|

市场调查报告书

商品编码

1473283

CMP设备及耗材:市场分析与预测CMP Equipment and Consumables: Market Analysis and Forecasts |

||||||

促进者

化学机械平坦化 (CMP) 市场涵盖设备和浆料领域,在半导体产业需求不断增长的推动下,目前正经历一个动态成长和创新的时期。随着奈米製程尺寸的进步和每个晶片功能的增加,半导体元件的复杂性不断增加,CMP 在製造过程中的作用从未如此重要。这种精确的材料去除製程对于确保连续光刻和蚀刻步骤之间的晶圆表面平整度至关重要,并且随着装置变得越来越小,课题变得越来越严峻。

CMP 设备市场正在见证旨在提高平坦化製程的效率、准确性和一致性的重大技术进步。製造商正专注于开发能够处理更大晶圆的设备,并满足微调材料去除率的需求。这包括增强抛光垫调节技术、抛光头和载体技术,以及整合更复杂的端点检测系统以防止过度抛光。此外,还非常重视自动化和软体集成,CMP 设备现在配备了先进的监控和调整功能,以最大程度地减少人为错误并即时适应不断变化的製程条件。

同时,CMP 浆料市场随着设备的进步而不断发展,以满足先进半导体装置中新材料和复杂结构的严格要求。浆料配方变得更加多样化和专业化,以满足特定的材料去除需求,例如铜、钨和介电材料。

浆料的开发需要磨料颗粒尺寸、浓度和化学添加剂之间的微妙平衡,以实现所需的去除率和表面光洁度,同时最大限度地减少缺陷的发生。环境考量也是重中之重,推动了环境友善浆料组合物的开发,以减少浪费并且对工人来说更安全。

市场成长是由消费性电子产品、高效能电脑平台和资料储存解决方案快速成长的需求所推动的,所有这些都需要先进的半导体晶片。此外,汽车产业越来越依赖电动车和驾驶辅助系统的电子元件,促进了 CMP 市场的扩张。5G 技术和物联网的兴起将进一步加速对半导体的需求,间接推动对更有效率、更高吞吐量的 CMP 製程的需求。

然而,CMP 市场面临着设备和材料成本高昂、需要持续创新以跟上半导体进步步伐以及管理复杂的供应链等课题。半导体产业的全球性也使 CMP 市场面临地缘政治紧张局势和贸易争端的影响,这可能会影响材料采购、製造和销售。

综上所述,CMP设备及浆料市场正处于关键时刻,机会与课题并存。随着半导体产业不断课题技术极限,CMP 在製造先进装置中的重要性不断增长。适应市场快速技术变化的能力以及设备和耗材的创新能力将是满足未来半导体製造流程需求的关键因素。

关于本报告

本报告分析了全球 CMP 设备和耗材市场,提供了技术概述、市场基本结构、CMP 设备和耗材的主要类型和特点、用户需求以及整体市场规模趋势。

目录

第一章简介

第二章执行摘要

- 介绍

- 市场机会

第三章 展平方法

- 平整度的必要性

- 光刻

- 气相沉积

- 蚀刻

- 应用领域

- 电介质

- 金属

- 平整技术

- 局部扁平化

- 整体扁平化

- 化学机械抛光

- 背景状况

- 研究工作

- 优点和缺点

- 加工参数

- 设备加工参数

第四章 CMP耗材

- 泥

- 类型

- pH值的影响

- 氧化剂

- 颗粒形态的影响

- 化学品配送管理

- 浆料供应商简介

- 磨料供应商

- CMP后清洗

- 抛光垫

- 类型

- 表现

- 无浆垫

第五章 CMP设备

- 单头方法

- 优势

- 坏处

- 多头方法

- 设备简介

- Applied Materials

- Ebara

- Strasbaugh

- Novellus

- Nikon

- Doosan Mecatec

- 其他参与企业

- 集群工具

- 竞争性非 CMP 工具

第六章 使用者问题

- 拥有成本

- 用户要求

- 供应商基准

- 价格

- 供应商的承诺和态度

- 供应商能力

- 系统特点

- 用户和供应商之间的协同

- 设备评估期间的回馈

- 设备製造过程中的回馈

- 可靠性

- 设备可维护性

第七章 市场预测

- 介绍

- 市场预测的先决条件

- 设备市场

- 介绍

- CMP抛光机市场

- 消耗品市场

- 泥

- 软垫

Driving Forces

The Chemical Mechanical Planarization (CMP) market, encompassing both the equipment and slurry sectors, is currently experiencing a dynamic period of growth and innovation, driven by the escalating demands of the semiconductor industry. As the complexity of semiconductor devices continues to increase, with the push towards smaller nanometer processes and the integration of more functions per chip, the role of CMP in the manufacturing process has become more critical than ever. This precision material removal process is essential for ensuring the planarity of wafer surfaces between successive lithography and etching steps, a requirement that becomes increasingly challenging as device geometries shrink.

The CMP equipment market is witnessing significant technological advancements aimed at improving the efficiency, accuracy, and consistency of the planarization process. Manufacturers are focusing on developing equipment that can accommodate the increasing size of wafers and the need for finer control over material removal rates. This includes enhancements in pad conditioning techniques, head and carrier technologies, and the integration of more sophisticated endpoint detection systems to prevent over-polishing. The emphasis on automation and software integration is also prominent, with CMP equipment increasingly featuring advanced monitoring and adjustment capabilities to minimize human error and adapt to varying process conditions in real time.

Simultaneously, the CMP slurry market is evolving in tandem with equipment advancements to meet the stringent requirements of new materials and complex structures found in advanced semiconductor devices. Slurry formulations are becoming more diverse and specialized, tailored to specific material removal needs, such as copper, tungsten, or dielectric materials.

The development of slurry involves a delicate balance between abrasive particle size, concentration, and chemical additives to achieve the desired removal rate and surface finish, while minimizing defectivity. Environmental considerations are also coming to the forefront, with a push towards developing more eco-friendly slurry compositions that reduce waste and are safer for workers.

Market growth is being fueled by the burgeoning demand for consumer electronics, highperformance computing platforms, and data storage solutions, all of which require advanced semiconductor chips. Additionally, the automotive sector's increasing reliance on electronic components for electric vehicles and driver assistance systems is contributing to the expansion of the CMP market. The rise of 5G technology and the Internet of Things (IoT) further compounds the demand for semiconductors, indirectly driving the need for more efficient and capable CMP processes.

However, the CMP market faces challenges, including the high cost of equipment and materials, the need for continual innovation to keep pace with semiconductor evolution, and the management of supply chain complexities. The global nature of the semiconductor industry also exposes the CMP market to geopolitical tensions and trade disputes, which can impact material sourcing, manufacturing, and sales.

In conclusion, the CMP equipment and slurry market is at a critical juncture, with opportunities and challenges in equal measure. As the semiconductor industry continues to push the boundaries of technology, the importance of CMP in manufacturing advanced devices will only grow. The market's ability to adapt to rapid technological changes, along with its capacity to innovate in both equipment and consumables, will be key factors in meeting the future demands of the semiconductor manufacturing process.

About This Report

This 225-page report provides an overview of the current market size and growth trajectory for CMP equipment and slurry markets. Include historical data, forecasts, and factors driving market expansion or contraction.

It discusses the latest trends shaping the CMP equipment and slurry markets, such as advancements in semiconductor technology, materials diversity, environmental sustainability, automation, and global market expansion.

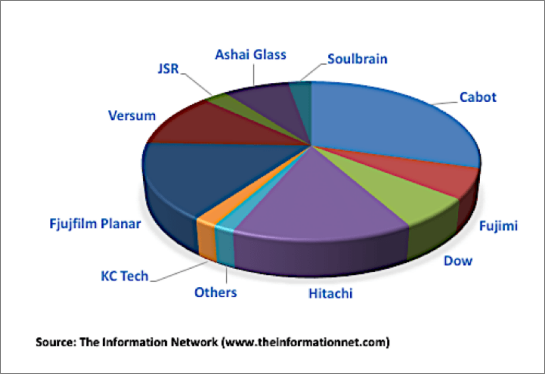

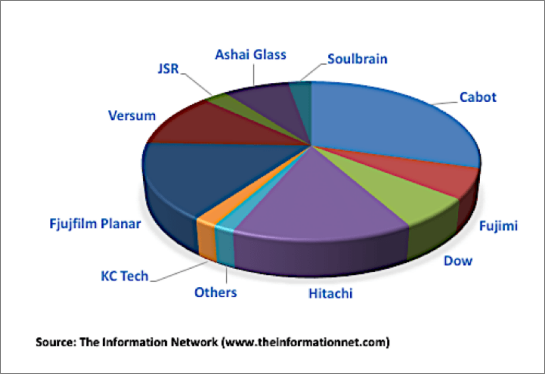

Key Players operating in the CMP equipment and slurry markets and analyzed and forecast, along with their market share, key product offerings, and competitive strategies. Slurry markets are analyzed by slurry type and slurry supplier:

Oxide slurry

- ILD Slurry

- STI Slurry,

W Slurry

Copper slurry

- Cu Barrier Slurry

- Cu Slurry Step 1

This report identifies key challenges facing the CMP equipment and slurry markets, such as rising production costs, technological barriers, geopolitical tensions, and competitive pressures. It provides insights into the future outlook for CMP equipment and slurry markets, including anticipated growth opportunities, emerging technologies, potential disruptors, and strategic recommendations for stakeholders.

Table of Contents

Chapter 1. Introduction

Chapter 2. Executive Summary

- 2.1. Introduction

- 2.2. Market Opportunities

Chapter 3. Planarization Methods

- 3.1. Need for Planarity

- 3.1.1. Lithography

- 3.1.2. Deposition

- 3.1.3. Etching

- 3.2. Applications

- 3.2.1. Dielectrics

- 3.2.2. Metals

- 3.3. Planarization Techniques

- 3.3.1. Local Planarization

- 3.3.1.1. Deposition-Etchback

- 3.3.1.2. ECR

- 3.3.1.3. Oxide Reflow

- 3.3.1.4. Spin-on-Glass

- 3.3.1.5. TEOS-Ozone

- 3.3.1.6. Laser

- 3.3.2. Global Planarization

- 3.3.2.1. Spin-On Polymer

- 3.3.2.2. Polyimide Coating

- 3.3.2.3. Isotropic Etch

- 3.3.2.4. Spin Etch Planarization

- 3.3.2.5. Electropolishing

- 3.3.1. Local Planarization

- 3.4. CMP

- 3.4.1. Background

- 3.4.2. Research Efforts

- 3.4.3. Advantages and Disadvantages

- 3.4.4. Process Parameters

- 3.4.4.1. STI Planarization

- 3.4.4.2. Copper CMP

- 3.4.4.3. Low-K Integration

- 3.4.4.4. Defect Density

- 3.4.4.5. Metrology

- 3.4.5. Device Processing Parameters

- 3.4.5.1. Memory Devices

- 3.4.5.2. Logic Devices

Chapter 4. CMP Consumables

- 4.1. Slurries

- 4.1.1. Types

- 4.1.2. pH Effects

- 4.1.3. Oxidizers

- 4.1.4. Particle Morphology Effects

- 4.1.5. Chemical Distribution Management

- 4.1.6. Slurry Supplier Profiles

- 4.1.7. Abrasive Suppliers

- 4.2. Post-CMP Clean

- 4.3. Polishing Pads

- 4.3.1. Types

- 4.3.2. Performance

- 4.3.3. Slurryless Pads

Chapter 5. CMP Equipment

- 5.1. Single-Head Approach

- 5.1.1. Advantages

- 5.1.2. Disadvantages

- 5.2. Multi-Head Approach

- 5.2.1. Advantages

- 5.2.2. Disadvantages

- 5.3. Equipment Profiles

- 5.3.1. Applied Materials

- 5.3.2. Ebara

- 5.3.3. Strasbaugh

- 5.3.4. Novellus

- 5.3.5. Nikon

- 5.3.6. Doosan Mecatec

- 5.3.7. Other Entrants

- 5.4. Clustered Tools

- 5.5. Competitive Non-CMP Tools

Chapter 6. User Issues

- 6.1. Cost of Ownership

- 6.2. User Requirements

- 6.3. Benchmarking a Vendor

- 6.3.1. Pricing

- 6.3.2. Vendor Commitment and Attitudes

- 6.3.3. Vendor Capabilities

- 6.3.4. System Capabilities

- 6.4. User-Supplier Synergy

- 6.4.1. Feedback During Equipment Evaluation

- 6.4.2. Feedback During Device Production

- 6.5. Reliability

- 6.6. Equipment Maintainability

Chapter 7. Market Forecast

- 7.1. Introduction

- 7.2. Market Forecast Assumptions

- 7.3. Equipment Market

- 7.3.1. Introduction

- 7.3.2. CMP Polisher Market

- 7.4. Consumable Market

- 7.4.1. Slurry

- 7.4.2. Pads

List of Figures

- 1.1. Process Integration for CMP

- 3.1. Levels of Integration of Dynamic Rams

- 3.2. Planarization Lengths of Various Methods

- 3.3. Normalized Removal Rates

- 3.4. Reduced Complexity With Copper

- 3.5. Copper Loss From CMP

- 3.6. CMP Copper Process Technologies

- 3.7. CMP Performance Improvements

- 3.8. Polish Endpoint Control

- 4.1. Effect of Nitrate Ions on the Cu Removal Rate

- 4.2. Removal Rate of Ta

- 4.3. Bulk Chemical Distribution System

- 4.4. Through The Brush Chemical Delivery

- 4.5. Megasonics Post-CMP Clean

- 4.6. Micrograph Of 3M Slurryless Pad

- 6.1. Effect of Tool MTBF on CMP Cost

- 6.2. Removal Rate Vs Throughput and CMP Cost

- 7.1. Worldwide CMP Polisher Market

- 7.2. Worldwide CMP Slurry Market Forecast

- 7.3. CMP Slurry Market by Application

- 7.4. ILD Slurry Market Share

- 7.5. STI Slurry Market Share

- 7.6. Copper Barrier Slurry Market Share

- 7.7. Copper Step 1 Slurry Market Share

- 7.8. Worldwide CMP Pad Market Forecast

- 7.9. CMP PAD Market Shares

List of Tables

- 3.1. Interconnect Levels of Logic Device

- 3.2. Typical Process Specifications

- 3.3. Organic Polymers for IMD Applications

- 3.4. CMP Process Variables

- 3.5. Optimized CMP and Post-CMP Clean Parameters

- 3.6. Interconnect Materials by Segment

- 4.1. CMP Slurry Suppliers

- 4.2. Abrasive Suppliers and Products

- 4.2. Oxide CMP Pad Properties and Performance

- 6.1. Polisher Equipment Targets

- 6.2. Post-CMP Clean Equipment Targets

- 7.1. Worldwide CMP Polisher Market Forecast

- 7.2. Worldwide CMP Polisher Market Shares

- 7.3. Worldwide CMP Slurry Market Forecast

- 7.4. Worldwide Slurry Market Shares

- 7.5. Worldwide CMP Pad Market Forecast