|

市场调查报告书

商品编码

1272691

自动贴标机市场-增长、趋势、COVID-19 的影响和预测 (2023-2028)Automatic Labeling Machine Market - Growth, Trends, and Forecasts (2023 - 2028) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

在预测期内,自动贴标机市场预计将以 3.32% 的复合年增长率註册。

由于技术进步和数字化进步,对标籤的需求与时俱进。 化妆品和家庭必需品有多种包装和材料可供选择。 不断变化的环境增加了对更快、更自动化的贴标设备的需求。

主要亮点

- 市场的主要驱动力是食品和饮料行业对快速准确的标籤解决方案和自动化的需求不断增长。 随着标籤设备市场的快速扩张,顶级製造商正在努力融入最新的技术趋势并改进产品功能。 据 Packaging World News 报导,终端客户对 RFID(射频识别)标籤解决方案的需求正以健康的速度增长,占贴标机市场近四分之一的收入份额。

- 标籤跟踪和防伪功能使产品製造商可以轻鬆跟踪发货情况。 标籤还可以通过确保产品在不中断的情况下到达客户手中来防止篡改。 对防止欺诈和盗窃的安全标籤的需求不断增长,预计也将推动对该设备的需求。

- 客户对产品多样性的需求不断增加,这是推动贴标机市场扩张的一个主要因素。 每天都有更多的产品被生产并推向市场以满足消费者的需求。 智能和有效的标籤越来越受欢迎,以确保收入和保持产品相关性。 为了应对这些挑战,消费品製造商越来越需要能够处理不同材料并支持不同技术的适应性强的贴标机。

- 为了适应产品多样性,工程公司正在开发针对不同包装具有不同功能的贴标机。 由于投资成本高,而且需要训练有素的专业人员来操作机器,小型企业引进贴标机是负担不起的。 与包装、标籤和其他操作一样,对一台机器上的一体化解决方案的需求可能会推高机器成本并影响市场增长。

- 由于线上和线下渠道对各种食品和医药产品的需求增加,COVID-19 大流行的出现正在推动市场增长,尤其是食品和饮料包装机械以及医药包装机械。

自动贴标机市场趋势

食品和饮料包装自动化需求的增长推动了增长

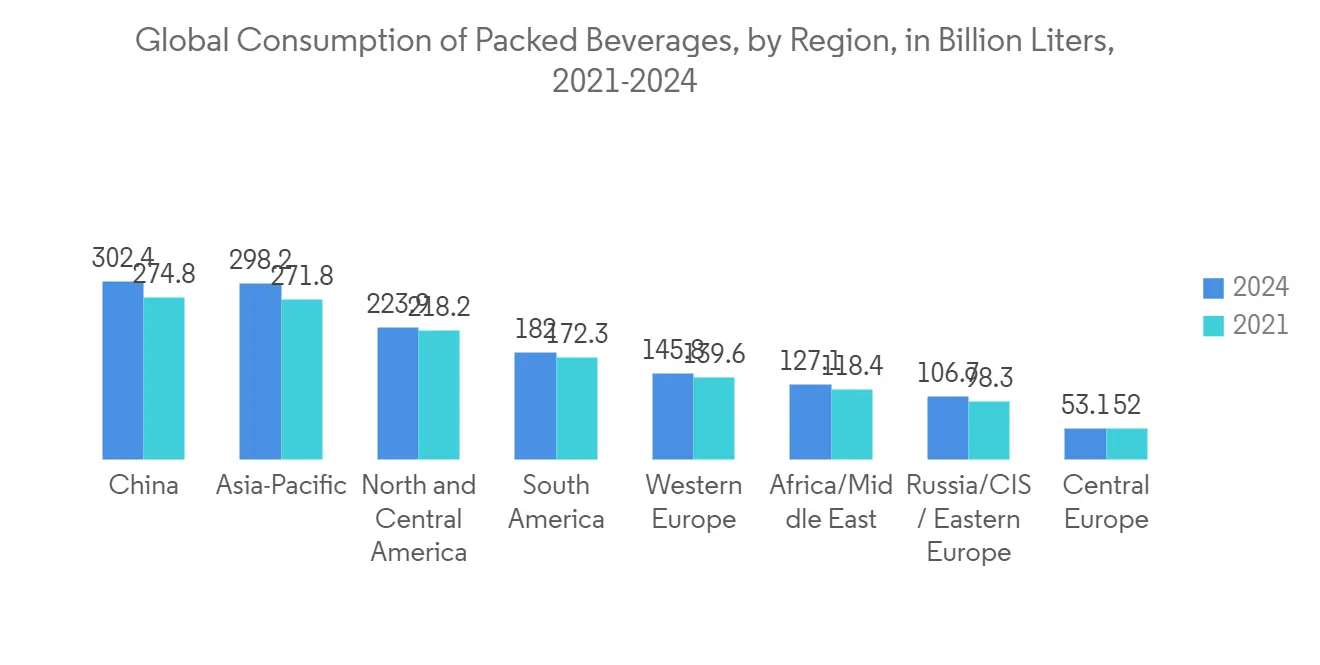

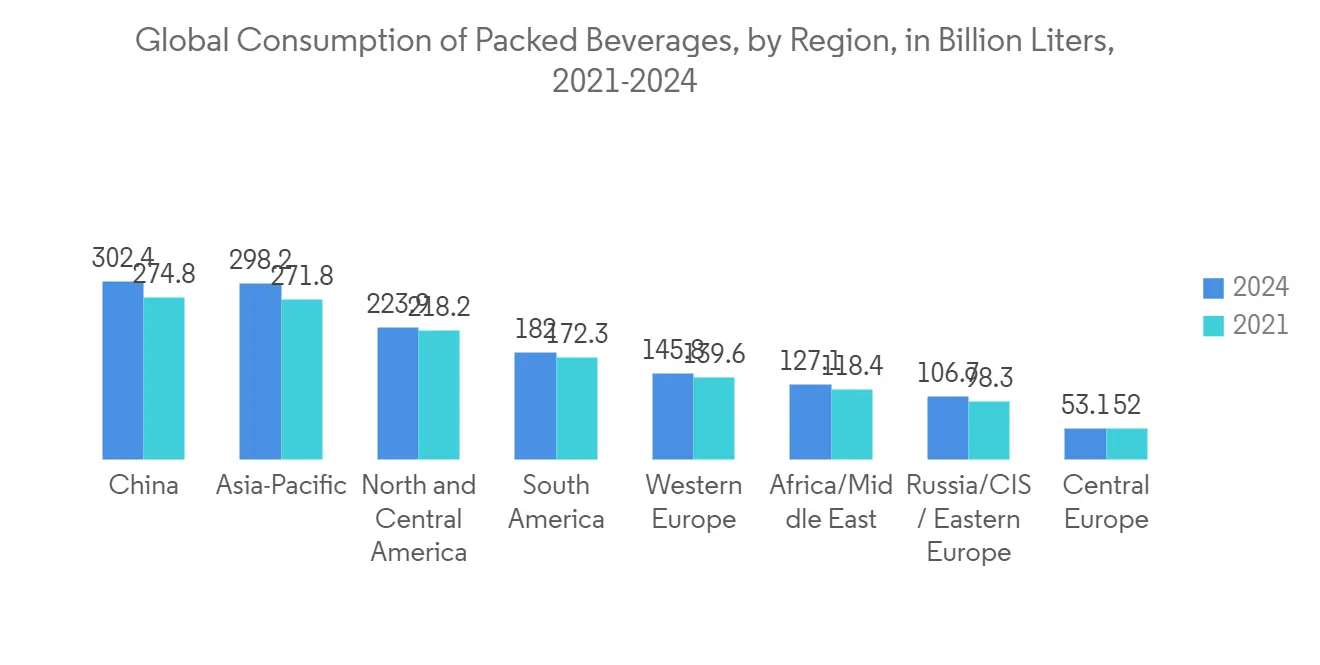

- 食品和饮料行业对自动化的需求正在推动所研究的市场。 随着消费者对产品细节的关注度越来越高,标籤在提供产品信息和增加销量方面发挥着重要作用。 製造商现在正在迁移到自动化标籤系统,以满足食品和饮料行业不断增长的需求。

- 食品和饮料製造商面临多项挑战,包括劳动力短缺、需求增加以及供应链持续中断。 食品包装自动化对这些公司起着重要作用,因为它可以在不增加劳动力的情况下提高生产率。 随着未来几年需求的增加和劳动力短缺的持续,包装自动化将变得更加重要。 这就是製造商转向技术的原因。 未来十年,工业 4.0 技术的发展可能会显着改变食品製造业。

- 自动化包装还可以提高食品和饮料的一致性以及对员工和消费者的安全性。 质量控製程序通常耗时且重复。 从事这些工作的工人在轮班期间可能会行动迟缓且容易出错,从而导致有缺陷或不安全的产品继续在生产线上流下。

- 儘管 COVID-19 大流行导致劳动力短缺,但对自动化的投资仍在增加。 技术正在使食品公司更加敏捷和响应变化。 随着技术的进步,新机器被用于所有同时手工完成所有工作的行业。 食品包装是最受认可的行业之一,它完全接受了当今的科学进步。

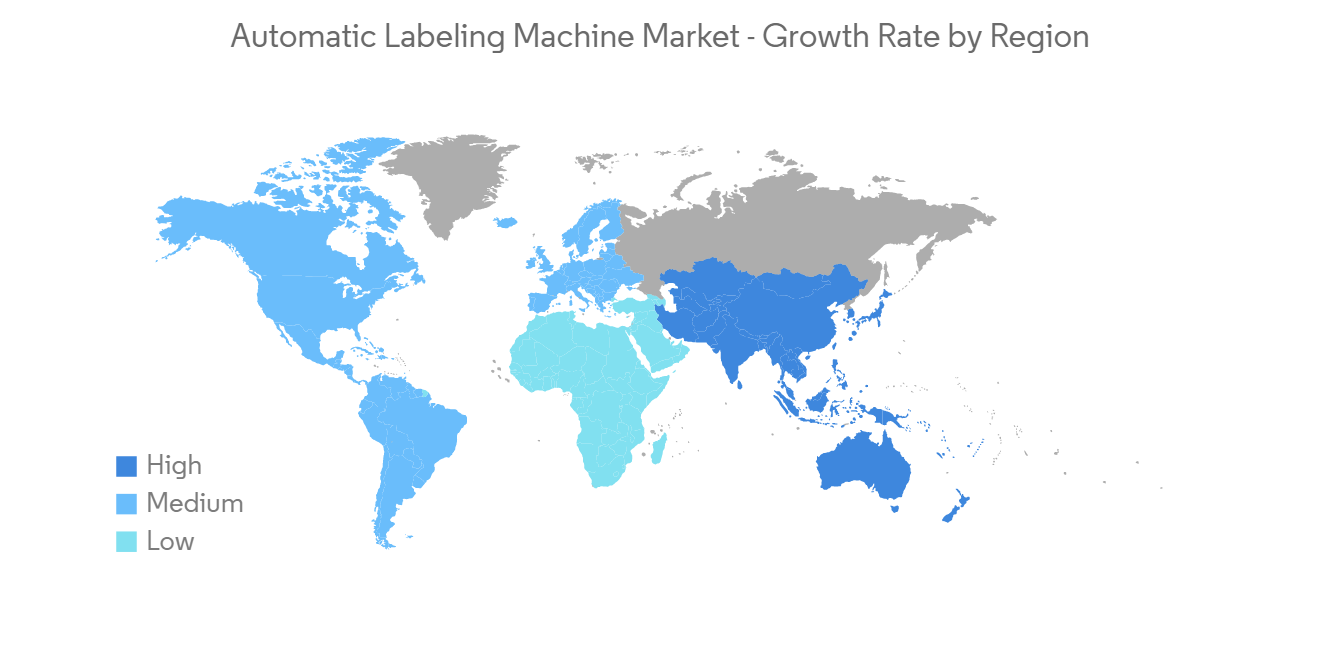

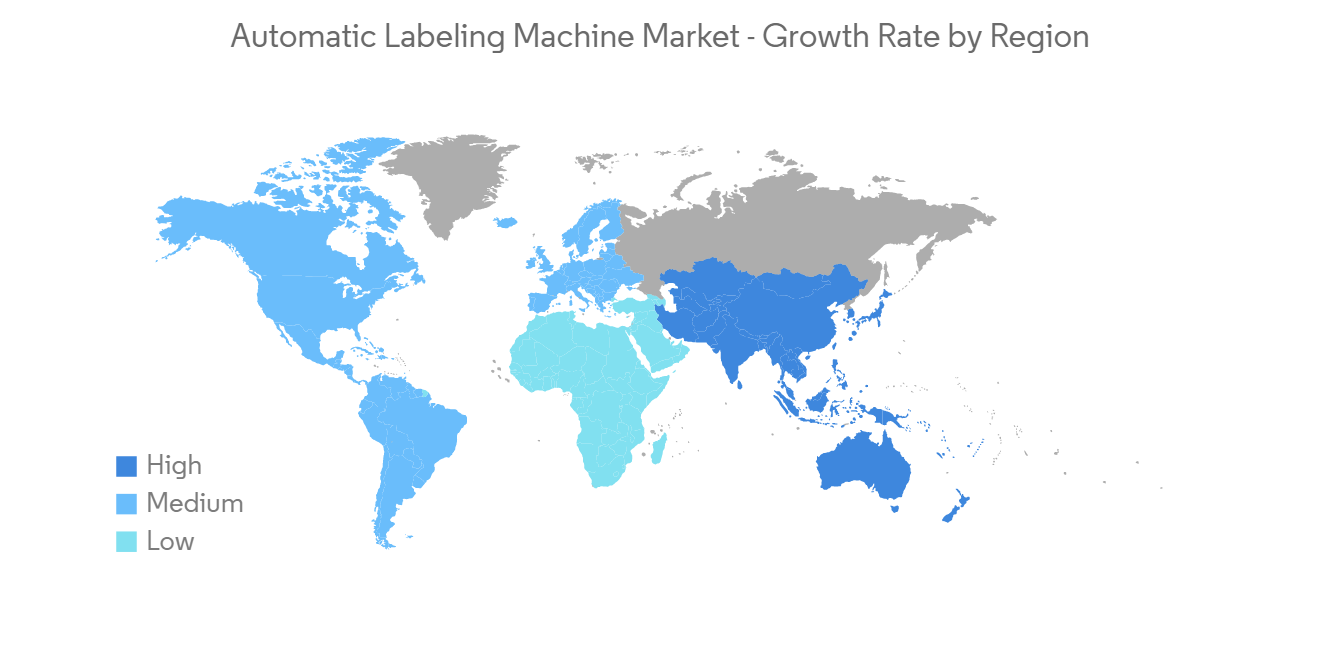

具有高增长潜力的亚太地区

- 亚太地区是世界上人口最多的地区。 随着消费者对包装意识的增强,食品行业对包装和高速、高质量标籤解决方案的需求也在增加。 在亚太地区,中国和台湾已成为自动贴标机的主要出口国。

- 食品和饮料、製药和化工等行业对提高生产力的需求不断增长以及技术进步是推动中国贴标机需求的主要因素。 中国监管机构要求在进出口糖果、葡萄酒、坚果、罐头食品和奶酪等食品时进行标籤验证和产品质量检验。

- 近年来,贴标机在印度发展迅猛。 2022 年 6 月,总部位于孟买的 Printgraph Converting Machinery 与 Macrt 和 Perfect Printgraph Engineers 在第 15 届 Printpack India 上推出了数字标籤印刷机。 这台名为 TruWo 的机器满足了印刷和包装行业的需求,他们正在寻找技术来补充他们现有的印刷能力。

- 在过去二十年中,日本威士忌越来越受欢迎,导致出口到世界各地的威士忌数量增加。 然而,已经证实日本威士忌生产的法规和传统不一定与其他国家相匹配。

自动贴标机行业概况

自动贴标机市场拥有大量公司和中等盈利能力 (CAGR),导致市场竞争激烈。 总体而言,竞争对手之间的竞争强度预计在预测期内会增加。 市场上的主要参与者是 Accutek Packaging Equipment、SIDEL(Tetra Laval Group)、Barry-Wehmiller Group 和 Krones AG。

- 2022 年 7 月 - 为了提供化学品桶的可追溯性,德国密封桶专家 Duttenhofer 投资了 Herma 的集成二维码标籤和打印应用系统。底部。 该公司使用 Herma 的标籤解决方案已有一段时间,对根据 VPA 9 法规生产的技术和标籤材料感到满意。

- 2022 年 6 月,BOBST 集团宣布推出首个 BOBST Connect 订阅计划。 这个以用户为中心的平台将加工商和品牌所有者与自动化数字工作流程联繫起来,使他们能够完全访问和控制製造过程。 BOBST Connect 通过提供洞察力和解决方案来提高生产率、质量和效率,帮助您充分利用设备生成的大量数据。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

内容

第一章介绍

- 研究假设和市场定义

- 本次调查的范围

第二章研究方法论

第 3 章执行摘要

第 4 章市场洞察

- 市场概览

- 价值链分析

- 行业吸引力 - 波特五力分析

- 供应商的议价能力

- 买家的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争公司之间的敌对关係

- 评估 COVID-19 对行业的影响

- 价格分析

- 进出口分析

- 贴标机分销商和备件供应商

- 售后服务分析

第 5 章市场动态

- 市场驱动因素

- 对食品和饮料包装自动化的需求增加

- 扩大对自动贴标机的采用

- 市场製约因素

- 应对与贴标机相关的高成本和趋势

第 6 章市场细分

- 按类型

- 压敏/不干胶贴标机

- 套标机

- 不干胶贴标机

- 其他类型

- 最终用户

- 医药

- 食物

- 饮料

- 个人护理

- 化学品

- 其他最终用户

- 按地区

- 北美

- 美国

- 加拿大

- 欧洲

- 英国

- 德国

- 法国

- 其他欧洲

- 亚太地区

- 印度

- 中国

- 日本

- 其他亚太地区

- 拉丁美洲

- 墨西哥

- 巴西

- 其他拉丁美洲地区

- 中东和非洲

- 阿拉伯联合酋长国

- 沙特阿拉伯

- 其他中东和非洲地区

- 北美

第七章竞争格局

- 公司简介

- Sacmi Imola S.C.

- Accutek Packaging Equipment Companies Inc.

- Krones AG

- SIDEL(Tetra Laval Group)

- Barry-Wehmiller Group Inc.

- Herma HMB

- Nita Labeling Systems

- World pack Automation Systems

- Bobst Group SA

- KHS GmbH

- ProMach Inc.

第八章投资分析

第九章市场机会与未来趋势

The automatic labeling machine market is expected to register a CAGR of 3.32% over the forecast period. The necessity of labeling has significantly increased over time due to technological improvements and the digital transition. Cosmetics and home essentials come in a variety of packaging and material options. The need for more rapid and automated labeling equipment has grown due to the shifting environment.

Key Highlights

- The market is primarily driven by the growing demand for high-speed and accurate labeling solutions and automation in the food and beverage industry. While the labeling machine market is expanding quickly, top manufacturers are working to improve their product features by incorporating cutting-edge technological trends. The demand for RFID (radio frequency identification) labeling solutions among end customers is growing at a healthy rate, accounting for close to one-fourth of the revenue share of the market for labeling machines, according to Packaging World News.

- The tracking and anti-counterfeiting functions on labels make it simple for product manufacturers to keep track of shipments. Labels also protect against tampering by guaranteeing that products are delivered to clients without disruption. The growing demand for security labeling to prevent fraud and theft is also expected to increase the demand for this equipment.

- The rising customer demand for increased product diversity is a major factor driving the market expansion for labeling machines. More products are produced and introduced to the market daily to cater to consumer demand. To ensure revenue and keep products relevant, smart and effective labeling is becoming increasingly popular. Manufacturers of consumer goods are increasingly in need of adaptable labeling machines that can work with a variety of materials and support various technologies to solve these challenges.

- To address product variability, engineering companies have developed labelers with different capabilities that address various packages. Labeling machine installation in small-scale businesses is not affordable, as it requires significant investment costs and trained professionals to operate the machine. The demand for all-in-one solutions in one machine, like packaging, labeling, and other operations, has raised the cost of machines, which can impact the market's growth.

- The emergence of the COVID-19 pandemic has boosted market growth, particularly for food and beverage packaging and pharmaceutical packaging machinery, due to increased demand for various foods and medicines through online and offline channels.

Automatic Labeling Machine Market Trends

Increasing Demand for Automation in Food and Beverage Packaging to Witness Growth

- Demand for automation in the food and beverage industry is driving the market studied. As consumers become more conscious about product details, labels play a crucial role in providing information about the product and boosting sales. Manufacturers are now shifting to automated labeling systems to meet the growing food and beverage industry demand.

- Food and beverage manufacturers face several issues, including labor shortages, increased demand, and persistent supply chain disruptions. Food packaging automation can be critical for these organizations since it increases manufacturing productivity without the need for additional labor. Packaging automation will likely become more important as demand rises over the next few years and manpower shortages persist. Thus, manufacturers are turning to technology. Developments in Industry 4.0 technologies may transform food manufacturing in the coming decade.

- Packaging automation can also improve the consistency and safety of food and beverage items for workers and consumers. Quality control procedures are frequently time-consuming or repetitive. Workers allocated to these jobs tend to slow down and make mistakes throughout a shift, potentially allowing defective or unsafe products to progress further along the manufacturing line.

- Despite the COVID-19 pandemic-related labor scarcity, investments in automation are increasing. Technology allows food enterprises to be more agile and adaptable to change. With the advancement of technology, new machines are being used in all industries where everything is done manually simultaneously. Food packaging is one of the most recognized businesses fully embracing today's scientific evolution.

Asia-Pacific is Expected to Have a High Growth Rate

- Asia-Pacific is home to the largest population in the world. With increasing consumer awareness regarding packaging, the demand for packaging in the food industry and high-speed and high-quality labeling solutions is increasing. China and Taiwan are the major exporters in the Asia-Pacific region for automatic labeling machines.

- Increasing demand for productivity improvements across industries like food and beverage, pharmaceutical, and chemical, as well as technological advancements, are some of the main factors driving labeling machine demand in China. Chinese regulators require imported and exported (but not domestic) food items such as candy, wine, nuts, canned food, and cheese to have labels verified and products tested for quality before goods can be imported or exported.

- In India, labeling machinery witnessed significant growth in recent years. In June 2022, Printgraph Converting Machinery, a Mumbai-based company, along with Macrt and Perfect Printgraph Engineers, launched a digital label printer at the 15th Printpack India. The machine, known as TruWo, will meet the printing and packaging industry demand, which is looking for complementing technology to add to its existing print capabilities.

- The rising popularity of Japanese whisky over the past two decades has increased the spirit being exported worldwide. It has been observed that the Japanese regulations and traditions of whisky-making do not necessarily line up with that of other countries.

Automatic Labeling Machine Industry Overview

The automatic labeling machine market has many companies and moderate profitability (CAGR), creating strong market share competition. Overall, the intensity of competitive rivalry is expected to be high during the forecast period. The key players in the market are Accutek Packaging Equipment, SIDEL (Tetra Laval Group), Barry-Wehmiller Group, and Krones AG.

- July 2022 - To offer traceability for drums carrying chemicals, German tight-head drum specialist Duttenhofer invested in an integrated solution from Herma comprising the labels for QR codes and a print-and-apply system. It has been utilizing Herma's labeling solution for some time and is pleased with both using the technology and the label material, which was created following VPA 9 regulations.

- In June 2022, BOBST Group announced the launch of the first subscription plan of BOBST Connect. This user-centric platform links converter and brand owners to an automated and digital workflow and grants them full access and control of the manufacturing process. BOBST Connect assists customers in making the most of the quantity of data their equipment generates by offering insights and various solutions to improve productivity, quality, and efficiency.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definitions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Value Chain Analysis

- 4.3 Industry Attractiveness - Porter's Five Forces Analysis

- 4.3.1 Bargaining Power of Suppliers

- 4.3.2 Bargaining Power of Buyers

- 4.3.3 Threat of New Entrants

- 4.3.4 Threat of Substitute Products

- 4.3.5 Intensity of Competitive Rivalry

- 4.4 Assessment of Impact of COVID-19 on the Industry

- 4.5 Pricing Analysis

- 4.6 Import and Export Analysis

- 4.7 Distributors and Spare Parts Providers of Labeling Machines

- 4.8 After-Sales Service Analysis

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Increasing Demand for Automation in Food and Beverage Packaging

- 5.1.2 Growing Adoption of Automatic Labeling Machine

- 5.2 Market Restraints

- 5.2.1 High Cost Associated with Labeling Machines and Coping with Trends

6 MARKET SEGMENTATION

- 6.1 By Type

- 6.1.1 Pressure-sensitive/Self-adhesive Labelers

- 6.1.2 Sleeve Labelers

- 6.1.3 Glue-based Labelers

- 6.1.4 Other Types

- 6.2 By End User

- 6.2.1 Pharmaceutical

- 6.2.2 Food

- 6.2.3 Beverages

- 6.2.4 Personal Care

- 6.2.5 Chemicals

- 6.2.6 Other End Users

- 6.3 By Geography

- 6.3.1 North America

- 6.3.1.1 United States

- 6.3.1.2 Canada

- 6.3.2 Europe

- 6.3.2.1 United Kingdom

- 6.3.2.2 Germany

- 6.3.2.3 France

- 6.3.2.4 Rest of Europe

- 6.3.3 Asia-Pacific

- 6.3.3.1 India

- 6.3.3.2 China

- 6.3.3.3 Japan

- 6.3.3.4 Rest of Asia-Pacific

- 6.3.4 Latin America

- 6.3.4.1 Mexico

- 6.3.4.2 Brazil

- 6.3.4.3 Rest of Latin America

- 6.3.5 Middle East & Africa

- 6.3.5.1 United Arab Emirates

- 6.3.5.2 Saudi Arabia

- 6.3.5.3 Rest of Middle East & Africa

- 6.3.1 North America

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Sacmi Imola S.C.

- 7.1.2 Accutek Packaging Equipment Companies Inc.

- 7.1.3 Krones AG

- 7.1.4 SIDEL (Tetra Laval Group)

- 7.1.5 Barry-Wehmiller Group Inc.

- 7.1.6 Herma HMB

- 7.1.7 Nita Labeling Systems

- 7.1.8 World pack Automation Systems

- 7.1.9 Bobst Group SA

- 7.1.10 KHS GmbH

- 7.1.11 ProMach Inc.