|

市场调查报告书

商品编码

1438115

测量软体:市场占有率分析、产业趋势与统计、成长预测(2024-2029)Metrology Software - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

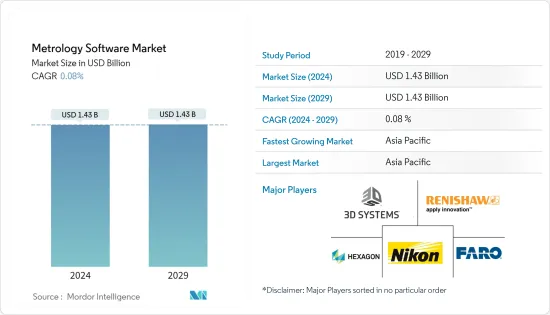

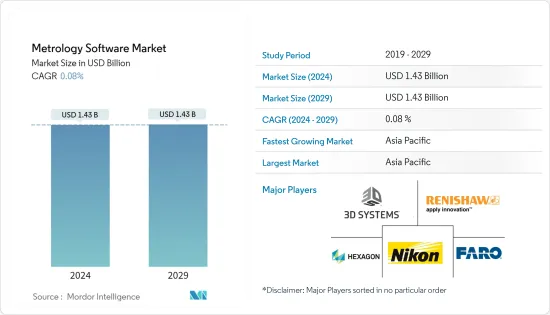

计量软体市场规模预计到2024年为14.3亿美元,预计到2029年将达到14.3亿美元,在预测期内(2024-2029年)增长0.08%,以复合年增长率增长。

测量解决方案正在见证从简单收集或收集资料的工具转变为可以分析和处理资料的工具的转变。由于测量是在生产过程中而不是在测量室中进行的,因此工厂和生产线对以模组化方式使用的计量的需求不断增长,这影响了对标准测量仪器的需求。

主要亮点

- 使用计量软体检查製成品是预计未来五年推动全球计量软体市场成长的关键因素之一。先进奈米技术、智慧材料、软性电子产品和绿色製造是推动电子製造计量解决方案需求的主要因素。

- 随着数位化趋势在各领域持续发展,计量领域已经意识到数位转型的必要性。随着世界走向数位转型,该产业也拥抱这种转型,使计量软体市场在预测期内进一步成长。

- 计量软体将 CAD、ERP、MRP 和 PLM 之间的点连接起来。测量是完成设计/建造过程时面临的首要挑战之一。通常需要 CAD 后测量资料来收集缺失的特征资料、塑造复杂的表面轮廓,并支持製造、工程、工具製造、组装指导和质量检验。有。

- 计量解决方案预计将成为电子製造品质检测活动的关键。在快速发展的电子製造业中,最终用户的目标是承担涉及新产品设计和开发的计划。

- 半导体製造中的统计製程控制使公司能够透过从每天处理的数千个晶圆中仅抽取少量晶圆来最大限度地提高产量比率和品质。因此,计量/检测系统收益成长落后于整体设备成长。

- 新冠肺炎 (COVID-19) 疫情对科技业产生了重大影响。电子供应价值链和原材料供应的中断正在对科技业产生负面影响。

- 然而,疫情迫使该产业寻找更安全、更创新的方式来平稳有效地运作。另一方面,由于冠状病毒封锁限制了製造业活动,市场受到影响。

测量软体市场趋势

航太部门将经历显着成长

- 自飞行诞生以来,技术以惊人的速度发展,飞机现在也更加先进。计量学在航太的应用对于这项进展至关重要。计量的重要性预计在未来几十年将进一步增加,从而推动计量软体市场的发展。

- 更轻、更有效率、更安全的飞机由复合材料製成,这对于航太生产的持续发展至关重要。复合材料重量轻、坚固且耐用。它还可以形成比钢或铝等金属更复杂的形状,这有两个优点。公司受益于更少的紧固件和接头以及更少的弱点。由于零件数量较少,组装时间也保持在最低限度。

- 复合材料零件的使用对于航太製造的未来生产更轻、更有效率的飞机至关重要。复合材料飞机可以降低营运成本,但製造成本通常更高。复合材料比钢或铝更轻、更坚固、更耐用,这使得计量辅助组装对于维持製造过程的成本效益至关重要。随着复合材料零件变得越来越普遍,计量作为付加组件的重要性得到了越来越广泛的认可。

- 复合材料的缺点是比金属材料更昂贵。然而,这正是计量学发挥作用的地方,它支持组装过程开发更具成本效益的生产程序。随着主要民航机製造商越来越多地使用复合材料,预计飞机计量的重要性将会增加。

- 儘管复合材料有许多优点,但使用需要精确组装以达到非常严格的公差的材料是很困难的。在製造中使用计量可以避免代价高昂的错误以及材料浪费和返工。此外,航太业要求层级供应商进行 100% 的检查,因此公司必须为最困难的测量任务提供准确性、可重复性和可靠性。据波音公司预计,2022年北美民航服务市场需求约1.45兆美元。

亚太地区占最大市场占有率

- 亚太地区预计将出现计量软体解决方案的最高增长,因为该地区是各种汽车和航太相关企业的所在地,并且人们对高精度计量解决方案的兴趣与日俱增。

- 中国是世界製造地。随着製造流程的精度和复杂性迅速提高,计量软体市场预计将推动该行业的发展,因为中国目前在国内外拥有多个製造设施。

- 在华为和中国移动的支援下,海尔在智慧工厂中成功应用了结合5G和行动边缘运算的创新製造解决方案。这些解决方案将 5G 边缘运算与製造环境中的人工智慧和机器视觉整合在一起。它们适用于不同的製造场景,可以执行不同的功能。计量软体解决方案可以透过快速执行品质控制检查来节省製造成本,准确度超过 99%。与没有此功能的情况相比,准确率至少提高 10%。预计此类案例将推动该地区的市场成长。

- 该公司在日本建立了各种合作伙伴关係和协作,以进一步加强其测量和测试解决方案并改善其影响力和客户群。许多公司一直在寻求有效的技术来帮助他们完全自动化并增强具有成本效益的视觉检测和测量解决方案,从而显着改善品管并降低製造成本。

- 例如,2021 年 9 月,Nikon Metrology NY 使用最新版本的 Inspect-X 软体发布了新的偏移 CT 重建演算法。该软体可以扫描更关键的零件,并且可以在更高的几何放大倍率下运行。 Offset.CT 模组可与 180kV 至 450kV 的所有 Nikon Metrology X 光 CT 系统搭配使用。最新的 Rotating.Target 2.0、可调节 FID 和 Offset.CT 的组合可显着缩短週期时间并提高分辨率,即使在处理大型复杂组件时也是如此。

计量软体产业概述

测量软体市场拥有众多参与者,并且仍保持适度竞争。市场上的主要企业正在采取合作伙伴关係、创新和收购等策略来加强其产品供应并获得永续的竞争优势。

2022 年 9 月:蔡司工业品质解决方案推出捆绑到单一平台中的蔡司 3D 计量软体,该平台也提供许多数位服务。蔡司品质套件为计量学家提供了各种软体产品,以获取最新的新闻、活动、培训优惠、直觉的线上协助和更新。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3 个月分析师支持

目录

第一章简介

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章市场洞察

- 市场概况

- 产业吸引力-波特五力分析

- 新进入者的威胁

- 买方议价能力

- 供应商的议价能力

- 替代产品的威胁

- 竞争公司之间的敌意强度

- 评估 COVID-19 对产业的影响

第五章市场动态

- 市场驱动因素

- 加速製造流程自动化

- 消费者对高品质产品的需求

- 对智慧、有效的资料收集、分析和评估以及强大的资料管理和报告工具的需求日益增长

- 市场限制因素

- 缺乏意识挑战市场成长

第六章市场区隔

- 按行业 按最终用户

- 车

- 航太

- 电子製造业

- 其他最终用户领域

- 按地区

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- 中东和非洲

第七章 竞争形势

- 公司简介

- Nikon Metrology NV

- 3D Systems Inc.

- Creaform Inc.(AMETEK Inc.)

- Faro Technologies

- Carl Zeiss AG

- Hexagon AB

- LK Metrology Ltd

- Renishaw PLC

- Perceptron Inc.(Atlas Copco)

- Innovmetric Software Inc.

- Fluke Corporation

- Metrologic Group(Sandvik AB)

- Autodesk Inc.

第八章投资分析

第9章市场的未来

The Metrology Software Market size is estimated at USD 1.43 billion in 2024, and is expected to reach USD 1.43 billion by 2029, growing at a CAGR of 0.08% during the forecast period (2024-2029).

Metrology solutions are witnessing a shift from merely a tool that gathers or collects data to one capable of data analysis and processing. Measurements are conducted in the production process rather than in measuring rooms, fostering the demand for metrology used in a modularized method in plants and production lines and impacting the demand for standard measuring instruments.

Key Highlights

- The use of metrology software to inspect manufactured products is one of the critical factors expected to drive the growth of the global metrology software market in the next five years. Advanced nanotechnology, smart materials, flexible electronics, and green manufacturing are the principal factors driving demand for metrology solutions in electronic manufacturing.

- Due to the ongoing digitalization trend across all sectors, the metrology field has noticed the need to change digitally. As the world shifts toward digital transformation, the industry also embraces the transformation, allowing the metrology software market to grow more during the forecast period.

- Metrology software connects the dots among CAD, ERP, MRP, and PLM. Metrology is one of the first challenges when working down the design/build process. Post-CAD measurement data is often necessary to collect missing feature data, create geometry for complex surface profiles, and support manufacturing, engineering, toolmaking, assembly guidance, and quality verification.

- Metrology solutions are expected to become indispensable to electronic manufacturing quality inspection activities. In the rapidly-growing electronic manufacturing industry, end users aim to undertake projects involving new product designs and development.

- Statistical process control for semiconductor manufacturing enables the company to maximize yield and quality by simply sampling a small number of wafers out of thousands processed daily. Thus, revenue growth in metrology/inspection systems lags behind the increase in overall equipment.

- With the outbreak of COVID-19, there has been a significant impact on the technology sector. Disruptions of an electronic supply-value chain and raw material supply have adversely impacted the technology industry.

- However, the pandemic compelled industries to find safer and more innovative ways to operate smoothly and effectively. On the other hand, the market was hampered due to limited manufacturing activities carried out due to covid lockdown.

Metrology Software Market Trends

Aerospace Sector to Witness Significant Growth

- Since the dawn of flying, technology has advanced at a breakneck pace, and planes are now vastly more sophisticated. The use of metrology in aerospace has been critical to this progress. Metrology's importance is expected to only rise in the following decades, thus driving the metrology software market.

- Aircraft that are lighter, more efficient, and safer are made with composite materials, essential to the continued development of aerospace production. Composite materials are light, incredibly robust, and long-lasting. They may also be molded into more intricate shapes than metals like steel and aluminum, which has two benefits. Companies profit from fewer fasteners and joints, resulting in fewer weak places. Because there are fewer components, assembly time is also minimized.

- To construct lighter, more efficient planes, the usage of composite parts is critical in the future of aerospace manufacturing. While composite-part airplanes have reduced operational costs, their production costs are often higher. Composites are more expensive than steel and aluminum because they are lighter, stronger, and more durable, and metrology-assisted assembly is crucial for keeping the production process cost-effective. As composite parts grow increasingly common, metrology's significance as a value-added component is becoming more widely recognized.

- The disadvantage of composite materials is that they are more expensive than their metallic counterparts. However, metrology comes into play here, supporting the assembly process in developing more cost-effective production procedures. The crucial significance of metrology in aircraft is expected to only grow as the usage of composite materials develops among the significant commercial plane builders.

- Despite its numerous advantages, composite is tough to work with material requiring precise assembly with very tight tolerances. Using metrology in manufacturing helps avoid costly mistakes and scrap or rework material. Also, with the aerospace industry demanding 100% inspection from their Tier-1 suppliers, companies must deliver accuracy, repeatability, and dependability for the most challenging measurement tasks. According to Boeing, in 2022, the market demand for Civil Aviation Services in North America is approximately USD 1045 billion.

Asia-Pacific Occupies the Largest Market Share

- Due to the presence of various automotive giants and aerospace establishments in the region and their increasing interest in high-accuracy metrology solutions, Asia-Pacific is expected to have the highest growth of metrology software solutions.

- China is a global manufacturing hub. Since the precision and complexity in manufacturing processes have been increasing rapidly, the metrology software market is expected to boost this area, as China currently has several national and international manufacturing facilities.

- With support from Huawei and China Mobile, Haier has successfully applied innovative manufacturing solutions combining 5G and mobile edge computing in its smart factories. These solutions integrate 5G edge computing with artificial intelligence and machine vision in manufacturing environments. These apply to various manufacturing scenarios where they can perform various functions. The metrology software solutions can save manufacturing costs by rapidly performing QC checks with over 99% accuracy, at least 10% more accurate than without the function. Such instances are expected to drive the market's growth in the region.

- Companies have had various partnerships and collaborations in Japan to enhance their measurement and inspection solutions further and improve their presence and customer base. Various companies have been seeking an effective technology that can help to fully automate and enhance better cost-effective visual inspection and measurement solutions that significantly improve quality control and reduce manufacturing costs.

- For instance, in September 2021, Nikon Metrology NY released a new offset CT reconstruction algorithm with the latest version of its Inspect-X software. This software can scan more significant components and can be done at higher geometric magnifications. The Offset.CT module can be used with all Nikon Metrology X-ray CT systems from 180kV to 450kV. This combination of the latest Rotating.Target 2.0, adjustable FID, and Offset.CT significantly reduces cycle time and provides better resolution even when dealing with large and complex components.

Metrology Software Industry Overview

The metrology software market is moderately competitive with the presence of many players in the market. The key players in the market are adopting strategies such as partnerships, innovations, and acquisitions to enhance their product offerings and gain sustainable competitive advantage.

In September 2022: ZEISS Industrial Quality Solutions launched ZEISS 3D metrology software bundled on a single platform that additionally offers many digital services. ZEISS Quality Suite offers metrologists various software products to access current news, events, training offers, intuitive online help, and updates.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Threat of New Entrants

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Bargaining Power of Suppliers

- 4.2.4 Threat of Substitute Products

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Assessment of the Impact of COVID-19 on the Industry

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Increased Drive Toward Automation of Processes in Manufacturing Industry

- 5.1.2 Demand for High-quality Products from Consumers

- 5.1.3 Increasing Need for Intelligent and Effective Data Acquisition, Analysis, and Evaluation and Powerful Data Management and Reporting Tools

- 5.2 Market Restraints

- 5.2.1 Lack of Awareness to Challenge the Market Growth

6 MARKET SEGMENTATION

- 6.1 By End-user Vertical

- 6.1.1 Automotive

- 6.1.2 Aerospace

- 6.1.3 Electronic Manufacturing

- 6.1.4 Other End-user Verticals

- 6.2 By Geography

- 6.2.1 North America

- 6.2.2 Europe

- 6.2.3 Asia Pacific

- 6.2.4 Latin America

- 6.2.5 Middle East & Africa

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles*

- 7.1.1 Nikon Metrology NV

- 7.1.2 3D Systems Inc.

- 7.1.3 Creaform Inc. (AMETEK Inc.)

- 7.1.4 Faro Technologies

- 7.1.5 Carl Zeiss AG

- 7.1.6 Hexagon AB

- 7.1.7 LK Metrology Ltd

- 7.1.8 Renishaw PLC

- 7.1.9 Perceptron Inc. (Atlas Copco)

- 7.1.10 Innovmetric Software Inc.

- 7.1.11 Fluke Corporation

- 7.1.12 Metrologic Group (Sandvik AB)

- 7.1.13 Autodesk Inc.