|

市场调查报告书

商品编码

1522865

电容式接近感测器:市场占有率分析、产业趋势/统计、成长预测 (2024-2029)Capacitive Proximity Sensor - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

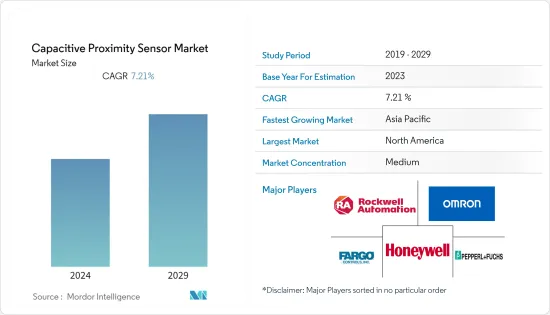

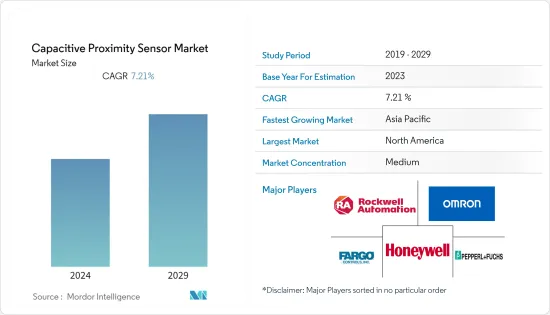

预计2024年电容式接近感测器市场规模为27亿美元,2029年达38.2亿美元,预测期间(2024-2029年)复合年增长率为7.20%。

电容式接近感测器是设计用于检测金属和非金属目标的感测设备。它还可以检测机械限位开关无法看到的轻质或小型物体。它利用电容的介电原理,在感测器表面附近形成检测场,形成检测区域。这些感测器透过记录感测器读取的电容变化来工作。

主要亮点

- 电容的变化取决于感测目标的大小和距离。典型的电容式接近感测器类似于具有两个平行板的电容器,并且感测两个板的电容。该感测器由高频振盪器和放大器组成。当物体接近感测器的感测表面时,环路的电容会变化,导致高频振盪器振盪。放大器将振盪和停止状态转换为电讯号,然后将其转换为二进位开关讯号。

- 电容式接近感测器具有较宽的灵敏度频宽,可透过非金属墙壁检测物体。它们也以其较长的使用寿命而闻名,使其在各种应用中都可靠。这些感测器高度灵敏,甚至可以准确检测最小的偏转,使其适用于各种应用,包括运动、位移、化学成分、电场、压力、加速度、液位和流体成分。

- 製造设施和生产工厂的成长是电容式接近感测器市场的主要驱动因素。这些感测器可以简化并减少生产功能的时间消耗,同时提高可靠性、准确性并减少工作人员的参与。

- 此外,虽然电容式接近感测器具有许多优点,但其感测能力存在一些限制,可能会阻碍其发展。电容式接近感测器对材料的介电特性敏感。虽然它可以检测金属、液体和塑胶等多种物质,但对于低介电常数或高电导率的物质却很难检测。

- COVID-19 的疫情和全球封锁法规对工业活动产生了严重影响。封锁的影响包括劳动力短缺、供应链中断、製造过程中使用的原材料缺乏、可能迫使最终产品生产和超出预算的价格波动以及运输问题。

电容式接近感测器的市场趋势

消费性电子实现大幅成长

- 电容式触控技术使用感测器取代更广泛的家用电子电器中的按钮和薄膜开关,从智慧型手机和平板电脑到笔记型电脑和其他类似电子设备。

- 电容式触控感测器利用静电场,并透过感测静电场的微小变化将表面积转换为多个感测机会。此外,此类感测器可以检测和量化任何导电或具有不同于空气的电介质,从而更容易以非机械方式接收刺激。

- 该技术同样适用于按钮、滑桿、开关、垫片、触控萤幕和接近感测器,使设计人员能够将他们的智慧型手机设计提升到一个新的水平。因此,行动装置具有多种可以使用电容式触控感应来实现的智慧功能。

- 电容式触控感应创建了一种特殊的手势介面,允许用户用一隻手操作行动电话并用拇指控制各种功能。例如,行动电话方面的简单 4 段电容式滑桿感应器可实现向上滑动、向下滑动、向上滑动、向下滑动、单选项卡、双选项卡和长按等功能。

- 这些功能可用于所有智慧型手机应用程序,以在萤幕之间浏览、上下捲动文件以及选择或取消选择图示。这种单手操作介面增强了行动电话的便利性和简洁性,改善了使用者体验。爱立信预计,到2023年,全球智慧型手机行动网路用户数将达到67.18亿,将进一步推动市场成长。

亚太地区占比较大

- 预计亚太地区在预测期内将实现最高成长率,其中包括中国、日本、印度、韩国和台湾在内的多个国家将大量采用工业机器人。

- 由于汽车和半导体製造业的大规模采用,中国在机器人应用感测器的区域采用率中占据主导地位。机器人中使用电容式接近感测器来避免碰撞并安全高效地执行任务。此外,这些感测器还用于在组装和其他製造过程中精确定位和引导零件。

- 政府增加对改善先进製造业的援助可能会对市场成长率产生正面影响。中国政府推出了一项名为「中国製造2025」的国家主导产业政策,旨在让中国在全球高科技製造业中占优势。

- 到2025年,国家目标实现机器人产业营业利润年均成长20%。五年计画旨在拓展机器人应用的广度和深度,持续增加我国机器人的数量。

- 它还旨在促进更加稳定和强大的供应链并推进行业标准化。由于机器人技术涉及触摸、接近检测等各种类型的感测器,该领域的成长将推动市场成长率。

电容式接近感测器产业概述

电容式接近感测器市场已被细分和研究,目的是透过将产品供应扩展到特定应用、加强分销管道和存在、提高产品可自订性等来获得竞争优势。主要企业包括罗克韦尔自动化公司、欧姆龙公司、英飞凌科技股份公司、Fargo Controls Inc. 和 Pepperl+Fuchs GmbH。

- 2023 年 10 月 - AutomationDirect 将巴鲁夫 BCS 系列电容式接近感测器纳入其广泛的物体侦测感测器系列中。这些感测器有多种款式可供选择,包括 12-30mm 管状、50mm 圆形和紧凑长方体,感应距离长达 30mm。这些进步预计也将扩大市场潜力。

- 2023 年 9 月 - ROHM 宣布开发 RPR-0720,这是一款紧凑型 2.0mm x 1.0mm 接近感测器,专为需要分离和接近检测的应用而设计。这种新型微型VCSEL接近感测器将极大地促进无线耳机和穿戴式装置的小型化和增加电池容量。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3 个月分析师支持

目录

第一章简介

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章市场洞察

- 市场概况

- 产业价值链分析

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 买方议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争公司之间敌对关係的强度

- COVID-19 和其他宏观经济因素对市场的影响

第五章市场动态

- 市场驱动因素

- 对非接触式感测技术的需求不断增长

- 市场限制因素

- 感测能力的限制

第六章 市场细分

- 按类型

- 触摸感应器

- 动作感测器

- 位置感测器

- 其他的

- 按最终用户产业

- 卫生保健

- 製造业

- 车

- 消费性电子产品

- 食品与饮品

- 金属/矿业

- 航太/国防

- 其他的

- 按地区

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- 中东/非洲

第七章 竞争格局

- 公司简介

- Rockwell Automation Inc.

- Omron Corporation

- Infineon Technologies AG

- Fargo Controls Inc.

- Pepperl+Fuchs GmbH

- STMicroelectronics NV

- Hans Turck GmbH & Co. KG

- TMSS France(YAGEO Corporation)

- Microchip Technology Inc.

- Sick AG

- Eaton Corporation

第八章 市场机会及未来趋势

The Capacitive Proximity Sensor Market size is estimated at USD 2.70 billion in 2024, and is expected to reach USD 3.82 billion by 2029, growing at a CAGR of 7.20% during the forecast period (2024-2029).

A capacitive proximity sensor is a sensing device designed to detect metallic and non-metallic targets. It may detect lightweight or small objects that mechanical limit switches cannot see. They use dielectric principles of capacitance to establish a sensing field near the sensor's face, creating a detecting zone. These sensors operate by recording a change in the capacitance read by the sensor.

Key Highlights

- The amount of capacitance varies depending on the size and distance of the sensing object. An ordinary capacitive proximity sensor is similar to a capacitor with two parallel plates, where the capacity of the two plates is detected. The sensor consists of a high-frequency oscillator and an amplifier. When an object approaches the sensor's detection surface, the capacitance of the loop varies, causing the high-frequency oscillator to vibrate. Amplifiers transform the oscillation and stop states into electrical signals, which are then turned into binary switching signals.

- Capacitive proximity sensors have a wide sensitivity band, enabling them to detect objects through non-metallic walls. They are known for their long operational lifespan, making them reliable for various applications. These sensors are highly sensitive and can accurately detect very small deflections, making them suitable for various applications like motion, displacement, chemical composition, electric field, pressure, acceleration, fluid level, and fluid composition.

- The growth in manufacturing facilities and production plants is a major driver for the capacitive proximity sensors market. These sensors can simplify and decrease the time consumption in production functions while enhancing the dependability, accuracy, and involvement of a low task force.

- Moreover, while capacitive proximity sensors offer numerous advantages, they have some limitations in sensing capabilities that can hinder their growth. Capacitive proximity sensors are sensitive to the dielectric properties of materials. While they can detect a wide range of materials, including metals, liquids, and plastics, they struggle with certain materials that have low dielectric constants or are highly conductive.

- The COVID-19 outbreak and lockdown restrictions worldwide severely affected industrial activities. The effects of the lockdown include labor shortages, disruptions in the supply chain, lack of availability of raw materials utilized in the manufacturing process, fluctuating prices that could force the production of the final product to increase and go beyond budget, shipping problems, etc.

Capacitive Proximity Sensors Market Trends

Consumer Electronics to Witness Major Growth

- In capacitive touch technologies, sensors have replaced buttons and membrane switches across a larger range of consumer electronic devices, from smartphones and tablets to laptops and other similar electronic devices.

- Capacitance-based touch sensors convert a surface area into several sensing opportunities by utilizing an electrostatic field and sensing very small changes in the capacitive field. Moreover, sensors like these can detect and quantify anything conductive or have a different dielectric than air, facilitating non-mechanical methods of receiving stimuli.

- This technology lends itself equally well to buttons, sliders, switches, touch pads, touch screens, and proximity sensors, enabling designers to take smartphone design to much higher levels. As a result, there are a variety of intelligent features that can be implemented using capacitive touch sensing in mobile devices.

- With capacitive sensing, creating a special gesture interface allows users to operate phones with a single hand and control various functions using their thumb. For instance, a simple four-segment capacitive slider sensor on the side of the phone enables such features as swipe up, swipe down, flick up, flick down, single tab, double tab, long press, etc.

- These features may be used with all smartphone applications to browse between screens, scroll a document up and down, or select or deselect an icon. Such a single-handed interface can increase the phone's convenience and simplicity, thus enhancing the user experience. According to Ericsson, by 2023, 6.718 billion smartphone mobile network subscriptions will be adopted across the globe, which would further boost the market's growth.

Asia-Pacific to Hold Major Share

- Asia-Pacific is anticipated to record the highest growth rate during the forecast period, with the noteworthy installation of industrial robots in several countries, including China, Japan, India, South Korea, and Taiwan.

- China is dominating the regional adoption rate of sensors for robotic applications due to the massive deployment in the country's dominating automotive and semiconductor manufacturing industries. Capacitive proximity sensors are used in robots to avoid collisions and perform tasks safely and efficiently. Moreover, these sensors are used to accurately position and guide parts during assembly or other manufacturing processes.

- The growing government aid in improving the advanced manufacturing sector will positively impact the market growth rate. The government of China launched "Made in China 2025", a state-led industrial policy that seeks to make China dominant in global high-tech manufacturing.

- By 2025, the country aims to exceed its average annual operating income growth rate by 20% in the robotics industry. The five-year plan set out objectives to expand the breadth and depth of robotic applications to continue to increase the number of robots in the country.

- It also aims to promote a more stable and robust supply chain and better standardize the industry. As robotics involve various types of sensors in touch, proximity detection, and so on, the sector's growth is set to boost the market growth rate.

Capacitive Proximity Sensors Industry Overview

The capacitive proximity sensor market is fragmented and studied, and the company intends to achieve a competitive edge by expanding its product offerings to specific applications, strengthening its distribution channels and presence, and offering greater customization of its products. Some significant players include Rockwell Automation Inc., Omron Corporation, Infineon Technologies AG., Fargo Controls Inc., and Pepperl + Fuchs GmbH, among others.

- October 2023 - AutomationDirect incorporated Balluff BCS series capacitive proximity sensors into their extensive collection of object detection sensors. These sensors are offered in various styles, such as 12-30 mm tubular, 50 mm round, and small rectangular bodies, and they provide sensing distances of up to 30mm. These advancements are also projected to amplify the market's potential.

- September 2023 - ROHM disclosed the development of a compact 2.0 mm X 1.0 mm proximity sensor, known as the RPR-0720, specifically designed for applications that necessitate attachment/detachment and proximity detection. This novel compact VCSEL proximity sensor significantly contributes to wireless earbuds and wearable devices' enhanced miniaturization and battery capacity.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Value Chain Analysis

- 4.3 Industry Attractiveness - Porter's Five Forces Analysis

- 4.3.1 Bargaining Power of Suppliers

- 4.3.2 Bargaining Power of Buyers

- 4.3.3 Threat of New Entrants

- 4.3.4 Threat of Substitute Products

- 4.3.5 Intensity of Competitive Rivalry

- 4.4 Impact of COVID-19 Aftereffects and Other Macroeconomic Factors on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Increase in Demand for Non-contact Sensing Technology

- 5.2 Market Restraints

- 5.2.1 Limitations in Sensing Capabilities

6 MARKET SEGMENTATION

- 6.1 By Type

- 6.1.1 Touch Sensors

- 6.1.2 Motion Sensors

- 6.1.3 Position Sensors

- 6.1.4 Other Types

- 6.2 By End-user Industry

- 6.2.1 Healthcare

- 6.2.2 Manufacturing

- 6.2.3 Automotive

- 6.2.4 Consumer Electronics

- 6.2.5 Food and Beverage

- 6.2.6 Metals and Mining

- 6.2.7 Aerospace and Defense

- 6.2.8 Other End-user Industries

- 6.3 By Geography

- 6.3.1 North America

- 6.3.2 Europe

- 6.3.3 Asia-Pacific

- 6.3.4 Latin America

- 6.3.5 Middle East & Africa

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles*

- 7.1.1 Rockwell Automation Inc.

- 7.1.2 Omron Corporation

- 7.1.3 Infineon Technologies AG

- 7.1.4 Fargo Controls Inc.

- 7.1.5 Pepperl + Fuchs GmbH

- 7.1.6 STMicroelectronics NV

- 7.1.7 Hans Turck GmbH & Co. KG

- 7.1.8 TMSS France (YAGEO Corporation)

- 7.1.9 Microchip Technology Inc.

- 7.1.10 Sick AG

- 7.1.11 Eaton Corporation