|

市场调查报告书

商品编码

1435795

石油和天然气流量积算器:市场占有率分析、行业趋势/统计、成长预测(2024-2029)Flow Computer Oil Gas - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

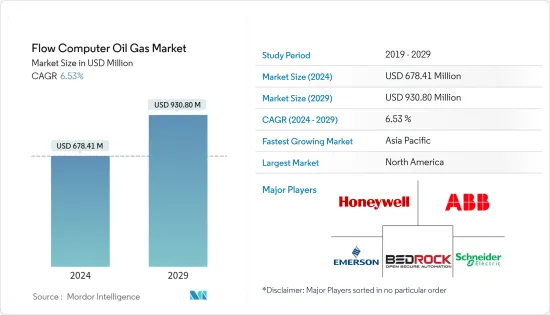

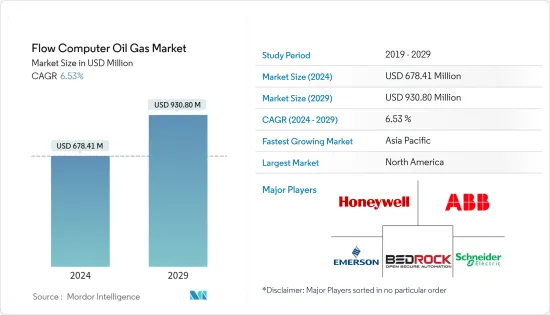

石油和天然气流量积算器的市场规模预计到 2024 年为 6.7841 亿美元,预计到 2029 年将达到 9.308 亿美元,在预测期内(2024-2029 年)复合年增长率为 6.53%。

流量积算器的整体功能是使用行业标准演算法来计算和记录天然气和某些碳氢化合物在通过管道分段时的流量。这些仪表可包括但不限于孔板流量计、超音波流量计、线性流量计和科氏流量计。典型的孔板测量应用需要差压变送器、静压感测器和温度探头。

主要亮点

- 传统的石油和天然气生产场地设计每个垫片有一到两口井。相较之下,现代生产井垫片设计整合了许多井,每口井都能够生产石油、天然气和水。井口和设施控制过去是在不同的位置进行的,但越来越多的站点正在同一个地方进行所有操作:井垫片。现代油气天然气田经济需要将测量和控制集中在一个地方。

- 对井口的集中增加了对由复杂控制演算法支援的流量积算器以及向多个使用者提供即时和历史资料的能力的需求。随着越来越多的用户认识到更好的资料分析以及资料收集、存储、处理和传输的要求带来的竞争优势和生产力提升,对高科技流量积算器的需求正在不断增加。Masu。

- 石油和天然气行业的许多相关人员正在寻求开发一个具有整合测量和控制、边缘运算、先进连接性和固有网路安全性的单一、强大的平台。这项因素扩大了流量积算器的处理能力。

- 如果有人未授权存取石油和天然气公司的基础设施,公司面临的最重大风险包括破坏/停电、设备损坏、生产中断、公共中断、产品品质、侦测洩漏、违规、非法管道窃听和安全。骇客试图透过某些策略来破坏通讯,例如 DNS 劫持、对网路邮件和企业 VPN 伺服器的攻击,甚至是公共资讯的资料收集,或者他们试图在企业网路中建立存在以进行间谍活动。您可能会找到一种方法保留它。

- 由于 COVID-19感染疾病,美国和其他非欧佩克国家的石油和天然气行业供应增长缓慢。国际能源总署 (IEA) 的一项研究显示,2020 年全球石油需求预计将萎缩。 IEA 估计,由于 COVID-19感染疾病对经济和运输的影响,包括全球范围内的大范围停产,每日原油需求将从 2019 年的 1.011 亿桶增加到 2020 年的 9,170 万桶。2020 年可能会下降。

石油和天然气流量积算器市场趋势

流量积算器不断发展的资料运算能力

- 许多公司正在为石油和天然气行业开发流量电脑的处理能力,以创建一个具有整合测量和控制、边缘运算、先进连接性和固有流量积算器性的单一、强大的平台。

- 像 Quorum 这样的许多公司已经提供了整合解决方案,可以满足价值链上游、中游和下游部分的核心处理需求。 Quorum 为美国超过 75% 的顶级石油和天然气生产商提供软体平台。

- 传统技术流量计的新技术和进一步的产品改进也有助于提高此类系统的资料收集能力。涡流街和涡轮供应商已开始提供具有两个感测器的流量计和同时校准的双流量计。 FCI 扩展了其自我调整感测器技术 (AST),推出了 ST80 系列热式质量流量计,该流量计提高了製程工业中空气/气体流量测量的量程可调范围、精度、延长了使用寿命和可靠性。

- 这些感测器的引入为流量积算器创建新的内部和外部应用创造了可能性。例如,预测性维护与虚拟和扩增实境实境功能相结合可以实现远端维护和技术支持,从而降低日常业务中的流量测量成本。

- 这些感测器的推出为流量积算器创建新的外部和内部应用创造了可能性。例如,预测性维护以及虚拟和扩增实境实境功能可实现远端维护和技术支持,从而降低日常业务中的流量测量成本。

北美占最大市场占有率

- 北美是世界主要石油和天然气生产国之一。根据美国能源资讯署(EIA)的数据,2020年,美国每天生产1,840万桶石油(MMb/day),每天消耗约1,812万桶石油。此外,该国每天出口851万桶石油,每天进口约786万桶石油。

- 政府的支持也推动了石油和天然气行业流量测量设备的成长,并在推动流量积算器市场方面发挥关键作用。例如,安全与环境执法局 (BSEE) 的直接最终规则于 2021 年 2 月底生效。

- 据美国运输部称,它还拥有超过 260 万英里的管道,每年运输 100 万立方英尺天然气和数千亿吨石油。

- 如此庞大的管道网路需要气体计量站,增加了对超音波、孔板和其他流量计等流量计量解决方案的需求。

- 该地区推出的新型流量积算器对于典型的 SCADA 流程非常有用。例如,艾默生电气用于石油和天然气的 FB1000 和 FB2000流量积算器可以与 SCADA 和其他现场设备集成,以加速部署并最大限度地减少现场时间。

油气流量积算器产业概述

石油和天然气市场流量积算器的竞争形势适度巩固,ABB Ltd、霍尼韦尔国际公司和施耐德电气公司等少数厂商占据市场主导地位。市场的一些最新发展是:

- 2020 年 2 月 - Bedrock Automation 将流量积算器功能完全整合到现有 OSA 平台中。全新 OSA+Flow 系列将业界领先的 Flow-Cal 测量应用与 Bedrock Automation 平台的高效能、安全性和简单性结合。

- 2021 年 2 月 - Quorum 宣布与能源产业整合规划、执行和准备软体供应商 Aucerna 合併,并收购 TietoEVRY 的整个石油和天然气软体业务。 Quorum 表示,此交易确立了 Quorum 的全球领导者地位。能源软体横跨能源价值链的上、中、下游环节。

- 2021 年 3 月 - 公司宣布犹他天然气公司透过实施 FLOWCAL 气体测量软体实现了计划里程碑。实施后,测量过程按时且在预算范围内,我们成功完成了第一个月度结算週期。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3 个月分析师支持

目录

第一章简介

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章市场洞察

- 市场概况

- 产业价值链分析

- COVID-19 市场影响评估

第五章市场动态

- 市场驱动因素

- 对可靠流程和高科技运算系统的需求不断增长

- 流量积算器的资料运算能力不断发展

- 市场限制因素

- 网路安全威胁阻碍了先进流运算系统的广泛普及

- 石油和天然气价格的动态变化导致基础设施投资减少

第六章市场区隔

- 副产品

- 硬体

- 软体

- 按地区

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- 中东/非洲

第七章 竞争形势

- 公司简介

- Schneider Electric SE

- ABB Ltd.

- Honeywell International Inc.

- Emerson Electric Company

- Bedrock Automation Platforms, Inc.(Maxim Integrated Products, Inc.)

- Yokogawa Electric Corporation

- Quorum Business Solutions, Inc.

- OMNI Flow Computers, Inc.

- Dynamic Flow Computers, Inc.

- Flowmetrics Inc.

第八章投资分析

第9章市场的未来

The Flow Computer Oil Gas Market size is estimated at USD 678.41 million in 2024, and is expected to reach USD 930.80 million by 2029, growing at a CAGR of 6.53% during the forecast period (2024-2029).

The overall function of a flow computer is to calculate and record the flow rate using industry-standard algorithms as natural gas and several hydrocarbons pass through a segmented section of the pipeline. These meters could be but are not limited to orifice meters, ultrasonic meters, linear meters, or Coriolis meters. A typical orifice measurement application requires a differential pressure transmitter, static pressure transducer, and temperature probe.

Key Highlights

- Traditional oil and gas production site designs had one or two wells per pad. In contrast, modern production well pad designs integrate numerous wells, each of which may produce oil, natural gas, and water. Whereas wellhead and facility controls were once performed in separate locations, many more sites perform everything at the same location: the well pad. The economics of the modern oil and gas field requires concentrating measurement and control in a single location.

- The concentration at the wellhead has increased the demand for flow computers, which are supported by sophisticated control algorithms and the ability to provide real-time and historical data to multiple users. As more and more users discover the competitive advantage and productivity improvements they can gain from better data analysis and the requirements to collect, store, process, and transmit data, increasing the demand for high-tech flow computers increases.

- The development of a rugged, single platform equipped with consolidated measurement and controls, edge computing, advanced connectivity, and intrinsic cybersecurity is being sought after by many players in the oil and gas industry. This factor has led to expanding flow computer processing capabilities.

- The most critical risks that a company will face if somebody gets unauthorized access to oil and gas companies' infrastructure are planted sabotage/shutdown, equipment damage, production disruption, utility interruption, product quality, undetected spills, compliance violation, illegal pipeline tapping, safety violation, etc. Specific tactics threaten hackers to try and compromise communications or find a way to maintain a presence in corporate networks for espionage purposes, such as DNS hijacking, attacking webmail and corporate VPN servers, or even scraping publicly available information for data.

- Due to the COVID-19 pandemic, the oil and gas industry witnessed a slowdown in supply growth in the United States and other non-OPEC countries. The global oil demand is expected to contract in 2020, according to a study by the International Energy Agency (IEA). IEA had predicted that the daily need for crude oil was likely to decrease in 2020, from 100.1 million barrels in 2019 to 91.7 million barrels in 2020, due to the economic and mobility impacts of the COVID-19 pandemic which included widespread shutdowns across the world.

Flow Computer Oil Gas Market Trends

Evolving Data Computational Capacity of Flow Computers

- The development of single, rugged platform equipped with consolidated measurement and controls, edge computing, advanced connectivity and intrinsic cyber security by many players for the oil and gas industry has led to the expansion of flow computer processing capabilities.

- Many players like Quorum are already offering integrated solutions for core processing demands across the upstream, midstream and downstream segments of the value chain. Quorum offers its software platform to more than 75% of the top oil and gas producers in the United States.

- Further product improvements in new and traditional technology flowmeters are also contributing to the data capturing ability of such systems. Vortex and turbine suppliers have now started offering flowmeters with two sensors and simultaneously calibrated dual flowmeter. FCI expanded its Adaptive Sensor Technology (AST) to offer ST80 Series Thermal Mass Flow Meter that has enhanced the rangeability, accuracy, extended service life, and reliability for process industry air/gas flow measurement.

- The introduction of these sensors have led to the possibility to create new internal and external applications for flow computeres. For instance, predictive maintenance along with virtual- and augmented-reality capabilities has the potential to enable remote maintenance and technical support thereby reducing flow measurement costs in day to day operations.

- The launch of these sensors has led to the possibility of creating new external and internal applications for flow computers. For instance, predictive maintenance and virtual- and augmented-reality capabilities can enable remote maintenance and technical support, thereby, reducing flow measurement costs in day-to-day operations.

North America to Hold the Largest Market Share

- North America is one of the significant producers of oil and gas across the globe. According to U.S. Energy Information Administration (EIA), in 2020, the United States produced 18.40 million barrels per day (MMb/d) of petroleum and consumed about 18.12 MMb/d. In addition, the country exported 8.51 MMb/d and imported about 7.86 MMb/d of petroleum.

- The government's support is also triggering the growth in the flow measurement devices in the oil and gas industry, which plays a significant role in driving the market for flow computers. For instance, the Bureau of Safety and Environment Enforcement (BSEE) direct final rule came into effect at the end of February 2021.

- Also, according to the United States Department of Transportation, there are more than 2.6 million miles of pipeline that delivers million cubic feet of natural gas and hundreds of billions of tons of petroleum every year.

- Such a vast network of pipelines requires gas metering stations raising the demand for flow metering solutions such as ultrasonic, orifice, and other flow meters.

- The new flow computers launched in the region are conducive to the typical SCADA processes. For instance, the FB1000 and FB2000 flow computers for oil and gas offered by Emerson Electric can be integrated with SCADA and other field devices to accelerate deployment and minimize the time in the field.

Flow Computer Oil Gas Industry Overview

The competitive landscape for the Flow Computer in the Oil and Gas Market is moderately consolidated, with few players like ABB Ltd, Honeywell International Inc., Schneider Electric SE dominating the market. Some of the recent developments of the market are as follows:-

- Feb 2020 - Bedrock Automation has introduced full integration of its flow computer functionality into the existing OSA platform. The new OSA + Flow family integrates industry-leading Flow-Cal measurement applications with the high performance, security, and simplicity of the Bedrock Automation platform.

- Feb 2021 - Quorum announced the merger with Aucerna, a provider of integrated planning, execution, and reserves software for the energy industry, and acquisition of TietoEVRY's entire oil and gas software business As per Quorum, this deal will position Quorum as a global leader for energy software across the upstream, midstream, and downstream sectors of the energy value chain.

- March 2021 - The company announced that Utah Gas Corp. achieved its project milestone with the implementation of FLOWCAL gas measurement software. After the implementation, measurement processes were on time and within budget, and the successfully completed its first monthly close cycle.company

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Value Chain Analysis

- 4.3 Assessment of Impact of COVID-19 on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Growing Need for Reliable Flow and High-tech Computing Systems

- 5.1.2 Continually Evolving Data Computational Capacity of Flow Computers

- 5.2 Market Restraints

- 5.2.1 Cyber-Security Threats Deterring Deployment of Advanced Flow Computer Systems

- 5.2.2 Dynamic Changes in Oil & Gas Prices leading to Reduced Investment in Infrastructure

6 MARKET SEGMENTATION

- 6.1 By Offering

- 6.1.1 Hardware

- 6.1.2 Software

- 6.2 By Geography

- 6.2.1 North America

- 6.2.2 Europe

- 6.2.3 Asia Pacific

- 6.2.4 Latin America

- 6.2.5 Middle East and Africa

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Schneider Electric SE

- 7.1.2 ABB Ltd.

- 7.1.3 Honeywell International Inc.

- 7.1.4 Emerson Electric Company

- 7.1.5 Bedrock Automation Platforms, Inc. (Maxim Integrated Products, Inc.)

- 7.1.6 Yokogawa Electric Corporation

- 7.1.7 Quorum Business Solutions, Inc.

- 7.1.8 OMNI Flow Computers, Inc.

- 7.1.9 Dynamic Flow Computers, Inc.

- 7.1.10 Flowmetrics Inc.