|

市场调查报告书

商品编码

1637780

工业物联网 (IIoT):市场占有率分析、行业趋势和统计、成长预测(2025-2030 年)Industrial Internet Of Things (IIoT) - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

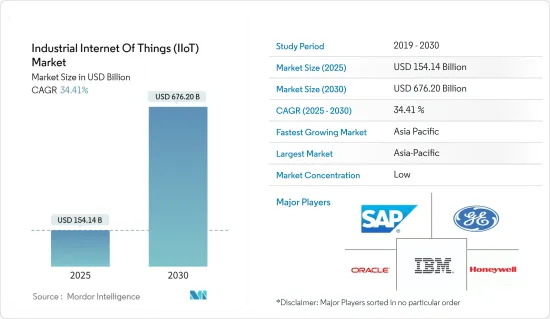

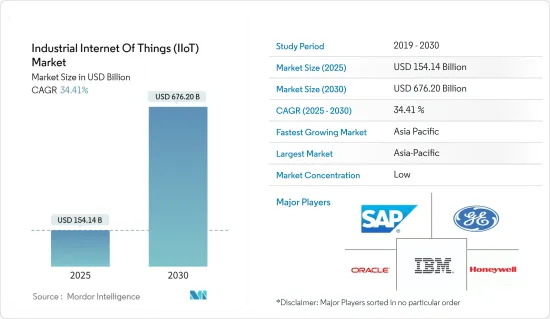

工业物联网市场规模在 2025 年预计为 1,541.4 亿美元,预计到 2030 年将达到 6,762 亿美元,预测期内(2025-2030 年)的复合年增长率为 34.41%。

主要亮点

- 巨量资料和机器学习 (ML) 等技术越来越多地被用于利用连网装置产生的资料来改善机器对机器 (M2M)通讯并简化工作流程。此外,物联网製造中的製造成本和感测器成本的下降也进一步推动了需求。

- 由于提高电源效率可带来利润率增加等显着优势,各公司正积极投资该市场。根据微软的研究,物联网对于製造业变得越来越重要。业界 87% 的物联网决策者已经采用了物联网,大多数人表示物联网对其组织的成功至关重要,并且对这项技术感到满意。

- 此外,由于其下一代功能,工业IoT中边缘运算的利用率和需求正在迅速增加。例如,义大利高科技公司SECO今年宣布与高通技术国际有限公司建立策略伙伴关係。此次伙伴关係旨在推出与工业物联网(IIoT)一致的创新边缘运算产品和解决方案。根据协议,SECO 将被任命为 Qualcomm Technologies IIoT 设计中心合作伙伴,并负责为主要针对OEM客户的即用型硬体解决方案创建特定的参考设计。

- Google、亚马逊网路服务和微软等市场现有企业正在寻求加强与边缘运算公司的合作,为工业用户提供一站式解决方案。此外,随着全球安装的工业机器人数量的增加,对低延迟和低抖动通讯的需求预计将大幅增加,从而极大地推动对 IIoT 解决方案的需求。

- AWS IoT TwinMeker 引入了三种新的实体建模功能,以简化真实系统数位双胞胎的建立、部署和扩充性:首先,现在支援元资料操作,包括汇入、汇出和更新。变得更容易来自外部来源或不同 AWS 帐户的装置模型和元资料。这简化了大型实体模型的建立。其次,增加了AWS IoT TwinMaker的服务配额,以支援具有更多实体和组件的数位双胞胎。第三,复合组件类型的引入为建构复杂组件提供了更大的灵活性和效率。

- 此外,元资料批次操作和复合组件现在可在 AWS IoT SiteWise 中访问,从而可在 AWS IoT TwinMaker 普遍可用的所有地区实现行业采用(元资料批量操作除外,因为AWS GovCloud 中无法存取)。建模体验我们的客户。预计此类发展将影响未来和正在进行的 IIoT计划,这些项目在可预见的未来可能会被视为不必要的,并可能被推迟或取消。

工业物联网 (IIoT) 市场趋势

製造业占很大市场占有率

在各个行业中,製造业在投资额和市场占有率方面占据主导地位,离散製造业和流程製造业都在积极投资物联网应用。此外,人们也越来越重视物联网在工业中的整合,尤其是随着工业 4.0 的出现。物联网提供了优化营运、减少停机时间、提高效率、促进资料主导决策的手段,最终有助于提高利润率,同时降低收益。物联网采用的投资报酬率)。

例如,Ubisense 的一项研究追踪了物体的精确位置、运动和交互,研究结果清晰地展现了 2023 年製造业的状况,其中 62% 的製造商组装物联网技术。纳入采用率的大幅成长凸显了人们越来越认识到物联网在简化业务和提高生产力方面具有巨大潜力。

未来几年,公共产业、离散製造、流程製造和生命科学领域将对物联网解决方案进行最多投资。许多使用案例预计将透过基于条件的设备追踪和维护继续增强资产追踪、资产寿命和物理距离执行能力。

随着决策者越来越倾向于采用物联网解决方案,预计该行业的采用率将高于其他行业。根据通用电气的一项调查,58%的製造商认为物联网对于其工业业务的数位转型是必不可少的。

Capgemini SA的研究也显示,各垂直产业对高潜力用例的平均采用率仅次于通讯,製造业专注于製造资产维护、製造智慧和产品品质优化,高达33%。

此外,未来几年工业机器人在製造业的应用预计将进一步增加。例如,根据 IFR 的预测,全球製造业对先进机器人的需求将会成长。由于这些发展,预计未来几年製造业的其他各个方面,包括内部物流、库存和仓库管理也将自动化。

根据微软的一项调查,87% 的製造业决策者支援采用,其中主要使用案例包括工业自动化、品质和合规性、生产计画和调度、供应链和物流以及工厂安全和保障。

亚太地区占有最大市场占有率

预计工业IoT将比消费者物联网占据更大的市场占有率。

随着中美关係变得紧张,中国正在转向日本的物联网专业知识,以减少对美国的依赖。因此,中国已邀请IVC成员代表参加多场中国物联网主题研讨会。中国也请求IVC协助建立一个国际组织,专注于研究和实施职场更好的IIoT技术。

此外,政府在该地区实施 IIoT使用案例发挥关键作用。 「数位印度」和「印度製造」等政府倡议正在抑制製造业的发展。 「印度製造」宣传活动从物联网中受益匪浅,为製造组织的永续提供了创新途径。

智慧先进製造和快速转型中心 (SAMARTH) Udyog Bharat 4.0倡议旨在提高印度製造业对製造业 4.0 的认识,并使相关人员能够应对与智慧製造相关的挑战。

工业物联网 (IIoT) 产业概览

在当前的工业 4.0 时代,全球大多数製造公司都在使用物联网,因此工业物联网 (IIoT) 市场呈现分散化。这导致了激烈的市场竞争,现在每家公司都能够使用物联网提供服务。市场的一些关键发展包括:

2023 年 4 月 - 西门子推出西门子 Xcelerator,这是一个全球开放的数位业务平台,旨在更快、更广泛地为加拿大客户释放数位化优势。该平台将加速工业、建筑、电网和行动等各领域的价值创造的数位转型。西门子 Xcelerator 不断扩大的市场促进了客户、合作伙伴和开发商之间的无缝互动和交易。我们透过精心挑选的支援物联网的硬体、软体和数位服务组合来简化数位转型,并以服务形式提供,符合互通性、灵活性和开放性的设计原则。该平台正在与包括加拿大设施和营运管理公司 Dexterra Group 在内的关键参数合作。

2023 年 7 月-Honeywell宣布收购 SCADAfence,该公司专门提供监控广泛的操作技术(OT) 物联网 (IoT) 网路的网路安全解决方案。 SCADAfence 以其在资产发现、威胁侦测和安全管治的专业知识而闻名,这些都是工业和建筑管理网路安全工作的重要组成部分。

此外,SCADAfence 产品线无缝配置为 Honeywell Connected Enterprise 内 Honeywell Forge Cybersecurity + 套件的一部分。这项策略倡议与Honeywell对数位化、永续性和 OT 网路安全 SaaS 解决方案的关注相一致。此次整合使Honeywell能够提供全面的企业 OT 网路安全解决方案,为需要对情境察觉进行更高安全控制的一线经理、营运经理和 CISO 提供服务。此外,此次收购将增强Honeywell的网路安全能力,并增强其快速扩张的OT网路安全产品组合,提高客户的营运安全性、可靠性和效率。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第 1 章 简介

- 研究假设和市场定义

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场动态

- 市场概况

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 买家的议价能力

- 新进入者的威胁

- 竞争对手之间的竞争

- 替代品的威胁

- 产业价值链分析

- COVID-19 对 IIoT 市场的影响

- 法律规范

- 市场驱动因素

- 数位化和工厂感测器的普及

- 对自动化和高效流程的需求不断增加

- 市场限制

- 与资料安全和隐私、设备连接和互通性相关的问题

第五章 市场区隔

- 按类型

- 硬体

- 软体

- 服务和连接

- 按最终用户产业

- 製造业

- 运输

- 石油和天然气

- 公共产业

- 其他最终用户产业

- 按地区

- 北美洲

- 欧洲

- 亚太地区

- 世界其他地区

第六章 竞争格局

- 公司简介

- Amazon Web Services Inc.

- Telefonaktiebolaget LM Ericsson

- Fujitsu Ltd

- Mitsubishi Electric Corporation

- SAP SE

- Siemens AG

- Honeywell International Inc.

- Emerson Electric Co.

- OMRON Corporation

- IBM Corporation

- Robert Bosch GmbH

- Oracle Corporation

- PTC Inc.

- Telit Communications Plc

- NXP Semiconductors NV

- Cisco Systems Inc.

- Cypress Semiconductor Corporation

- General Electric Company

第七章 供应商分类及主要供应商定位

第八章投资分析

第九章 市场机会与未来趋势

The Industrial Internet Of Things Market size is estimated at USD 154.14 billion in 2025, and is expected to reach USD 676.20 billion by 2030, at a CAGR of 34.41% during the forecast period (2025-2030).

Key Highlights

- Technologies, such as big data and machine learning (ML), are being used increasingly to harness the data generated from connected devices to improve machine-to-machine (M2M) communication and streamline workflow. Also, declining manufacturing and sensor costs in producing IoTs further drive the demand.

- Significant advantages, such as large-scale profit margins through improvements in power efficiency, attract companies to invest in the market aggressively. According to a study by Microsoft, IoT is increasingly becoming indispensable to the manufacturing industry. 87% of IoT decision-makers in the industry have adopted IoT, and the vast majority say IoT is critical to the success of their company and that they are satisfied with the technology.

- Furthermore, the utilization and demand for edge computing in Industrial IoT are rapidly increasing due to its next-generation capabilities. For instance, in the current year, SECO, an Italian high-tech company, has announced a strategic partnership with Qualcomm Technologies International, Ltd-the goal of introducing innovative edge computing products and solutions tailored for the industrial Internet of Things (IIoT). Under the agreement, SECO is appointed Qualcomm Technologies IIoT design center partner, responsible for creating specific reference designs for readily available hardware solutions, primarily targeting OEM customers.

- Market incumbents like Google, Amazon Web Services, and Microsoft aim to establish more collaborative partnerships with edge-computing companies to provide one-stop solutions to industrial users. Further, the growing number of industrial robot installations globally is expected to create considerable demand for low latency and jitter communications, significantly improving the need for IIoT solutions.

- AWS IoT TwinMeker introduces three new entity modeling features to streamline the creation, deployment, and scalability of digital twins for real-world systems: Firstly, customers can now perform metadata bulk operations, including import, export, and update, facilitating the seamless migration of equipment models and metadata for external sources or different AWS accounts. This simplifies the creation of entity models at scale. Secondly, AWS IoT TwinMaker service quotas have been increased to support digital twins with higher entity and component counts. Third, introducing composite component types enhances flexibility and efficiency in constructing complex components.

- Moreover, metadata bulk operations and composite components are accessible in AWS IoT SiteWise, ensuring a consistent modeling experience for industrial customers across all regions where AWS IoT TwinMaker is generally available, except for metadata bulk operations, which are inaccessible in AWS GovCloud. Such developments were expected to influence future and current ongoing IIoT projects as they might be deemed non-essential and either postponed or canceled for the foreseeable future.

Industrial Internet of Things (IIoT) Market Trends

Manufacturing to Hold Major Market Share

Amongst the industries, the manufacturing industry holds a significant share of investment and market share, with both discrete and process manufacturing intensely investing in IoT adoption. Furthermore, there is a strong emphasis on integrating IoT within the industry, especially with the emergence of Industry 4.0. IoT is making significant strides in discrete and process manufacturing by providing avenues for operational optimization, downtime reduction, enhanced efficiency, facilitating data-driven decision-making, and ultimately contributing to increasing profit margins while minimizing costs, thus ensuring a swift return on investment (ROI) in IoT adoption.

For instance, according to the survey of Ubisense, a precise location, movement, and interaction of things tracker, the survey provides a clear snapshot of the 2023 manufacturing landscape, indicating that 62% of manufacturers have incorporated IoT technologies into their manufacturing or assembly processes. This significant increase in adoption highlights are growing acknowledgement of IoT's substantial potential to streamline operations and boost productivity.

In the upcoming years, utilities, discrete manufacturing, process manufacturing, and life sciences sectors will spend the most on IoT solutions. Most use cases are anticipated to continue enhancing asset tracking, asset life, and the ability to enforce physical distance through condition-based equipment tracking and maintenance.

The adoption rates from the industry are expected to be higher than any other industry due to the increased propensity of decision-makers to adopt IoT solutions. According to a study by General Electric, 58% of manufacturers mentioned IoT is required to transform industrial operations digitally.

In addition, a study by Capgemini found that industrial manufacturing held the second-highest average implementation percentage of high potential use cases by industries after telecom, which stood at 33%, focusing on production asset maintenance, manufacturing intelligence, and product quality optimization.

In addition, the adoption of industrial robots in manufacturing industries is expected to increase further over the coming years. For instance, according to IFR, the global demand for advanced robots in manufacturing is expected to grow; owing to such developments, various other aspects of the manufacturing industry, such as in-house logistics, inventory, and warehouse management etc., are also expected to be automated over the coming years.

According to a study by Microsoft, 87% of the manufacturing industry's decision-makers favored adoption, with industrial automation, quality & compliance, production planning & scheduling, supply chain and logistics, and plant safety & security being the primary use cases.

Asia Pacific To Hold Maximum Market Share

Industrial IoT is expected to represent a larger market share than consumer IoT.

Due to the straining US-China relationship, China is turning to Japanese IoT expertise to reduce dependency on the US. Thus, China has invited IVC member representatives to several Chinese symposiums addressing the IoT topic. China has also asked the IVC to help form an international organization focusing on researching and implementing better IIoT technology in the workplace.

Furthermore, the government plays a significant role in implementing the use cases of IIot in the region. Government initiatives like Digital India and Make in India are impeding the manufacturing industry. The make in India campaign immensely benefited from IoT for providing innovative ways for the sustainable development of manufacturing organizations.

The Smart Advanced Manufacturing and Rapid Transformation Hub (SAMARTH) Udyog Bharat 4.0 initiative aims to enhance awareness about manufacturing 4.0 within the Indian manufacturing industry and help stakeholders address the challenges related to smart manufacturing.

Industrial Internet of Things (IIoT) Industry Overview

The industrial internet of things market is fragmented as the majority of manufacturing companies across the world are using IoT after the current evolution of industry 4.0. This makes the market highly competitive and allows companies to provide services in IoT. Some of the key developments in the market are:

April 2023 - Siemens has introduced its global open digital business platform Siemens Xcelerator, aiming to rapidly and broadly unlock digitalisation benefits for its Canadian customers. This platform expedites digital transformation in value generation across various sectors such as industry, buildings, grids, and mobility. Siemens Xcelerator's expanding marketplace facilitates seamless interactions and transactions among customers, partners, and developers. It simplifies digital transformation by providing a curated portfolio of IoT-enabled hardware, software, and digital services adhering to design principles like interoperability, flexibility, and openness as a service. The platform collaborates with critical parameters, including Dexterra Group, are Canadian facilities and operations management company.

July 2023 - Honeywell has announced its acquisition of SCADAfence, which specializes in cyber security solutions for monitoring extensive operational technology (OT) Internet of Things (IoT) networks. SCADAfence is known for its expertise in asset discovery, threat detection, and security governance, crucial elements for cyber security initiatives in industrial and building management.

Moreover, the SCADAfence product lineup is set to seamlessly become part of the Honeywell Forge Cybersecurity+ suite within Honeywell Connected Enterprise. This strategic move aligns with Honeywell's emphasis on digitalization, sustainability, and OT cyber security SaaS solutions. The integration empowers Honeywell to deliver a comprehensive enterprise OT cyber security solution, catering to site managers, operations management, and CISOs in their quest for enhanced security management in situational awareness. Furthermore, this acquisition reinforces Honeywell's cyber security prowess and enhances its rapidly expanding OT cyber security portfolio, improving operational security, reliability, and customer efficiency.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Threat of New Entrants

- 4.2.4 Intensity of Competitive Rivalry

- 4.2.5 Threat of Substitutes

- 4.3 Industry Value Chain Analysis

- 4.4 COVID-19 Impact on the IIoT market

- 4.5 Regulatory Framework

- 4.6 Market Drivers

- 4.6.1 Proliferation of digitization and adoption of sensors in plants

- 4.6.2 Growing demand for automated and efficient process

- 4.7 Market Restraints

- 4.7.1 Issues Related to Security and Privacy of Data and Connectivity of Devices and Interoperability

5 MARKET SEGMENTATION

- 5.1 Type

- 5.1.1 Hardware

- 5.1.2 Software

- 5.1.3 Services & Connectivity

- 5.2 End-user Vertical

- 5.2.1 Manufacturing

- 5.2.2 Transportation

- 5.2.3 Oil and Gas

- 5.2.4 Utility

- 5.2.5 Other End-user Verticals

- 5.3 Geography

- 5.3.1 North America

- 5.3.2 Europe

- 5.3.3 Asia Pacific

- 5.3.4 Rest of the World

6 COMPETITIVE LANDSCAPE

- 6.1 Company Profiles

- 6.1.1 Amazon Web Services Inc.

- 6.1.2 Telefonaktiebolaget LM Ericsson

- 6.1.3 Fujitsu Ltd

- 6.1.4 Mitsubishi Electric Corporation

- 6.1.5 SAP SE

- 6.1.6 Siemens AG

- 6.1.7 Honeywell International Inc.

- 6.1.8 Emerson Electric Co.

- 6.1.9 OMRON Corporation

- 6.1.10 IBM Corporation

- 6.1.11 Robert Bosch GmbH

- 6.1.12 Oracle Corporation

- 6.1.13 PTC Inc.

- 6.1.14 Telit Communications Plc

- 6.1.15 NXP Semiconductors NV

- 6.1.16 Cisco Systems Inc.

- 6.1.17 Cypress Semiconductor Corporation

- 6.1.18 General Electric Company