|

市场调查报告书

商品编码

1640493

电磁阀:市场占有率分析、产业趋势与统计、成长预测(2025-2030)Solenoid Valves - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

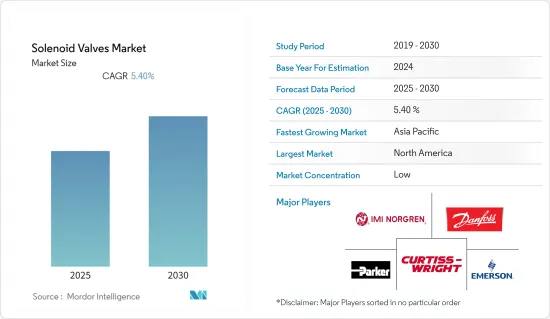

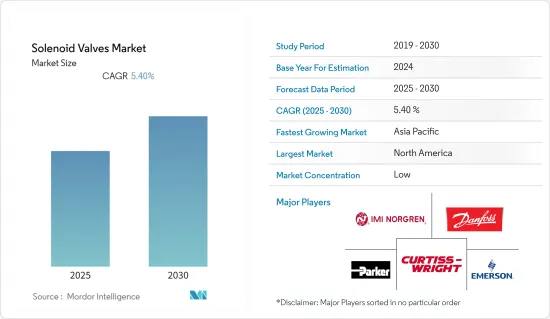

预测期内,电磁阀市场预计将以 5.4% 的复合年增长率成长。

电磁阀市场的发展主要受到製程自动化的日益普及以及电磁阀在各个製程环节的部署日益增多的推动。例如,这些阀门经常用于水处理厂。除了帮助去除污水中的有机污染物外,它还有多种用途。

关键亮点

- 水处理领域使用了许多电磁阀,包括塑胶、黄铜和不銹钢。用于各种设备的进气阀、水箱填充、软水器的服务阀、大型气动或水力阀门的先导阀等。

- 此外,电磁阀在食品加工产业最常使用,是食品加工的最佳选择之一。许多电磁阀的设计可承受恶劣的室温以及潮湿、腐蚀性的条件。电磁阀通常由不銹钢製成,因为这种材料具有耐污染性。

- 电磁阀也可以用于水力发电(一种可再生能源),作为控制水流的系统中的组件。可再生能源计划的增加预计将推动所研究市场的发展。例如,今年11 月,作为卡纳塔克邦投资的一部分,ABC Cleantech 与卡纳塔克邦政府签署了一份谅解备忘录,将建立一个年产能为20 万吨的绿色氢气生产装置和一个年产能为100 万吨的绿色氨生产装置吨。

- 电磁阀在医疗领域至关重要,因为它们有助于向使用医疗人工呼吸器的患者输送正确浓度和流速的气体。此外,电磁阀可以非常快速且精确地调节氧气流量(增量小至每分钟半升),确保有效的患者照护。 COVID-19 疫情增加了对关键医疗设备的需求,从而增加了对电磁阀的需求。

- 医疗领域也见证了几种满足某些关键应用需求的电磁阀创新。例如,今年 4 月,艾默生扩展了其 ASCO 090 系列微型电磁阀产品线,包括 090 系列,该系列为氧气疗法、压迫疗法和气体分析设备中的气体控制提供了轻巧、节省空间的解决方案。了三个双向阀配置。

- 然而,阻碍市场扩大的因素之一是电磁线圈故障。如果施加了错误的电压,线圈可能会发生故障,甚至烧坏。突波和尖峰也会损坏线圈。烧毁的线圈无法修復,必须更换。

电磁阀市场趋势

食品和饮料行业预计将占据主要市场占有率

- 食品级电磁阀和电磁阀歧管用于许多食品处理应用,尤其是饮料分配机。特殊要求包括食品级密封和阀体材料(316 SS),以免改变饮料的味道。电磁阀的设计可承受恶劣的温度、湿度和腐蚀性条件,使其成为食品和饮料行业的首选阀门。由于其抗污染性能,不銹钢被用于製造这些阀门以确保其使用寿命。

- 电磁阀通常用于肉类和屠宰行业、水果和蔬菜罐头厂、鱼罐头厂、腌製系统、饮料(软饮料、葡萄酒、烈酒)和调理食品行业、乳製品行业、油脂行业、动物饲料行业。用于製造业和其他行业。根据《印度时报》报道,到2023年,47%的印度家庭将消费冷饮。

- 据经合组织称,2016年至2022年间,全球肉类产量将从3.17亿吨增加到3.45亿吨以上。肉类产量的增加可能会促进所研究市场的成长。

- 此外,气动电磁阀主要用于食品和饮料行业,因为它们比主要使用油的液压电磁阀清洁得多。它们可以被密封以防止任何产品被困在其内部腔内。因此,产品污染的风险降低了。

- 然而,加工动物饲料、谷物和奶粉可能会产生危险且多尘的环境。当灰尘与空气混合时,就会产生可被火花或火焰点燃的爆炸性环境。潮湿和一般使用也会导致电磁线圈故障并产生火源。因此,我们建议在所有危险环境中使用 ATEX 等级电磁阀。

亚太地区市场预计将实现高成长

- 由于人口成长、燃料和石油产品需求大幅增加以及中阶可支配收入的提高,亚太地区是食品饮料、汽车、发电、石油天然气和医药製药领域电磁阀安装量最大的地区。快的市场之一。

- 据英国石油公司(BP)称,中国是亚太地区最大的石油消费国,去年每天消耗 1,550 万桶石油。同年,印度成为该地区第二大石油消费国,每日消费量为 495 万桶。此外,亚太地区石油产量2020年将达742.8万桶/日,2021年将达到733.5万桶/日。该地区强劲的石油和天然气行业预计将为电磁阀市场的成长提供大量机会。

- 此外,该地区汽车产量的增加预计将推动市场发展。电子机械驱动阀也构成汽车电磁阀。这些阀门可调节流体或空气流经汽车系统和马达的速度。当电流流过螺线管中的导线时,就会发生磁反应,螺线管就会将电能转换为机械能。电磁阀通常用于液压系统和动力流体。

- 据印度汽车工业商协会(SIAM)称,印度是世界上重要的汽车製造国之一。上一财年,印度汽车产量约2,290万辆,比上年度有所成长。根据中国工业协会统计,截至今年4月,我国商用车产量为21万辆,乘用车产量为99.6万辆。当月汽车产量为120万辆,季减46.2%,年减46.1%。

- 根据日本经济产业省统计,在日本金属製品领域,去年电磁阀的产量与前一年同期比较增加了 3,200 吨(+19.38%)。因此,日本2021年的产量达到了19,660吨。生产量如此大幅度的增长表明电磁阀的采用可能会增加。

电磁阀产业概况

电磁阀市场竞争激烈。在目前的市场情势下,市场主要企业之间存在相当大的整合。 ABB 收购通用电气工业系统公司、艾默生电气公司收购安沃驰 (Aventics) 等倡议,帮助许多供应商提高了市场占有率。

第二个是紧凑且久经考验的 50.806 压力调节器系列的新版本。这两种产品都是按照 DIN EN ISO 18562(评估医疗应用中呼吸道生物相容性的标准)设计的。

2023年11月,艾默生推出全新电磁阀ASCO系列。此阀门采用直接作用、高流量设计,与同类阀门相比,具有更优异的流量功率比。为了在最小功率水平下实现高流速,327C 系列采用平衡阀瓣设计,使其适合用于炼油厂、发电厂和化学加工厂。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第 1 章 简介

- 研究假设和市场定义

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场动态

- 市场概况

- 市场驱动因素

- 电磁阀在水和饮料产业的应用日益广泛

- 持续转向可再生能源计划推动需求

- 市场限制

- 需求和成本降低的动态性质

- 产业相关人员分析

- 产业吸引力-波特五力分析

- 新进入者的威胁

- 买家的议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争对手之间的竞争

- COVID-19 对电磁阀市场的影响

- 行业标准和法规

第五章 技术简介

- 电磁阀的演变及其在汽车(电动和自动驾驶汽车)等关键行业中的新应用

- 关键设计和技术考虑因素

第六章 市场细分

- 按类型

- 直动式

- 试运行

- 双向

- 三通

- 四方

- 尺寸

- 超紧凑

- 超小型

- 微型

- 小振膜

- 大振膜

- 按最终用户产业

- 食品和饮料(过滤系统、进料系统、食品加工等)

- 车

- 按类型

- 气压悬吊

- 燃油喷射和废气控制

- 安全保障体系

- 传动系统

- 其他(门系统、暖通空调等)

- 按应用

- 乘客

- 商用车

- 越野

- 化工和石化

- 储能装置方向控制阀

- 隔离阀

- 发电

- 蒸气控制及供料装置

- 升降和泵浦系统

- 洪水系统

- 石油和天然气

- 钻井系统

- 萃取系统

- 下游供应

- 医疗与製药(医疗设备与空气清净系统)

- 其他最终用户(例如农业、航太、纺织业)

- 地区

- 北美洲

- 美国

- 加拿大

- 欧洲

- 德国

- 英国

- 义大利

- 法国

- 亚洲

- 中国

- 日本

- 印度

- 澳洲和纽西兰

- 其他的

- 墨西哥

- 巴西

- 非洲

- 其他(土耳其等)

- 北美洲

第七章 竞争格局

- 公司简介

- IMI Precision Engineerng

- Danfoss Industries Ltd

- Curtiss Wright Corporation

- Emerson Electric Co.

- Parker Hannifin Corporation

- AirTAC International Group

- KANKEO SANGYO Co. Ltd

- Anshan Solenoid Valve Co. Ltd

- CEME SpA

- The Lee Company

- Kendrion NV

- Peter Paul Electronics Co., Inc.

第八章投资分析

第九章 市场展望

The Solenoid Valves Market is expected to register a CAGR of 5.4% during the forecast period.

The market for solenoid valves is primarily driven by the growing popularity of process automation and the increased deployment of solenoid valves in various process sectors. For instance, these valves are frequently used in water treatment facilities. They assist in removing organic pollutants from contaminated water and have several other uses.

Key Highlights

- Numerous solenoid valves, including those composed of plastic, brass, and stainless steel, are used in the water treatment sector. They can be used for various equipment intake valves, tank filling, service valves on water softeners, piloting larger actuated valves with air or water, and more.

- Further, the solenoid valve is one of the most commonly used in the food processing industry and is a great option for food processing. Many solenoid valves are designed to withstand harsh room temperatures and moist, corrosive conditions. Solenoid valves are often constructed with stainless steel because of the material's resistance to contaminants.

- A solenoid valve can also be used in hydropower, a kind of renewable energy, as a component of a system to control the flow of water. The rise in renewable energy projects is expected to drive the studied market. For instance, in November this year, as part of Invest Karnataka, ABC Cleantech and the Government of Karnataka signed an MoU for the establishment of a green hydrogen production unit with an annual capacity of 0.2 million tonnes and a green ammonia production unit with an annual capacity of 1 million tonnes, both integrated with 5 GW of renewable energy projects and costing an estimated USD 6 billion.

- The solenoid valves are of utmost importance in the medical sector as they facilitate delivering the correct concentration of gas and rate of flow to a patient on medical ventilators. In addition, solenoid valves moderate the oxygen flow rate with great speed and precision (increments as small as half a liter per minute) which provides effective patient care. The COVID-19 pandemic augmented the demand for critical medical equipment, thereby increasing the demand for solenoid valves.

- The medical sector is also witnessing several solenoid valve innovations catering to specific vital applications. For instance, in April this year, Emerson expanded its ASCO Series 090 line of miniature solenoid valves, adding a three-way Series 090 valve configuration to enable lighter, space-efficient solutions for gas control in oxygen therapy, compression therapy, and gas analyzer devices.

- However, one of the reasons that can hinder market expansion is solenoid coil failure, which has various possible causes. The coil could malfunction and perhaps burn out if the wrong voltage is applied. Electrical surges or spikes could also harm the coil. Coils that have burned out are beyond repair and must be replaced.

Solenoid Valves Market Trends

The Food and Beverage Sector is Anticipated to Hold a Major Market Share

- Food-grade solenoid valves and solenoid valve manifolds are used for many food handling applications, especially in beverage dispensing machines. Special requirements include food-grade seals and valve body materials (316 SS) for unaltered beverage taste. The solenoid valves are designed to resist adverse temperature, humidity, and corrosive conditions, making them the most preferred valves in the food and beverage industry. Due to its contaminant resistance, stainless steel is used to construct these valves to ensure their longevity.

- Solenoid valves are commonly used in the Meat and Abattoir Industry, Fruit and Vegetable Canneries, Fish Canneries, Salting Systems, Beverage (Soft Drinks, Wines, Spirits) and Ready Meal Industry, Dairy Industry, Oils and Fats Industry, Animal Feed Production Industry, and other Industries. According to Times of India, In 2023, cold beverages had penetrated 47% of Indian households.

- According to OECD, between 2016 and 2022, the global production volume of meat increased from 317 million metric tons to over 345 million metric tons. Such an increase in meat production is likely to boost the growth of the studied market.

- Moreover, the use of pneumatic solenoid valves is predominantly witnessed in the food and beverage industry as they are much cleaner than hydraulic solenoid valves, which mainly use oil. They can be sealed to prevent any product from being trapped within its internal cavities. Thus, lessening the risk of product contamination.

- However, when processing animal fodder, cereals, and powdered milk, a dusty hazardous environment is produced. Dust, when mixed with air, can create a potentially explosive atmosphere that a spark or flame could ignite. There is always a chance that due to moisture or general usage, the solenoid coil may fail and generate an ignition source. So, for all hazardous environments, an ATEX-rated solenoid valve is advisable to be used.

The Asia Pacific Region is Expected to Witness a High Market Growth

- Asia Pacific is expected to stand as one of the fastest-growing markets for solenoid valve installations in food & beverage, automotive, power generation, oil & gas, healthcare & pharmaceutical, owing to the rising population, a significant increase in demand for fuel and petroleum products, and the increasing disposable income of the middle-class population in the region.

- According to British Petroleum (BP), China is the largest oil consumer in the Asia-Pacific region, consuming 15.5 million barrels per day last year. In the same year, India consumed over 4.95 million barrels daily, making it the second-largest oil consumer in the region. Also, the oil production in the Asia Pacific region amounted to 7,428 thousand barrels per day in 2020 and 7,335 thousand barrels per day in 2021. Such a robust oil and gas sector in the region is anticipated to offer numerous opportunities for the growth of the solenoid valve market.

- Further, the rise in the production of automotive vehicles in the region is expected to drive the market. Electromechanically operated valves also comprise automotive solenoid valves. These valves regulate the rate at which fluid or air flows through automotive systems and motors. When electric current flows through the solenoid's wire, it produces a magnetic reaction, which is how solenoids transform electrical energy into mechanical energy. Solenoid valves are often used with hydraulic systems and power fluids..

- According to the Society of Indian Automobile Manufacturers (SIAM), India was one of the significant manufacturers in terms of global automobile production. The total number of automobiles produced in India during the last fiscal year was approximately 22.9 million units, an increase over the previous year. Further, according to the China Association of Automobile Manufacturers, 210,000 commercial vehicles and 996,000 passenger automobiles were produced in China as of April this year. The industry produced a total of 1.2 million automobiles during the month, a decrease of 46.2% from the previous month and 46.1% year-over-year.

- According to METI(Japan), in Japan's fabricated metals sector, the production volume of solenoid-operated valves increased by 3.2 thousand tonnes (+19.38%) last year compared to the previous year. As a result, Japan's output volume reached 19.66 thousand tonnes in 2021. Such a huge rise in the production volume hints at the possibility of an increase in the adoption of solenoid valves.

Solenoid Valves Industry Overview

The Solenoid Valves Market is highly competitive. In the current market scenario, there is a considerable consolidation among top players in the market. Acquisitions, such as ABB of General Electric Industrial Systems and by Emerson Electric Co. of Aventics have helped a number of vendors to improve their market share as suppliers of solenoid valves and other industrial automation solutions.

In November 2023, Kendrion presents new pressure regulators and new pinch valve at COMPAMED 2023,both high-flow pressure regulator, which is designed for particularly high flow rates with low pressure losses, and the other is a new version of the compact and proven 50.806 pressure regulator family. Both products are designed in accordance to DIN EN ISO 18562, the standard for assessing the biocompatibility of the respiratory tract in medical applications.

In November 2023, Emerson has introduced the new ASCO Series solenoid valve. The valve features a directacting, high flow design that provides an advantage over similar valves in terms of the ratio of flowing volts to power. In order to allow high flows at minimum power levels, the Series 327C design features a balanced poppet structure, making it suitable for use in refineries, power plants and chemical processing plants.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Growing adoption for solenoid valves in the water treatment and beverage industries

- 4.2.2 Ongoing shift to renewable energy-based projects to drive demand

- 4.3 Market Restraints

- 4.3.1 Dynamic nature of demand and cost reduction

- 4.4 Industry Stakeholder Analysis

- 4.5 Industry Attractiveness - Porter's Five Forces Analysis

- 4.5.1 Threat of New Entrants

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Bargaining Power of Suppliers

- 4.5.4 Threat of Substitute Products

- 4.5.5 Intensity of Competitive Rivalry

- 4.6 Impact of COVID-19 on the Solenoid Valves Market

- 4.7 Industry Standards & Regulations

5 TECHNOLOGY SNAPSHOT

- 5.1 Evolution of Solenoid valves and emerging applications in key verticals such as Automotive (Electric vehicles & Autonomous vehicles)

- 5.2 Major design and technical considerations

6 MARKET SEGMENTATION

- 6.1 By Type

- 6.1.1 Direct Acting

- 6.1.2 Pilot Operated

- 6.1.3 Two Way

- 6.1.4 Three Way

- 6.1.5 Four Way

- 6.2 By Size

- 6.2.1 Micro-miniature

- 6.2.2 Sub-miniature

- 6.2.3 Miniature

- 6.2.4 Small Diaphragm

- 6.2.5 Large Diaphragm

- 6.3 By End-user Industry

- 6.3.1 Food and Beverage (Filtration Systems, Feeder systems, Food Processing, etc.)

- 6.3.2 Automotive

- 6.3.2.1 By Type

- 6.3.2.1.1 Air Suspension

- 6.3.2.1.2 Fuel Injection & Emission Control

- 6.3.2.1.3 Safety & Security Systems

- 6.3.2.1.4 Transmission Systems

- 6.3.2.1.5 Others (Door Systems, HVAC, etc.)

- 6.3.2.2 By Application

- 6.3.2.2.1 Passenger

- 6.3.2.2.2 Commercial

- 6.3.2.2.3 Off-road

- 6.3.3 Chemical & Petrochemical

- 6.3.3.1 Direction-based control valves for storage units

- 6.3.3.2 Isolation-based valves

- 6.3.4 Power Generation

- 6.3.4.1 Steam control & Feeder units

- 6.3.4.2 Lifts & Pumping Systems

- 6.3.4.3 Deluge Systems

- 6.3.5 Oil and Gas

- 6.3.5.1 Drilling Systems

- 6.3.5.2 Extraction Systems

- 6.3.5.3 Downstream supply

- 6.3.6 Healthcare & Pharmaceutical (Medical Devices & Air Purification Systems)

- 6.3.7 Other end-user verticals (Agriculture, Aerospace, Textile, etc.)

- 6.4 Geography

- 6.4.1 North America

- 6.4.1.1 United States

- 6.4.1.2 Canada

- 6.4.2 Europe

- 6.4.2.1 Germany

- 6.4.2.2 United Kingdom

- 6.4.2.3 Italy

- 6.4.2.4 France

- 6.4.3 Asia

- 6.4.3.1 China

- 6.4.3.2 Japan

- 6.4.3.3 India

- 6.4.4 Australia and New Zealand

- 6.4.5 Rest of the World

- 6.4.5.1 Mexico

- 6.4.5.2 Brazil

- 6.4.5.3 Africa

- 6.4.5.4 Others (Turkey, etc.)

- 6.4.1 North America

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 IMI Precision Engineerng

- 7.1.2 Danfoss Industries Ltd

- 7.1.3 Curtiss Wright Corporation

- 7.1.4 Emerson Electric Co.

- 7.1.5 Parker Hannifin Corporation

- 7.1.6 AirTAC International Group

- 7.1.7 KANKEO SANGYO Co. Ltd

- 7.1.8 Anshan Solenoid Valve Co. Ltd

- 7.1.9 CEME SpA

- 7.1.10 The Lee Company

- 7.1.11 Kendrion NV

- 7.1.12 Peter Paul Electronics Co., Inc.