|

市场调查报告书

商品编码

1433927

雷达液位传送器:市场占有率分析、产业趋势、成长预测(2024-2029)Radar Level Transmitter - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

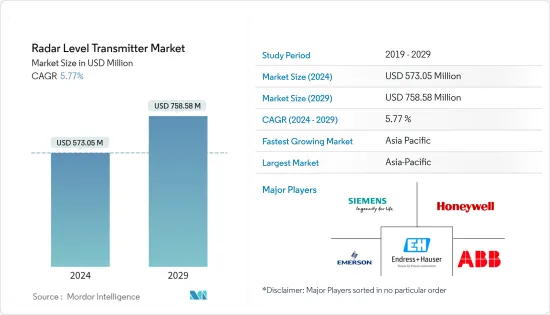

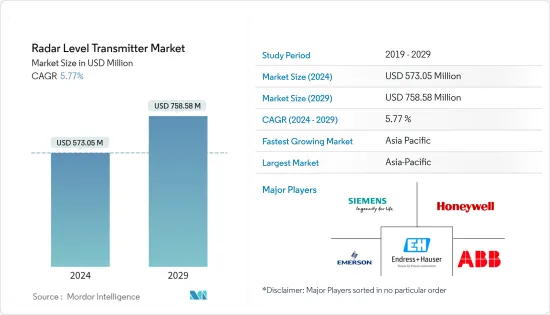

雷达液位传送器市场规模预计到 2024 年为 5.7305 亿美元,预计到 2029 年将达到 7.5858 亿美元,在预测期内(2024-2029 年)增长 5.77%。复合年增长率为

冠状病毒也没有影响供应商,因为一些供应商仅为食品业提供雷达液位传送器并提供服务。相比之下,其他公司仅服务于石油和天然气行业。食品相关产品的製造现在被认为是一项基本服务,这些设施需要长时间工作才能满足需求,这使得食品加工供应商利润最高。然而,从供应方面来看,由于供应链中断,供应商在采购零件方面遇到了困难。

主要亮点

- 液位测量技术广泛应用于建筑、工业、污水、製造、石油和天然气等众多领域。雷达物位测量是基于计算完成感测器和感测物位之间的传输所需的时间。

- 儘管雷达液位传送器的性能在过去几年中有所提高,但成本并没有以类似的速度增加。与其他一些液位测量技术相比,现在更加经济实惠。然而,该产品的经济效益并不仅限于投资收益(ROI)。随着建立新技术水准所需的专业知识减少,安装和营运成本也显着降低。

- 数位讯号处理和雷达组件设计的显着改进使得非接触式和接触式雷达能够以更低的价格拥有更广泛的应用。对于某些雷达液位传送器,运作频率已移至W频段。在此频谱内,工作频率为 78 GHz 至 80 GHz 及以上的设备目前比其他设备更受欢迎。

- 对于最终用户而言,无需关注工作频率,因为某些等级的应用程式更适合较低的运作频率。此外,高频在安装方面提供了前所未有的弹性。因此,减少了修改安装设备的过程连接的需要。较高频率的另一个好处是设备讯号比 C 频段操作设备的讯号窄得多。

雷达液位传送器市场趋势

接触系统(波导雷达)技术占有最大份额

- 在介电常数导致电反射率的应用中,雷达发射器可能具有挑战性。如果存在导电率较低的材料,例如丙烷或液化天然气,则讯号可能会微弱地反弹。这就是 GWR 派上用场的地方。 GWR 将能量集中到棒中并显示介电常数的变化,从而实现以前无法看到的测量。

- 讯号强度和效率的显着改进使得 GWR 可用于锅炉级应用。新的 GWR 设计具有越来越多的创新功能,使您能够更接近被测量的感测器、微处理器和製程。高温应用依靠压力装置来指示液位,但雷达和 GWR 逐渐得到改进,以允许它们在这些环境中使用。

- 例如,在快速启动和循环的发电和蒸气生产中,蒸气内的动态变化迅速,导致传统的压力相关液位测量技术不准确。这种不准确性可能会导致残留物并造成严重的锅炉涂层问题。它会损坏零件和涡轮叶片,并因过度排污而浪费能源。为了确保在所有操作过程中准确测量蒸气内的液位,使用者正在转向 GWR液位传送器,该变送器可以直接测量液位,作为一种不受製程介质属性变化影响的技术。

- 公司正在致力于产品创新,这正在帮助他们克服这项挑战。例如,Mangetrol International Inc. 开发了一种创新的探头设计,其中包括新的冷凝控制技术 (CCT) 与其自己的取得专利的自动蒸气补偿 (ASC) 相结合。带有 CCT 的新型蒸气探头消除了冷凝而导致的误差,从而实现最佳性能。罗斯蒙特提供基于 GWR 技术的 5300 液位发送器。此传送器适用于液体、浆料和固体的困难测量,并为液位和界面应用提供最新的可靠性和安全功能。

亚太地区占最大市场占有率份额

- 由于化学品、石化和采矿等成熟的工业基础,亚太地区的雷达液位传送器市场预计将显着成长。由于这些国家的快速经济成长和大规模都市化,中国和印度为提供雷达液位传送器的厂商提供了令人兴奋的机会。

- 除了主要企业提供的产品外,市场上国内厂商提供的产品也在成长。例如,SBEM Pvt.(普纳普纳)提供 138 系列非接触式连续脉衝雷达液位传送器,用于散装固体和液体的液位指示。

- 化学、石化、食品和饮料行业正在关注该地区的发展。此类水密集型产业需要处理设施,并且预计所研究市场的需求将会更大。此外,全部区域新兴经济体的都市化很高,对现有用水和污水基础设施的压力也越来越大。这增加了对液位监测解决方案的需求,部分是为了提高资产效率,部分是为了实现节水目标。

雷达液位传送器产业概况

全球雷达液位传送器市场适度分散。在市场上营运的公司利用策略合作倡议提供专业产品、扩大市场占有率并提高盈利。市场上营运的公司也从事新兴企业的併购,这将有助于完善雷达液位传送器服务市场组合,增强产品能力,从而提供利润丰厚的扩张机会。市场的最新发展包括:

- 2020 年 12 月 - AMETEK Drexelbrook 推出了用于 Impulse GWR 的大型同轴感测器,扩展了其波导雷达和物位测量产品。即使在高黏度液体中,新型 1.66 英尺直径探头也能提供可靠的精度。 Impulse GWR 的新型同轴感测器选项使材料在与黏性流体一起使用时能够轻鬆地从探头中流出。

- 2021 年 3 月—AMETEK 宣布已完成对 Magnetrol International、Crank Software 和 EGS Automation (EGS) 等三家公司的收购。该公司在这些收购上花费了约 2.7 亿美元,年销售额合计约 1.2 亿美元。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3 个月分析师支持

目录

第一章简介

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章市场动态

- 市场概况

- COVID-19 对市场的影响

- 市场驱动因素

- 用水和污水产业对雷达液位传送器的需求增加

- 雷达液位传送器提供可靠性、准确性和稳定性

- 市场挑战

- 测量精度和高成本的技术挑战

- 产业价值链分析

- 波特五力分析

- 新进入者的威胁

- 买家/消费者的议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争公司之间敌对关係的强度

第五章市场区隔

- 科技

- 接触法(导波雷达)

- 非接触式(自由空间雷达)

- 调频连续波雷达

- 脉衝雷达

- 目的

- 液体、浆料、界面

- 固体的

- 最终用户产业

- 油和气

- 食品和饮料

- 用水和污水

- 化工/石化

- 金属/矿业

- 其他最终用户产业

- 地区

- 北美洲

- 欧洲

- 亚太地区

- 世界其他地区

第六章 竞争形势

- 公司简介

- Siemens AG

- Emerson Electric Co.

- Endress+Hauser Management AG

- ABB Limited

- Honeywell International Inc.

- VEGA Grieshaber KG

- Krohne Messtechnik

- Yokogawa Electric Corporation

- Ametek Inc.

- Magnetrol International Inc.

- Schneider Electric SE

- Pepperl+Fuchs Pvt. Ltd

- Automation Products Group Inc.

- Nivelco Process Control Corp.

- Matsushima Measure Tech Co. Ltd

第七章 投资分析

第八章市场的未来

The Radar Level Transmitter Market size is estimated at USD 573.05 million in 2024, and is expected to reach USD 758.58 million by 2029, growing at a CAGR of 5.77% during the forecast period (2024-2029).

Coronavirus's impact has not been the same on the vendors since some of them offer and service radar-level transmitters only for the food sector. In contrast, others provide only for the oil & gas sector. Nowadays, vendors who cater to food processing are most profitable since the manufacturing of food-related items has been deemed under essential services, and those facilities have been working extra hours to fulfill the demand. However, from the supply side, the vendors face issues procuring the components due to disruption in the supply chain

Key Highlights

- Level measurement technology is widely used across many sectors such as construction, industrial, wastewater, manufacturing, oil, and gas, among others. Radar level measurement is based on calculating the time required for completion of the trip between the transducer and the sensed material level.

- The performance of radar level transmitters has improved over the last few years, but their costs haven't increased at a similar rate. They have become more affordable compared to several other level measurement technologies. However, the product's economic benefit isn't limited to return on investment (ROI) also. As the expertise required to set up newer level technologies has decreased, installation and operations costs have even gone down significantly.

- For both non-contacting or contacting radar, significant improvements in digital signal processing and radar component design have allowed them to handle a broader range of applications even as the price has dropped. In the case of some radar level transmitters, the operating frequency has moved to the W band. Within this frequency spectrum, instruments operating from 78 GHz to over 80 GHz are now more popular than other variants.

- To an end-user, the focus should not be the operating frequency because some level applications are better-suited for lower operating frequencies. Moreover, the higher frequency provides unprecedented flexibility in terms of installation. Thus, the need to retrofit the process connections where instruments are installed has decreased. Another benefit of higher frequency is the instrument signal is much narrower than the signal from instruments operating in the C band.

Radar Level Transmitter Market Trends

Contact System (Guided Wave Radar) Technology to Hold Maximum Market Share

- Radar transmitter can have a hard time in applications with different dielectric constants that cause electric reflectivity. If there is a material with low conductivity like propane or LNG, signals can bounce back weak. This is where GWR can help because it focuses energy down a rod, which shows changes in the dielectric constant, and allows readings that couldn't be seen before.

- The significant increase in signal strength and efficiency allows GWR to be used in boiler-level applications. Newer GWR designs have sensors, microprocessors and mounting innovations that enable them to get even closer to the process they're measuring. While high-temperature applications used to rely on pressure devices to indicate level, gradual improvement in radar and GWR are allowing them to also serve in these environments.

- For instance, in case of power and steam generation which undergo fast starts and cycling operations, dynamics in the steam drum rapidly change causing inaccuracies in traditional level measurement techniques that rely on pressure.This inaccuracy may lead to carryover which can cause coating of critical boiler components and turbine blades, or it may waste energy due to excessive blowdowns. To ensure accurate level measurement in the steam drum during all operations, users have moved towards GWR level transmitters to directly measure the level as this technology is not affected by changes in process media characteristics.

- Companies are working towards product innovations, which is helping to overcome this challenge. For instance, Mangetrol International Inc has developed an innovative probe design that includes new Condensation Control Technology (CCT) coupled with its original patented Automatic Steam Compensation (ASC). Th e new steam probe with CCT eliminates inaccuracies caused by condensation so that optimal performance can be achieved. Rosemount provides 5300 Level transmitter based on GWR technology. This transmitter is suitable for challenging measurements on liquids, slurries, and solids, providing modern reliability and safety features in level and interface applications.

Asia Pacific Occupies the Largest market Share

- The market for radar level transmitters in the Asia-Pacific region is anticipated to witness significant growth owing to the established base of industries, such as chemicals & petrochemicals and mining industries. Due to rapid economic growth and large-scale urbanization in these countries, China and India provide exciting opportunities for players offering radar-level transmitters.

- In addition to the products offered by the key players, the market is also witnessing the growth of product offerings from domestic players. For example, SBEM Pvt., Pune, India, Ltd has been offering non-contact, continuous Pulsed Radar-based Level transmitter series 138 for level indication of bulk solids & liquids.

- The chemicals and petrochemicals, food & beverages industries are observing development in the region. Water-intensive industries such as these require treatment facilities and are expected to generate greater demand for the market studied. Besides, the high rate of urbanization in emerging countries across the region has increased the pressure on existing water and wastewater infrastructure. This, in turn, has pushed the demand for level monitoring solutions, partly to improve asset efficiency and partly to meet water conservation goals.

Radar Level Transmitter Industry Overview

The global radar level transmitter market is moderately fragmented. The companies operating in the market are leveraging strategic collaborative initiatives to offer specialized products, increase their market share, and increase their profitability. The companies operating in the market are also into mergers and acquisitions of start-ups that help in improving the served market portfolio on radar level transmitters to strengthen their product capabilities, thus offering lucrative expansion opportunities. Some of the recent developments in the market are:

- December 2020 - AMETEK Drexelbrook expanded its guided wave radar, level measurement offering with the introduction of an enlarged coaxial sensor for The Impulse GWR. The new 1.66' diameter probe offers reliable accuracy within high viscosity liquids. The new coaxial sensor option for The Impulse GWR allows the material to easily flow off of the probe when used with viscous fluids.

- March 2021 - AMETEK announced that it had completed the acquisition of three companies, including Magnetrol International, Crank Software, and EGS Automation (EGS). The company spent nearly USD 270 million on these acquisitions, which have combined annual sales of approximately USD120 million.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Overview

- 4.2 Impact of COVID-19 on the Market

- 4.3 Market Drivers

- 4.3.1 Rising Demand for Radar Level Transmitters in the Water and Wastewater Industry

- 4.3.2 High Reliability, Precision, and Stability Offered by Radar Level Transmitters

- 4.4 Market Challenges

- 4.4.1 Technical Challenges Related to Accuracy in Measurements and High Cost

- 4.5 Industry Value Chain Analysis

- 4.6 Porters Five Force Analysis

- 4.6.1 Threat of New Entrants

- 4.6.2 Bargaining Power of Buyers/Consumers

- 4.6.3 Bargaining Power of Suppliers

- 4.6.4 Threat of Substitute Products

- 4.6.5 Intensity of Competitive Rivalry

5 MARKET SEGMENTATION

- 5.1 Technology

- 5.1.1 Contact System (Guided Wave Radar)

- 5.1.2 Noncontact System (Free Space Radar)

- 5.1.2.1 FMCW Radar

- 5.1.2.2 Pulsed Radar

- 5.2 Application

- 5.2.1 Liquids, Slurries, and Interfaces

- 5.2.2 Solids

- 5.3 End-user Industry

- 5.3.1 Oil and Gas

- 5.3.2 Food and Beverages

- 5.3.3 Water and Wastewater

- 5.3.4 Chemicals and Petrochemical

- 5.3.5 Metals and Mining

- 5.3.6 Other End-user Industries

- 5.4 Geography

- 5.4.1 North America

- 5.4.2 Europe

- 5.4.3 Asia-Pacific

- 5.4.4 Rest of the World

6 COMPETITIVE LANDSCAPE

- 6.1 Company Profiles

- 6.1.1 Siemens AG

- 6.1.2 Emerson Electric Co.

- 6.1.3 Endress+Hauser Management AG

- 6.1.4 ABB Limited

- 6.1.5 Honeywell International Inc.

- 6.1.6 VEGA Grieshaber KG

- 6.1.7 Krohne Messtechnik

- 6.1.8 Yokogawa Electric Corporation

- 6.1.9 Ametek Inc.

- 6.1.10 Magnetrol International Inc.

- 6.1.11 Schneider Electric SE

- 6.1.12 Pepperl+Fuchs Pvt. Ltd

- 6.1.13 Automation Products Group Inc.

- 6.1.14 Nivelco Process Control Corp.

- 6.1.15 Matsushima Measure Tech Co. Ltd