|

市场调查报告书

商品编码

1690079

自动化 3D 列印:市场占有率分析、产业趋势与统计、成长预测(2025-2030 年)Automated 3D Printing - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

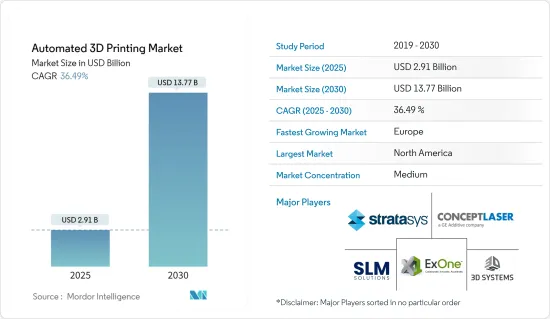

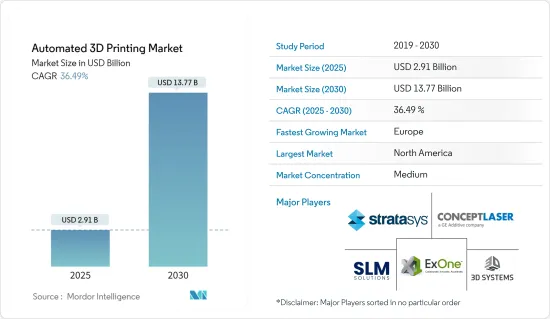

自动化 3D 列印市场规模预计在 2025 年为 29.1 亿美元,预计到 2030 年将达到 137.7 亿美元,预测期内(2025-2030 年)的复合年增长率为 36.49%。

预计研发投入的增加和工业自动化中机器人的应用增加将推动市场成长。

主要亮点

- 在过去的几年里,3D 列印经历了从原型製作和小批量生产到大规模生产技术的稳定转变,产业和非列印机供应商将重点转向自动化。此外,随着积层製造趋势的发展,硬体正从用作原型製作、工具和单一零件生产的独立系统,发展成为整合数位量产线中的核心系统,从而增加了新兴无人工厂的机会。

- 人工智慧和机器学习技术正在增材製造业的各种应用中寻找自己的位置。例如,麻省理工学院(MIT)的研究人员应用机器学习的资料驱动特性来自动化发现新 3D 列印材料的流程。利用机器学习,对韧性、抗压强度等材料性能因素进行演算法优化,迅速超越了传统的3D列印材料配方方法。研发部门开发了一个名为 AutoOED 的免费开放原始码材料优化平台,以便其他研究人员可以进行材料优化。

- 同样,2022 年 1 月,来自德国和加拿大的一组组织启动了一项新的合作,利用 3D 列印和人工智慧实现零件夹持流程的自动化。自适应雷射增材製造过程感测的人工智慧增强 (AI-SLAM)计划旨在创建强大的基于 AI 的软体,可自主操作指向性能量沉积技术(DED) 3D 列印机。该软体透过演算法控制列印过程,以更好地修復受损部件的表面不规则。弗劳恩霍夫雷射技术研究所 (ILT) 和软体公司 BCT 是该德国财团的成员。在加拿大,该研究将由加拿大国家研究委员会 (NRC)监督。麦吉尔大学将协调这项研究,机器学习公司 Braintoy 将协助编程 AI 模型。

- 此外,参与者正在采取各种市场开发措施来巩固其在市场中的地位。例如,2021年4月,Mosaic宣布了其自动化3D列印平台Array。该平台为四台 Element HT 印表机装载和卸载材料、开始列印、移除列印件并储存它们以准备开始下一次列印。 Array 的设计具有最大的灵活性,它采用自动贩卖机式的机械臂,透过取出列印件、将其放在一边并为下一次列印装载干净的床来确保最大的产量。

- 2021 年 10 月,总部位于温哥华的 3D 列印产业自动化技术开发商 3DQue 宣布推出适用于 Creality CR-10 和 CR-6 SE 的两款全新 Quinly 自动化套件。 Quinly 是虚拟3D 列印机操作员,由 Raspberry Pi 驱动,Raspberry Pi 是一套可自行运作桌上型 3D 列印机的硬体和软体套件。该技术旨在透过消除手工劳动,使 3D 列印更具可扩展性。它主要针对印刷实验室、按需製造商、教育机构以及任何寻求自动化、大量零件生产的人。

- 此外,由于供应链中断以及对治疗和材料的新需求,COVID-19 疫情大大加速了製药、医疗设备和製造业的技术进步。供应链的缺陷导致医护人员难以获得所需的物资,医院也缺乏个人防护工具(PPE)和对抗病毒的医疗设备。因此,积层製造(AM)——自动化 3D 列印——因其在快速生产复杂整体零件甚至机械系统方面的可近性和灵活性而成为值得关注的製造流程之一。

自动化 3D 列印市场趋势

汽车产业可望推动市场成长

- 汽车作为当今的主要交通途径,是人类生活中不可或缺的一部分。目前,全球道路上行驶的汽车超过 13 亿辆,预计到 2035 年将增长到 18 亿辆。其中,乘用车约占 74%,轻型商用车、卡车、巴士、长途客车和小型巴士占剩余的 26%。

- 3D 列印可用于製造模具和热成型工具,以快速生产夹具、夹具和固定装置。这使得汽车製造商能够以低成本生产样品和工具,从而消除了投资高成本模具时未来生产损失。 2014 年,Local Motors 推出了首款 3D 列印电动车。此后,宝马集团等其他老字型大小企业也纷纷效仿,采用自动化 3D 列印技术。在美国几家大型汽车製造商中,大约 80% 至 90% 的初始原型组装都是透过 3D 列印完成的,而且自动化趋势还在持续增长。最受欢迎的部件包括排气部件、进气部件和管道部件。这些部件经过数位化设计、3D 列印、快速安装到汽车上,然后反覆测试。

- 自动化 3D 列印在汽车行业最常见的应用可能是创建夹具和固定装置等製造辅助工具。使用传统方法创建製造工具非常昂贵且耗时,且几何限制会降低製造过程的效率并限制最终用途零件的几何形状。 3D 列印製造工具更轻、更符合人体工学,使工厂工人能够更轻鬆、更安全地完成工作。

- 此外,汽车製造所涉及的生产量非常巨大,每个零件的运行次数高达数十万次。这是目前大多数 3D 列印技术难以企及的。然而,许多高端汽车製造商将汽车产量限制在数千辆,因此自动化 3D 列印成为可行的选择。

- 根据世界经济论坛预测,到2035年,全自动驾驶汽车的销售量将占全球汽车市场的25%,高于与前一年同期比较。此外,马达製造商的多项措施也促进了市场的成长。 2020年3月,英国工程公司Equipmake开发出功率密集型永磁马达。该马达是与 3D 列印专家 Hieta 合作设计的。 Equipmake 的 Ampere马达重量接近 10 公斤,但可提供 295 匹马力的功率。

- 此外,支架是一种常见的小型部件,当工程师受到传统製造方法的限制时,以前很难对其进行最佳化。现在,工程师可以设计最佳化的支架,并藉助3D列印实现这些设计。劳斯莱斯最近展示了其支架的 3D 列印功能。该公司展示了大量经过 DfAM 优化和 3D 列印的金属汽车零件,其中许多看起来像支架。虽然原型製作仍然是 3D 列印在汽车行业的主要应用,但该技术在工具方面的应用正在迅速扩大。大众汽车内部已使用 3D 列印多年。该公司的黏着剂喷涂成型技术也用于製造这些组件。福斯汽车也于2021年7月宣布,将与西门子、惠普合作,实现结构件3D列印工业化。

预计北美将占据较大的市场占有率

- 北美是全球自动化 3D 列印的主要市场之一,其中美国占据该地区的大部分份额。该国不断增长的需求归因于大大小小的众多供应商的存在。例如,总部位于加州卡尔斯巴德的 Forecast 3D 公司为医疗保健、汽车、航太、消费品和设计产业提供多种材料的 3D 列印服务。

- 在强大的人工智慧应用快速发展的推动下,闭合迴路控制系统长期以来一直是积层製造工程师的基本目标。例如,通用电气纽约尼斯卡尤纳增材研究实验室的调查团队开发了一个专有的机器学习平台,该平台使用高解析度摄影机逐层监控列印过程,检测出肉眼通常看不到的条纹、凹坑、孔洞和其他问题。此外,还可以使用电脑断层扫描 (CT) 影像将这些资料与预先记录的缺陷资料库即时进行比较。利用高解析度影像和电脑断层扫描资料,训练 AI 系统预测整个列印过程中的困难并检测缺陷。

- 此外,市场正见证各种与聚合物3D列印相关的技术专利。例如,2020年8月,工业3D列印自动化和智慧后列印解决方案提供商之一PostProcess Technologies Inc.获得了聚合物3D列印自动化后列印技术的专利。 SVC 技术是 PostProcess 增材製造系列 3D 列印聚合物支撑去除和树脂去除解决方案的一部分。此取得专利的方法使用正在申请专利的清洗剂和专有演算法,确保 3D 列印组件在列印后均匀、一致且可靠地暴露于清洗剂和空化中。

- 此外,各种供应商都在该地区扩建设施,主要是为了应对供应链挑战和各个终端用户垂直领域日益增长的需求。例如,2021年2月,Roboze宣布将在德克萨斯州休士顿开设美国总部,以促进国内生产回流并解决供应链问题。 Roboze 计划在未来两年内招聘 100 多名员工,扩大其在美国工程和製造能力,以满足航太、石油天然气和移动等行业对 3D 列印技术日益增长的需求。

- 同样,2021 年 4 月,Roboze 宣布推出 Roboze Automate,这是一套工业自动化系统,它将采用超级聚合物和复合材料的客製化 3D 列印引入到极端终端用户应用的生产工作流程中。随着美国开始大力推动基础建设,该国正面临金属短缺的问题,影响能源、交通、製造业等各产业。 Roboze 将 PEEK(一种理想的金属替代品的新型聚合物平台技术)与与 B&R 合作开发的 PLC 工业自动化系统相结合。

自动化 3D 列印产业概览

自动化 3D 列印市场竞争激烈,几家主要参与者竞相抢占更大的市场份额,然而,主要参与者已经占据了很大比例的消费者,并且正在投资研发并与硬体供应商合作以进一步开发和创新。主要企业包括 Stratasys Ltd、3D Systems Corporation、The ExOne Company 等。

- 2022 年 2 月 - Viaccess-Orca、ShipParts.com 和 SLM Solutions 宣布了一项新技术解决方案,可实现积层製造(AM) 的直接云端列印。这种全自动软体执行透过控制允许列印的数量、持续时间和参数来保护与零件资料相关的製造商的智慧财产权 (IP)。基于 VO 的 SMP 软体库和 SLM Solutions 的韧体韧体的本地集成,该 Cloud-to-Print 解决方案让製造商充满信心,在获得列印许可时他们的 IP 受到保护。

- 2022 年 1 月 - 着名的增材製造 (AM) 软体和服务供应商 Materialise NV、品质保证软体供应商 Sigma Labs, Inc. 和 Materialise 合作开发了可增强金属 AM 应用可扩展性的技术。新平台将 Sigma Labs 的 PrintRite3D 感测器技术与 Materialise 控制平台结合,使用户能够即时识别和纠正金属建构问题。

- 2022 年 1 月-PostProcess Technologies 宣布增加一条新的自动化、智慧印后解决方案系列。新款 VORSA 500 利用 PostProcess 技术为 3D 列印的 FDM 零件提供一致、免持的支撑结构拆除。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第 1 章 简介

- 研究假设和市场定义

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场洞察

- 市场概况

- 产业价值链分析

- 产业吸引力-波特五力分析

- 新进入者的威胁

- 买家的议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争对手之间的竞争强度

- COVID-19 产业影响评估

第五章 市场动态

- 市场驱动因素

- 增加研发投入

- 机器人在工业自动化的应用日益广泛

- 市场挑战

- 营运挑战

第六章 市场细分

- 奉献

- 硬体

- 软体

- 服务

- 流程

- 自动化生产

- 物料输送

- 零件处理

- 后製处理

- 多处理

- 按最终用户产业

- 工业生产

- 车

- 航太和国防

- 消费性产品

- 卫生保健

- 活力

- 其他最终用户产业

- 地区

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- 中东和非洲

第七章 竞争格局

- 公司简介

- Stratasys Ltd

- Concept Laser Inc.(GE Additive)

- The ExOne Company

- SLM Solutions Group AG

- 3D Systems Corporation

- Universal Robots AS

- Formlabs

- PostProcess Technologies Inc.

- Materialise NV

- Authentise Inc.

- DWS Systems

- Coobx AG

- ABB Group

第八章投资分析

第九章 市场机会与未来趋势

The Automated 3D Printing Market size is estimated at USD 2.91 billion in 2025, and is expected to reach USD 13.77 billion by 2030, at a CAGR of 36.49% during the forecast period (2025-2030).

The increasing investments in R&D and growth in the adoption of robotics for industrial automation are expected to propel market growth.

Key Highlights

- Over the last few years, 3D printing has constantly experienced a shift from the prototyping and small batches phase to mass production technology with a growing adoption rate across the industries, where the industrial and non-printer vendors have shifted their focus toward automation. Also, with the evolutionary trend for additive manufacturing, hardware growing beyond stand-alone systems that are used for prototyping, tooling, and single-part production to be used as core systems within integrated digital mass production lines is driving the number of opportunities in the emerging lights-out factories.

- Artificial Intelligence and machine learning technologies are finding their way through various applications in the additive manufacturing industry. For instance, researchers from MIT have applied the data-driven nature of machine learning to automate the process of discovering new 3D printing materials. With machine learning, material performance factors, such as toughness and compression strength, were optimized using an algorithm that quickly outperformed conventional methods of 3D printing material formulation. The researchers developed a free, open-source materials optimization platform called AutoOED, allowing other researchers to conduct their material optimization.

- Similarly, in January 2022, a group of organizations from Germany and Canada formed a new collaboration to use 3D printing and AI to automate the process of fixing parts. The Artificial Intelligence Enhancement of Process Sensing for Adaptive Laser Additive Manufacturing (AI-SLAM) project aims to create powerful AI-based software that can run directed energy deposition (DED) 3D printers automatically. To more successfully repair uneven surfaces on damaged components, the software will algorithmically regulate the printing process. The Fraunhofer Institute for Laser Technology (ILT) and a software company BCT are part of the German consortium. In Canada, the work will be overseen by the National Research Council of Canada (NRC). McGill University will coordinate the research, and machine learning firm Braintoy will help program the AI models.

- Furthermore, there have been various developments in the market by players to enhance their position in the market. For instance, in April 2021, Mosaic launched Array, an automated 3D printing platform, which loads and unloads materials for its four Element HT printers, starts prints, removes prints, and stores them so that the next prints can begin. The Array is designed for maximum flexibility with its vending machine-style robotic arm that removes prints, places them to the side, and loads a clean bed for the next print, ensuring maximum output.

- In October 2021, 3DQue, a Vancouver-based developer of automation technology for the 3D printing industry, announced the launch of two new Quinly automation kits for the Creality CR-10 and CR-6 SE. Quinly is a virtual 3D printer operator served by a Raspberry Pi, a hardware and software kit capable of running desktop 3D printers on its own. The technology is designed to make 3D printing more scalable by taking manual labor out of the equation. It is primarily aimed at print labs, on-demand manufacturers, educational institutions, and anyone else seeking automated mass part production.

- Additionally, due to the disruption of supply chains and new demands for treatments and materials, the COVID-19 pandemic has significantly accelerated technological advancements in the pharmaceutical, medical device, and manufacturing sectors. The supply chain shortages have made it hard for medical personnel to get the supplies they need, generating a shortage of personal protection equipment (PPE) and medical devices in hospitals for fighting off the virus. Owing to this, additive manufacturing (AM) (automated 3D printing) has emerged as one remarkable fabrication process because of its accessibility and flexibility to produce complex and monolithic parts or even mechanical systems quickly.

Automated 3D Printing Market Trends

The Automotive Segment is Expected to Drive the Market's Growth

- Automobiles are an essential part of human lives as the main mode of transportation today. Currently, there are over 1.3 billion motor vehicles on the road globally, with that number expected to rise to 1.8 billion by the year 2035. Passenger cars comprise roughly 74% of these statistics, while light commercial vehicles and heavy trucks, buses, coaches, and minibusses make up the remaining 26%.

- 3D printing can be used in making molds and thermoforming tools for the rapid manufacturing of grips, jigs, and fixtures. This allows automakers to produce samples and tools at low costs and eliminate future production losses when investing in high-cost tooling. The first-ever 3D-printed electric car was launched in 2014 by Local Motors. Subsequently, other established firms, like the BMW group, have also followed suit in terms of adopting automated 3D printing techniques. In several major US auto manufacturers, around 80%-90% of each initial prototype assembly has been 3D printed, with an increasing trend toward automation. Some of the popular components are parts of the exhaust, air intake, and ducting. These parts are designed digitally, 3D printed, and fitted on a car in short order, then tested through multiple iterations.

- Perhaps the most popular use of automated 3D printing in the automotive space is fabricating manufacturing aids like jigs and fixtures. Making manufacturing tools using traditional means is rather costly and time-consuming, and geometry limitations translate into less efficient manufacturing processes and more constraints on the geometry of end-use parts. Manufacturing tools that are 3D printed are lighter and more ergonomic, making it easier and safer for factory workers to perform their duties.

- Furthermore, the production volumes associated with automotive manufacturing are very high, tallying to hundreds of thousands of runs for every part. That would be difficult for most 3D printing technologies to keep up with (for now). But many high-end automobile manufacturers limit the production runs of their cars to only a few thousand units, which makes automated 3d printing a viable option.

- According to the World Economic Forum, more than 12 million fully autonomous cars are expected to be sold per year-on-year 2035, covering 25% of the global automotive market. Also, several initiatives taken by the electric motor manufacturers are leading to the growth of the market. In March 2020, UK-based engineering company Equipmake developed a power-dense permanent magnet electric motor. The motor was designed in collaboration with Hieta, a 3D printing specialist. Equipmake's Ampere motor will weigh near to 10kg but provide an output of 295bhp.

- Furthermore, Brackets are small and rather mundane parts, which were very difficult to optimize in the past time when engineers were constrained by the traditional manufacturing methods. Currently, engineers can design optimized brackets and bring these designs to life with the help of 3D printing. Rolls Royce recently showcased the capabilities of 3D printing for brackets. The company showed off a large batch of DfAM-optimized and 3D-printed automotive metal parts, many of which look to be bracketed. While prototyping remains the primary application of 3D printing within the automotive industry, using the technology for tooling is rapidly catching on. One major example of this is Volkswagen, which has been using 3D printing in-house for a number of years. Their binder jetting technology is also in use to construct the component. Also, in July 2021, Volkswagen stated that it is partnering with Siemens and HP to industrialize 3D printing of structural parts, which can be significantly lighter than equivalent components made of sheet steel.

North America is Expected to Hold a Major Market Share

- North America is one of the significant markets for Automated 3D printing globally, with the United States accounting for a significant share in the region. The country's rising demand can be attributed to the vast presence of small and big vendors. For instance, Forecast 3D in Carlsbad, CA, offers 3D printing services in a variety of materials to the healthcare, automotive, aerospace, consumer products, and design industries.

- Closed-loop control systems have long been a fundamental aim for additive manufacturing engineers due to the rapid development of powerful AI applications. For instance, Researchers at GE's Niskayuna Additive Research Lab, New York, created a proprietary machine-learning platform that uses high-resolution cameras to monitor the printing process layer by layer and detect streaks, pits, holes, and other problems that are typically invisible to the naked eye. Further, The data is compared in real-time to a pre-recorded flaws database utilizing computer tomography (CT) imaging. The AI system will be trained to forecast difficulties and detect flaws throughout the printing process using the high-resolution image and CT scan data.

- Furthermore, the market is witnessed with various technology patents for polymer 3D printing. For instance, in August 2020, PostProcess Technologies Inc., one of the providers of automated and intelligent post-printing solutions for industrial 3D printing, received a patent for automated post-printing technology for polymer 3D printing. The SVC technology is part of PostProcess's additive manufacturing family of 3D printed polymer support removal and resin removal solutions. This patented method uses patent-pending detergents and proprietary algorithms to ensure that 3D printed components are exposed to detergent and cavitation uniformly, consistently, and reliably during post-printing.

- Also, various vendors are expanding facilities into the region, primarily to address the supply chain challenges and growing demand in various end-user verticals. For instance, in February 2021, Roboze announced the opening of its US headquarters in Houston, Texas, to facilitate the reshoring of domestic production and address supply chain issues. Roboze will be able to increase its engineering and production capacity in the United States with plans to hire over 100 employees in the next two years and address a growing demand for 3D printing technology in industries such as aerospace, oil and gas, and mobility.

- Similarly, in April 2021, Roboze announced the launch of Roboze Automate, the industrial automation system to bring customized 3D printing with super polymers and composites into the production workflow for extreme end-user applications. The United States is experiencing a metals deficit that is affecting each of the industry areas as it begins an infrastructure push that spans from energy to transportation to manufacturing. Roboze combined its novel polymer platform technology, PEEK, an ideal metals replacement technology, with a PLC industrial automation system developed in partnership with B&R.

Automated 3D Printing Industry Overview

The automated 3D printing market is competitive and consists of several major players who are trying to gain a larger share, but top players have gained a major proportion of consumers and also investing in R&D and partnerships with hardware vendors for more developments and innovations. Some of the key players include Stratasys Ltd, 3D Systems Corporation, and The ExOne Company, among others.

- February 2022 - Viaccess-Orca, ShipParts.com, along with SLM Solutions, announced a new technology solution that enables direct Cloud-to-Print for additive manufacturing (AM). This fully automated software execution protects the manufacturer's intellectual property (IP) associated with part data by controlling the quantity, duration, and parameters of acceptable prints. Based on the native integration of VO's SMP software library and SLM Solutions machine firmware, this Cloud-to-Print solution allows manufacturers to be fully confident that their IP will be protected when printing is licensed.

- January 2022 - Materialise NV, a renowned provider of additive manufacturing (AM) software and services, Sigma Labs, Inc., a provider of quality assurance software, and Materialise, together have developed a technology to enhance the scalability of metal AM applications. The new platform combines Sigma Labs' PrintRite3D sensor technology to Materialise Control Platform to enable the users to identify and correct metal build issues in real-time.

- January 2022 - PostProcess Technologies announced the addition of a new solution lineup of automated, intelligent post-printing solutions for additive manufacturing (AM) to its portfolio. The new VORSA 500 leverages PostProcess technology for consistent, hands-free support structure removal on 3D printed FDM parts.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Value Chain Analysis

- 4.3 Industry Attractiveness - Porter's Five Forces Analysis

- 4.3.1 Threat of New Entrants

- 4.3.2 Bargaining Power of Buyers

- 4.3.3 Bargaining Power of Suppliers

- 4.3.4 Threat of Substitute Products

- 4.3.5 Intensity of Competitive Rivalry

- 4.4 Assestment of the Impact of COVID-19 on the Industry

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Increasing Investments in R&D

- 5.1.2 Growth in Adoption of Robotics for Industrial Automation

- 5.2 Market Challenges

- 5.2.1 Operational Challenges

6 MARKET SEGMENTATION

- 6.1 Offering

- 6.1.1 Hardware

- 6.1.2 Software

- 6.1.3 Services

- 6.2 Process

- 6.2.1 Automated Production

- 6.2.2 Material Handling

- 6.2.3 Part Handling

- 6.2.4 Post-Processing

- 6.2.5 Multiprocessing

- 6.3 End-user Vertical

- 6.3.1 Industrial Manufacturing

- 6.3.2 Automotive

- 6.3.3 Aerospace and Defense

- 6.3.4 Consumer Products

- 6.3.5 Healthcare

- 6.3.6 Energy

- 6.3.7 Other End-user Verticals

- 6.4 Geography

- 6.4.1 North America

- 6.4.2 Europe

- 6.4.3 Asia Pacific

- 6.4.4 Latin America

- 6.4.5 Middle-East and Africa

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Stratasys Ltd

- 7.1.2 Concept Laser Inc. (GE Additive)

- 7.1.3 The ExOne Company

- 7.1.4 SLM Solutions Group AG

- 7.1.5 3D Systems Corporation

- 7.1.6 Universal Robots AS

- 7.1.7 Formlabs

- 7.1.8 PostProcess Technologies Inc.

- 7.1.9 Materialise NV

- 7.1.10 Authentise Inc.

- 7.1.11 DWS Systems

- 7.1.12 Coobx AG

- 7.1.13 ABB Group