|

市场调查报告书

商品编码

1445525

生物基聚丙烯:市场占有率分析、产业趋势与统计、成长预测 (2024:2029)Bio-based Polypropylene - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

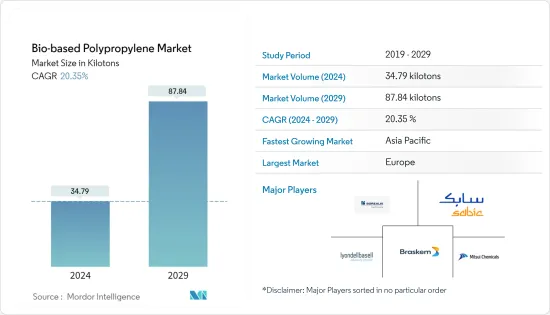

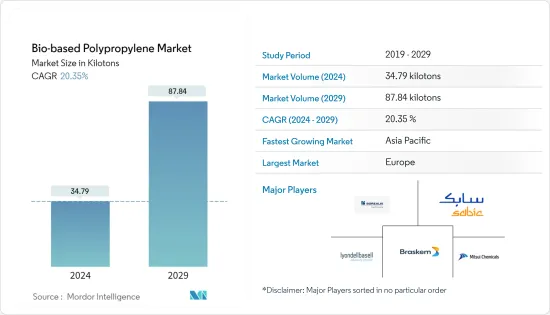

2024年生物基聚丙烯市场规模预计为34,790 MT,预计到2029年将达到87,840 MT,在预测期内(2024-2029年)复合年增长率为20.35%增长。

由于原料短缺和产品需求减少,COVID-19 的影响是负面的。然而,疫情过后,纺织业的激增促进了生物基聚丙烯的消费。

主要亮点

- 推动市场的主要因素是对传统塑胶使用的环境担忧日益加剧,以及越来越多地用可再生材料取代化石原料。

- 另一方面,生物基材料的高成本阻碍了市场成长。

- 政府加大鼓励生物基材料使用的诱因预计将为市场提供新的机会。

- 由于德国和法国的需求激增,预计欧洲将主导研究市场。

生物基聚丙烯市场趋势

射出成型应用的需求不断成长

- 生物基聚丙烯由于其高熔点、优异的疲劳性能、耐热性和耐化学性以及环保性,被用于包装、汽车、电子和医疗产业的各种射出成型应用。

- 包装应用对生物基聚丙烯的需求正在稳步增长,例如有机食品或具有特定要求的奢侈品牌产品的包装。

- 此外,世界各国政府正在创新、资源效率和气候变迁等各种政策的背景下推广生质塑胶包装。

- 最近的一项消费者调查发现,永续性是全球 60% 消费者重视的购买标准,其中美国为 61%,略高于全球平均。

- 此外,中国大量生产塑料,并透过贸易出口获得收入。这为各种包装公司创造了巨大的生产能力。根据ITC统计,2021年,中国出口塑胶及製品价值约1,310.7亿美元,较上年(2020年)成长36%,出口额约963.8亿美元。

- 2021年全球生质塑胶产能成长16%,达到240万吨。 2021年可生物分解性生质塑胶占总产能160万吨。

- 据 Middelharnis射出成型专家 SFA Packaging 称,大多数食品均采用射出成型聚丙烯包装出货。

- 环境问题导致更多消费者和製造商更喜欢环保包装选择,从而推动了对生物基聚丙烯市场的需求。

欧洲主导市场

- 欧洲是生物基聚丙烯产业的重要枢纽,约占50%的市场占有率。我们在该行业的研发方面排名靠前。

- 大多数欧洲国家对生物分解性塑胶(包括生物基聚丙烯)的使用有严格的政府法规。政府不断提倡使用环保产品。

- 生物基聚丙烯主要用于包装产业。欧洲是包装行业的主要消费者之一,并开发了各种包装细分市场。

- 德国是欧洲最大的塑胶消费国。包装行业塑胶使用量的增加增加了对塑胶的需求。 2021 年,德国包装产业创造了 296 亿欧元(345.5 亿美元)的收益。与前一年相比减少至 263 亿欧元(307 亿美元)。

- 此外,德国政府也提倡在包装产业中使用生物基和回收材料。例如,德国上议院联邦参议院核准了一项新的包装方法,鼓励包装废弃物的回收。这对于生质塑胶产业来说是一个重要讯号。因为生物基材料和回收材料首次被认为是同样可行的解决方案,可以使包装更具永续并减少对有限化石资源的依赖。

- 此外,多年来电子商务行业的普及和零售市场的成长为该地区的生物基聚丙烯市场提供了巨大的成长机会。

- 2021年,德国B2C电子商务产业创造了约867亿欧元(1,010亿美元)的收入。自 COVID-19感染疾病在全球蔓延以来,网路购物有所增加。在电子商务领域,德国2021年排名第六,仅次于中国、美国、英国、日本和韩国。特别是,行动商务变得越来越重要。目前,有72.6亿人使用智慧型手机,预计到2026年这数字将达到75亿人。

- 上述因素预计将在未来几年推动欧洲生物基聚丙烯市场的发展。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3 个月分析师支持

目录

第一章简介

- 调查先决条件

- 调查范围

第二章调查方法

第三章执行摘要

第四章市场动态

- 促进因素

- 关于使用传统塑胶的环境问题日益严重

- 可可再生材料越来越多地取代化石原料

- 抑制因素

- 昂贵的生物基材料

- 其他限制因素

- 产业价值链分析

- 波特五力分析

- 供应商的议价能力

- 消费者议价能力

- 新进入者的威胁

- 替代产品和服务的威胁

- 竞争程度

第五章市场区隔

- 目的

- 射出成型

- 纺织品

- 电影

- 其他用途

- 地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 其他亚太地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 其他欧洲国家

- 世界其他地区

- 亚太地区

第六章 竞争形势

- 併购、合资、合作与协议

- 市场占有率(%)**/排名分析

- 主要企业采取的策略

- 公司简介

- Biobent Management Services Inc.

- Borealis AG

- Borouge

- Braskem

- FKuR

- INEOS

- INTER Ikea SYSTEMS BV

- LyondellBasell Industries Holdings BV

- Mitsui Chemicals Inc.

- SABIC

第七章市场机会与未来趋势

- 政府加大奖励措施,促进生物基材料的使用

- 其他机会

The Bio-based Polypropylene Market size is estimated at 34.79 kilotons in 2024, and is expected to reach 87.84 kilotons by 2029, growing at a CAGR of 20.35% during the forecast period (2024-2029).

The impact of COVID-19 was negative due to the raw materials shortage and declined demand for the product. However, an upsurge in the textile industry propelled bio-based polypropylene consumption after the pandemic.

Key Highlights

- The major factors driving the market are the rising environmental concerns regarding using conventional plastics and the increasing replacement of fossil-based feedstock with renewable materials.

- On the flip side, the high cost of bio-based materials is hindering the market's growth.

- Increasing incentives by the government promoting bio-based materials use is expected to provide new opportunities for the market.

- Europe is estimated to dominate the market studied owing to the surging demand in Germany and France.

Bio-based Polypropylene Market Trends

Growing Demand from Injection Molding Application

- Due to its high melting point, good fatigue properties, heat and chemical resistivity, and eco-friendly nature, bio-based polypropylene is used in various injection molding applications in packaging, automotive, electronics, and medical industries.

- The demand for bio-based polypropylene in packaging applications, such as wrapping organic food and premium and branded products with particular requirements, is rising steadily.

- Moreover, governments worldwide are promoting bioplastic packaging in the context of various policies for innovation, resource efficiency, and climate change.

- According to a recent consumer study, sustainability is a valuable purchase criterion for 60% of consumers globally, with the US boasting a percentage a little above the global average at 61%.

- Furthermore, China is significantly involved in producing high amounts of plastics, generating revenues from trade exports. It is, thereby, creating significant production capacities for various packaging companies. According to ITC, in 2021, China exported plastics and articles valued at about USD 131.07 billion, a 36% rise in exports from the previous year (2020), valued at around USD 96.38 billion.

- The global production capacity of bioplastics increased by 16% in 2021 to 2.4 million metric tons. Biodegradable bioplastics accounted for 1.6 million metric tons of the total capacity in 2021.

- According to the injection mold specialist SFA Packaging from Middelharnis, most foods come in injection mold packaging made of polypropylene.

- Due to environmental concerns, more consumers and manufacturers are preferring eco-friendly packaging options, boosting the demand for the bio-based polypropylene market.

Europe to Dominate the Market

- Europe is a significant hub for the bio-based polypropylene industry, with about 50% of the market share. It ranks high in R&D in this industry.

- Government regulations in most European countries regarding using bio-degradable plastics, including bio-based polypropylene, are stringent. The government is continuously pushing the usage of eco-friendly products.

- Bio-based polypropylenes are majorly used in the packaging industry. Europe is one of the leading consumers in the packaging industry and is developing various packaging segments.

- Germany is the largest plastic consumer in Europe. The increasing plastic usage in the packaging industry propelled the plastic demand. In 2021, the packaging industry in Germany generated EUR 29.6 billion (USD 34.55 billion) in revenue. It decreased compared to the previous year to EUR 26.3 billion (USD 30.70 billion).

- Moreover, the German government is promoting bio-based and recycled materials used in the packaging industry. For instance, Germany's Bundesrat, the upper house of parliament, approved a new packaging law to boost the recycling of packaging waste. It is an important signal for the bioplastics industry as, for the first time, bio-based and recycled materials are recognized as equally viable solutions to make packaging more sustainable and reduce our dependency on finite fossil resources.

- Additionally, the popularity of the e-commerce segment and the growing retail market gave a vast growth opportunity to the bio-based polypropylene market in the region through the years.

- In 2021, the B2C e-commerce sector in Germany generated around EUR 86.7 billion (USD 101 billion). Online shopping is on the rise after COVID-19 spread across the globe. In the e-commerce sector, Germany was in sixth place after China, the United States, Great Britain, Japan, and South Korea, in 2021. In particular, mobile commerce is becoming increasingly important. Currently, 7.26 billion people use smartphones, and this is estimated to reach 7.5 billion by 2026.

- The abovementioned factors are expected to drive the market for bio-based polypropylene in Europe in the coming years.

Bio-based Polypropylene Industry Overview

The bio-based polypropylene market is partially consolidated, with the major players dominating a significant portion. Some companies operating in the market (in no particular order) are Borealis AG, Braskem, Mitsui Chemicals Inc., SABIC, and LyondellBasell Industries Holdings BV.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Rising Environmental Concerns Regarding the Usage of Conventional Plastics

- 4.1.2 Increasing Replacement of Fossil-based Feedstock with Renewable Materials

- 4.2 Restraints

- 4.2.1 High Cost of Bio-based Materials

- 4.2.2 Other Restraints

- 4.3 Industry Value Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Consumers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION (Market Size in Volume)

- 5.1 Application

- 5.1.1 Injection Molding

- 5.1.2 Textiles

- 5.1.3 Films

- 5.1.4 Other Applications

- 5.2 Geography

- 5.2.1 Asia-Pacific

- 5.2.1.1 China

- 5.2.1.2 India

- 5.2.1.3 Japan

- 5.2.1.4 South Korea

- 5.2.1.5 Rest of Asia-Pacific

- 5.2.2 North America

- 5.2.2.1 United States

- 5.2.2.2 Canada

- 5.2.2.3 Mexico

- 5.2.3 Europe

- 5.2.3.1 Germany

- 5.2.3.2 United Kingdom

- 5.2.3.3 France

- 5.2.3.4 Italy

- 5.2.3.5 Rest of Europe

- 5.2.4 Rest of the World

- 5.2.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Share(%)**/Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 Biobent Management Services Inc.

- 6.4.2 Borealis AG

- 6.4.3 Borouge

- 6.4.4 Braskem

- 6.4.5 FKuR

- 6.4.6 INEOS

- 6.4.7 INTER Ikea SYSTEMS BV

- 6.4.8 LyondellBasell Industries Holdings BV

- 6.4.9 Mitsui Chemicals Inc.

- 6.4.10 SABIC

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Increasing Incentives by the Government Promoting the Usage of Bio-based Materials

- 7.2 Other Opportunities