|

市场调查报告书

商品编码

1273541

热喷涂涂料市场 - 增长、趋势、COVID-19 影响和预测 (2023-2028)Thermal Spray Coatings Market - Growth, Trends, and Forecasts (2023 - 2028) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

在预测期内,热喷涂涂层市场预计将以超过 6% 的复合年增长率增长。

2020 年,由于飞机产量下降和原材料短缺,COVID-19 严重影响了行业的发展。 然而,大流行后航空航天业的增长预计将增加热喷涂涂层的消耗。

主要亮点

- 热喷涂涂层在航空航天领域的广泛使用、在医疗设备中的使用增加以及热喷涂陶瓷涂层的日益普及正在推动市场增长。

- 政府对热喷涂涂层的严格监管以及工艺可靠性和一致性问题可能会限制市场增长。

- 在石油和天然气行业的应用不断增加、热喷涂技术的进步以及热喷涂处理材料的回收利用有望为所研究市场中的製造商提供许多机会。

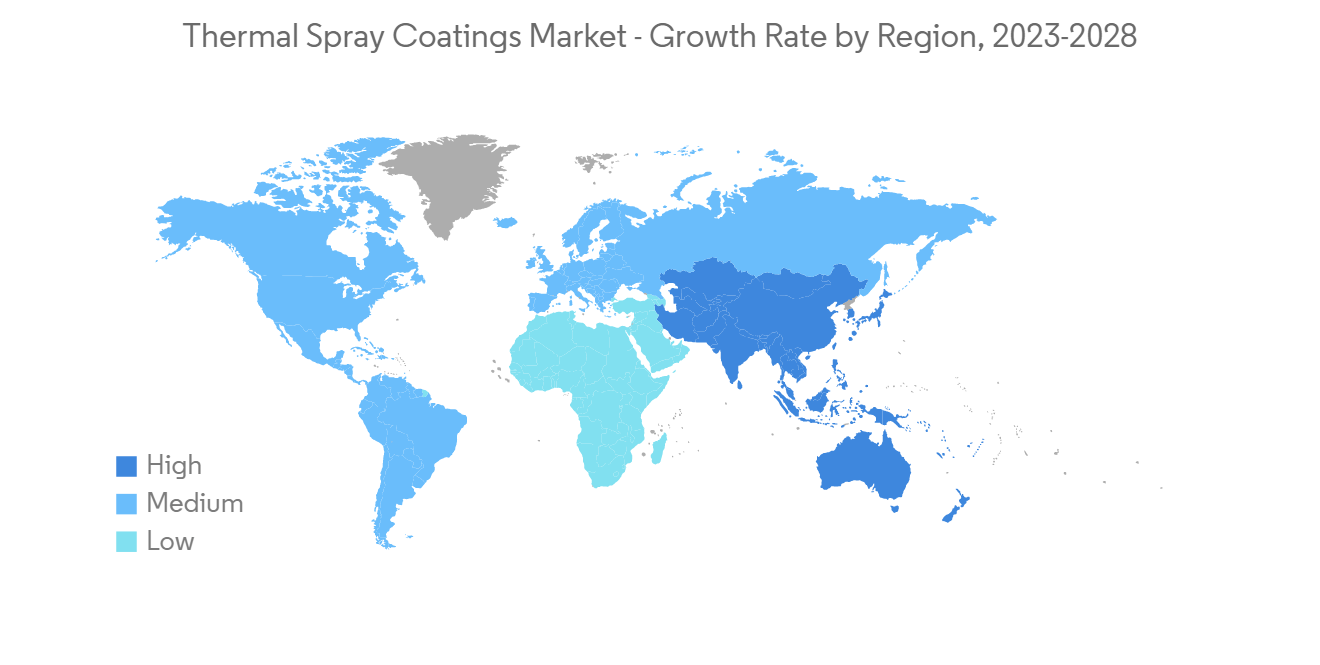

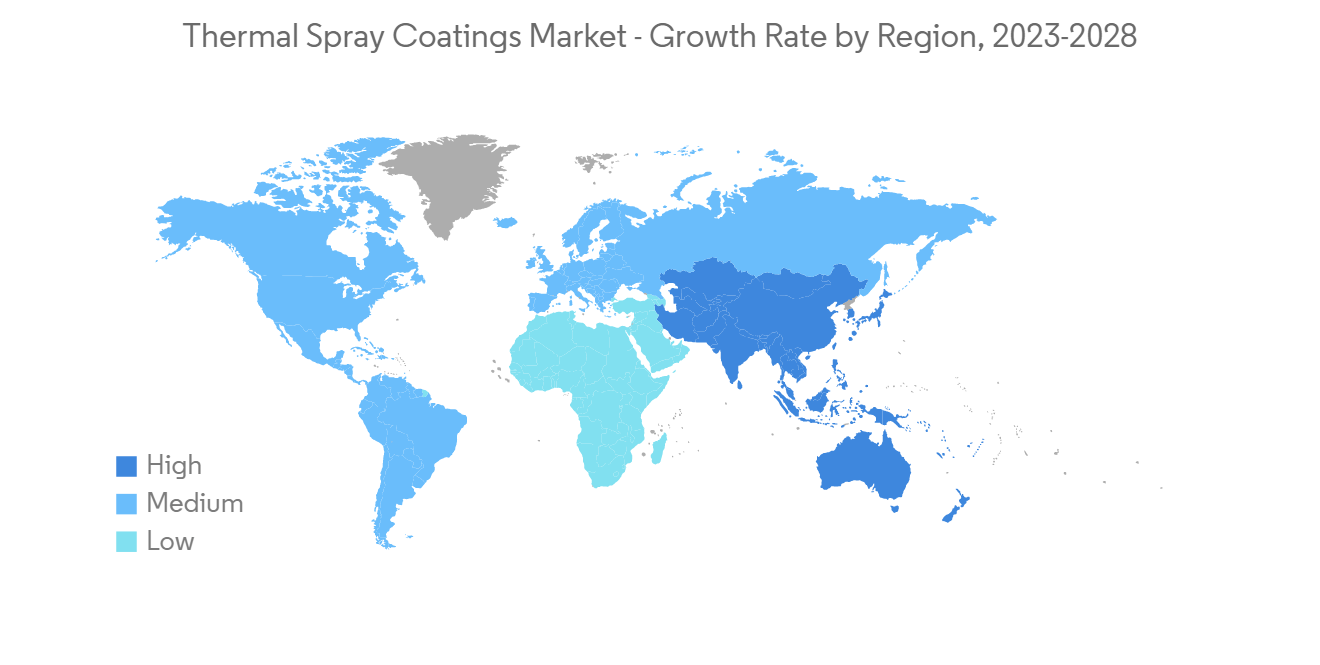

- 由于在航空航天工业和医疗设备中的应用越来越多,北美在全球热喷涂涂料市场占据主导地位。

热喷涂层市场趋势

航空航天业的需求不断增长

- 在航空航天领域,热喷涂层被广泛用于保护飞机部件和修復老化部件。 在飞机燃气轮机上使用热喷涂涂层可提高耐腐蚀性、抗污染物性、提高热效率、减少氮氧化物 (NOx) 排放、驱动系统、高耐热性和提高部件性能。它具有多种优势,比如更长的寿命。

- 热喷涂主要用于曲轴、活塞环、气缸和阀门等喷气发动机零件的各种用途。 除此之外,起落架涂层(起落架内的轴承和轴)也用于承受着陆和起飞期间的力。

- 许多用于製造飞机零件和设备的超级合金材料具有良好的氧化性能,但不耐腐蚀或侵蚀。 飞机部件暴露在极端高温、高压和磨蚀等恶劣环境中。 热喷涂涂层通过延长部件寿命和提高性能为昂贵的发动机部件提供重要保护

- 氧化锆、铝青铜和钴钼等热喷涂涂层分别用于火箭燃烧室、压缩机空气密封件和高压喷嘴的涂层。 涡轮气封、燃料喷嘴和涡轮叶片均涂有钴铬、氧化铝和碳化铬。 高速氧燃料 (HVOF) 喷涂和等离子喷涂工艺是该领域使用的主要工艺。

- 到 2021 年,美国将贡献约 891 亿美元的航空航天出口,成为领先的航空航天出口国。 该国是波音和洛克希德马丁等主要航空航天製造商的所在地。 截至 2021 年,12 家最大的航空航天和国防公司中有 6 家位于美国。

- 由于消费者收入的增加和对交通基础设施的投资,预计亚太和中东/非洲地区的航空业将快速扩张。

- 亚太航空公司连续第四个月实现强劲的国际增长,5 月份同比恢復 453.3%,高于 2022 年 1 月的 103.5%。

- 此外,预计 2021 年航空航天製造业的产值约为 1.48 万亿日元(139.6 亿美元),高于上一财年的约 1.61 万亿日元(151.9 亿美元)。

- 在预测期内,诸如此类的因素预计会增加航空航天业热喷涂涂层的消耗量。

北美主导市场

- 北美是全球热喷涂涂料市场中最大的区域市场。 由于对以有竞争力的成本提高性能以及遵守所有法规和行业标准的需求不断增长,预计美国仍将是该地区热喷涂涂层的主要市场。

- 美国是世界上最大的汽车工业生产国之一。 大流行后,该国的汽车产量在 2021 年实现了稳健增长。 2021年汽车产量将达到917万辆,同比增长4%。

- 此外,航空航天零部件向法国、中国和德国等国家/地区的强劲出口,以及美国强劲的消费者支出,都在推动航空航天业的製造活动。

- 根据美国联邦航空管理局 (FAA) 的数据,由于航空货运量增加,商用飞机机队总数预计将从 2021 年的 5,791 架增加到 2037 年的 8,270 架。 此外,由于现有飞机的老化,预计美国主线航空公司的机队将增加到每年 54 架飞机。

- 2021 年,加拿大的航空航天业对该国的 GDP 贡献了约 240 亿美元。 加拿大的航空航天业将其 75% 以上的产品出口到六大洲的 190 多个国家。

- 在预测期内,上述因素将反过来增加该地区对热喷涂涂层的需求。

热喷涂层行业概况

全球热喷涂涂料市场较为分散,顶级企业之间为争夺全球市场份额展开了激烈的竞争。 许多市场领导者都是垂直整合的,拥有广泛的材料和设备产品组合,是整个热喷涂涂层市场的一部分。 市场上的主要参与者包括 OC Oerlikon Management AG、Praxair S.T. Technologies Inc. Linde PLC)、Chromalloy Gas Turbine LLC、Kennametal Inc.、TOCALO 等(排名不分先后)。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

内容

第一章介绍

- 调查先决条件

- 本次调查的范围

第二章研究方法论

第 3 章执行摘要

第四章市场动态

- 主持人

- 热喷涂层在医疗设备中的使用增加

- 热喷涂陶瓷涂层越来越受欢迎

- 扩大在航空航天工业中的应用

- 约束因素

- 流程可靠性和一致性问题

- 严格的热喷涂涂层政府法规

- 工业价值链分析

- 波特的五力分析

- 供应商的议价能力

- 消费者的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第 5 章市场细分

- 粉末涂料

- 陶瓷氧化物

- 硬质合金

- 金属

- 聚合物和其他粉末涂料

- 过程

- 燃烧

- 电能

- 最终用户行业

- 航空航天

- 工业燃气轮机

- 汽车

- 电子产品

- 医疗设备

- 能源/电力

- 石油和天然气

- 其他最终用户行业

- 地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 澳大利亚和新西兰

- 其他亚太地区

- 北美

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 意大利

- 法国

- 其他欧洲

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 中东和非洲

- 沙特阿拉伯

- 南非

- 其他中东和非洲地区

- 亚太地区

第六章竞争格局

- 併购、合资、合作、合同等。

- 市场份额 (%)/排名分析

- 主要公司采用的策略

- 公司简介

- APS Materials Inc.

- ASB Industries Inc.

- Bodycote PLC

- Chromalloy Gas Turbine LLC

- Chromalloy Gas Turbine LLC

- Eurocoating SpA

- FM Industries Inc.

- FW Gartner Thermal Spraying(Curtis-Wright)

- Kennametal Inc.

- Oerlikon Metco

- Praxair S.T. Technology, Inc.

- The Fisher Barton Group(Thermal Spray Technologies)

- Thermion

- TOCALO Co. Ltd

第七章市场机会与未来趋势

- 石油和天然气行业的应用增加

- 先进的热喷涂技术(冷喷涂工艺)

The market for thermal spray coatings is expected to register a CAGR of more than 6% during the forecast period.

In 2020, COVID-19 severely impacted industry growth due to decreased aircraft production and raw materials shortage. However, the growing aerospace industry post-pandemic is expected to increase thermal spray coatings consumption.

Key Highlights

- The extensive usage of thermal spray coatings in the aerospace sector increased usage in medical devices, and the rising popularity of thermal spray ceramic coatings primarily drives the market's growth.

- Stringent government regulations for thermal spray coatings and issues regarding process reliability and consistency will likely restrain the market growth.

- The increasing applications in the oil and gas industry, advancements in spraying technology, and recycling of thermal spray processing materials are expected to provide numerous opportunities for the manufacturers in the market studied.

- North America dominated the global spray coatings market due to increased application in the aerospace industry and medical devices.

Thermal Spray Coatings Market Trends

Increasing Demand from the Aerospace Industry

- In the aerospace sector, thermal spray coatings are extensively used as protective coatings to protect aircraft components and repair old ones. The usage of thermal spray coatings for aircraft gas turbines provides various advantages, such as better corrosion resistance, resistance from contaminants, improved thermal efficiency, reduced emissions of nitrogen oxide (NOX), actuation systems, and to provide high thermal resistance, and increased component life.

- Thermal sprays are primarily employed for various purposes in jet engine components, such as crankshafts, piston rings, cylinders, valves, etc. In addition to these, they are also applied in the landing gear coating (bearings and axles inside the landing gear) to withstand the forces during landing and take-off.

- Most superalloy materials used to manufacture aircraft components and equipment possess good oxidation characteristics but are not corrosion and erosion resistant. Aviation components are subjected to harsh environments, exceptionally high heat, pressures, and abrasive chemicals. Thermal spray coatings significantly protect expensive engine components by extending the component life and improving performance.

- Thermal spray coatings, such as zirconium oxide, aluminum bronze, and cobalt-molybdenum, are used for coating purposes in rocket combustion chambers, compressor air seals, and high-pressure nozzles, respectively. In addition, chromium cobalt, aluminum oxide, and chromium carbide coatings are employed in turbine air seals, fuel nozzles, and turbine vanes. High-velocity oxy-fuel (HVOF) spray and plasma spray processes are the majorly used processes in this sector.

- In 2021, the United States contributed some USD 89.1 billion in aerospace exports, making it the leading country in aerospace exports. The country is home to some of the leading manufacturers in the aerospace sector, including Boeing and Lockheed Martin. As of 2021, six of the 12 leading aerospace and defense companies are based in the United States.

- Asia-Pacific and the Middle East & African regions are expected to witness rapid expansion in the aviation sector, owing to rising consumer incomes and investments in transportation infrastructure shortly.

- Asia-Pacific airlines registered substantial international growth four months in a row, reaching a year-on-year recovery rate of 453.3% in May, a significant increase from 103.5% in January 2022.

- Moreover, in 2021, the production value in the aerospace manufacturing industry was estimated to amount to approximately JPY 1.48 trillion (USD 13.96 billion), down from around JPY 1.61 trillion (USD 15.19 billion) in the previous fiscal year.

- All the factors mentioned above are expected to boost the consumption of thermal spray coatings in the aerospace industry during the forecast period.

North America to Dominate the Market

- North America represented the largest regional market for global thermal spray coatings. The United States is expected to remain the region's primary market for thermal spray coatings, owing to the increasing demand for improved performance at competitive costs and meeting all the regulations and industry standards.

- The United States is one of the world's largest producers of the automotive industry. The country's automotive production recorded robust growth in 2021 after the pandemic. In 2021, automotive production stood at 9.17 million units 2021, a 4% growth from the previous year.

- Additionally, strong exports of aerospace components to countries such as France, China, and Germany, along with robust consumer spending in the United States, are driving the manufacturing activities in the aerospace industry.

- According to the Federal Aviation Administration (FAA), the total commercial aircraft fleet is expected to reach 8,270 by 2037 from 5,791 in 2021, owing to the growth in air cargo. Also, the US mainliner carrier fleet is expected to grow to 54 aircraft per year due to the existing fleet getting older.

- The Canadian aerospace industry contributed around USD 24 billion to the country's GDP in 2021. The Canadian aerospace industry exports over 75% of its products to over 190 countries across six continents.

- Such factors above, in turn, increase the demand for thermal spray coatings in the region during the forecast period.

Thermal Spray Coatings Industry Overview

The global thermal spray coatings market is fragmented, with intense competition among the top players to capture a significant global market share. Most market leaders are vertically integrated, with a broad product portfolio of materials and equipment that is part of the overall thermal spray coatings market. Major players in the market include OC Oerlikon Management AG, Praxair S.T. Technologies Inc. (Linde PLC), Chromalloy Gas Turbine LLC, Kennametal Inc., and TOCALO Co. Ltd, among others (not in any particular order).

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Increased Usage of Thermal Spray Coatings in Medical Devices

- 4.1.2 Rising Popularity of Thermal Spray Ceramic Coatings

- 4.1.3 Growing Application in Aerospace Industry

- 4.2 Restraints

- 4.2.1 Issues Regarding Process Reliability and Consistency

- 4.2.2 Stringent Government Regulations for Thermal Spray Coatings

- 4.3 Industry Value-chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Consumers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION (Market Size in Value)

- 5.1 Powder Coating Materials

- 5.1.1 Ceramic Oxides

- 5.1.2 Carbides

- 5.1.3 Metals

- 5.1.4 Polymers and Other Powder Coating Materials

- 5.2 Process

- 5.2.1 Combustion

- 5.2.2 Electric Energy

- 5.3 End-user Industry

- 5.3.1 Aerospace

- 5.3.2 Industrial Gas Turbines

- 5.3.3 Automotive

- 5.3.4 Electronics

- 5.3.5 Medical Devices

- 5.3.6 Energy and Power

- 5.3.7 Oil and Gas

- 5.3.8 Other End-user Industries

- 5.4 Geography

- 5.4.1 Asia-Pacific

- 5.4.1.1 China

- 5.4.1.2 India

- 5.4.1.3 Japan

- 5.4.1.4 South Korea

- 5.4.1.5 Australia & New Zealand

- 5.4.1.6 Rest of Asia-Pacific

- 5.4.2 North America

- 5.4.2.1 United States

- 5.4.2.2 Canada

- 5.4.2.3 Mexico

- 5.4.3 Europe

- 5.4.3.1 Germany

- 5.4.3.2 United Kingdom

- 5.4.3.3 Italy

- 5.4.3.4 France

- 5.4.3.5 Rest of Europe

- 5.4.4 South America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Rest of South America

- 5.4.5 Middle East and Africa

- 5.4.5.1 Saudi Arabia

- 5.4.5.2 South Africa

- 5.4.5.3 Rest of Middle East and Africa

- 5.4.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Share (%)**/Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 APS Materials Inc.

- 6.4.2 ASB Industries Inc.

- 6.4.3 Bodycote PLC

- 6.4.4 Chromalloy Gas Turbine LLC

- 6.4.5 Chromalloy Gas Turbine LLC

- 6.4.6 Eurocoating SpA

- 6.4.7 FM Industries Inc.

- 6.4.8 FW Gartner Thermal Spraying (Curtis-Wright)

- 6.4.9 Kennametal Inc.

- 6.4.10 Oerlikon Metco

- 6.4.11 Praxair S.T. Technology, Inc.

- 6.4.12 The Fisher Barton Group (Thermal Spray Technologies)

- 6.4.13 Thermion

- 6.4.14 TOCALO Co. Ltd

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Increasing Applications in the Oil and Gas Industry

- 7.2 Advancements in Spraying Technology (Cold Spray Process)