|

市场调查报告书

商品编码

1432547

工业控制系统:市场占有率分析、产业趋势与统计、成长预测(2024-2029)Industrial Control Systems - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

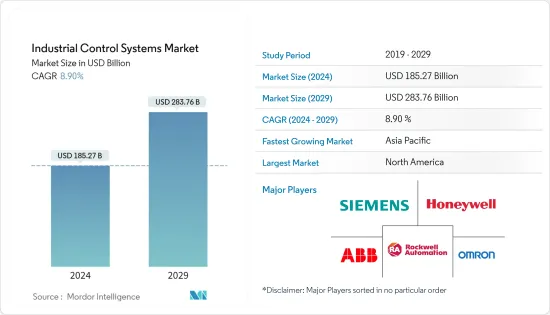

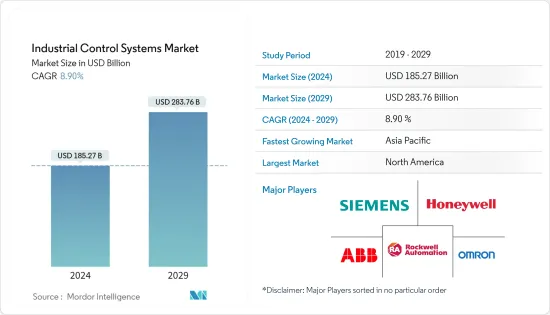

工业控制系统市场规模预计到2024年为1852.7亿美元,预计到2029年将达到2837.6亿美元,在预测期内(2024-2029年)增加89亿美元,复合年增长率为%。

不断上升的人事费用以及製造商按期完成任务的巨大压力导致工厂自动化程度的提高。工厂自动化正在加速 ICS 市场的发展。

主要亮点

- 2021 年 9 月,罗克韦尔自动化的 Studio 5000 模拟介面与 Ansys Twin Builder 联手,为自动化和流程工程师提供基于模拟的数位双胞胎。使用者可以在虚拟环境中建立和测试设计,从而节省昂贵的实体原型的时间和金钱。

- 此外,该系统的效率、可靠性和更快的工作速度最大限度地减少了与人为错误相关的品管问题。此外,製造业对大规模生产的需求增加了对工业控制的需求,以满足不断增长的人口的需求。

- 连接工业设备和机械并获取即时资料在提供可视化的 SCADA、HMI、PLC 系统和软体的实施中发挥关键作用。这使您能够减少产品故障、减少停机时间、安排维护,并从反应状态转变为预测和规格决策阶段。

- 此外,德国工业 4.0 和法国工业计划等政府措施可能会推动对 IIoT 解决方案的需求,进而推动对 ICS 安全解决方案和服务的需求。严重的网路灾难可能导致重大财务损失、品牌受损、消费者信任丧失、智慧财产权被盗、安全问题甚至死亡。因此,为了保护生态系统免受经济、营运或人员损失,ICS 可能需要安全机制来审核并确保合规性。

- 互联设备和感测器的高采用率以及 M2M通讯的可用性导致製造业中资料点的爆炸性增长。根据 Zebra 最新的 Manufacturing Vision 研究,基于物联网和 RFID 的智慧资产追踪解决方案预计到 2022 年将取代基于电子表格的传统方法。根据工业物联网 (IIoT) 公司微软公司的一项研究,85% 的公司至少拥有一个 IIoT使用案例计划。这一数字可能会增加,因为 94% 的受访者表示他们将在 2021 年之前实施 IIoT 策略。

- 由于大流行,组织必须遵守严格的要求,同时确保员工和客户的安全。结果,对自动化解决方案的需求突然激增。在可预见的未来,这可能被视为一个值得注意的趋势。随着世界继续对抗冠状病毒感染疾病(COVID-19)大流行的迅速蔓延,事实证明,机器人工厂自动化对于保障人员安全和处理最终用户所需的物资至关重要,发挥着重要作用。

工业控制系统市场趋势

工业控制系统广泛应用于食品饮料产业

- 由于经济成长和可支配收入增加,食品饮料行业的需求逐年增加。人口成长也对该产业做出了贡献。

- 2022年6月,百事印度公司宣布追加投资18.6亿卢比,扩建位于北方邦马图拉Kosi Kalan的食品製造工厂,生产Doritos玉米片品牌。百事公司对其最大的待开发区製造厂(生产乐事洋芋片)的总投资将达到 102.2 亿卢比。

- 此外,这家宠物食品製造商还计划投资 1.45 亿美元,对其位于阿肯色州史密斯堡的加工工厂进行 20 万美元的扩建和设备升级。该计划于近日核准。该计划预计将于2022年完工,将进一步推动市场成长。

- 食品和饮料行业各个自动化阶段的成功整合可以在供应链中创造价值,并确保长期竞争力和高效生产。因此,食品公司正在寻找透过流程自动化来提高可靠性、提高生产力、减少废弃物和降低总成本的方法。这种自动化要求也使得控制对于公司的生产变得更加重要。

- 报告显示,美国食品公司2021年净销售额约294亿美国,与前一年同期比较增加70亿美元。 美国 Foods 是美国一家主要的食品服务分销公司。

- 此外,製程自动化的引入还减少了每个工厂所需的工人数量,同时为工业运营商提供了产品定价的弹性。在预测期内,控制如此巨额开支的需求不断增长可能会进一步加速工业製程自动化市场的成长。

北美市场占据主导地位

- 北美正处于第四次工业革命的边缘。产生的资料大规模用于生产,同时与整个供应链中的各种製造系统整合。

- 该地区也是世界上最大的汽车市场之一,拥有超过 13 家主要汽车製造商。汽车製造是该地区製造业最大的收益来源之一。汽车产业大量采用工业控制系统和自动化技术,该地区提供了巨大的市场成长机会。

- 此外,2021年10月,丰田宣布到2030年将在美国投资34亿美元用于汽车电池的研发和生产。该公司计划与该公司的金属贸易部门丰田通商(Toyota Tsusho)合作组建一家新公司,并在美国建立一家新的汽车电池工厂。

- 在该国运营的几家主要供应商正在推出新的更新,透过工业控制系统的开发来支持智慧工厂的发展。这种技术进步显示所研究市场的区域成长。

- 例如,2021年3月,美国GE Digital推出了CIMPLICITY和Tracker软体,这是一种多产业HMI/SCADA和MES路由解决方案,有助于优化营运效率。 Tracker 专为大量製造商(包括汽车公司)使用而设计。 CIMPLICITY 面向在多个地点设有远端营运中心的公司。

- 此外,政府政策的支持和具有竞争力的天然气价格使美国和加拿大的化学公司能够建造工厂、扩建、自动化和控制其设施。因此,预计北美地区工业控制的成长也将在预测期内进一步推动调查市场。

工业控制系统产业概况

工业控制系统市场较为分散。参与者专注于研发活动以获得竞争优势。这些主要企业在创新、定价和服务的基础上竞争。新兴市场的扩张将有助于现有主要企业扩大销售网络。提供工业互联网平台的公司包括GE Digital、西门子股份公司、施耐德电气股份公司、SAP、ABB集团、发那科、霍尼韦尔国际公司、博世和思科系统公司。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3 个月分析师支持

目录

第一章简介

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章市场洞察

- 市场概况

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 买方议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争公司之间的敌对关係

- 产业价值链分析

- 评估 COVID-19 对产业的影响

第五章市场动态

- 市场驱动因素

- 工业安全技术的进步

- 製造业大规模生产的需求

- 市场挑战

- 缺乏技术纯熟劳工

第六章市场区隔

- 按系统

- 监控和资料采集系统(SCADA)

- 集散控制系统(DCS)

- 可程式逻辑控制器(PLC)

- 机器执行系统(MES)

- 产品生命週期管理 (PLM)

- 企业资源规划(ERP)

- 人机介面 (HMI)

- 其他系统

- 按最终用户产业

- 油和气

- 化工/石化

- 电力

- 生命科学

- 食品和饮料

- 金属/矿业

- 其他终端用户产业(用水和污水、纸浆和造纸、水泥、玻璃、纺织等)

- 按地区

- 北美洲

- 美国

- 加拿大

- 欧洲

- 德国

- 英国

- 法国

- 其他欧洲国家

- 亚太地区

- 中国

- 印度

- 日本

- 其他亚太地区

- 拉丁美洲

- 巴西

- 阿根廷

- 墨西哥

- 其他拉丁美洲

- 中东/非洲

- 阿拉伯聯合大公国

- 沙乌地阿拉伯

- 南非

- 其他中东和非洲

- 北美洲

第七章 竞争形势

- 公司简介

- Siemens AG

- ABB Automation Company

- Omron Corporation

- Honeywell International Inc.

- Rockwell Automation Inc.

- Schneider Electric SE

- Emerson Electric Co.

- Yokogawa Electric Corporation

- GLC Controls Inc.

- Mitsubishi Electric Corporation

第八章投资分析

第9章市场的未来

The Industrial Control Systems Market size is estimated at USD 185.27 billion in 2024, and is expected to reach USD 283.76 billion by 2029, growing at a CAGR of 8.90% during the forecast period (2024-2029).

The rising cost of labor, coupled with the immense pressure on manufacturers to meet deadlines, has resulted in the increased adoption of automation in factories. The automation of factories has fueled the market for ICS.

Key Highlights

- In September 2021, the Studio 5000 Simulation Interface from Rockwell Automation interfaced with Ansys Twin Builder, using simulation-based digital twins to help automation and process engineers. Users may build and test designs in a virtual environment, saving time and money on expensive physical prototypes.

- In addition, the quality control issue involved with human error is minimized, owing to efficiency, reliability, and faster work rate of systems. Moreover, the demand for mass production in manufacturing industries fuels the need for industrial controls to cater to the needs of the growing population.

- Connecting the industrial equipment and machinery and obtaining real-time data have played a key role in the adoption of SCADA, HMI, PLC systems, and software that offer visualization; thus, enabling reducing the faults in the product, reducing downtime, scheduling maintenance, and switching from being in the reactive state to predictive and prescriptive stages for decision-making.

- Moreover, government efforts such as Germany's industry 4.0 and France's plan industrial are likely to drive demand for IIoT solutions, which may, in turn, enhance demand for ICS security solutions and services in the future. A serious cyber catastrophe may result in significant financial losses, brand damage, loss of consumer trust, theft of intellectual property, safety concerns, and even death. As a result, to protect its ecosystem from any financial, operational, or human losses, ICS may need security mechanisms to audit and assure compliance.

- Due to the high rate of adoption of connected devices and sensors and the enabling of M2M communication, there has been a surge in the data points generated in the manufacturing industry. According to Zebra's latest manufacturing vision study, smart asset tracking solutions based on IoT and RFID are expected to overtake traditional, spreadsheet-based methods by 2022. A study by Industrial IoT (IIoT) company, Microsoft Corporation, established that 85% of companies have at least one IIoT use case project. This number is likely to increase, as 94% of respondents said they would implement IIoT strategies by 2021.

- The pandemic's impact has forced organizations to adhere to strict requirements while ensuring their employees' and customers' safety. As a result, the need for automated solutions witnessed a sudden spike. This could be observed as a notable trend in the foreseeable future. As the world is continuously fighting the rapid spread of the COVID-19 pandemic, factory automation with robotics is playing a very crucial role in helping to safeguard the people and in processing the supplies needed by the end user.

Industrial Control Systems Market Trends

Food and Beverage Sector to Widely Use Industrial Control Systems

- The demand for the food and beverage industry is growing yearly because of the economy's growth and disposable incomes. The increasing population is also contributing to this industry.

- In June 2022, PepsiCo India announced an additional INR 1.86 crore investment in expanding its food manufacturing plant in Kosi Kalan, Mathura, Uttar Pradesh, to produce the Doritos cornflakes brand. PepsiCo's total investment in its largest Greenfield Foods manufacturing plant, which manufactures Lay's potato chips, will then reach Rs 1,022 crore.

- Moreover, the Pet food manufacturer plans to invest USD145 million in a 200,000 of expansion and equipment upgrades at their FORT SMITH, AR processing facility. The project has recently received approval. The project is expected to be completed in 2022, further driving the market growth.

- Successful integration of different automation stages in the food and beverage industry leads to value-creation in the supply chain, which ensures a long-term competitive edge and efficient production. Hence, food companies are finding ways to improve reliability, increase productivity, reduce waste and decrease total cost through process automation. With this automation requirement, controls are also becoming significant to a company's production.

- According to the report, US Foods generated approximately 29.49 billion US dollars in net sales in 2021. This represents a seven-billion-dollar increase over previous years. US Foods is a leading food service distributor in the United States.

- In addition, the adoption of process automation has also reduced the number of workers required per plant while providing flexibility in product pricing for industrial operators. Such a rising need for controlling significant expenses is likely to further proliferate the growth of the industrial process automation market during the forecast period.

North America to Dominate the Market

- North America is on the verge of the fourth industrial revolution. The data generated is being used on a large scale for production while integrating the data with various manufacturing systems throughout the supply chain.

- The region is also one of the largest automotive markets in the world and is home to over 13 major auto manufacturers. Automotive manufacturing has been one of the largest revenue generators, in the region, in the manufacturing sector. As the automotive industry accounts for the significant adoption of industrial control systems and automation technologies, the region offers a huge opportunity for market growth.

- Furthermore, in October 2021, Toyota announced to invest USD 3.4 billion in US automotive battery development and production through 2030. It intends to establish a new company and construct a new US automotive battery plant in collaboration with Toyota Tsusho, the automaker's metals trading arm, and a Toyota Group unit.

- Multiple major key vendors operating in the country are launching new updates to help in the growth of smart factories with developments in industrial control systems. Such technological advancement is indicative of the growth of the region in the studied market.

- For instance, in March 2021, GE Digital, headquartered in the United States, launched CIMPLICITY and Tracker software which are multi-industry HMI/SCADA and MES routing solutions that help in the optimization of efficiency in operations. Tracker is dedicated to the usage amongst high-volume manufacturers, including automotive companies. CIMPLICITY is aimed at companies with remote operations centres at multiple locations.

- Moreover, supporting government policies and competitively priced natural gases are enabling the US and Canadian chemical companies to build plants, expand, automate, and control their facilities. Hence, the growth of the industrial controls in the North American region is also expected to further drive the market studied over the forecast period.

Industrial Control Systems Industry Overview

The industrial control system market is fragmented. The players are focusing on R&D activities to attain a competitive advantage. These key players compete based on innovation, pricing, and service. Expansion in the emerging market helps the established key players to extend their sales networks. GE Digital, Siemens AG, Schneider Electric AG, SAP, ABB Group, Fanuc, Honeywell International Inc., Bosch, and Cisco Systems are some companies that provide the industrial internet platform.

- October 2021- Dragos raises USD 200 million in series D funding at a post-money valuation of USD 1.7 billion to protect industrial customers from cyberattacks. According to the company, this is the largest funding round and highest valuation ever achieved by an operational technology (OT) cybersecurity company.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porters Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Industry Value Chain Analysis

- 4.4 Assessment of Impact of COVID-19 on the Industry

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Advancements in Industrial Safety Technology

- 5.1.2 Demand for Mass Production in Manufacturing Sector

- 5.2 Market Challenges

- 5.2.1 Lack of Skilled Workforce

6 MARKET SEGMENTATION

- 6.1 By System

- 6.1.1 Supervisory Control and Data Acquisition System (SCADA)

- 6.1.2 Distributed Control System (DCS)

- 6.1.3 Programmable Logic Controller (PLC)

- 6.1.4 Machine Execution System (MES)

- 6.1.5 Product Lifecycle Management (PLM)

- 6.1.6 Enterprise Resource Planning (ERP)

- 6.1.7 Human Machine Interface (HMI)

- 6.1.8 Other Systems

- 6.2 By End User Industry

- 6.2.1 Oil and Gas

- 6.2.2 Chemical and Petrochemical

- 6.2.3 Power

- 6.2.4 Life Sciences

- 6.2.5 Food and Beverage

- 6.2.6 Metals and Mining

- 6.2.7 Other End User Industries (Water and Wastewater, Pulp and Paper, Cement, Glass, and Textile, among others)

- 6.3 By Geography

- 6.3.1 North America

- 6.3.1.1 United States

- 6.3.1.2 Canada

- 6.3.2 Europe

- 6.3.2.1 Germany

- 6.3.2.2 United Kingdom

- 6.3.2.3 France

- 6.3.2.4 Rest of Europe

- 6.3.3 Asia Pacific

- 6.3.3.1 China

- 6.3.3.2 India

- 6.3.3.3 Japan

- 6.3.3.4 Rest of the Asia Pacific

- 6.3.4 Latin America

- 6.3.4.1 Brazil

- 6.3.4.2 Argentina

- 6.3.4.3 Mexico

- 6.3.4.4 Rest of the Latin America

- 6.3.5 Middle East & Africa

- 6.3.5.1 United Arab Emirates

- 6.3.5.2 Saudi Arabia

- 6.3.5.3 South Africa

- 6.3.5.4 Rest of the Middle East & Africa

- 6.3.1 North America

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Siemens AG

- 7.1.2 ABB Automation Company

- 7.1.3 Omron Corporation

- 7.1.4 Honeywell International Inc.

- 7.1.5 Rockwell Automation Inc.

- 7.1.6 Schneider Electric SE

- 7.1.7 Emerson Electric Co.

- 7.1.8 Yokogawa Electric Corporation

- 7.1.9 GLC Controls Inc.

- 7.1.10 Mitsubishi Electric Corporation