology

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 360° synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Product Type

- 2.2.3 Source

- 2.2.4 Recycling Method

- 2.2.5 End use

- 2.3 TAM Analysis, 2025-2034

- 2.4 CXO perspectives: Strategic imperatives

- 2.4.1 Executive decision points

- 2.4.2 Critical success factors

- 2.5 Future Outlook and Strategic Recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier Landscape

- 3.1.2 Profit Margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.1.5 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.2 Industry pitfalls and challenges

- 3.2.3 Market opportunities

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.4.1 North America

- 3.4.2 Europe

- 3.4.3 Asia Pacific

- 3.4.4 Latin America

- 3.4.5 Middle East & Africa

- 3.5 Porter's analysis

- 3.6 PESTEL analysis

- 3.7 Price trends

- 3.7.1 By region

- 3.8 Future market trends

- 3.9 Technology and Innovation landscape

- 3.9.1 Current technological trends

- 3.9.2 Emerging technologies

- 3.10 Patent Landscape

- 3.11 Trade statistics (Note: the trade statistics will be provided for key countries only)

- 3.11.1 Major importing countries

- 3.11.2 Major exporting countries

- 3.12 Sustainability and Environmental Aspects

- 3.12.1 Sustainable Practices

- 3.12.2 Waste Reduction Strategies

- 3.12.3 Energy Efficiency in Production

- 3.12.4 Eco-friendly Initiatives

- 3.13 Carbon Footprint Considerations

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 LATAM

- 4.2.1.5 MEA

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New Product Launches

- 4.6.4 Expansion Plans

Chapter 5 Market Estimates and Forecast, By Product Type, 2025 - 2034 (USD Million, Kilo Tons)

- 5.1 Chopped carbon fiber

- 5.2 Milled carbon fiber

- 5.3 Carbon fiber mat

- 5.4 Others

Chapter 6 Market Estimates and Forecast, By Source, 2025 - 2034 (USD Million, Kilo Tons)

- 6.1 Key trends

- 6.2 Automotive scrap

- 6.3 Aerospace scrap

- 6.4 Other

Chapter 7 Market Estimates and Forecast, By Recycling Method, 2025 - 2034 (USD Million, Kilo Tons)

- 7.1 Key trends

- 7.2 Mechanical Recycling

- 7.3 Chemical Recycling

- 7.4 Pyrolysis

- 7.5 Solvolysis

- 7.6 Others

Chapter 8 Market Estimates and Forecast, By End Use, 2025 - 2034 (USD Million, Kilo Tons)

- 8.1 Key trends

- 8.2 Aerospace and Defense

- 8.3 Automotive

- 8.4 Wind Energy

- 8.5 Sports and Leisure

- 8.6 Construction

- 8.7 Electronics

- 8.8 Others

Chapter 9 Market Estimates and Forecast, By Region, 2025 - 2034 (USD Million, Kilo Tons)

- 9.1 Key trends

- 9.2 North America

- 9.2.1 U.S.

- 9.2.2 Canada

- 9.3 Europe

- 9.3.1 Germany

- 9.3.2 UK

- 9.3.3 France

- 9.3.4 Italy

- 9.3.5 Spain

- 9.3.6 Rest of Europe

- 9.4 Asia Pacific

- 9.4.1 China

- 9.4.2 India

- 9.4.3 Japan

- 9.4.4 Australia

- 9.4.5 South Korea

- 9.4.6 Rest of Asia Pacific

- 9.5 Latin America

- 9.5.1 Brazil

- 9.5.2 Mexico

- 9.5.3 Argentina

- 9.5.4 Rest of Latin America

- 9.6 Middle East & Africa

- 9.6.1 Saudi Arabia

- 9.6.2 South Africa

- 9.6.3 UAE

- 9.6.4 Rest of Middle East & Africa

Chapter 10 Company Profiles

- 10.1 Gen 2 Carbon

- 10.2 Carbon Conversions

- 10.3 Vartega

- 10.4 SGL Carbon

- 10.5 Toray Industries

- 10.6 Mitsubishi Chemical

- 10.7 Procotex Corporation

- 10.8 Shocker Composites

- 10.9 Carbon Fiber Recycling

- 10.10 CFK Valley Stade

- 10.11 Zoltek (Toray Group)

- 10.12 Karborek

- 10.13 Alpha Recyclage

- 10.14 Sigmatex

- 10.15 Carbon Clean Tech

- 10.16 Recycled Carbon Fiber Ltd

- 10.17 Composite Recycling Ltd

- 10.18 Adherent Technologies

- 10.19 Carbon Fiber Remanufacturing

- 10.20 Fiberline Composites