|

市场调查报告书

商品编码

1521625

卫生纸加工机:市场占有率分析、产业趋势、成长预测(2024-2029)Tissue Paper Converting Machines - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

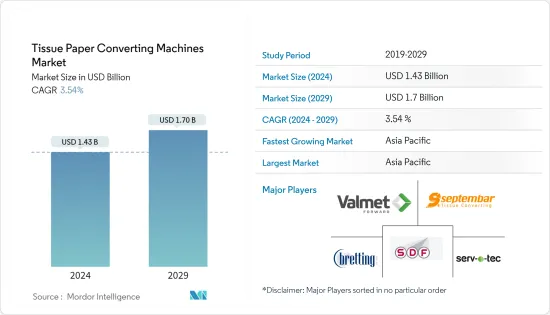

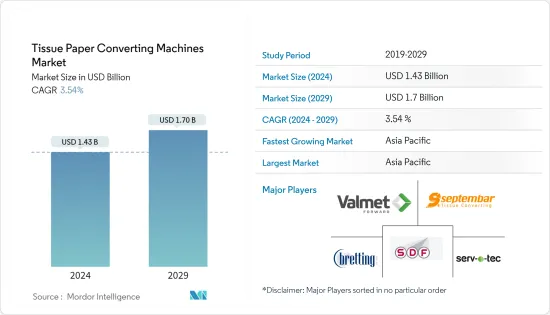

生活用纸加工机械市场规模预计到 2024 年为 14.3 亿美元,预计到 2029 年将达到 17 亿美元,在预测期内(2024-2029 年)复合年增长率为 3.54%。

薄页纸的生产对环境有巨大的影响。生活用纸由回收的废纸和原浆製成,会产生温室气体排放(原浆估计比废纸多排放 30%)。随着人们对环境永续性的日益关注,卫生纸加工机械製造商正在广泛实施绿色製造模式。这包括使用回收材料、减少水和能源消耗以及采用尽量减少对环境影响的製程。

主要亮点

- 在生活用纸製造中,研发集中在几个主要领域,包括节能、纤维节省、最终产品品质和机器运作能力。引流和流浆箱是卫生纸生产中能源最集中的阶段。製造商正在积极探索新的智慧选项来优化该区域,实现更好的浆料均质化,促进更快的等级变化,并增加流浆箱的高度,以实现一致性。这些努力对于提高整个流程的效率、降低能源消耗、提高薄页纸产品的品质至关重要。

- 智慧技术与自动化的整合正在兴起,有助于提高整体工作效率、减少浪费并提高准确性。此外,随着人事费用的上升和对更高效率的要求,对高速、全自动加工线的需求正在扩大。全自动加工机器连接缠绕和包装等不同流程,消除浪费并减少人工干预的需要。随着领先公司向新的製造领域扩张,他们正在大力投资利用尖端机器人、视觉和人工智慧进行最佳化。

- 创新的加工技术有助于有效利用原料,特别是纸纤维。精密切割和压花技术是减少材料浪费的方法的例子,先进的控制系统优化了製造过程中的水和化学品消耗。

- 建立卫生纸加工厂所需的初始投资包括取得土地、建造或重建建筑物、购买和安装机械以及开发基础设施的费用。大部分资金用于流动资金,但机械设备费用可占总投资的25%以上。确保足够的资金来支付这些成本可能很困难,特别是对于小型新业务而言。有限的财务资源、风险意识和监管合规性等因素使资金筹措过程更加复杂。为了应对这些挑战,公司可以寻求合作伙伴关係,考虑政府支持计划,制定全面的产业计画,并优化成本以提高财务可行性。

- 根据AFRY(造纸业专家)和Suzano(全球领先的纸张和纸浆製造商)发布的报告,全球纸张消费量将从2021年的4,100万吨增加到2032年的5,500万吨,预计将大幅增加。全球对生活用纸不断增长的需求将为许多中小型生产商进入生活用纸製造业创造机会,这可能会增加对加工机械的需求。

生活用纸加工机械市场趋势

卫生捲纸加工线成为最大的机器类型部分

- 包括厕所用卫生纸在内的普通生活用纸产品占据了加工机械市场的大部分。由于人口增长、都市化和卫生标准提高等因素,厕所用卫生纸的需求预计将稳步增长。

- 根据人口研究所预测,2023年全球都市化率为57%。北美、拉丁美洲和加勒比海地区是都市化最高的地区,五分之四以上的人口居住在都市区。

- 此外,针对湿纸巾应用的加工设备製造商可以透过开发能够高效生产高品质、防潮纸巾的机器而受益。此外,湿纸巾包装和分配器系统的创新为製造商提供了实现机器产品差异化并响应不断变化的市场需求的机会。

- 日益增长的环境问题和消费者对永续性议题的认识不断提高,正在推动厕所用卫生纸纸业采用环保做法。製造商正在投资可加工再生纤维、减少废弃物并最大限度降低能源消耗的加工设备。对生物分解性和环保厕所用卫生纸产品的需求促使製造商投资于能够处理物料输送的机械。

- 此外,消费者对个人化和创新厕所用卫生纸产品的偏好促使製造商投资灵活的加工设备。需要能够生产各种产品的机器,包括不同的纸张尺寸、层配置、压花图案和包装选项。定制能力使製造商能够瞄准利基市场并在竞争格局中使他们的产品脱颖而出。此外,可支配收入较高的消费者倾向于购买和投资更多豪华压花卫生纸。

- 纸巾产品製造商认识到消费者对压花纸巾有美学。品牌通常使用压花来增强独特的图案、标誌和其他特殊功能,以提高消费者的忠诚度和一致的购买意愿。儘管压花卫生纸特别适合美学吸引力和其他消费者偏好,但重要的是不要忽视产品的品质。

- 压花会影响组织特性,尤其是机械强度和硬度。透过设计正确的压花图案和工艺,正确的组合可以促进层压,从而产生客户认为高品质的多层成品。透过与压花专家合作,您可以在品质和美观方面使您的卫生纸产品脱颖而出。

亚太地区预计将占据主要市场占有率

- 日本在成田国际机场的厕所里安装了一项独特的功能:智慧型手机清洁纸,从而提高了其清洁声誉。为了提高公共便利性,人们采取了一种新颖的方法,鼓励人们从厕所用卫生纸旁的分配器中取出一张纸来消毒智慧型手机萤幕。这种清洁纸的推出是基于研究结果,该结果表明智慧型手机萤幕上比马桶座圈上更容易生长细菌。研究表明,海外游客一直对日本公共卫生间的清洁度和适应性感到惊讶。预计这将对目标市场产生影响。

- 印度的卫生纸产业目前正在透过创新和收购进行整合。这使得公司能够提高市场地位、扩大产品范围并投资先进的加工技术来满足不断增长的需求。都市化的加速、Swachh Bharat 等政府倡议对卫生的日益关注,以及医疗保健和酒店业需求的大幅增加,预计将推动纸巾、餐巾纸、厕所用卫生纸和毛巾纸的消费。

- 2024 年 1 月,製浆造纸行业领先公司安得拉纸业有限公司 (APL) 获得董事会核准,在其 Kadiyam 工厂安装最先进的卫生纸机。该机器采用最先进的技术,生产能力为每天 100 吨,使公司能够实现产品系列的多样化。拟增加产能为每年 35,000 吨(TPA),生产各种等级的面纸、厕所纸、餐巾纸、毛巾等。该公司计划在 15 个月内开始生产。

- 为了加强我们在中国国内市场的生产能力,我们进口了包括最新TAD技术的高端卫生纸机。例如,恆安新增两台维美德混合型卫生纸机,主要用于生产优质面纸和厨房纸巾。

- 此前,恆钢已安装了两台拓斯克TAD卫生纸机。第一步是利用先进技术和设备开发差异化产品,提升产品的使用效能。例如,新的卫生纸机械技术和加工机械推出了厚度改进的产品。 Mind Act Upon Mind的云系列纸巾、维达的羊绒感官系列卫生纸以及Villejoy的采用TAD技术的热风厨房毛巾都是此类产品发布的一些例子。

- 印尼造纸业蓬勃发展,卫生纸机市场预计将成长。这种增长是由对薄纸产品的需求快速增长、对製造能力的投资、技术进步和不断变化的环境考虑所推动的。

- 卫生纸机供应商可以透过提供创新解决方案并满足纸张製造商的特定需求来利用这些机会。 2023年11月,印尼国际纸链工业展(Paper Chain Indonesia)在印尼雅加达JIEXPO展览中心拉开序幕。

生活用纸加工机械产业概况

卫生纸加工机械市场高度分散。主要公司包括 CG Bretting Manufacturing Company, Inc.、Valmet Oyj、9 September Tissue Converting、Serv-o-Tec GmbH 和 SDF Schnitt-Druck-Falz Spezialmaschinen GmbH。市场参与者正在采取联盟和收购等策略来加强其产品供应并获得永续的竞争优势。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3 个月分析师支持

目录

第一章简介

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章市场洞察

- 市场概况

- 产业吸引力-波特五力分析

- 产业生态系分析-供应商、材料製造商等。

第五章市场动态

- 市场驱动因素

- 卫生纸製造业自动化趋势不断发展

- 加工技术创新提高永续性

- 市场限制因素

- 薄页纸加工厂设备成本高

- 主要技术创新与发展—生活用纸加工设备及辅助设备

- 行业标准和法规

第六章 市场细分

- 依技术

- 自动的

- 半自动

- 按机器类型

- 卫生纸加工线

- 厨房捲纸

- 折迭式纸巾生产线

- 餐巾纸加工线

- 独立系统

- 按地区

- 北美洲

- 美国

- 加拿大

- 欧洲

- 德国

- 法国

- 义大利

- 英国

- 亚洲

- 日本

- 印度

- 中国

- 印尼

- 澳洲/纽西兰

- 拉丁美洲

- 中东/非洲

- 北美洲

第七章生活用纸需求趋势及其对生产设备市场的影响

第八章 卫生纸加工机械市场趋势

- 未来市场趋势及主要成长预期

- 製造商面临的主要挑战与 OMET 主要竞争对手的创新

- 比较分析 - OMET Srl 与 OMET Srl 主要竞争对手

- 技术见解 - 组织加工机

第9章 竞争格局

- 公司简介

- CG Bretting Manufacturing Company, Inc.

- Valmet Oyj

- 9.Septembar Tissue Converting

- SERV-O-TEC GMBH

- SDF Schnitt-Druck-Falz Spezialmaschinen GmbH

- ZAMBAK KAGIT

- Omet Srl

- Kawanoe Zoki Co. Ltd

- MTorres Disenos Industriales SAU

- Baosuo Paper Machinery Manufacture Co. Ltd(Baosuo Enterprise)

- A.Celli Paper SpA(italia Technology Alliance SpA)

- United Converting Tissue SRL

- Futura SpA

- Paper Converting Machine Company(PCMC)

- Fujian Tmx Machinery Manufacturing Co. Ltd

- Chan Li Machinery Co. Ltd

- Unimax Group Engineering & Development Corporation

- ICM Makina

第十章 客户名单

The Tissue Paper Converting Machines Market size is estimated at USD 1.43 billion in 2024, and is expected to reach USD 1.70 billion by 2029, growing at a CAGR of 3.54% during the forecast period (2024-2029).

Tissue paper production has a significant impact on the environment. Tissue paper is made from recycled wastepaper and virgin pulp, contributing to greenhouse gas emissions (estimates state that virgin pulp contributes 30% more than wastepaper). With the escalating concerns about environmental sustainability, tissue paper converting equipment manufacturers are extensively implementing green manufacturing models. This includes using recycled materials, reducing water and energy consumption, and adopting processes that minimize environmental impact.

Key Highlights

- In tissue paper manufacturing, research and development efforts remain focused on several key areas, including energy saving, fiber saving, final product quality, and the ability to run the machine. The approach flow and headbox area are some of the most energy-intensive stages in tissue-making. Manufacturers are actively exploring new smart options to optimize this area, aiming to achieve better stock homogenization, facilitate quick grade changes, and work toward higher consistencies in the headbox. These efforts are essential for improving overall process efficiency, reducing energy consumption, and enhancing the quality of tissue paper products.

- The integration of smart technology and automation is on the rise, helping to improve overall operational efficiency, reduce waste, and enhance accuracy. Also, the demand for high-speed, fully automated converting lines is expanding, along with rising labor costs and efficiency demands. The fully automatic converting machines reduce waste and the need for human intervention by connecting different processes, such as winding and packaging. Major companies spend heavily on cutting-edge robots, vision, and artificial intelligence-driven optimization as they expand into new manufacturing areas.

- Innovative converting technologies facilitate the efficient utilization of raw materials, particularly paper fibers. Precision cutting and embossing techniques are examples of methods that reduce material waste, while advanced control systems optimize the consumption of water and chemicals during manufacturing.

- The initial investment needed to establish a tissue-converting plant can be substantial, covering expenses like land procurement, building construction or renovation, machinery purchase and installation, and infrastructure development. Much of the capital will be required as working capital, while the cost of machinery and equipment can be as high as 25% or more of the total investment. Securing enough capital for these costs can be tough, especially for small or new businesses. Factors like limited financial resources, perceived risk, and regulatory compliance further complicate the funding process. To address these challenges, businesses may seek partnerships, explore government support programs, develop thorough business plans, and optimize costs to enhance financial viability.

- According to a report published by AFRY (Paper industry specialist) and Suzano (a key global paper and pulp producer), the global consumption of paper is expected to rise to a massive 55 million tons in 2032 from 41 million tons in 2021. This rising demand for tissue paper across the globe would open opportunities for many small and medium-scale producers to enter the tissue paper manufacturing industry, thereby increasing the demand for converting equipment.

Tissue Paper Converting Machines Market Trends

Toilet Roll Converting Lines to be the Largest Machine Type Segment

- Regular tissue products, including toilet paper, constitute a significant portion of the market for converting machinery. The demand for toilet paper is expected to rise steadily due to factors such as population growth, urbanization, and improving hygiene standards.

- According to the Population Reference Bureau, in 2023, the degree of urbanization worldwide was 57 %. North America, Latin America, and the Caribbean were the regions with the highest level of urbanization, with over four-fifths of the population residing in urban areas.

- Moreover, manufacturers of converting machinery targeting wet paper towel applications can capitalize by developing machinery capable of efficiently producing high-quality, moisture-resistant paper towels. Additionally, innovations in packaging and dispensing systems for wet paper towels present opportunities for manufacturers to differentiate their machinery offerings and cater to evolving market needs.

- Growing environmental concerns and increasing consumer awareness of sustainability issues are driving the adoption of eco-friendly practices in the toilet paper industry. Manufacturers invest in converting machinery capable of processing recycled fibers, reducing waste, and minimizing energy consumption. Demand for biodegradable and environmentally friendly toilet paper products prompts manufacturers to invest in machinery capable of handling recycled material.

- Furthermore, consumer preferences for personalized and innovative toilet paper products are driving manufacturers to invest in flexible converting machinery. Machinery capable of producing a variety of products, including different sheet sizes, ply configurations, embossing patterns, and packaging options, are in high demand. Customization capabilities enable manufacturers to cater to niche markets and segregate their products in a competitive landscape. In addition, consumers with higher disposable incomes often are more inclined to buy and invest more in luxurious embossed toilet tissue.

- Manufacturers of tissue products are aware of consumers' aesthetic associations with embossed tissue. Brands commonly utilize embossing to reinforce unique patterns, logos, or other special features to drive consumer loyalty and purchases consistently. Embossed toilet tissue is especially well-suited for aesthetic appeal and other consumer preferences; however, it is important not to overlook product quality.

- The embossing process can impact certain tissue attributes, particularly mechanical strength, and stiffness. By designing an appropriate embossing pattern and process, the correct combination can facilitate lamination, resulting in multi-ply finished products that customers perceive as high quality. By partnering with embossing machinery experts, toilet tissue products can be qualitatively and aesthetically distinguished.

Asia Pacific is Expected to Hold Significant Market Share

- Japan enhanced its reputation for cleanliness by introducing a unique addition to the toilets at Narita International Airport: smartphone cleaning paper. In a fresh approach to public convenience, individuals are encouraged to tear off a paper sheet from a dispenser beside the regular toilet paper roll to sanitize their phone screens. This introduction of cleaning paper was a response to research indicating that smartphone screens tend to harbor more germs than toilet seats. Surveys have consistently shown that tourists from other countries are consistently amazed by the cleanliness and adaptability of Japan's public restrooms. This is expected to impact the target market.

- The tissue paper sector in India is currently experiencing consolidation through innovation and acquisitions. This has allowed companies to enhance their market position, broaden their product range, and invest in advanced converting technologies to meet the growing demand. The escalating urbanization, increased focus on hygiene resulting from government initiatives like Swachh Bharat, and a significant rise in the demand from the healthcare and hospitality industries are projected to drive the consumption of tissue paper, napkins, and toilet and towel-grade paper.

- In January 2024, Andhra Paper Limited (APL), a top player in the paper and pulp industry, received approval from its Board of Directors to install a cutting-edge tissue paper machine at its Kadiyam manufacturing facility. The machine will employ state-of-the-art technology and have a daily production capacity of 100 tons, allowing diversification of the company's product portfolio. The proposed capacity addition is set at 35,000 Tons Per Annum (TPA) for producing various grades of tissue paper, including facial, toilet, napkin, and towel-grade tissue. The company aims to commence production within an estimated 15 months.

- To enhance production capacity within China's domestic market, high-end tissue machines, including the latest TAD technology, have been imported. For instance, Hengan incorporated two additional Valmet Hybrid tissue machines primarily used to produce superior facial tissue and kitchen towels.

- Before this, Hengan had implemented two Toscotec TAD tissue machines. The initial step involved the development of differentiated products using advanced technology and equipment to enhance the performance of products during usage. For instance, products with improved thickness were introduced by implementing novel tissue machine technology and converting machines. Cloud series tissue by Mind Act Upon Mind, cashmere sensory series toilet roll by Vinda, and hot air kitchen towels with TAD technology by Virjoy are some examples of such product launches.

- The proliferation of the paper industry in Indonesia is poised to drive growth in the tissue paper machine market. This growth will be fueled by surging demand for tissue paper products, investments in manufacturing capacity, technological advancements, and evolving environmental considerations.

- Tissue paper machine suppliers can capitalize on these opportunities by offering innovative solutions and addressing the specific needs of paper manufacturers. In November 2023, the Indonesia International Paper Chain Industry Exhibition (Paper Chain Indonesia) was launched at the JIEXPO Exhibition Center in Jakarta, Indonesia.

Tissue Paper Converting Machines Industry Overview

The tissue paper converting machines market is highly fragmented. There is the presence of major players like C.G. Bretting Manufacturing Company, Inc., Valmet Oyj, 9 September Tissue Converting, Serv-o-Tec GmbH, and SDF Schnitt-Druck-Falz Spezialmaschinen GmbH. Players in the market are adopting tactics such as partnerships and acquisitions in order to enhance their product offerings as well as gain a sustainable competitive advantage.

- January 2024 - United Converting Tissue SRL announced its collaboration with Lila Kagit in Turkey to supply a new Nexus Series Automatic Converting Line.

- January 2024 - Valmet will provide Suzano Papel e Celulose in Brazil with a comprehensive tissue line comprising a tissue-making line, converting equipment, and a biomass boiler. Although the total order value is undisclosed, such an order typically amounts to around EUR 100 million (USD 108 million).

- November 2023 - Valmet's acquisition of Korber Group's Business area tissue represents a strategic move aimed at expanding its market presence and diversifying its product portfolio in the tissue industry. The acquisition provides Valmet access to innovative converting and packaging technologies and services tailored to the tissue sector.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.3 Industry Ecosystem Analysis - Suppliers, Material Manufacturers, Etc.

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Growing Trend of Automation in Tissue Manufacturing Industry

- 5.1.2 Innovation in the Converting Technologies to Improve Sustainability

- 5.2 Market Restraints

- 5.2.1 High Setup Cost for Tissue-converting Plant

- 5.3 Key Innovations and Developments - Tissue-converting and Auxiliary Equipment

- 5.4 Industry Standards and Regulations

6 MARKET SEGMENTATION

- 6.1 By Technology

- 6.1.1 Automatic

- 6.1.2 Semi-automatic

- 6.2 By Machine Type

- 6.2.1 Toilet Roll Converting Lines

- 6.2.2 Kitchen Roll Converting Lines

- 6.2.3 Folded Tissue Converting Lines

- 6.2.4 Paper Napkin Converting Lines

- 6.2.5 Standalone Systems

- 6.3 By Geography***

- 6.3.1 North America

- 6.3.1.1 United States

- 6.3.1.2 Canada

- 6.3.2 Europe

- 6.3.2.1 Germany

- 6.3.2.2 France

- 6.3.2.3 Italy

- 6.3.2.4 United Kingdom

- 6.3.3 Asia

- 6.3.3.1 Japan

- 6.3.3.2 India

- 6.3.3.3 China

- 6.3.3.4 Indonesia

- 6.3.4 Australia and New Zealand

- 6.3.5 Latin America

- 6.3.6 Middle East and Africa

- 6.3.1 North America

7 TISSUE PAPER DEMAND TRENDS AND IMPACT ON THE PRODUCTION & EQUIPMENT MARKET

8 MARKET TRENDS IN THE TISSUE CONVERTING MACHINES INDUSTRY

- 8.1 Future Market Trends and Key Growth Expectations

- 8.2 Key Challenges for Manufacturers Vs. Innovations By Key Competitors of OMET

- 8.3 Comparative Analysis - OMET Srl Vs. Key Competitors

- 8.4 Technology Insights - Tissue Converting Machines

9 COMPETITIVE LANDSCAPE

- 9.1 Company Profiles*

- 9.1.1 C.G. Bretting Manufacturing Company, Inc.

- 9.1.2 Valmet Oyj

- 9.1.3 9.Septembar Tissue Converting

- 9.1.4 SERV-O-TEC GMBH

- 9.1.5 SDF Schnitt-Druck-Falz Spezialmaschinen GmbH

- 9.1.6 ZAMBAK KAGIT

- 9.1.7 Omet Srl

- 9.1.8 Kawanoe Zoki Co. Ltd

- 9.1.9 MTorres Disenos Industriales S.A.U

- 9.1.10 Baosuo Paper Machinery Manufacture Co. Ltd (Baosuo Enterprise)

- 9.1.11 A.Celli Paper SpA (italia Technology Alliance SpA)

- 9.1.12 United Converting Tissue SRL

- 9.1.13 Futura SpA

- 9.1.14 Paper Converting Machine Company (PCMC)

- 9.1.15 Fujian Tmx Machinery Manufacturing Co. Ltd

- 9.1.16 Chan Li Machinery Co. Ltd

- 9.1.17 Unimax Group Engineering & Development Corporation

- 9.1.18 ICM Makina