|

市场调查报告书

商品编码

1522869

金属硅:市场占有率分析、产业趋势与统计、成长预测(2024-2029)Silicon Metal - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

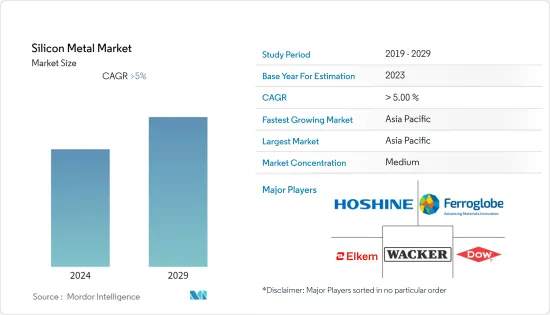

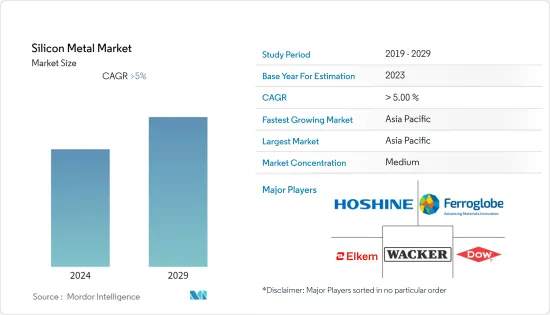

预计2024年金属硅市场规模为327万吨,预计2029年将达425万吨,预测期间(2024-2029年)复合年增长率为5.41%。

COVID-19 阻碍了有机硅胶金属市场。由于景气衰退、消费者支出减少以及生产和供应链中断,许多依赖硅胶金属的行业,如汽车、建筑和电子产品,在疫情期间需求下降。然而,随着停产和监管的放鬆,使用硅胶金属的行业復苏,基础设施计划、汽车生产、半导体製造和可再生能源设备对硅胶的需求增加,推动了对硅胶金属的需求。

主要亮点

- 汽车产业对硅胶的需求快速成长、太阳能电池产业的使用增加以及其他各种最终用户对硅胶的需求不断增加,预计将导致全球硅胶金属市场的扩大。

- 然而,能源成本的波动正在阻碍金属硅市场的成长。

- 透过改善现有技术和增加可再生能源产业的需求来降低生产成本的多项措施预计将在未来一段时间内为市场相关人员提供成长机会。

- 亚太地区拥有最高的市场占有率,并可能在预测期内主导硅金属市场。

金属硅市场趋势

太阳能板领域主导市场

- 硅约占当今销售模组的 95%,是太阳能发电中使用最广泛的半导体材料。冶金硅可以透过精製製程转化为高纯度硅,用于半导体和太阳能电池。因此,适合製造太阳能电池。

- 太阳能是世界上规模最大、成长最快的产业之一。根据国际能源总署(IEA)的数据,该部门占世界净能源产能的近三分之二。

- 国际能源总署(IEA)公布的资料显示,2022年,太阳能发电量增加了创纪录的270太瓦时,达到约1,300太瓦时,增加了26%。 2022年,太阳能在所有可再生技术中表现出最强劲的绝对发电量成长,历史上首次超过风电。

- 美国在 2022 年推出的《通货膨胀削减法案》(IRA) 中纳入了对太阳能发电的慷慨新资助。投资税额扣抵和生产税额扣抵预计将显着促进太阳能产能和供应链的成长。

- 国际能源总署(IEA)公布的资料显示,巴西2022年新增太阳能发电容量约11吉瓦,是2021年成长速度的两倍。鑑于工业和电力零售商对可再生能源的持续需求,预计中期部署将保持在这一水平。

- 根据新和可再生能源部(MNRE)发布的资料,截至年终,印度太阳能发电装置量排名世界第四。截至2022年11月,太阳能发电累积设备容量已达约720万千瓦。目前,印度太阳能电价极具竞争力,已实现市电平价。

- 上述新兴市场预计将在整个预测期内推动太阳能产业市场中的硅胶。

亚太地区主导市场

- 亚太地区,尤其是中国,是全球最大的硅胶金属生产国。该地区受惠于石英、煤炭等原料蕴藏量丰富以及低成本劳动力,支持建立大型金属硅生产设施。

- 金属硅最重要的用途是硅胶黏剂、密封剂、润滑剂、化学品、其他物质和铝合金。汽车、建筑、工业和其他最终用户领域是这些产品的主要应用。

- 中国新能源车产销量将大幅成长,到2022年销量将达722万辆,占全球电动车销量的64%。

- 政府对电动车、混合动力汽车和燃料电池车的推广预计将在预测期内推动市场发展。该国对电动车不断增长的需求正在推动对半导体、铝合金和有机硅黏剂的需求。

- 中国工业协会发布的报告显示,2022年,中国汽车出口311万辆,其中乘用车253万辆,商用车58万辆,比2021年增长54.4%。

- 晶科能源、天合光能、晶澳太阳能等全球顶级太阳能製造公司的总部均位于中国。过去两年,中国的太阳能电池製造业大幅成长。国际能源总署(IEA)公布的资料显示,2022年将新增太阳能发电容量100GW,较2021年成长近60%,中国计画新增太阳能发电容量持续领先。

- 行动电话、笔记型电脑和其他电器产品製造业的投资是中国的重要投资领域。全球各大製造商都在中国市场投入大量资金,以满足未来的需求成长。

- 由于这些因素,中国预计在亚太地区主导金属硅市场。

金属硅产业概况

金属硅市场部分整合。主要企业(排名不分先后)包括合盛硅业、Ferroglobe、Elkem ASA、Dow 和 Wacker Chemie AG。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第一章简介

- 调查先决条件

- 调查范围

第二章调查方法

第三章执行摘要

第四章市场动态

- 促进因素

- 汽车产业需求快速成长

- 增加太阳能产业的使用

- 各种最终用户对硅胶的需求增加

- 抑制因素

- 能源成本波动

- 其他阻碍因素

- 产业价值链分析

- 波特五力分析

- 供应商的议价能力

- 买方议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第五章市场区隔(市场规模)

- 产品类别

- 冶金级

- 化学级

- 目的

- 铝合金

- 半导体

- 太阳能板

- 硅胶衍生物

- 其他用途(建筑/基础设施)

- 地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 马来西亚

- 印尼

- 泰国

- 越南

- 其他亚太地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 义大利

- 西班牙

- 法国

- 土耳其

- 俄罗斯

- 北欧的

- 其他欧洲国家

- 南美洲

- 巴西

- 阿根廷

- 哥伦比亚

- 南美洲其他地区

- 中东/非洲

- 沙乌地阿拉伯

- 南非

- 奈及利亚

- 卡达

- 埃及

- 阿拉伯聯合大公国

- 其他中东/非洲

- 亚太地区

第六章 竞争状况

- 併购、合资、联盟、协议

- 市场占有率(%)**/排名分析

- 主要企业策略

- 公司简介

- Anyang Huatuo Metallurgy Co., Ltd.

- Dow

- Elkem ASA

- Ferroglobe

- Hoshine Silicon Industry Co., Ltd.

- Liasa

- Minasligas

- Mississipi Silicon

- PCC SE

- RIMA INDUSTRIAL

- RusAL

- Shin-Etsu Chemical Co., Ltd.

- Wacker Chemie AG

- Zhejiang kaihua yuantong silicon industry co. LTD.

第七章 市场机会及未来趋势

- 透过创新现有技术降低生产成本的倡议

- 可再生能源领域需求增加

The Silicon Metal Market size is estimated at 3.27 Million tons in 2024, and is expected to reach 4.25 Million tons by 2029, growing at a CAGR of 5.41% during the forecast period (2024-2029).

The COVID-19 hampered the silicone metal market. Many industries that utilize silicone metal, such as automotive, construction, and electronics, experienced decreased demand during the pandemic due to economic downturns, reduced consumer spending, and disruptions in production and supply chains. However, as lockdowns and restrictions eased, industries that utilize silicone metal recovered, and there was increased demand for silicone from infrastructure projects, automotive production, semiconductor manufacturing, and renewable energy installations, which boosted the demand for silicone metals.

Key Highlights

- Surging demand for silicone from the automotive industry, increasing use in the solar industry, and increasing demand for silicones from various other end users are expected to increase the market for silicone metal globally.

- However, volatility in energy costs is hindering the growth of the silicon metal market.

- Several measures to reduce production costs by improving current technologies and increasing demand from the renewable energy sector are expected to create growth opportunities for the market players in the upcoming period.

- The Asia-Pacific holds the highest market share and is likely to dominate the silicon metal market during the forecast period.

Silicon Metal Market Trends

Solar Panels Segment to Dominate the Market

- Silicon, which accounts for about 95% of the modules sold today, is the most extensively used semiconductor material in photovoltaics. In the process of purification, metallurgical silicon can be transformed into high-purity silicon that is used to make semiconductors and solar cells. Therefore, it is suitable for the manufacture of photovoltaic cells.

- Solar energy is one of the largest and fastest-growing sectors worldwide. The sector is responsible for nearly two-thirds of global net energy capacity, according to the International Energy Agency.

- According to the data published by the International Energy Agency (IEA), in 2022, solar PV production increased by a record 270 TWh, which increased by 26%, reaching almost 1300 TWh. It demonstrated the most considerable absolute generation growth of all renewable technologies in 2022, surpassing wind for the first time in history.

- The United States included generous new funding for solar PV in the Inflation Reduction Act (IRA) introduced in 2022. Investment and production tax credits will likely significantly boost the growth of PV capacity and supply chains.

- According to the data published by the International Energy Agency (IEA), in 2022, Brazil added almost 11 gigawatts of solar PV capacity, doubling its growth rate for 2021. In view of the continued demand for renewable energy from industry and power retailers, deployment is projected to be maintained at this level over the medium term.

- According to the data published by the Ministry of New and Renewable Energy (MNRE), India held the fourth position in solar PV deployment worldwide as of the end of 2022. The Cumulative installed capacity of solar power reached around 7.2 GW as of November 2022. Today, India's solar tariffs are very competitive, and grid parity has been achieved.

- The developments mentioned above are expected to drive the market for silicone metal in the solar industry through the forecast period.

Asia-Pacific to Dominate the Market

- Asia-Pacific, particularly China, is the largest producer of silicone metal globally. The region benefits from abundant reserves of raw materials like quartz and coal, as well as access to low-cost labor, which supports the establishment of large-scale silicon metal production facilities.

- The most critical applications of silicon metal are silicone adhesives, sealants, lubricants, chemicals, and other substances, as well as aluminum alloys. The automotive, building and construction, industrial, and other end-user sectors are the primary uses of these products.

- The production and sales of new energy vehicles increased significantly in China, with the number of units sold reaching 7.22 million by 2022, representing 64 % of all EV sales worldwide.

- The market is projected to be driven by the government's promotion of EVs, hybrids, and fuel-cell vehicles in the forecast period. The rising demand for electric vehicles in this country increases the need for semiconductors, aluminum alloys, and silicon adhesives.

- According to the report released by the China Association of Automobile Manufacturers (CAAM), in 2022, China exported 3.11 million vehicles, including 2.53 million passenger cars and 580,000 commercial vehicles, an increase of 54.4 % compared to 2021.

- The top global solar PV manufacturing companies, such as JinkoSolar, Trina Solar, and JA Solar, are headquartered in China. Solar cell manufacturing in China has been increasing significantly in the past two years. According to the data published by the International Energy Agency (IEA), with 100 GW capacity of solar PV added in 2022, almost 60% more than in 2021, China continues to lead in terms of solar PV capacity additions.

- Investment in the manufacture of mobile phones, laptops, and other electrical appliances is a significant area for investment in China. In order to meet the upcoming increase in demand, large manufacturers from around the world have invested substantial capital into China's market.

- Due to these factors, Asia-Pacific region China is expected to dominate the silicon metal market.

Silicon Metal Industry Overview

The silicon metal market is partially consolidated. The major players (not in any particular order) include Hoshine Silicon Industry Co., Ltd, Ferroglobe, Elkem ASA, Dow, and Wacker Chemie AG, among others.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Surging Demand from the Automotive Industry

- 4.1.2 Increasing Use in the Solar Industry

- 4.1.3 Increasing Demand for Silicones from Different End Users

- 4.2 Restraints

- 4.2.1 Volatility in Energy Costs

- 4.2.2 Other Restraints

- 4.3 Industry Value Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Buyers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION (Market Size in Volume)

- 5.1 Product Type

- 5.1.1 Metallurgy Grade

- 5.1.2 Chemical Grade

- 5.2 Application

- 5.2.1 Aluminum Alloys

- 5.2.2 Semiconductors

- 5.2.3 Solar Panels

- 5.2.4 Silicone Derivatives

- 5.2.5 Other Applications (Construction and Infrastructure)

- 5.3 Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 India

- 5.3.1.3 Japan

- 5.3.1.4 South Korea

- 5.3.1.5 Malaysia

- 5.3.1.6 Indonesia

- 5.3.1.7 Thailand

- 5.3.1.8 Vietnam

- 5.3.1.9 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 Italy

- 5.3.3.4 Spain

- 5.3.3.5 France

- 5.3.3.6 Turkey

- 5.3.3.7 Russia

- 5.3.3.8 NORDIC

- 5.3.3.9 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Colombia

- 5.3.4.4 Rest of South America

- 5.3.5 Middle-East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 South Africa

- 5.3.5.3 Nigeria

- 5.3.5.4 Qatar

- 5.3.5.5 Egypt

- 5.3.5.6 UAE

- 5.3.5.7 Rest of Middle-East and Africa

- 5.3.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Share(%)**/Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 Anyang Huatuo Metallurgy Co., Ltd.

- 6.4.2 Dow

- 6.4.3 Elkem ASA

- 6.4.4 Ferroglobe

- 6.4.5 Hoshine Silicon Industry Co., Ltd.

- 6.4.6 Liasa

- 6.4.7 Minasligas

- 6.4.8 Mississipi Silicon

- 6.4.9 PCC SE

- 6.4.10 RIMA INDUSTRIAL

- 6.4.11 RusAL

- 6.4.12 Shin-Etsu Chemical Co., Ltd.

- 6.4.13 Wacker Chemie AG

- 6.4.14 Zhejiang kaihua yuantong silicon industry co. LTD.

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Efforts to Reduce the Cost of Production by Innovating the Existing Technology

- 7.2 Increasing Demand from Renewable Energy Sector