|

市场调查报告书

商品编码

1913297

橡胶加工化学品市场机会、成长要素、产业趋势分析及2026年至2035年预测Rubber Processing Chemicals Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2026 - 2035 |

||||||

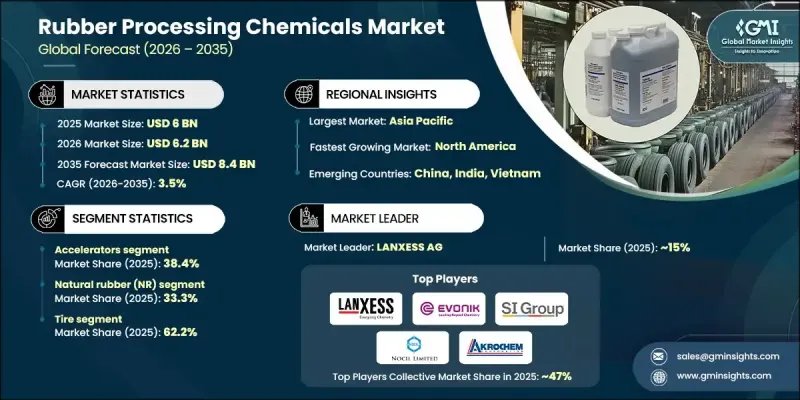

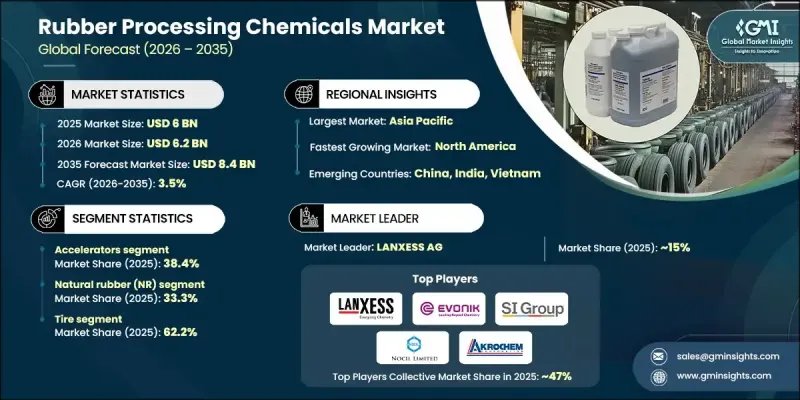

全球橡胶加工化学品市场预计到 2025 年将达到 60 亿美元,到 2035 年将达到 84 亿美元,年复合成长率为 3.5%。

橡胶加工化学品在橡胶製造中发挥至关重要的作用,它们能够提升天然橡胶和合成橡胶的耐久性、加工效率和功能性能。这些组合药物透过提高硫化效率、耐劣化性、黏合性能、阻燃性和整体材料稳定性,为橡胶生产的关键阶段提供支援。市场成长受到交通运输、工业生产、基础设施建设以及永续性驱动型生产实践的持续变革的影响。製造商越来越重视环保化学解决方案,以符合不断变化的法规结构和企业永续性目标。因此,市场正稳步转向先进的清洁化学技术,这些技术在保持性能的同时,也能减少对环境的影响。各种工业应用领域对高品质橡胶产品的需求不断增长,加上橡胶混合技术的进步,持续增强了长期需求。现代製造系统的扩展以及全球市场对性能一致性的日益增长的期望,进一步推动了橡胶加工化学品的稳定发展。

| 市场覆盖范围 | |

|---|---|

| 开始年份 | 2025 |

| 预测年份 | 2026-2035 |

| 起始值 | 60亿美元 |

| 预测金额 | 84亿美元 |

| 复合年增长率 | 3.5% |

预计到2025年,促进剂市占率将达到38.4%,并在2035年之前以3.7%的复合年增长率成长。其主导地位归功于促进剂在控制硫化行为和将生胶转化为耐用弹性材料方面发挥的关键作用。由于促进剂在实现最佳强度、柔软性和耐热性方面发挥重要作用,因此在所有橡胶製作流程中都不可或缺。

2025年,天然橡胶市占率占比达到33.3%,预计到2035年将以3.8%的复合年增长率成长。其主导地位源自于其固有的机械优势,能够满足严苛的性能要求。天然橡胶独特的分子结构使其在市场波动中仍保持着重要性,确保了对性能要求极高的橡胶应用领域拥有稳定的需求。

美国橡胶加工化学品市场预计2025年将达到10亿美元。该国的成长得益于成熟的製造业基础以及汽车和工业橡胶生产的强劲需求。完善的供应体系和对先进橡胶配方技术的持续投资,共同促成了北美市场稳定的发展趋势。

目录

第一章调查方法和范围

第二章执行摘要

第三章业界考察

- 生态系分析

- 供应商情况

- 利润率

- 每个阶段的附加价值

- 影响价值链的因素

- 中断

- 产业影响因素

- 司机

- 产业潜在风险与挑战

- 市场机会

- 成长潜力分析

- 监管环境

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- 中东和非洲

- 波特五力分析

- PESTEL 分析

- 科技与创新趋势

- 当前技术趋势

- 新兴技术

- 价格趋势

- 按地区

- 依产品类型

- 未来市场趋势

- 专利趋势

- 贸易统计(HS编码)(註:仅提供主要国家的贸易统计)

- 主要进口国

- 主要出口国

- 永续性和环境方面

- 永续努力

- 减少废弃物策略

- 生产中的能源效率

- 环保倡议

- 考虑到碳足迹

第四章 竞争情势

- 介绍

- 公司市占率分析

- 按地区

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- 中东和非洲

- 按地区

- 企业矩阵分析

- 主要市场公司的竞争分析

- 竞争定位矩阵

- 重大进展

- 併购

- 伙伴关係与合作

- 新产品发布

- 扩张计划

第五章 依产品类型分類的市场估算与预测,2022-2035年

- 加速器

- 噻唑类

- 磺胺

- Thiram

- 胍类

- 二硫代氨基甲酸

- 硫代磷酸盐

- 硫脲

- 醛胺

- 劣化

- 抗氧化剂

- 抗臭氧剂

- 蜡

- 硅烷偶合剂

- 乙氧基硅烷

- 甲氧基硅烷

- 巯基硅烷

- 新型耦合系统

- 硅烷替代品

- 加工助剂和塑化剂

- 塑化剂

- 胜肽剂

- 分散剂

- 处理加速器

- 释放剂

- 润滑剂

- 生物基加工助剂

- 阻燃剂

- 卤素阻燃剂

- 磷基阻燃剂

- 矿物填料

- 其他的

第六章 依橡胶类型分類的市场估算与预测,2022-2035年

- 天然橡胶(NR)

- SBR(溶液/乳液)

- 丁腈橡胶(NBR)

- EPDM

- 丁基橡胶和卤化丁基橡胶

- 特种橡胶

第七章 按应用领域分類的市场估算与预测,2022-2035年

- 胎

- 汽车(非轮胎应用)

- 工业产品

- 建造

- 电线电缆

- 医疗保健

- 消费品

- 航太

第八章 2022-2035年各地区市场估算与预测

- 北美洲

- 美国

- 加拿大

- 欧洲

- 德国

- 英国

- 法国

- 西班牙

- 义大利

- 其他欧洲地区

- 亚太地区

- 中国

- 印度

- 日本

- 澳洲

- 韩国

- 亚太其他地区

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- 其他拉丁美洲地区

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 阿拉伯聯合大公国

- 其他中东和非洲地区

第九章:公司简介

- LANXESS AG

- Evonik Industries

- SI Group

- Nocil Limited

- Akrochem Corporation

- Sennics Co., Ltd.

- RT Vanderbilt

- KUMHO PETROCHEMICAL

- Duslo as

- Struktol Company

- Robinson Brothers

- Sinopec Corp.

- China Sunsine

- Eastman Chemical

- Arkema SA

The Global Rubber Processing Chemicals Market was valued at USD 6 billion in 2025 and is estimated to grow at a CAGR of 3.5% to reach USD 8.4 billion by 2035.

Rubber processing chemicals play a foundational role in rubber manufacturing by enhancing durability, processing efficiency, and functional performance of both natural and synthetic rubber. These formulations support critical stages of rubber production by improving curing efficiency, resistance to degradation, adhesion properties, flame resistance, and overall material stability. Market growth is shaped by ongoing changes in transportation, industrial manufacturing, infrastructure development, and sustainability-driven production practices. Manufacturers are increasingly prioritizing environmentally responsible chemical solutions to align with evolving regulatory frameworks and corporate sustainability goals. As a result, the market is steadily transitioning toward advanced and cleaner chemistries that maintain performance while reducing environmental impact. The growing need for high-quality rubber products across diverse industrial applications, combined with advancements in rubber formulation technologies, continues to reinforce long-term demand. Expansion of modern manufacturing systems and rising expectations for performance consistency across global markets further support the steady evolution of rubber processing chemicals.

| Market Scope | |

|---|---|

| Start Year | 2025 |

| Forecast Year | 2026-2035 |

| Start Value | $6 Billion |

| Forecast Value | $8.4 Billion |

| CAGR | 3.5% |

The accelerators segment held a 38.4% share in 2025 and is expected to grow at a CAGR of 3.7% through 2035. This dominance is attributed to their indispensable function in controlling curing behavior and enabling the transformation of raw rubber into durable, elastic materials. Accelerators remain essential across all rubber processing activities due to their role in achieving optimal strength, flexibility, and thermal resistance.

The natural rubber segment accounted for 33.3% share in 2025 and is forecast to grow at a CAGR of 3.8% by 2035. Its leadership stems from inherent mechanical advantages that support demanding performance requirements. The unique molecular structure of natural rubber continues to sustain its relevance despite market fluctuations, ensuring consistent demand across performance-focused rubber applications.

U.S. Rubber Processing Chemicals Market generated USD 1 billion in 2025. Growth in the country is supported by a mature manufacturing base and strong demand from automotive and industrial rubber production. A well-established supply ecosystem and continued investment in advanced rubber formulations contribute to stable market momentum across North America.

Key companies active in the Rubber Processing Chemicals Market include Evonik Industries, LANXESS AG, Eastman Chemical, Arkema S.A., SI Group, China Sunsine, Nocil Limited, KUMHO PETROCHEMICAL, Robinson Brothers, R.T. Vanderbilt, Akrochem Corporation, Duslo a.s., Sennics Co., Ltd., Sinopec Corp., and Struktol Company. Companies operating in the Global Rubber Processing Chemicals Market are reinforcing their market position through innovation-led product development and sustainability-focused strategies. Many players are investing in research to create high-performance formulations that comply with stricter environmental standards while maintaining efficiency and durability. Capacity expansion in emerging manufacturing regions and strengthening distribution networks remain key priorities. Strategic collaborations with rubber producers help companies deliver customized solutions and improve long-term customer engagement.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 360° synopsis

- 2.2 Key market trends

- 2.2.1 Product Type

- 2.2.2 Rubber Type

- 2.2.3 Application

- 2.2.4 Regional

- 2.3 TAM Analysis, 2025-2035

- 2.4 CXO perspectives: Strategic imperatives

- 2.4.1 Executive decision points

- 2.4.2 Critical success factors

- 2.5 Future outlook and strategic recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.1.5 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.2 Industry pitfalls and challenges

- 3.2.3 Market opportunities

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.4.1 North America

- 3.4.2 Europe

- 3.4.3 Asia Pacific

- 3.4.4 Latin America

- 3.4.5 Middle East & Africa

- 3.5 Porter's analysis

- 3.6 PESTEL analysis

- 3.7 Technology and innovation landscape

- 3.7.1 Current technological trends

- 3.7.2 Emerging technologies

- 3.8 Price trends

- 3.8.1 By region

- 3.8.2 By product type

- 3.9 Future market trends

- 3.10 Patent landscape

- 3.11 Trade statistics (HS code)( Note: the trade statistics will be provided for key countries only)

- 3.11.1 Major importing countries

- 3.11.2 Major exporting countries

- 3.12 Sustainability and environmental aspects

- 3.12.1 Sustainable practices

- 3.12.2 Waste reduction strategies

- 3.12.3 Energy efficiency in production

- 3.12.4 Eco-friendly initiatives

- 3.13 Carbon footprint consideration

Chapter 4 Competitive Landscape, 2025

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 LATAM

- 4.2.1.5 MEA

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New product launches

- 4.6.4 Expansion plans

Chapter 5 Market Estimates and Forecast, By Product Type, 2022-2035 (USD Billion) (Kilo Tons)

- 5.1 Key trends

- 5.2 Accelerators

- 5.2.1 Thiazoles

- 5.2.2 Sulfenamides

- 5.2.3 Thiurams

- 5.2.4 Guanidines

- 5.2.5 Dithiocarbamates

- 5.2.6 Thiophosphates

- 5.2.7 Thioureas

- 5.2.8 Aldehyde amines

- 5.3 Antidegradants

- 5.3.1 Antioxidants

- 5.3.2 Antiozonants

- 5.3.3 Waxes

- 5.3.4 Silane coupling agents

- 5.4 Ethoxy silanes

- 5.4.1 Methoxy silanes

- 5.4.2 Mercaptosilanes

- 5.4.3 Novel coupling systems

- 5.4.4 Silane alternatives

- 5.5 Processing aids & plasticizers

- 5.5.1 Plasticizers

- 5.5.2 Peptizers

- 5.5.3 Dispersing agents

- 5.5.4 Processing promoters

- 5.5.5 Mold release agents

- 5.5.6 Lubricants

- 5.5.7 Bio-based processing aids

- 5.6 Flame retardants

- 5.6.1 Halogenated flame retardants

- 5.6.2 Phosphorus-based flame retardants

- 5.6.3 Mineral fillers

- 5.7 Others

Chapter 6 Market Estimates and Forecast, By Rubber Type, 2022-2035 (USD Billion) (Kilo Tons)

- 6.1 Key trends

- 6.2 Natural rubber (NR)

- 6.3 SBR (solution & emulsion)

- 6.4 Nitrile rubber (NBR)

- 6.5 EPDM

- 6.6 Butyl & halobutyl rubber

- 6.7 Specialty rubbers

Chapter 7 Market Estimates and Forecast, By Application, 2022-2035 (USD Billion) (Kilo Tons)

- 7.1 Key trends

- 7.2 Tire

- 7.3 Automotive (non-tire)

- 7.4 Industrial goods

- 7.5 Construction

- 7.6 Wire & cable

- 7.7 Medical & healthcare

- 7.8 Consumer goods

- 7.9 Aerospace

Chapter 8 Market Estimates and Forecast, By Region, 2022-2035 (USD Billion) (Kilo Tons)

- 8.1 Key trends

- 8.2 North America

- 8.2.1 U.S.

- 8.2.2 Canada

- 8.3 Europe

- 8.3.1 Germany

- 8.3.2 UK

- 8.3.3 France

- 8.3.4 Spain

- 8.3.5 Italy

- 8.3.6 Rest of Europe

- 8.4 Asia Pacific

- 8.4.1 China

- 8.4.2 India

- 8.4.3 Japan

- 8.4.4 Australia

- 8.4.5 South Korea

- 8.4.6 Rest of Asia Pacific

- 8.5 Latin America

- 8.5.1 Brazil

- 8.5.2 Mexico

- 8.5.3 Argentina

- 8.5.4 Rest of Latin America

- 8.6 Middle East and Africa

- 8.6.1 Saudi Arabia

- 8.6.2 South Africa

- 8.6.3 UAE

- 8.6.4 Rest of Middle East and Africa

Chapter 9 Company Profiles

- 9.1 LANXESS AG

- 9.2 Evonik Industries

- 9.3 SI Group

- 9.4 Nocil Limited

- 9.5 Akrochem Corporation

- 9.6 Sennics Co., Ltd.

- 9.7 R.T. Vanderbilt

- 9.8 KUMHO PETROCHEMICAL

- 9.9 Duslo a.s.

- 9.10 Struktol Company

- 9.11 Robinson Brothers

- 9.12 Sinopec Corp.

- 9.13 China Sunsine

- 9.14 Eastman Chemical

- 9.15 Arkema S.A.