|

市场调查报告书

商品编码

1892756

聚丙烯无规共聚物市场机会、成长驱动因素、产业趋势分析及预测(2026-2035年)Polypropylene Random Copolymer Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2026 - 2035 |

||||||

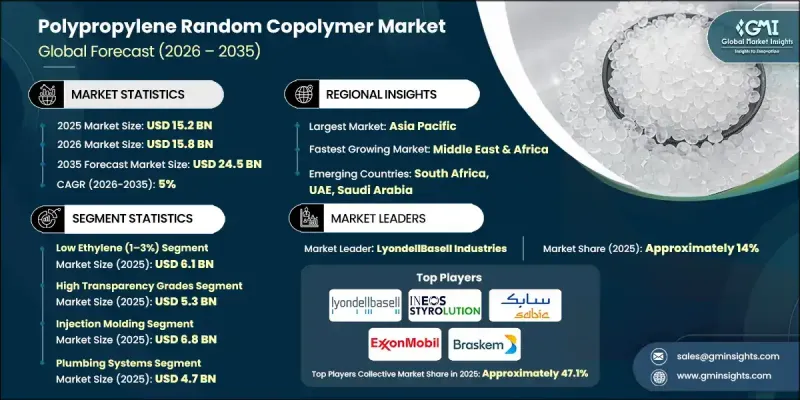

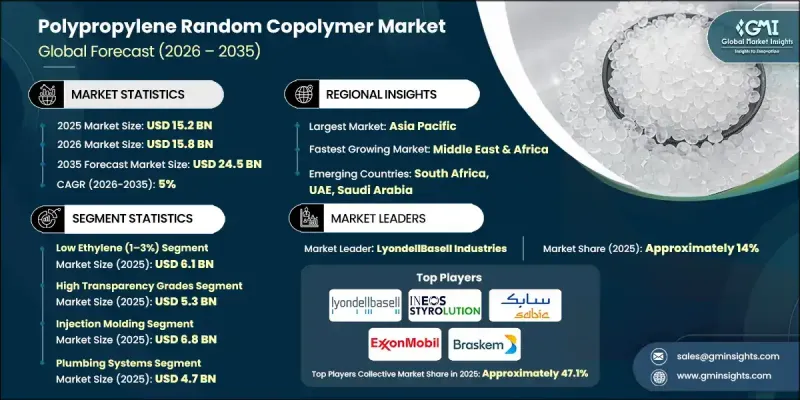

2025年全球聚丙烯无规共聚物市场价值为152亿美元,预计2035年将以5%的复合年增长率成长至245亿美元。

全球建筑活动的强劲成长支撑了市场扩张,这主要得益于加速的城市发展和大型基础设施项目,尤其是在亚太和拉丁美洲地区。聚丙烯无规共聚物因其耐久性、耐腐蚀性和长使用寿命而备受青睐,使其非常适合现代建筑的需求。其低维护成本的特性进一步巩固了其在长期建筑应用中的地位。同时,食品和消费品包装行业需求的成长也推动了市场发展,因为该材料具有更高的透明度、衝击强度和热稳定性。对产品安全性和品质日益重视,促使製造商转向多功能聚合物解决方案。医疗和製药行业也为市场成长做出了贡献,因为聚丙烯无规共聚物因其耐化学性、与灭菌製程的兼容性以及适用于精密应用而备受青睐。这些终端用户产业共同建构了一个稳定且多元化的需求基础,持续支撑着市场的稳定成长。

| 市场范围 | |

|---|---|

| 起始年份 | 2025 |

| 预测年份 | 2026-2035 |

| 起始值 | 152亿美元 |

| 预测值 | 245亿美元 |

| 复合年增长率 | 5% |

2025年,高透明度等级钢材市场规模达53亿美元,预计2026年至2035年将以5.3%的复合年增长率成长。这些等级钢材越来越多地应用于对视觉清晰度和美观性要求极高的应用领域,而抗衝击改性钢材则在需要更高韧性和耐久性的应用中不断扩大其市场份额。

2025 年,管道系统市场规模达到 47 亿美元,占市场份额的 30.7%,预计到 2035 年将以 4.8% 的复合年增长率成长。住宅和商业建筑对持久耐用、耐腐蚀管道的持续需求,以及医疗组件对化学稳定性和消毒相容性的稳定应用,都推动了管道系统的普及。

2025年北美无规聚丙烯共聚物市场规模预估为27亿美元,并在预测期内维持强劲成长。该地区的需求增长得益于持续的基础设施升级、工业管道领域应用的日益广泛、医疗和食品级应用领域的增长,以及对可回收和环保材料的日益重视。

目录

第一章:方法论

第二章:执行概要

第三章:行业洞察

- 产业生态系分析

- 供应商格局

- 利润率

- 每个阶段的价值增加

- 影响价值链的因素

- 中断

- 产业影响因素

- 成长驱动因素

- 产业陷阱与挑战

- 市场机会

- 成长潜力分析

- 监管环境

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- 中东和非洲

- 波特的分析

- PESTEL 分析

- 价格趋势

- 按地区

- 副产品

- 未来市场趋势

- 技术与创新格局

- 当前技术趋势

- 新兴技术

- 专利格局

- 贸易统计(註:仅提供重点国家的贸易统计)

- 主要进口国

- 主要出口国

- 永续性和环境方面

- 永续实践

- 减少废弃物策略

- 生产中的能源效率

- 环保倡议

- 碳足迹考量

第四章:竞争格局

- 介绍

- 公司市占率分析

- 按地区

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- MEA

- 按地区

- 公司矩阵分析

- 主要市场参与者的竞争分析

- 竞争定位矩阵

- 关键进展

- 併购

- 合作伙伴关係与合作

- 新产品发布

- 扩张计划

第五章:市场估计与预测:依乙烯含量划分,2022-2035年

- 低乙烯含量(1-3%)

- 中等乙烯(4-5%)

- 高乙烯含量(6-7%)

第六章:市场估算与预测:依等级划分,2022-2035年

- 高透明度等级

- 食品包装

- 医疗器材

- 抗衝击改质等级

- 水管

- 汽车零件

- 紫外线稳定等级

- 室外管道

- 农业应用

- 其他的

第七章:市场估算与预测:依加工形式划分,2022-2035年

- 射出成型

- 挤压

- 吹塑成型

第八章:市场估算与预测:依应用领域划分,2022-2035年

- 管道系统

- 热水管道

- 冷水管

- 医疗应用

- 注射器

- 无菌容器

- 食品包装

- 透明容器

- 瓶盖和封口

- 工业部件

- 化学品储罐

- 配件

- 其他的

第九章:市场估计与预测:依地区划分,2022-2035年

- 北美洲

- 我们

- 加拿大

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 欧洲其他地区

- 亚太地区

- 中国

- 印度

- 日本

- 澳洲

- 韩国

- 亚太其他地区

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- 拉丁美洲其他地区

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 阿联酋

- 中东和非洲其他地区

第十章:公司简介

- LyondellBasell Industries

- INEOS Styrolution

- SABIC

- ExxonMobil Chemical

- Braskem SA

- Formosa Plastics Corporation

- TotalEnergies

- Repsol

- Chevron Phillips Chemical

- Reliance Industries Limited

- Aquatherm GmbH

- Wefatherm GmbH

- Georg Fischer Piping Systems

- Uponor

- Astral Poly Technik Ltd.

The Global Polypropylene Random Copolymer Market was valued at USD 15.2 billion in 2025 and is estimated to grow at a CAGR of 5% to reach USD 24.5 billion by 2035.

Market expansion is supported by strong growth in global construction activity, driven by accelerating urban development and large-scale infrastructure projects, particularly across Asia-Pacific and Latin America. Polypropylene random copolymer continues to gain preference due to its durability, corrosion resistance, and long service life, making it well-suited for modern building requirements. Its low-maintenance profile further strengthens adoption across long-term construction applications. At the same time, rising demand from the food and consumer packaging sector is supporting market momentum, as the material offers improved clarity, impact strength, and thermal stability. Growing emphasis on product safety and quality has encouraged manufacturers to shift toward versatile polymer solutions. The medical and pharmaceutical industries are also contributing to growth, as polypropylene random copolymer is valued for its chemical resistance, compatibility with sterilization processes, and suitability for precision applications. Together, these end-use industries are creating a stable and diversified demand base that continues to support steady market growth.

| Market Scope | |

|---|---|

| Start Year | 2025 |

| Forecast Year | 2026-2035 |

| Start Value | $15.2 Billion |

| Forecast Value | $24.5 Billion |

| CAGR | 5% |

The high-transparency grades segment generated USD 5.3 billion in 2025 and is projected to grow at a CAGR of 5.3% from 2026 to 2035. These grades are increasingly adopted in applications where visual clarity and aesthetic quality are critical, while impact-modified variants are expanding their presence in uses requiring enhanced toughness and durability.

The plumbing systems segment accounted for USD 4.7 billion in 2025, representing a 30.7% market share, and is expected to grow at a CAGR of 4.8% through 2035. Sustained demand for long-lasting, corrosion-resistant piping in residential and commercial construction continues to drive adoption, alongside steady usage in medical components that require chemical stability and sterilization compatibility.

North America Polypropylene Random Copolymer Market was valued at USD 2.7 billion in 2025 and is expected to witness attractive growth during the forecast period. Demand in the region is supported by ongoing infrastructure upgrades, increasing adoption in industrial piping, rising use in medical and food-grade applications, and growing focus on recyclable and environmentally responsible materials.

Key companies operating in the Polypropylene Random Copolymer Market include SABIC, LyondellBasell Industries, Braskem S.A., ExxonMobil Chemical, INEOS Styrolution, and other established global producers. Companies in the Polypropylene Random Copolymer Market are strengthening their market position through capacity expansions, product grade differentiation, and investments in advanced polymer technologies. Many players are focusing on developing high-performance and specialty grades to meet evolving requirements in construction, packaging, and medical applications. Strategic partnerships with downstream manufacturers help secure long-term demand and application-specific innovation. Geographic expansion into high-growth regions supports volume growth, while sustainability initiatives, including recyclable and low-impact polymer solutions, enhance brand value.

Table of Contents

Chapter 1 Methodology

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 360° synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Ethylene Content

- 2.2.3 Grade

- 2.2.4 Processing Form

- 2.2.5 Application

- 2.3 TAM Analysis, 2026-2035

- 2.4 CXO perspectives: Strategic imperatives

- 2.4.1 Executive decision points

- 2.4.2 Critical success factors

- 2.5 Future Outlook and Strategic Recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier Landscape

- 3.1.2 Profit Margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.1.5 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.2 Industry pitfalls and challenges

- 3.2.3 Market opportunities

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.4.1 North America

- 3.4.2 Europe

- 3.4.3 Asia Pacific

- 3.4.4 Latin America

- 3.4.5 Middle East & Africa

- 3.5 Porter's analysis

- 3.6 PESTEL analysis

- 3.7 Price trends

- 3.7.1 By region

- 3.7.2 By product

- 3.8 Future market trends

- 3.9 Technology and Innovation landscape

- 3.9.1 Current technological trends

- 3.9.2 Emerging technologies

- 3.10 Patent Landscape

- 3.11 Trade statistics (Note: the trade statistics will be provided for key countries only)

- 3.11.1 Major importing countries

- 3.11.2 Major exporting countries

- 3.12 Sustainability and Environmental Aspects

- 3.12.1 Sustainable Practices

- 3.12.2 Waste Reduction Strategies

- 3.12.3 Energy Efficiency in Production

- 3.12.4 Eco-friendly Initiatives

- 3.13 Carbon Footprint Considerations

Chapter 4 Competitive Landscape, 2025

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 LATAM

- 4.2.1.5 MEA

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New Product Launches

- 4.6.4 Expansion Plans

Chapter 5 Market Estimates and Forecast, By Ethylene Content, 2022- 2035 (USD Billion, Kilo Tons)

- 5.1 Key trends

- 5.2 Low Ethylene (1-3%)

- 5.3 Medium Ethylene (4-5%)

- 5.4 High Ethylene (6-7%)

Chapter 6 Market Estimates and Forecast, By Grade, 2022 - 2035 (USD Billion, Kilo Tons)

- 6.1 Key trends

- 6.2 High Transparency Grades

- 6.2.1 Food packaging

- 6.2.2 Medical devices

- 6.3 Impact-Modified Grades

- 6.3.1 Plumbing pipes

- 6.3.2 Automotive parts

- 6.4 UV-Stabilized Grades

- 6.4.1 Outdoor piping

- 6.4.2 Agricultural applications

- 6.5 Others

Chapter 7 Market Estimates and Forecast, By Processing Form, 2022 - 2035 (USD Billion, Kilo Tons)

- 7.1 Key trends

- 7.2 Injection Molding

- 7.3 Extrusion

- 7.4 Blow Molding

Chapter 8 Market Estimates and Forecast, By Application, 2022 - 2035 (USD Billion, Kilo Tons)

- 8.1 Key trends

- 8.2 Plumbing Systems

- 8.2.1 Hot water pipes

- 8.2.2 Cold water pipes

- 8.3 Medical Applications

- 8.3.1 Syringes

- 8.3.2 Sterile containers

- 8.4 Food Packaging

- 8.4.1 Transparent containers

- 8.4.2 Caps & closures

- 8.5 Industrial Components

- 8.5.1 Chemical tanks

- 8.5.2 Fittings

- 8.6 Others

Chapter 9 Market Estimates and Forecast, By Region, 2022 - 2035 (USD Billion, Kilo Tons)

- 9.1 Key trends

- 9.2 North America

- 9.2.1 U.S.

- 9.2.2 Canada

- 9.3 Europe

- 9.3.1 Germany

- 9.3.2 UK

- 9.3.3 France

- 9.3.4 Italy

- 9.3.5 Spain

- 9.3.6 Rest of Europe

- 9.4 Asia Pacific

- 9.4.1 China

- 9.4.2 India

- 9.4.3 Japan

- 9.4.4 Australia

- 9.4.5 South Korea

- 9.4.6 Rest of Asia Pacific

- 9.5 Latin America

- 9.5.1 Brazil

- 9.5.2 Mexico

- 9.5.3 Argentina

- 9.5.4 Rest of Latin America

- 9.6 Middle East & Africa

- 9.6.1 Saudi Arabia

- 9.6.2 South Africa

- 9.6.3 UAE

- 9.6.4 Rest of Middle East & Africa

Chapter 10 Company Profiles

- 10.1 LyondellBasell Industries

- 10.2 INEOS Styrolution

- 10.3 SABIC

- 10.4 ExxonMobil Chemical

- 10.5 Braskem S.A.

- 10.6 Formosa Plastics Corporation

- 10.7 TotalEnergies

- 10.8 Repsol

- 10.9 Chevron Phillips Chemical

- 10.10 Reliance Industries Limited

- 10.11 Aquatherm GmbH

- 10.12 Wefatherm GmbH

- 10.13 Georg Fischer Piping Systems

- 10.14 Uponor

- 10.15 Astral Poly Technik Ltd.