|

市场调查报告书

商品编码

1440188

自卸卡车和矿用卡车 - 市场份额分析、行业趋势与统计、成长预测(2024 - 2029 年)Dump Trucks and Mining Trucks - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

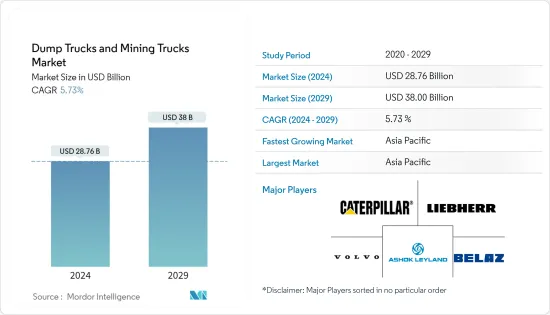

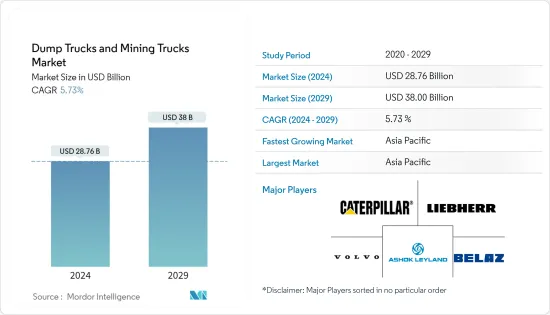

自卸车和矿用卡车市场规模预计到 2024 年为 287.6 亿美元,预计到 2029 年将达到 380 亿美元,在预测期内(2024-2029 年)CAGR为 5.73%。

由于对各种工业和基础设施项目开发所必需的矿物和矿石的持续需求,采矿活动增加,预计对矿用卡车的需求将会上升。全球采矿业需要更多熟练的人力资源。此外,在COVID-19爆发和产业停摆之后,这种情况预计将推动矿业公司提高生产效率,预计将推动更多矿用卡车的需求。此外,2021年是转型之年,采矿活动再次进入復原阶段,展现出巨大的成长潜力。

采矿业现在正面临政府严格的排放和进出口法规。必须提高生产力才能增加利润率。它促使公司透过安装感测器和分析资料来实现矿用卡车的自动化和电气化。随着全球电气化程度不断提高,原始设备製造商(OEM)正在提供电力传动系统。此外,包括远端资讯处理在内的技术方面也积极提高了需求。

预计亚太地区将拥有最大的采矿设备成长潜力,包括自卸车和矿用卡车等物料搬运设备。该地区的采矿产量和矿产潜力巨大,增加了自卸车和矿用卡车的需求。随着露天采矿产量的增加、设备维护的可预测性以及露天采矿的更换週期,该地区采矿设备的产量增加。

矿用自卸车市场趋势

预计电动卡车在预测期内将出现高成长率

过去几年,中国、印度和欧洲等自卸车和矿用卡车的重要市场都采用了严格的排放标准,如印度的巴拉特6标准、中国的国6标准和欧洲的欧6标准。它们使得电气化和混合动力化成为必要,特别是对于柴油引擎车辆,因为它们必须配备选择性催化还原(SCR)和废气再循环(EGR)技术。它将减少柴油引擎的硫烟灰和其他硫基排放。这些系统安装到柴油引擎中进一步推高了柴油车辆的价格,包括自卸卡车和矿用卡车。美国等许多国家也透过最近通过的《通货膨胀削减法案》为购买电动卡车提供直接税收抵免,从而促进电动卡车的销售。由于矿用卡车排放量占矿山总排放量的 60% 以上,因此这些措施预计将促进电动卡车在采矿业的采用。例如,

2022 年 9 月,瑞典 Kaunis Iron 开始与沃尔沃卡车合作测试 74 吨电动卡车。这些卡车经过测试,可在瑞典北部 Kaunisvaara 和 Pitkajarvi 之间 160 公里的公路上运输铁矿石。 Kaunis Iron 计划投资 5 亿瑞典克朗(4,800 万美元)使其卡车车队完全电气化。此外,矿业公司和原始设备製造商之间签订的在其矿山测试和部署电动运输卡车的重要合约进一步推动了电动自卸卡车和矿用卡车在全球的采用。例如,

2022 年 9 月,总部位于澳洲的 Newcrest Mining 宣布,它正在慢慢倾向于将其位于加拿大不列颠哥伦比亚省的 Brucejackgold 银矿的整个柴油卡车车队电气化为电池电动。这一转变预计到 2030 年将为 Newcrest Mining 减少 65,000 吨二氧化碳排放量。 Newcrest Mining 预计其整个车队(由12 辆柴油动力卡车组成)的电气化改造将于2022 年底完成。Newcrest Mining 的子公司Pretium Resources Inc. 于2020 年在其矿场完成了山特维克Z50 电池电动运输卡车试验。

由于基础设施领域的上述情况和发展,预计市场在预测期内将出现乐观增长。

预计亚太地区将在预测期内引领市场

亚太地区自卸车和矿用卡车市场成长的关键因素之一是中国、印度、日本、澳洲等国家采矿活动的增加。在中国东部,政府在家庭中安装了燃气管道但尚未定期供应天然气。它增加了人们用于取暖的煤炭消耗量。中国最大的煤炭生产省份山西放宽了严格的政府政策,并计划新增近1,100万吨焦炭产能以满足不断增长的需求。

中国的目标是尽量减少对煤炭进口的依赖。国家发展与改革委员会(原国家计委、国家发展计画委员会)表示,2021年全国煤炭产量将超过40亿吨。并争取新增煤炭产量3亿吨,相当于中国每年的进口量。预计这将大幅减少对煤炭进口的依赖。俄罗斯入侵乌克兰后,世界价格创下历史新高,产能的增加将减少该国对海外进口的依赖。此外,中国也是最大的钢铁生产国,全球约一半的钢铁产自中国。中国也生产全球约90%的稀土金属。

此外,印度对亚太地区矿业产量的提升也做出了同样的贡献。据印度矿业部称,截至 2022 财年,已有 1,245 个註册矿场在当前情况下积极报告并生产稳定的吞吐量。由于采矿业的巨大活动,该行业的各个利益相关者一直在引入新一代矿场矿物运输技术。例如,

2021 年9 月,印度煤炭有限公司与国有天然气公用事业公司GAIL 和印度采矿设备OWM BEML 签署了一份谅解备忘录,开展一个试点项目,使用液化天然气作为该国现有矿用自卸卡车的双燃料运转的替代燃料。为了减少碳排放,这些公司表示,他们已开始在奥里萨邦贾尔苏古达地区拉坎普尔矿的两辆100 吨级自卸卡车上安装液化天然气转换套件,该矿场是Mahanadi Coalfields Ltd (MCL) 的一部分。

区域参与者正在从建筑和采矿公司获得新合约。上述所有发展预计将有助于预测期内的市场成长。

矿用自卸车产业概况

全球自卸车和矿用卡车市场适度整合,活跃的本地和国际参与者数量有限。市场上一些主要的参与者包括卡特彼勒公司、斗山工程机械、日立建机、利勃海尔集团等。这些公司正在开发新技术并将其添加到现有车型中,推出新车型,并进入新的和未开发的市场。

矿业公司正在投资建立自己的业务,这可能为多家采矿设备製造商提供机会。例如,2021年3月,力拓公司宣布将在美国肯尼科特矿场开始生产碲。该公司宣布投资290万美元用于金属回收工艺,产能将达到每年20吨。这种金属用于生产光伏电池。

额外的好处:

- Excel 格式的市场估算 (ME) 表

- 3 个月的分析师支持

目录

第 1 章:简介

- 研究假设和市场定义

- 研究范围

第 2 章:研究方法

第 3 章:执行摘要

第 4 章:市场动态

- 市场驱动因素

- 市场限制

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 买家/消费者的议价能力

- 新进入者的威胁

- 替代产品的威胁

- 竞争激烈程度

第 5 章:市场区隔(市场规模,价值十亿美元)

- 按卡车类型

- 侧卸车

- 后自卸车

- 按燃料类型

- 内燃机

- 电的

- 按容量类型

- 200吨以下

- 超过200吨

- 按应用类型

- 矿业

- 建造

- 其他的

- 按地理

- 北美洲

- 美国

- 加拿大

- 北美其他地区

- 欧洲

- 德国

- 英国

- 法国

- 俄罗斯

- 欧洲其他地区

- 亚太地区

- 印度

- 中国

- 日本

- 韩国

- 澳洲

- 亚太其他地区

- 世界其他地区

- 巴西

- 墨西哥

- 阿拉伯聯合大公国

- 其他国家

- 北美洲

第 6 章:竞争格局

- 供应商市占率

- 公司简介

- Caterpillar, Inc.

- Hitachi Construction Machinery Co. Ltd.

- Komatsu Ltd.

- Liebherr Group

- BAS Mining Trucks

- Sany Heavy Industry Co., Ltd.

- Volvo Group

- Daimler Group

- BelAZ

- Ashok Leyland Ltd.

- Doosan Infracore

第 7 章:市场机会与未来趋势

The Dump Trucks and Mining Trucks Market size is estimated at USD 28.76 billion in 2024, and is expected to reach USD 38 billion by 2029, growing at a CAGR of 5.73% during the forecast period (2024-2029).

The demand for mining trucks is expected to rise on the backdrop of increased mining activity due to continuous demand for minerals and ores, which are necessary for various industries and infrastructural project development. The global mining industry needs more skilled human resources. Moreover, in the wake of the COVID-19 outbreak and industries shut down, the situation is expected to drive the mining companies to improve their production efficiency, which in turn is expected to drive the demand for more mining trucks. Moreover, 2021 was the year of transition where the mining activities again took their recovery phase exhibiting immense growth potential.

The mining industry is now witnessing the government's stringent emission and import-export regulations. Productivity must get improved to increase the profit margins. It is causing companies to automate and electrify mining trucks by installing sensors and analyzing their data. OEM is offering electric power trains amid rising electrification globally. In addition, technological aspects, including telematics, have also elevated the demand positively.

The Asia-pacific region is expected to hold the highest potential for the growth of mining equipment, including material handling equipment like Dump and mining trucks. The area offers immense potential in mining output and mineral mines, elevating the demand for dump trucks and mining trucks. With the increased production in surface mining, the predictable nature of equipment maintenance, and the replacement cycle in surface mining, the region observed an increase in the production of mining equipment.

Mining Dump Truck Market Trends

Electric Trucks are Projected to Witness a High Growth Rate During the Forecast Period

Over the past few years, significant markets for dump and mining trucks like China, India, and Europe have adopted stringent emissions norms, like Bharat 6 in India, China 6 standards in China, and Euro 6 in Europe. They have made electrification and hybridization necessary, especially for diesel engine vehicles, as they must be equipped with Selective Catalytic Reduction (SCR) and Exhaust Gas Recirculation (EGR) technologies. It will reduce the sulfur soot and other sulfur-based emissions from diesel engines. These systems' installation into diesel engines further pushed diesel vehicle prices, including dump trucks and mining trucks. Many countries like the United States are also promoting electric truck sales by providing direct tax credits for electric truck purchases through the recently passed Inflation Reduction Act. These measures are expected to boost electric truck adoption in the mining sector since mining trucks account for more than 60% of the total emissions from mines. For instance,

In September 2022, Kaunis Iron in Sweden began testing 74-ton electric trucks in association with Volvo Trucks. The trucks were tested to transport iron ore over a 160 km road between Kaunisvaara and Pitkajarvi in northern Sweden. Kaunis Iron plans to invest SEK 500 million (USD 48 million) to electrify its truck fleet completely. Additionally, significant contracts between mining companies and OEMs to test and deploy electric haul trucks at their mines are further boosting the adoption of electric dump and mining trucks worldwide. For instance,

In September 2022, Australia-based Newcrest Mining announced that it is slowly inclining its way towards electrifying its entire diesel truck fleet to battery-electric at its Brucejackgold-silver mine in British Columbia, Canada. This transition is expected to save 65000 tons CO2 emissions by 2030 for Newcrest Mining. Newcrest Mining expects the evolution of its entire fleet of 12 diesel-powered trucks to electrification to be completed by the end of 2022. Newcrest Mining's subsidiary Pretium Resources Inc. completed the Sandvik Z50 battery-electric haul truck trials at their mine in 2020.

Due to the abovementioned instances and developments in the infrastructure sector, the market is expected to witness optimistic growth over the forecast period.

Asia-Pacific is Projected to Lead the Market During the Forecast Period

One of the critical factors in the growth of the Asia-Pacific dump trucks and mining trucks market is the increase in mining activities in countries such as China, India, Japan, Australia, etc. In eastern China, the government fitted gas pipelines in households but had not yet supplied gas regularly. It increases the consumption of coal by people for heating purposes. China's largest coal-producing province, Shanxi, provided relaxation on stringent government policies and plans to add nearly 11 million tons of coke-producing capacities to meet growing demand.

China is aiming to minimize its coal import dependency. The NDRC (National Development and Reform Commission), formerly State Planning Commission and State Development Planning Commission, stated that the country produced more than 4 billion tons of coal in 2021. Further, they are striving to increase their coal output by 300 million tons, equal to China's annual import. It is expected to cut the reliance on coal imports dramatically. A rise in capacity would reduce the country's dependence on overseas imports after record-high world prices were hit in the wake of Russia's invasion of Ukraine. In addition, China is the largest steel producer, and about half of the world's steel is produced in the country. China also produces around 90% of the world's rare earth metals.

Moreover, India contributed equally to elevating the Asia-Pacific region's mining output. According to the Ministry of Mines in India, as of FY 2022, 1,245 mines were registered to report and produce steady throughput in the current scenario actively. Due to the immense activity from the mining industry, various stakeholders operating in the industry have been introducing new generation technologies for mineral hauling from the mine sites. For instance,

In September 2021, Coal India Limited signed an MoU with state gas utility GAIL and Indian mining equipment OWM BEML for a pilot project to use LNG as an alternative fuel for dual fuel operation of existing mining dump trucks in the country. Intending to reduce carbon emissions, the companies say they have initiated the process of fitting LNG conversion kits on two 100-ton class dump trucks at the Lakhanpurmine in Jharsuguda district, Odisha, part of Mahanadi Coalfields Ltd (MCL).

Regional players are getting new contracts from construction and mining companies. All the developments above are expected to help the market growth over the forecast period.

Mining Dump Truck Industry Overview

The global dump trucks and mining trucks market is moderately consolidated, with a limited number of active local and international players. Some major players in the market are Caterpillar, Inc., Doosan Infracore, and Hitachi Construction Machinery Co., Ltd., Liebherr Group, amongst others. The companies are developing and adding new technologies to their existing models, launching new models, and tapping into new and unexplored markets.

Mining companies are investing in setting up their operation, which might act as an opportunity pocket for several mining equipment manufacturers. For instance, in March 2021, Rio Tinto Company announced that it would start Tellurium production in Kennecott mine, US. The company announced an investment of USD 2.9 million for the metal recovery process and will have a production capacity of 20 tons per year. This metal is used in the production of photovoltaic cells.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Drivers

- 4.2 Market Restraints

- 4.3 Industry Attractiveness - Porter's Five Forces Analysis

- 4.3.1 Bargaining Power of Suppliers

- 4.3.2 Bargaining Power of Buyers/Consumers

- 4.3.3 Threat of New Entrants

- 4.3.4 Threat of Substitute Products

- 4.3.5 Intensity of Competitive Rivalry

5 MARKET SEGMENTATION (Market Size in Value USD Billion)

- 5.1 By Truck Type

- 5.1.1 Side dump truck

- 5.1.2 Rear Dump truck

- 5.2 By Fuel Type

- 5.2.1 IC Engine

- 5.2.2 Electric

- 5.3 By Capacity Type

- 5.3.1 Less than 200 metric ton

- 5.3.2 More than 200 metric ton

- 5.4 By Application Type

- 5.4.1 Mining

- 5.4.2 Construction

- 5.4.3 Others

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Rest of North America

- 5.5.2 Europe

- 5.5.2.1 Germany

- 5.5.2.2 United Kingdom

- 5.5.2.3 France

- 5.5.2.4 Russia

- 5.5.2.5 Rest of Europe

- 5.5.3 Asia Pacific

- 5.5.3.1 India

- 5.5.3.2 China

- 5.5.3.3 Japan

- 5.5.3.4 South Korea

- 5.5.3.5 Australia

- 5.5.3.6 Rest of Asia-Pacific

- 5.5.4 Rest of the World

- 5.5.4.1 Brazil

- 5.5.4.2 Mexico

- 5.5.4.3 United Arab Emirates

- 5.5.4.4 Other Countries

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Vendor Market Share

- 6.2 Company Profiles*

- 6.2.1 Caterpillar, Inc.

- 6.2.2 Hitachi Construction Machinery Co. Ltd.

- 6.2.3 Komatsu Ltd.

- 6.2.4 Liebherr Group

- 6.2.5 BAS Mining Trucks

- 6.2.6 Sany Heavy Industry Co., Ltd.

- 6.2.7 Volvo Group

- 6.2.8 Daimler Group

- 6.2.9 BelAZ

- 6.2.10 Ashok Leyland Ltd.

- 6.2.11 Doosan Infracore