|

市场调查报告书

商品编码

1405682

模塑纤维包装:市场占有率分析、行业趋势/统计、成长预测,2024-2029 年Molded Fiber Packaging - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts 2024 - 2029 |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

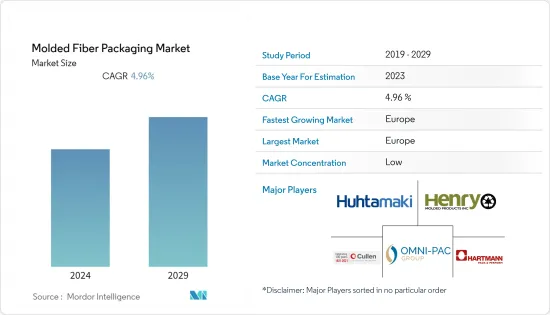

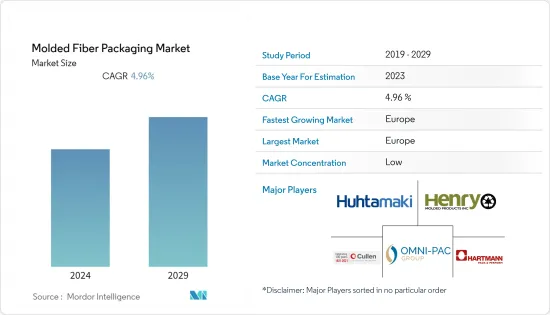

模塑纤维包装上年度的价值为133.1亿美元,预计未来五年将达到179.6亿美元,预测期内复合年增长率为4.96%。

对由可再生和可回收材料製成的永续包装的需求不断增长,导致人们对模塑纤维包装市场的潜力持续感兴趣。最终用户行业需求不断增长以及环保防护包装解决方案的应用等因素正在对市场进行排序。小麦和甘蔗渣等非木材废弃物常用于製造纸浆。

主要亮点

- 在花钱的地点和方式方面,现代消费者在购买时非常谨慎。在环境问题日益受到关注的时代,这种意识集中在包装的永续性。

- 纸浆包装由回收纸板和纸张等纤维材料或竹子、小麦和甘蔗等天然纤维製成,具有高度可回收性,在完成其初始功能后最多可再使用七次。此外,与常见的塑胶包装不同,模塑纸浆是生物分解性的,从而减少了用于製造包装物品的原材料数量。

- 儘管疫情在短期内给模塑纤维包装市场带来了挑战,但长期前景是积极的,因为它凸显了对卫生、永续性和必需产品的需求增加。製造商正在适应不断变化的市场条件并管理供应链中断,以满足对纸浆模塑包装解决方案不断增长的需求。

- 然而,自 COVID-19 以来,消费者行为发生了显着变化。买家比以往任何时候都更加关注产品的卫生、安全和永续性。在这场危机中,不断变化的消费者需求和以消费者为中心的方法可能仍然至关重要。随着市场更加适应当前情况,消费行为在预测期内肯定会改变。因此,后疫情时代模塑纤维包装的未来可能对需求面有利。

模塑纤维包装市场趋势

食品和饮料成为最大的终端用户产业

- 模塑纤维产品越来越多地用于食品相关领域,以取代塑料,满足对环保和永续产品不断增长的需求。食品市场应用有必须满足的严格标准。除了拉伸强度和耐热性等基本强度规格外,改善阻隔性能对于食品市场使用的材料也至关重要。

- 由模塑纸浆製成的食品包装产品包括翻盖和外带餐盒、蛋托盘和纸盒,以及水果、蔬菜、浆果和蘑菇托盘。市面上大多数食品包装都采用托盘。

- 此外,为了延缓食品中的化学、物理和微生物变化,包装必须具有阻隔性能,以减少食品与环境之间的气体和水蒸气的交换。因此,对水蒸气和氧气的渗透性已成为用于包装食品相关产品的材料中需要考虑的重要特性。

- 规模相对较大的电商、酒类等饮料产业预计防护包装产业的销售成长最为强劲。客製化模具的成本正在下降,模塑纤维的环境和性能优势也越来越被认可。

- 软性饮料製造商正在努力减少包装材料产生的污染和废弃物量。儘管人们对塑胶越来越持负面态度,但它仍然是世界各地软性饮料包装最常用的材料。然而,模塑纤维包装市场的许多公司正在扩大其足迹并推动该市场的研究领域。

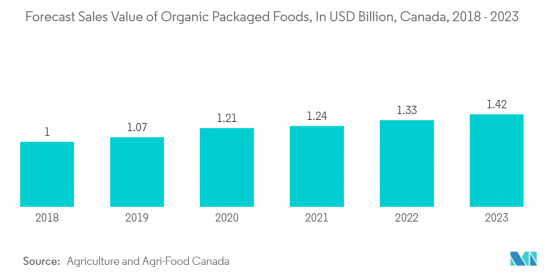

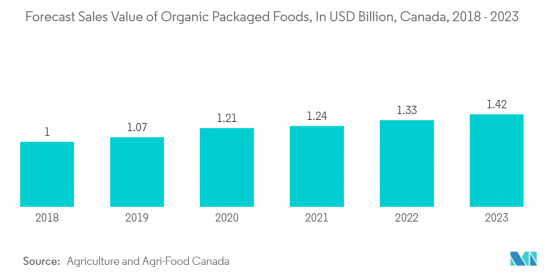

- 此外,根据加拿大农业和农业食品部的数据,2018 年包装食品销售额为 10 亿美元,预计 2023 年将达到 14.2 亿美元。食品业的成长预计将进一步推动模塑纤维包装市场。

预计欧洲将主导市场

- 西欧已成为模塑纤维包装最重要的市场之一,英国等已开发国家拥有大量城市人口和较高的可支配收入。根据英国包装联合会统计,英国包装製造业务年营业额为110亿英镑(139.9亿美元)。它拥有超过 85,000 名员工,占英国製造业的 3%。它也为英国经济做出了重大贡献,是包装供应链中的关键环节。

- 德国包装业以其在食品业的广泛应用而闻名。消费者正在寻找能够提供便利、保护和易于运输的产品,这推动了对各种包装中塑胶替代品的需求,特别是乳製品、肉类和家常小菜食品食品。此外,对一次性塑胶的严格限制和对永续包装的高需求正在推动市场扩张。

- 在义大利,对碗、托盘和其他产品的环保保护性包装的需求不断增长,预计将推动市场成长。模塑纤维包装是一种由植物纤维製成的 100% 可回收且环保的包装解决方案。模塑纤维包装生产所使用的原料是纸浆、天然纤维和水。模塑溶解浆产品主要用作食品产业的包装解决方案,推动了当前市场的发展。

- 西班牙的都市化、旅游业和电子商务市场扩张预计将为模塑纤维包装产业创造需求。西班牙等新兴欧洲经济体不断壮大的中阶正在创造需求并推动对防护性包装解决方案(例如坚固的模塑纤维包装)的市场发展。

- 东欧国家的外食正在蓬勃发展,预计东欧市场在预测期内将以最快的速度成长。东欧国家对用于鸡蛋、肉类和水果包装的模塑纸浆材料的需求可能会促进市场成长。

模塑纤维包装产业概述

模塑纤维包装市场高度分散,主要参与者包括 Huhtamaki OYJ、Henry Molded Products Inc.、Omni-Pac Group UK、Cullen Packaging Ltd. 和 Brodrene Hartmann A/S。市场参与者正在采取合作伙伴关係和收购等策略来增强其产品供应并获得永续的竞争优势。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第一章简介

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章市场洞察

- 市场概况

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 买方议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争公司之间敌对关係的强度

- 产业价值链分析

- COVID-19 市场影响评估

- 模塑纤维进出口分析

第五章市场动态

- 市场驱动因素

- 改变消费者对可回收和环保材料的偏好

- 可支配所得增加

- 最终用户对可重复使用和永续包装的需求不断增长

- 市场挑战

- 严格的政府法规

- 原料成本波动

第六章市场区隔

- 按类型

- 厚壁

- 转移

- 热成型

- 加工

- 按格式

- 湿的

- 干燥

- 按最终用户产业

- 食品与饮品

- 电子产品

- 卫生保健

- 其他的

- 按地区

- 北美洲

- 美国

- 加拿大

- 欧洲

- 英国

- 法国

- 德国

- 义大利

- 西班牙

- 其他欧洲国家

- 亚太地区

- 中国

- 日本

- 印度

- 其他亚太地区

- 拉丁美洲

- 巴西

- 墨西哥

- 其他拉丁美洲

- 中东/非洲

- 阿拉伯聯合大公国

- 沙乌地阿拉伯

- 南非

- 其他中东/非洲

- 北美洲

第七章竞争形势

- 公司简介

- Huhtamaki OYJ

- Henry Moulded Products Inc.

- Omni-Pac Group UK

- Cullen Packaging Ltd.

- Brodrene Hartmann A/S

- EnviroPAK Corporation

- Heracles Packaging Company SA

- Sabert Corporation

- Keiding Inc.

- Berkley International

第八章投资分析

第9章 市场的未来

Molded Fiber Packaging was valued at USD 13.31 billion in the previous year and is expected to reach USD 17.96 billion by the next five years, registering a CAGR of 4.96% during the forecast period.

The growing need for sustainable packaging made from renewable and recyclable materials is leading to continued interest in the potential of molded fiber packaging market. Factors such as expanding demand in end-user industries and applying envir onment-friendly protective packaging solutions are sorting the market. Waste non-wood products like wheat and bagasse are used more frequently to make pulp.

Key Highlights

- Consumers are now more aware of the long-term effects of their purchasing decisions than they were a decade ago. In terms of where and how to spend their money, modern consumers give their purchases careful consideration. This awareness is mostly focused on package sustainability in the modern period as environmental concerns increase. Over 83% of younger consumers (aged 44 and under) have indicated a willingness to spend more for items that employ sustainable packaging, according to Trivium Packaging's Global Buying Green recent report.

- PulPac developed and owned Dry Molded Fiber, a fiber-forming technology that can affordably and sustainably replace single-use plastic with fiber-based alternatives. Converters who set up their production can use this unique technique. PulPac created the PulPac Modula standardized machine platform with partners to hasten the transition. This platform is now accessible to licensees and is available at the PulPac Tech Centre for sample and bridge volume production. To align with global sustainability, quality, and productivity Scandicore, a key manufacturer of sustainability packaging, introduced the first paper tube lids ever produced using PulPac's ground-breaking dry molded fiber technology in February 2022. This spring, the first art print supplies with the revised cover will reach customers. PulPac will produce the bridge volumes.

- Also, molded pulp packaging has been a popular option for organizations wanting to reduce their environmental impact as the packaging sector has come under greater scrutiny in recent years. Pulp-based packaging, made from fibrous materials like recycled cardboard and paper or natural fibers like bamboo, wheat, or sugarcane, is highly recyclable and can be used up to seven more times after serving its initial function. Additionally, molded pulp is biodegradable, as opposed to typical plastic-based packaging, allowing for a reduction in the number of raw materials used to make packaging items.

- However, fluctuations in the cost of raw materials might hinder market growth. However, total fiber availability is a concern in the paper industry. Imports have climbed to three million tons, and numerous nations' governments have adopted import laws and restrictions and increased tariffs and excise levies. Due to a container shortage in December, international liners raised their prices.

- The pandemic presented challenges for the molded pulp packaging market in the short term, but its long-term prospects were positive as it emphasized on hygiene, sustainability, along with the growing demand for essential products. Manufacturers are adjusting to the changing market conditions and working to address supply chain disruptions to meet the rising demand for molded pulp packaging solutions.

- However, post-COVID-19, consumer behavior has changed substantially. Buyers are more concerned than ever before about products' hygiene, disability, and sustainability. The shoppers' evolving needs and a consumer-focused approach will remain crucial as this crisis continues. As the market adapts more to the current scenario, consumer behavior will undoubtedly change in the forecast period. Thus, the post-COVID future for molded fiber packaging looks favorable in terms of demand.

Molded Fiber Packaging Market Trends

Food and Beverages to be the Largest End-user Industry

- Molded fiber products are increasingly used in the food-related sector to replace plastics and meet the growing demand for eco-friendly and sustainable products. Applications for the food market are subject to strict standards and must comply with them. In addition to some basic strength specifications, such as tensile and thermal qualities, improved barrier properties are crucial for materials in the food market sector.

- The food packaging products made of molded pulp include clam-shell and takeout meal containers, egg trays and cartons, and fruit, vegetable, berry, and mushroom trays. The majority of the food packaging items on the market utilize trays.

- Further, the packaging must have barrier qualities that reduce the exchanges of gases and water vapor between the food and the environment to slow down food's chemical, physical, and microbiological changes. As a result, for materials intended for food-related product packaging, the permeability to water vapor and oxygen are crucial properties to consider.

- The relatively big e-commerce, wine, and other beverages segments are expected to see the most significant sales increases in the protective packaging industry. Prices for custom tooling are reducing, and people are becoming more conscious of molded fiber's environmental and performance benefits.

- Soft drink companies are still trying to decrease the amount of pollution and waste produced by their packaging materials. Even though people are becoming more negative towards plastic, it is still the most used material for soft drink packaging worldwide. However, many companies in the molded fiber packaging market are expanding their footprints, boosting the studied segment of the market.

- Further, according to Agriculture and Agri-Food Canada, the sales value of packaged foods in 2018 was valued at USD 1 billion and is expected to reach USD 1.42 billion In 2023. Such growth in the food industry would further drive the market for molded fiber packaging.

Europe is Expected to Dominate the Market

- Western Europe has emerged as one of the most important markets for mold fiber packaging, with industrialized countries such as the United Kingdom having a larger urban population and higher disposable income. The package manufacturing business in the United Kingdom generates GBP 11 billion (USD 13.99 billion) in yearly sales, according to the Packaging Federation of the United Kingdom. It employs over 85,000 people, accounting for 3% of the manufacturing workforce in the United Kingdom. It also substantially contributes to the UK economy and is an important link in the packaging supply chain.

- Germany's packaging business is known for its extensive use in the food industry. Consumers seek products that provide convenience, protection, and ease of transportation, which drives demand for various packaging, particularly plastic replacements in food products, particularly dairy food, meat, and prepared meals. Furthermore, strict limits on single-use plastics and high demand for sustainable packaging drive market expansion.

- In Italy, the growing demand for eco-friendly protective packaging in bowls, trays, and other products is anticipated to boost market growth. Molded fiber packaging is a 100% recyclable, environmentally friendly packaging solution made from plant fibers. The raw materials used to manufacture molded fiber packages are pulp, natural fibers, and water. Molded dissolving pulp products are used mainly as packaging solutions in the food industry, which is driving the market currently.

- Spain's growing urbanization, tourism, and e-commerce market are expected to generate demand for the molded fiber packaging industry. The expanding middle class in the emerging economies of Europe, like Spain, is creating demand for protective packaging solutions, such as heavy-duty molded pulp packaging, subsequently driving the market.

- With the rapidly increasing food service business in Eastern European countries, the Eastern European market is expected to grow at the quickest rate over the projection period. Eastern European countries' demand for molded pulp materials for egg, meat, and fruit packaging will likely contribute to market growth.

Molded Fiber Packaging Industry Overview

The molded fiber packaging market is highly fragmented, with the presence of major players like Huhtamaki OYJ, Henry Moulded Products Inc., Omni-Pac Group UK, Cullen Packaging Ltd., and Brodrene Hartmann A/S. Players in the market are adopting strategies such as partnerships and acquisitions to enhance their product offerings and gain sustainable competitive advantage.

In May 2023, Omni-Pac Group UK, a manufacturer of molded fiber packaging solutions, announced the opening of a new site of EUR 8 Million (USD 8.5 Million) and 60,000 square feet, located in the town of Scunthorpe, which will enable the company to increase its production capacity and create more than 100 new employment opportunities over a period of five years.

In December 2022, Cullen announced a customer acquisition. It will soon be supplying a wide range of its SRPs to CakeDecor, the UK's largest manufacturer and supplier of cake decorations. Cullen also manufactures a wide range of products for factory bakeries, fine food manufacturers, handicraft workshops, and leading UK supermarkets, building a reputation for quality.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitute Products

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Industry Value Chain Analysis

- 4.4 Assessment of the COVID-19 Impact on the Market

- 4.5 Import Export Analysis of Molded Fiber For Listed Countries

- 4.5.1 United States - Import and Export Analysis

- 4.5.2 United Kingdom - Import And Export Analysis

- 4.5.3 France - Import and Export Analysis

- 4.5.4 Germany - Import and Export Analysis

- 4.5.5 Italy - Import and Export Analysis

- 4.5.6 Sapin - Import and Export Analysis

- 4.5.7 China - Import and Export Analysis

- 4.5.8 Japan - Import and Export Analysis

- 4.5.9 India - Import and Export Analysis

- 4.5.10 Brazil - Import and Export Analysis

- 4.5.11 Mexico - Import and Export Analysis

- 4.5.12 United Arab Emirates - Import and Export Analysis

- 4.5.13 Saudi Arabia - Import and Export Analysis

- 4.5.14 South Africa - Import and Export Analysis

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Shift in Consumer Preferences Toward Recyclable and Eco-friendly Materials

- 5.1.2 Growing Disposable Income

- 5.1.3 Augmented Demand for Reusable and Sustainable Packaging From End Users

- 5.2 Market Challenges

- 5.2.1 Strict Government Rules and Regulations

- 5.2.2 Fluctuations in the Cost of Raw Materials

6 MARKET SEGMENTATION

- 6.1 By Type

- 6.1.1 Thick wall

- 6.1.2 Transfer

- 6.1.3 Thermoformed

- 6.1.4 Processed

- 6.2 By Formal Type

- 6.2.1 Wet

- 6.2.2 Dry

- 6.3 By End-user Industry

- 6.3.1 Food and Beverages

- 6.3.2 Electronics

- 6.3.3 Healthcare

- 6.3.4 Other End-user Industry

- 6.4 By Geography

- 6.4.1 North America

- 6.4.1.1 United States

- 6.4.1.2 Canada

- 6.4.2 Europe

- 6.4.2.1 United Kingdom

- 6.4.2.2 France

- 6.4.2.3 Germany

- 6.4.2.4 Italy

- 6.4.2.5 Spain

- 6.4.2.6 Rest of Europe

- 6.4.3 Asia Pacific

- 6.4.3.1 China

- 6.4.3.2 Japan

- 6.4.3.3 India

- 6.4.3.4 Rest of Asia Pacific

- 6.4.4 Latin America

- 6.4.4.1 Brazil

- 6.4.4.2 Mexico

- 6.4.4.3 Rest of Latin America

- 6.4.5 Middle East and Africa

- 6.4.5.1 United Arab Emirates

- 6.4.5.2 Saudi Arabia

- 6.4.5.3 South Africa

- 6.4.5.4 Rest of Middle East and Africa

- 6.4.1 North America

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Huhtamaki OYJ

- 7.1.2 Henry Moulded Products Inc.

- 7.1.3 Omni-Pac Group UK

- 7.1.4 Cullen Packaging Ltd.

- 7.1.5 Brodrene Hartmann A/S

- 7.1.6 EnviroPAK Corporation

- 7.1.7 Heracles Packaging Company SA

- 7.1.8 Sabert Corporation

- 7.1.9 Keiding Inc.

- 7.1.10 Berkley International