|

市场调查报告书

商品编码

1273305

二聚酸市场 - COVID-19 的增长、趋势、影响和预测 (2023-2028)Dimer Acid Market - Growth, Trends, and Forecasts (2023 - 2028) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

在预测期内,二聚酸市场的复合年增长率预计将超过 5%。

COVID-19 大流行阻碍了市场,因为封锁、社会疏远和贸易制裁对全球供应炼网络造成了巨大破坏。 由于活动暂停,建筑业出现下滑。 然而,预计 2021 年情况将有所改善,在预测期内使市场受益。

主要亮点

- 聚□胺树脂应用的扩展以及粘合剂和燃料油添加剂应用的扩展正在推动市场增长。

- 原材料价格的波动以及油菜籽、棉籽和豆油生产的不确定性预计会阻碍市场增长。

二聚酸市场走势

对醇酸树脂和粘合剂的需求不断扩大

- 二聚酸被称为二聚脂肪酸,属于二羧酸组。 二聚酸用于表面涂层、润滑剂和燃料添加剂。

- 二聚酸用于生产醇酸树脂,主要用于合成油漆和涂料,并因其特性而用于建筑行业。

- 2021 年,美国生产了 1239 亿磅树脂。 高密度聚乙烯 (HDPE) 是当年产量最大的树脂,产量为 220 亿磅。 线性低密度聚乙烯 (LLDPE) 产量相似,为 217 亿英镑。

- 二聚酸的特点包括分子量大、结晶和蒸馏困难、环状结构高度灵活、易溶于烃类、反应活性容易控制。

- 聚□胺热熔胶在製造过程中使用了大量的二聚酸。 由于其特性,这些热熔胶可用于金属、纸张、木材和许多塑料(如 PVC、表面处理的聚丙烯和聚乙烯)的出色粘合。

- 合成聚□胺因其耐用性和强度而常用于纺织品、汽车工业、地毯、厨具和运动服。 运输製造业是主要消费者,占聚□胺 (PA) 消费量的 35%。

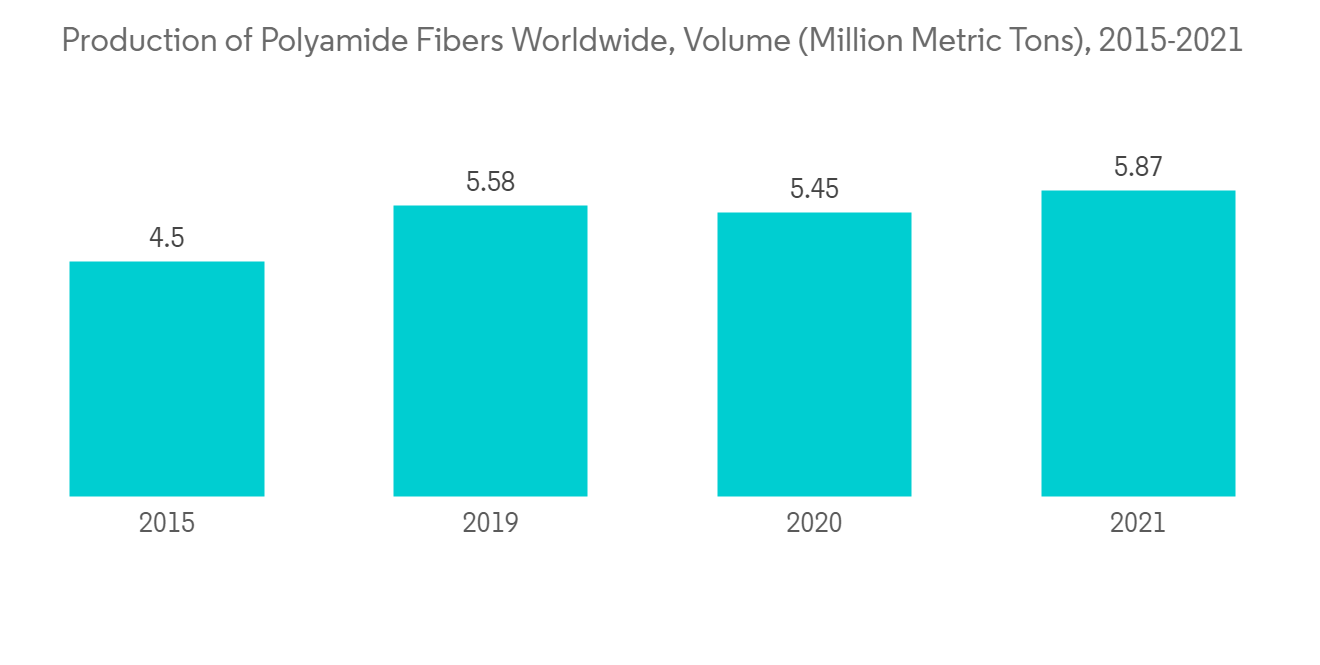

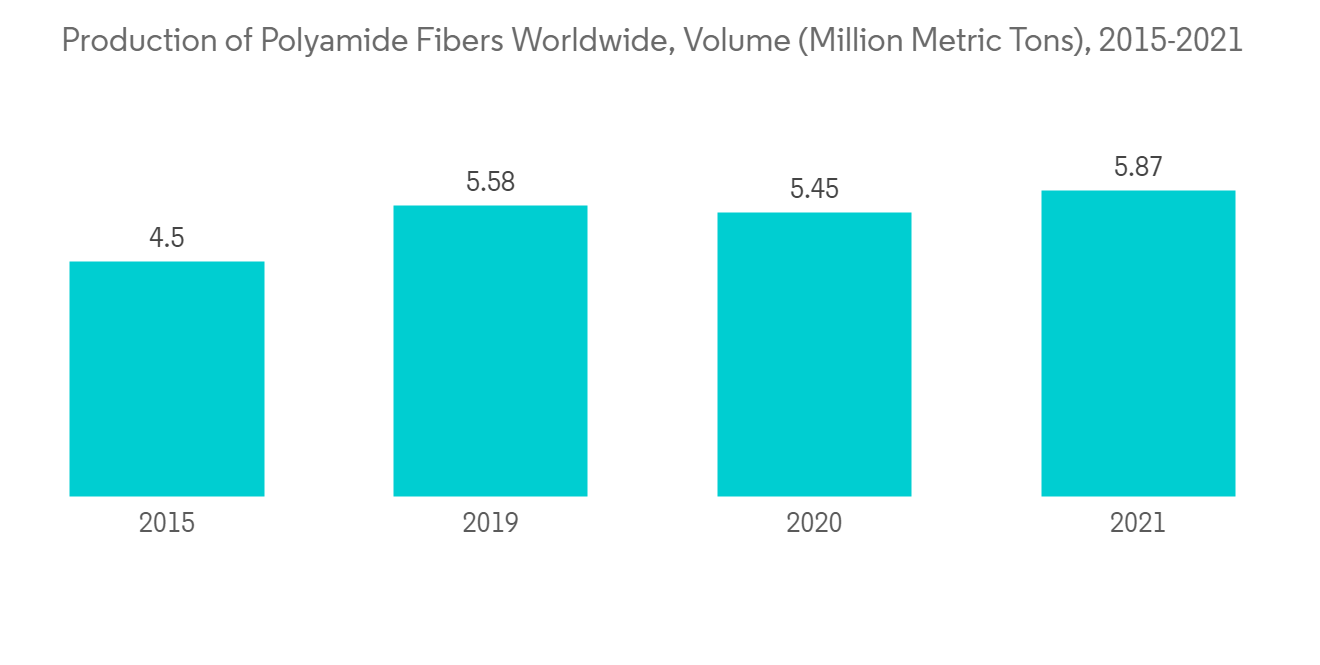

- 热熔胶具有高热稳定性、高熔点和对许多化合物的耐化学性。 这些特性使这些粘合剂在当前情况下比其他粘合剂要求更高。 2021年全球聚□胺产量为587万吨。

- 根据 Statista 的数据,到 2027 年,粘合剂的市场价值预计将增长到近 650 亿美元,而密封剂的市场价值预计将超过 150 亿美元。

- 在食品和饮料等终端用户行业的强劲需求推动下,包装行业越来越多地使用粘合剂,这推动了二聚酸市场的发展。

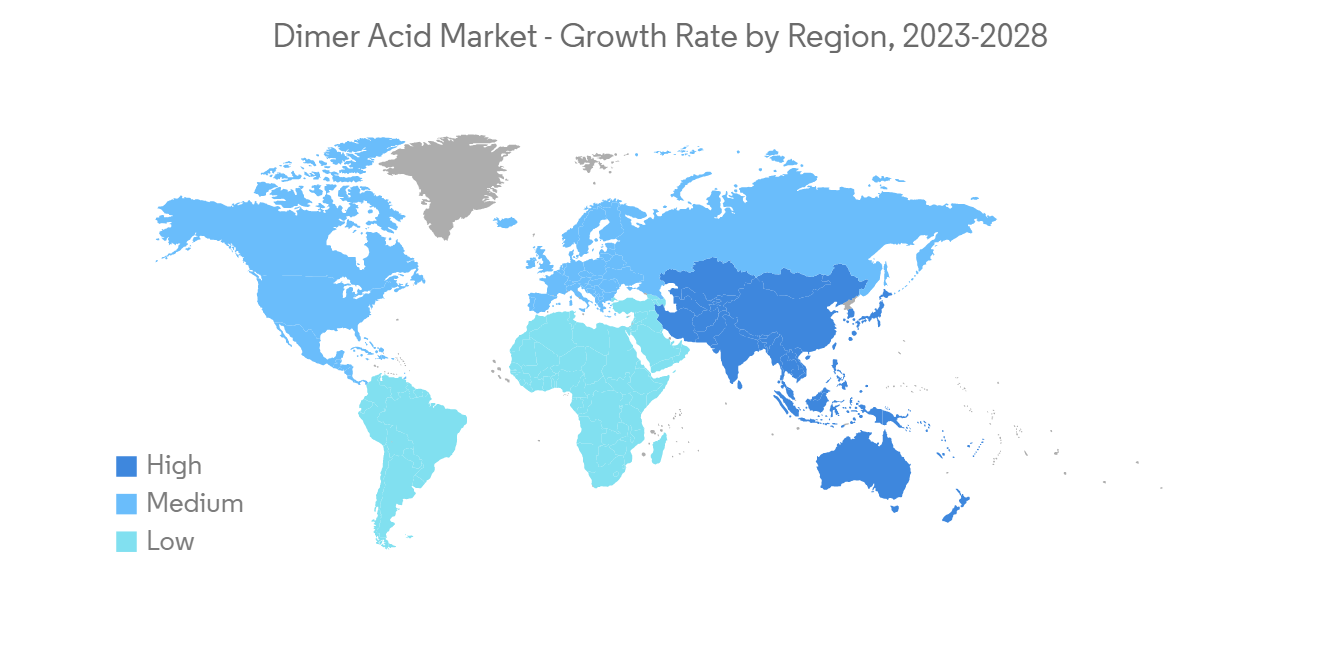

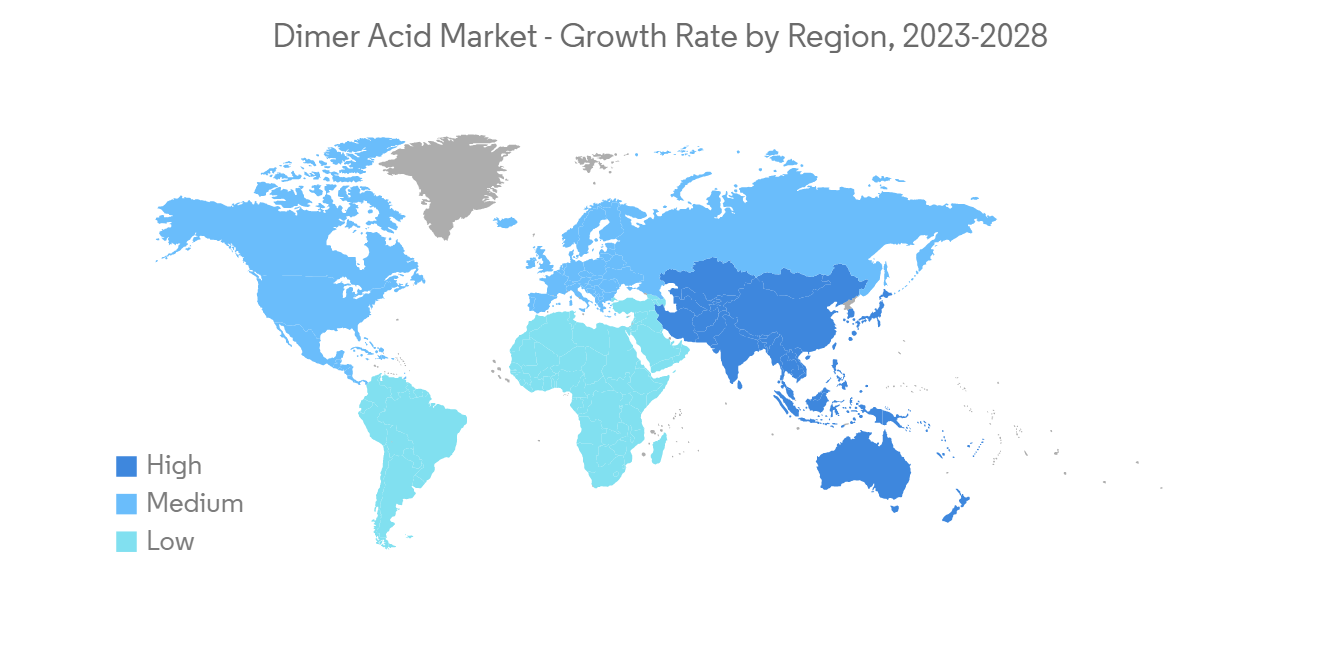

亚太地区主导市场

- 亚太地区的建筑业正在逐步发展,产量也在增加。 中国、印度和东盟国家其他行业的粘合剂需求正在增加对用于涂料和热熔胶製造的二聚酸的需求。

- 在建筑行业,油漆和涂层剂等树脂用于室内外装饰。 在这些应用中,二聚酸因其对高温、酸雨和雪等环境变化的抵抗力得到改善而被用于生产。

- 全球建筑行业的收入预计在未来几年稳步增长,到 2030 年将达到 4.4 万亿美元。 中国正在经历建筑业的巨大增长。 根据中国国家统计局的数据,2021 年中国建筑业产值约为 4.29 万亿美元。

- 在到 2025 年的未来五年内,中国将在重大建设项目上投资 1.43 万亿美元。 到 2022 年,印度将通过政府在基础设施和经济适用房方面的举措为建筑业贡献约 6400 亿美元。

- 製备聚酯的原料包括所有植物油、脂肪酸及其衍生物。 据美国农业部统计,2021年日本的植物油消费量约为7.5万吨。

- 到 2022 年,欧盟 27 国将成为葵花籽油消费量最大的国家,其次是中国和印度。 根据美国农业部的数据,2021 年中国人口消费了约 260 万吨葵花籽油。

- 各个行业涂料应用的增加以及各种应用对聚□胺树脂的需求不断增加,预计将在未来几年推动二聚酸市场。

二聚酸行业概况

二聚酸市场部分整合,少数大公司控制着很大一部分。 主要公司包括 BASF、Croda International、Oleon NV、Harima Chemicals 和 Emery Oleochemicals。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

内容

第一章介绍

- 调查先决条件

- 本次调查的范围

第二章研究方法论

第 3 章执行摘要

第四章市场动态

- 主持人

- 扩大聚□胺树脂的应用

- 粘合剂和燃料添加剂应用的扩展

- 约束因素

- 原材料价格波动

- 其他限制

- 工业价值链分析

- 波特的五力分析

- 供应商的议价能力

- 消费者的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第 5 章市场细分

- 用法

- 醇酸树脂

- 粘合剂/弹性体

- 润滑剂

- 聚□胺树脂

- 燃油添加剂

- 其他用途

- 地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 其他亚太地区

- 北美

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 意大利

- 其他欧洲

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 中东和非洲

- 沙特阿拉伯

- 南非

- 其他中东和非洲地区

- 亚太地区

第六章竞争格局

- 併购、合资、合作、合同等。

- 市场份额 (%)/排名分析

- 主要公司采用的策略

- 公司简介

- BASF

- Arizona Chemical

- Aturex Group

- Croda International

- Emery Oleochemicals

- Florachem Corp.

- Harima Chemicals

- Jinan Tongfa Resin Co. Ltd

- Nissan Chemical America Corp.

- Oleon NV

第7章 市场机会与未来动向

The market for dimer acid is expected to register a CAGR of more than 5% during the forecast period.

The market was hampered by the COVID-19 pandemic, as lockdowns, social distances, and trade sanctions triggered massive disruptions to global supply chain networks. The construction industry witnessed a decline due to the halt in activities. However, the condition recovered in 2021 is expected to benefit the market during the forecast period.

Key Highlights

- Increasing applications for polyamide resins and growing usage of adhesives and fuel oil additives are driving market growth.

- Fluctuating raw material prices and uncertainty in the production of rapeseed oil, cottonseed oil, and soybean oil are expected to hinder market growth.

Dimer Acid Market Trends

Growing Demand for Alkyd Resins and Adhesives

- Dimer Acid is known as dimerized fatty acids and belongs to the dicarboxylic acid group. Dimer acid finds its application in surface coatings, lubricants, and fuel additives.

- Dimer acid is used to manufacture alkyd resins, mainly used for synthetic paintings and coatings and employed in the construction industry due to their properties.

- In 2021, the United States produced 123.9 billion pounds of resins. High-density polyethylene (HDPE) was the most produced resin that year, with an output of 22 billion pounds. Linear low-density polyethylene (LLDPE) accounted for a similar production volume, at 21.7 billion pounds.

- The properties of dimer acid include high molecular weight, difficulty in crystallization and distillation, highly flexible cyclic structure, soluble in hydrocarbons, and easily controlled reactivity.

- Polyamide hot-melt adhesives largely use dimer acid in the manufacturing process. These hot-melt adhesives are used on metal, paper, wood, and many plastics, like PVC, surface-treated polypropylene, and polyethylene, for excellent adhesion purposes, due to their characteristics.

- Synthetic polyamides are commonly used in textiles, the automotive industry, carpets, kitchen utensils, and sportswear due to their high durability and strength. The transportation manufacturing industry is the major consumer, accounting for 35% of polyamide (PA) consumption.

- Hot-melt adhesives have high thermal stability, melting points, and chemical resistance to many compounds. These properties are increasing the demand for these adhesives over other adhesives in the current scenario. In 2021, global polyamide production stood at 5.87 million metric tons.

- According to Statista, by 2027, the market value of adhesives is expected to increase to nearly USD 65 billion, and sealants will amount to just over USD 15 billion.

- Due to the strong demand from end-user industries such as food and beverages, increasing applications for adhesives in the packaging industry are driving the market for dimer acid.

Asia-Pacific to Dominate the Market

- There have been gradual developments in the Asian-Pacific construction sector and the growing production. The demand for adhesives in China, India, and the ASEAN countries from other sectors is increasing the demand for dimer acid used in coatings and hot-melt adhesive production.

- The construction industry uses paints, coatings, and other resins for interior and exterior applications. These applications use dimer acid in production as it provides better durability against environmental changes, such as high temperatures, acid rain, and snow.

- The revenue of the global construction industry is expected to grow steadily over the next few years and reach USD 4.4 trillion by 2030. China is experiencing massive growth in its construction sector. According to the National Bureau of Statistics of China, in 2021, the construction output in China was valued at approximately USD 4.29 trillion.

- China is investing USD 1.43 trillion in major construction projects in the next five years till 2025. In 2022, India contributed about USD 640 billion to the construction industry due to government initiatives in infrastructure development and affordable housing.

- The raw materials used to prepare polyesters include all vegetable oils, fatty acids, and their derivatives. According to the US Department of Agriculture 2021, the consumption volume of vegetable oil in Japan amounted to around 75 thousand metric tons in 2021.

- In 2022, the leading country of sunflowerseed oil consumption was the EU-27, followed by China and India. According to the US Department of Agriculture, in 2021, China's population consumed around 2.6 million metric tons of sunflower seed oil.

- Increasing applications for coatings from various industries and growing demand for polyamide resins for different applications are expected to drive the market for dimer acid through the years to come.

Dimer Acid Industry Overview

The dimer acid market is partially consolidated, with a few major players dominating a significant portion. Some major companies are BASF, Croda International, Oleon NV, Harima Chemicals, and Emery Oleochemicals.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Increasing Applications for Polyamide Resins

- 4.1.2 Growing Usage of Adhesives and Fuel Additives

- 4.2 Restraints

- 4.2.1 Fluctuating Raw Material Prices

- 4.2.2 Other Restraints

- 4.3 Industry Value Chain Analysis

- 4.4 Porters Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Consumers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION (Market Size in Volume)

- 5.1 Application

- 5.1.1 Alkyd Resins

- 5.1.2 Adhesives and Elastomers

- 5.1.3 Lubricants

- 5.1.4 Polyamide Resin

- 5.1.5 Fuel Oil Additives

- 5.1.6 Other Applications

- 5.2 Geography

- 5.2.1 Asia-Pacific

- 5.2.1.1 China

- 5.2.1.2 India

- 5.2.1.3 Japan

- 5.2.1.4 South Korea

- 5.2.1.5 Rest of Asia-Pacific

- 5.2.2 North America

- 5.2.2.1 United States

- 5.2.2.2 Canada

- 5.2.2.3 Mexico

- 5.2.3 Europe

- 5.2.3.1 Germany

- 5.2.3.2 United Kingdom

- 5.2.3.3 France

- 5.2.3.4 Italy

- 5.2.3.5 Rest of Europe

- 5.2.4 South America

- 5.2.4.1 Brazil

- 5.2.4.2 Argentina

- 5.2.4.3 Rest of South America

- 5.2.5 Middle-East and Africa

- 5.2.5.1 Saudi Arabia

- 5.2.5.2 South Africa

- 5.2.5.3 Rest of Middle-East and Africa

- 5.2.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Share (%)/Ranking Analysis**

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 BASF

- 6.4.2 Arizona Chemical

- 6.4.3 Aturex Group

- 6.4.4 Croda International

- 6.4.5 Emery Oleochemicals

- 6.4.6 Florachem Corp.

- 6.4.7 Harima Chemicals

- 6.4.8 Jinan Tongfa Resin Co. Ltd

- 6.4.9 Nissan Chemical America Corp.

- 6.4.10 Oleon NV