|

市场调查报告书

商品编码

1407050

工业紧固件:市场占有率分析、产业趋势与统计、2024年至2029年成长预测Industrial Fasteners - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts 2024 - 2029 |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

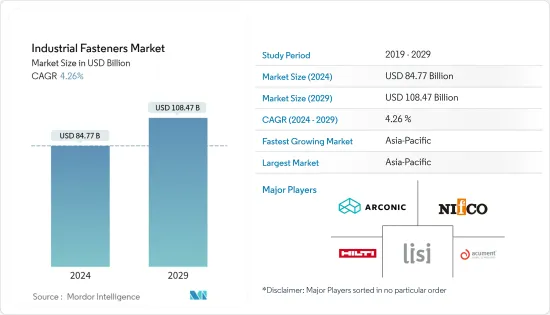

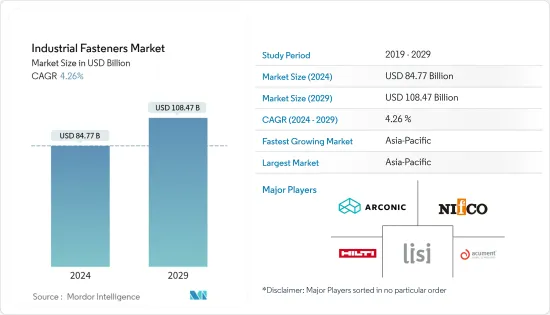

工业紧固件市场规模预计到2024年为847.7亿美元,预计到2029年将达到1084.7亿美元,在预测期内(2024-2029年)复合年增长率为4.26%,预计会增长。

该市场主要是由建筑、汽车和航太等各个行业不断增长的需求所推动的。

主要亮点

- 工业紧固件是由金属、塑胶、合金和其他材料製成的各种部件。它用于各种地方永久或半永久地连接或紧固两个或多个物体。其中许多是机械的,例如螺母、螺栓、螺柱、铰链、手柄、铆钉、旋钮、法兰和螺丝。对于工业应用,紧固件通常具有深螺纹。它们通常有型态,例如压紧端盖内六角螺丝、棒状螺纹、滚压端盖和未车削的 T 形螺母。

- 随着安全法规的显着增加和先进技术的普及,全球工业部门的成长是推动所研究市场发展的关键因素之一。汽车、製造、航太以及食品和饮料行业在过去几十年中出现了显着增长。例如,根据 OICA 的数据,2022 年全球汽车产量约为 8,500 万辆。

- 紧固件广泛应用于建设产业,以非永久性方式将两个或多个物体连接在一起,以防止分离、防止接头洩漏和传递负载。近年来,建筑业强劲成长,特别是在印度、中国和巴西等开发中国家中市场,预计将继续为所研究的市场带来成长机会。例如,根据巴西Odebrecht称,巴西基础建设产业的GDP预计将从2021年的813亿美元增加到2025年的992亿美元。

- 此外,航空工业技术的快速进步正在导致更新、更耐用的航太紧固件的生产。此硬体有助于有效容纳民航机、军用飞机、喷射机、弹道飞弹和太空火箭的零件。

- 然而,越来越多地用黏合和胶带取代金属紧固件(主要用于汽车行业的黏剂和 NVH 应用),预计将限制市场成长。

- 此外,工业紧固件,特别是金属紧固件容易生锈和腐蚀,而塑胶紧固件容易受热,也仍然是影响预测期内市场成长的主要挑战。

工业紧固件市场趋势

主导市场的金属

- 金属紧固件由多种材料製成,包括钢、不銹钢、黄铜、铝、青铜、镍、铜、钛和其他非铁金属。最终用户的材料选择主要取决于诸如所需强度、腐蚀环境的存在、应力、重量、电和磁性能、电气、所需的电镀/涂层、预期寿命和再生性等考虑因素。

- 金属紧固件可以采用多种製造方法製造,包括数控加工和冷镦。根据 Boulons Plus & Precision Bolts 的说法,超过 90% 的紧固件都是由钢製成的,因为与其他材料相比,钢具有固有的强度特性、可加工性以及相对较低的成本。此外,製造紧固件主要使用三种钢:合金钢、低碳钢和中碳钢。

- 工业紧固件中常用的不銹钢包括200、300和400系列,其中400系列是优选的,因为它提供高耐腐蚀,同时提高了强度、耐磨性和氧化性能,因此被主要使用。这些钢的分类是根据美国钢铁协会 (AISI) 的适用性进行的。

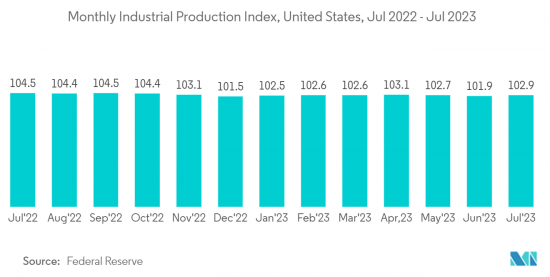

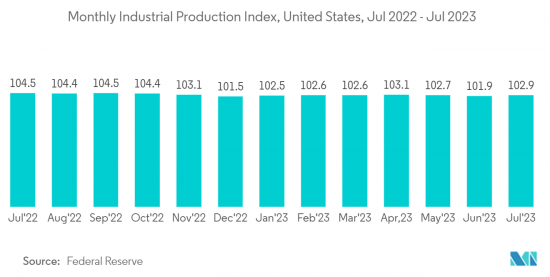

- 製造业、建设业和汽车工业等各行业的活动不断增加,推动了对工业金属紧固件的需求。例如,根据联准会的数据,2023 年 7 月美国製造业生产指数达到 102.9。

- 对金属紧固件的需求不断增加将鼓励供应商进一步扩大业务。例如,2023 年 7 月,Commercial Metals Company 从 MiddleGround Capital 收购了 EDSCO Fasteners LLC。 EDSCO Fasteners 是输电市场锚固解决方案的领先供应商之一,其产品包括混凝土电线杆、紧固件和包含螺栓设计系列。

亚太市场成长显着

- 从事汽车、机械和零件製造的跨国和国内公司对其产品的需求正在增加。此外,由于印度和中国主要製造地的製造业务迅速扩张,预计该市场将进一步成长。

- 由于存在多家中小企业,中国是该地区最大的工业紧固件生产国和出口国之一。行业公司正在投资塑胶和特殊紧固件的研究、开发和生产,以满足最终用户的应用需求并在竞争激烈的市场中保持成长。

- 在印度,工业紧固件的需求受到汽车产业强劲成长的推动。儘管面临疫情的挑战,印度汽车产业一直在稳步復苏,并受益于政府增加的投资和支持该产业的倡议。

- 此外,製造业已成为印度高成长产业之一。印度总理启动「印度製造」计划,使印度製造地。因此,未来几年工业紧固件的需求可能会增加。例如,为了支持汽车和其他製造业的本地化并减少进口依赖,印度政府实施了多项 PLI(生产挂钩奖励)计划。

- 日本也是亚太地区工业紧固件的重要市场。据日本紧固件协会称,日本紧固件产业由约 3,000 家製造商组成,每年生产价值约 1 兆日圆(69 亿美元)的紧固件。多年来,该地区强劲的经济成长也增强了市场。

工业紧固件产业概况

工业紧固件市场分散,由有影响力的参与者组成。其中一些重要参与者目前在市场占有率方面控制着市场。这些拥有显着市场份额的重要参与者正致力于扩大其海外基本客群。这些公司利用策略集体行动来增加市场占有率和盈利。主要市场参与者包括 LISI Group、Nifco Inc.、Acument Global Technologies, Inc. 和 Hilti Corporation。

2023 年 7 月,Triangle Fastener Corporation (TFC) 宣布收购 Connective Systems &Supply, Inc. (CSS)。具体来说,该公司收购了 CSS 的一部分业务,主要专注于金属建筑、屋顶和机械承包的紧固件。

2022 年 4 月,北美领先的特殊紧固件经销商 Lindfast Solutions Group (LSG) 宣布完成对总部位于多伦多的 Fasteners & Fittings, Inc. (F&F) 的收购。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第一章简介

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章市场洞察

- 市场概况

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 消费者议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争公司之间敌对关係的强度

- 产业价值链分析

- COVID-19 爆发对产业的影响

第五章市场动态

- 市场驱动因素

- 建筑和汽车市场强劲復苏

- 技术进步迅速,研发成本增加

- 市场挑战

- 在某些应用中越来越多地使用胶带和黏剂来取代金属紧固件

第六章市场区隔

- 按原料分

- 金属

- 塑胶

- 副产品

- 外螺纹紧固件

- 内螺纹紧固件

- 非螺纹紧固件

- 航太级紧固件

- 按用途

- 用于汽车

- 航太

- 建筑/施工

- 工业机械

- 家用电器

- 水暖产品

- 其他用途

- 按地区

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- 中东/非洲

第七章 竞争形势

- 公司简介

- Acument Global Technologies, Inc.

- Arconic Corporation

- LISI Group

- Nifco Inc.

- Hilti Corporation

- Stanley Black & Decker, Inc.

- MacLean-Fogg Company

- MISUMI Group Inc.

- Precision Castparts Corp.

- SFS Group

- Illinois Tool Works Inc.

第八章投资分析

第九章 市场未来展望

The Industrial Fasteners Market size is estimated at USD 84.77 billion in 2024, and is expected to reach USD 108.47 billion by 2029, growing at a CAGR of 4.26% during the forecast period (2024-2029).

The market is majorly driven by the rising demand from different industries like construction, automotive, and aerospace.

Key Highlights

- Industrial fasteners are an extensive range of components made up of metal, plastic, alloy, and other materials. They are used in many places to join or hold together two or more objects permanently or semi-permanently. Many of these are mechanical, such as nuts, bolts, studs, hinges, handles, rivets, knobs, flanges, and screws. For industrial applications, fasteners usually have a deep thread. They typically come in varied forms, such as clinched end-cap socket head cap screws, rod threaded with bar, and rolled end-cap unturned tee nuts.

- The growth of the global industrial sector, wherein the penetration of safety regulations and advanced technologies are increasing significantly, is among the significant factors driving the development of the studied market. Industries such as automotive, manufacturing, aerospace, food, and beverage, among others, have been reporting notable growth in the last few decades. For instance, according to OICA, in 2022, about 85 million motor vehicles were produced globally.

- Fasteners are extensively used in the construction industry to join multiple objects together in a non-permanent way to avoid their separation, preventing leakage of joints and transmitting loads. In recent years, the construction sector, especially in developing regions such as India, China, and Brazil, has witnessed strong growth, which is anticipated to continue to drive opportunities in the studied market. For instance, according to Odebrecht, a Brazilian company, Brazil's infrastructure construction sector's GDP is anticipated to reach USD 99.2 billion by 2025, from USD 81.3 billion in 2021.

- Further, the rapid advancement in technology in the aviation industry has led to the production of newer and more durable aerospace fasteners. The hardware helps to effectively hold the parts of commercial airplanes, military aircraft, jets, ballistic missiles, etc., and space-bound rockets.

- However, an increase in the substitution of metal fasteners for adhesives and tapes in bonding and NVH applications, majorly in the automotive industry, is expected to restrict the market growth.

- Additionally, the susceptibility of industrial fasteners, especially made of metals, to rust and corrosion, while of plastic fasteners to heat also continues to remain among the major challenges that will impact the studied market's growth during the forecast period.

Industrial Fasteners Market Trends

Metal Segment to Dominate the Market

- Metal fasteners are manufactured from various materials, such as steel, stainless steel, brass, aluminum, bronze, nickel, copper, titanium, and other non-ferrous metals. The selection of material by the end users is primarily based on considerations such as strength required, presence of corrosive environment, stresses, weight, electrical and magnetic properties, electrical, plating/coating required, expected life, and reusability.

- Metal fasteners can be manufactured using different fabrication methods, including CNC machining and cold heading. According to Boulons Plus & Precision Bolts, because of its inherent strength properties, workability, and relative cheapness compared to other materials, over 90% of fasteners are made from steel. Additionally, three types of steel are primarily used to manufacture fasteners: alloy steel and low and medium-carbon steel.

- Common stainless steels used for industrial fasteners include the 200, 300, and 400 series, out of which the 400 series is predominantly used as they offer high corrosion resistance with strength, wear resistance, and increased oxidation properties. These steel classifications are done based on their applicability by the American Iron & Steel Institute (AISI).

- The increasing activities across various sectors, such as manufacturing, construction, and automotive, drive the demand for metal industrial fasteners. For instance, according to the Federal Reserve, the manufacturing production index reached 102.9 in the United States in July 2023.

- The growing demand for metal fasteners encourages vendors to expand their presence further. For instance, in July 2023, Commercial Metals Company acquired EDSCO Fasteners LLC from MiddleGround Capital. EDSCO Fasteners is among the leading providers of anchoring solutions for the electrical transmission market, and its offerings include an engineered line of anchor cages, fasteners, and bolts that are primarily manufactured from rebar and used widely to secure high-voltage electrical transmission poles to concrete foundations.

The Asia-Pacific Market to Grow Significantly

- Several multinational and domestic players engaged in automotive, machinery, and Component Manufacturing Operations have increased the product demand across the Asia-Pacific. In addition, the key manufacturing hubs across India and China are further expected to foster market growth due to the rapid expansion of manufacturing operations in these countries.

- China is one of the largest producers and exporters of industrial fasteners in the region, owing to the presence of several small and medium-scale players. Industry players are investing in R&D and production of plastic and specialty fasteners to cater to application-specific demand by end-users and sustainably in the highly competitive market.

- In India, the demand for industrial fasteners is led by the strong growth in the automotive sector. Despite the challenges of the pandemic, the Indian automotive industry is recovering steadily, also benefiting from the increasing government investments and initiatives to support this sector.

- In addition, Manufacturing has emerged as one of the high-growth sectors in India. The Prime Minister of India launched the 'Make in India' program to make India a global manufacturing hub. Thus, the demand for industrial fasteners will likely rise in the coming years. For instance, to support localization and reduce import dependency on the auto and other manufacturing sectors, the Indian government has been running several PLI (production-linked incentive) schemes.

- Japan is also a significant market for industrial fasteners in the Asia Pacific. According to the Fasteners Institute of Japan, The Japanese fastener industry comprises approximately 3,000 manufacturers that produce around JPY 1 trillion (USD 6.9 billion) of fasteners annually. Over the years, the solid economic growth in the region has also strengthened the market.

Industrial Fasteners Industry Overview

The industrial fasteners market is fragmented and consists of some influential players. Some of these important actors currently manage the market in terms of market share. These significant players with a noticeable share in the market concentrate on expanding their customer base across foreign countries. These businesses leverage strategic collaborative actions to improve their market percentage and profitability. Some key market players include LISI Group, Nifco Inc., Acument Global Technologies, Inc., Hilti Corporation, etc.

In July 2023, Triangle Fastener Corporation (TFC) announced the acquisition of Connective Systems & Supply, Inc. (CSS). In particular, the company acquired the segment of CSS's business primarily focused on fasteners for metal building, roofing, and mechanical contractors.

In April 2022, LindFast Solutions Group (LSG), a major distributor of specialty fasteners in North America, announced the completion of its purchase of Toronto-based Fasteners and Fittings, Inc. (F&F), which has a leading position in imperial, metric, and stainless steel fasteners market.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness-Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Consumers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Industry Value Chain Analysis

- 4.4 Impact of COVID-19 Outbreak on the Industry

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Strong Revival in the Construction and Automotive Markets

- 5.1.2 Rapid Technological Advancement and Increased Spending in R&D

- 5.2 Market Challenges

- 5.2.1 Increase in the Substitution of Metal Fasteners by Tapes and Adhesives in Some Applications

6 MARKET SEGMENTATION

- 6.1 By Raw Materials

- 6.1.1 Metal

- 6.1.2 Plastic

- 6.2 By Products

- 6.2.1 Externally threaded fasteners

- 6.2.2 Internally threaded fasteners

- 6.2.3 Non-threaded fasteners

- 6.2.4 Aerospace grade fasteners

- 6.3 By Application

- 6.3.1 Automotive

- 6.3.2 Aerospace

- 6.3.3 Building and Construction

- 6.3.4 Industrial Machinery

- 6.3.5 Home Appliances

- 6.3.6 Plumbing Products

- 6.3.7 Other Applications

- 6.4 By Geography

- 6.4.1 North America

- 6.4.2 Europe

- 6.4.3 Asia-Pacific

- 6.4.4 Latin America

- 6.4.5 Middle-East and Africa

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Acument Global Technologies, Inc.

- 7.1.2 Arconic Corporation

- 7.1.3 LISI Group

- 7.1.4 Nifco Inc.

- 7.1.5 Hilti Corporation

- 7.1.6 Stanley Black & Decker, Inc.

- 7.1.7 MacLean-Fogg Company

- 7.1.8 MISUMI Group Inc.

- 7.1.9 Precision Castparts Corp.

- 7.1.10 SFS Group

- 7.1.11 Illinois Tool Works Inc.