|

市场调查报告书

商品编码

1642190

光学分类机-市场占有率分析、产业趋势与统计、成长预测(2025-2030 年)Optical Sorter - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

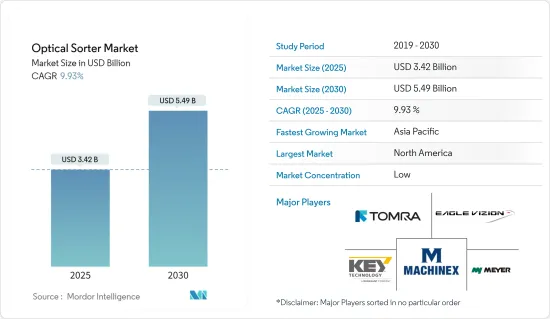

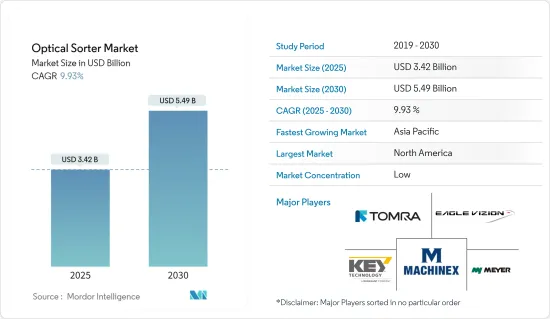

光学分类机市场在 2025 年的估值为 34.2 亿美元,预计到 2030 年将达到 54.9 亿美元,在市场估计和预测期(2025-2030 年)内,复合年增长率为 9.93%。

光学分选是使用摄影机和感测器(单独或组合)自动对固态产品进行分选的过程。根据所使用的感测器类型和部署的影像处理系统的有效性,光学分类机可以识别物体的颜色、大小、形状、结构特性和化学成分。光学分类机是一种自动化过程,使用摄影机和/或雷射与感测器和软体驱动的影像处理系统协同工作来分离固态材料。

关键亮点

- 光学分选系统用于识别生产线上的缺陷产品并根据可接受/定义的标准将其移除,以及从生产线上移除异物。它也用于製造使用不同等级和类型的材料的产品。光学分选系统的实施提高了产品质量,最大限度地提高了产量,增加了产量比率,同时降低了人事费用。

- 自动化可以减少错误并提高生产力,从而提高业务绩效。越来越多的行业采用自动化来加快流程并维持产品品质。这项策略减少了体力劳动,改善了卫生状况并加快了操作速度。食品、回收和采矿等关键产业是光学分分类机的主要市场,这些产业的自动化程度不断提高,预示着市场呈现积极的成长。

- 增强食品加工既改善了产品的口感,也延长了保存期限。加工食品包括经过不同程度加工的食品,从中度加工到高度加工。加工技术的不断创新和对加工食品的需求不断增加预计将推动食品和饮料加工设备市场的发展。

- 光学分类机所需的高额初始投资是市场成长的一大障碍。这些系统通常比其他传统解决方案更昂贵,这可能会阻止潜在买家,尤其是中小型企业。此外,维护这些系统的难度进一步增加了它们的整体成本,影响了销售和市场渗透。

- 国际货币基金组织曾预测,已开发经济体的成长将出现特别急剧的放缓,从 2022 年的 2.7% 降至 2023 年的 1.3%。北美是采用先进解决方案的主要市场之一,但也面临经济不稳定的问题,多家金融机构倒闭。许多经济学家认为,欧洲和中国的利率上升、高通膨和经济放缓将进一步影响该地区 2024 年的成长前景。

光学分类机的市场趋势

食品业占有较大市场占有率

- 回收部门包括对各种技术的研究,例如X射线传输、摄影机解决方案、雷射和近红外线感测器,这些技术用于全球回收行业的高效分类过程。本研究涵盖的回收领域包括金属和废料回收、城市废弃物回收、电子废弃物回收、不同类型的塑胶废弃物回收、纺织废弃物回收等。

- 光学废弃物分类是一种现代的、对环境负责的回收技术,它利用先进的摄影系统、感测器和机器学习演算法。这些技术可以快速且准确地识别不同类型的废弃物并对其进行分类,以便进行最佳处理或回收。该流程非常方便用户,并且对每种可回收材料使用颜色编码的袋子。使用者只需将这些袋子放入普通垃圾桶或投放区即可。然后,分拣厂根据颜色对袋子进行分类,并将其放入单独的容器中。

- 光学分类机提高了废弃物管理流程的效率、准确性和整体效益,彻底改变了回收业。它采用先进的摄影系统、感测器和机器学习演算法来高效、准确地识别和分类各种废弃物。这些系统能够检测不同材料的独特频谱特征,从而实现精确的识别和分离。该技术对于分类包含塑胶、玻璃、纸张和金属的消费后废弃物特别有用。

- 光学分选系统可以与自动废弃物收集系统结合使用,也可以添加到传统废弃物收集方法中并进行现代化改造。例如,Envac 与斯德哥尔摩 Valla Torg 的 Grow Smarter计划合作,将家庭产生的城市废弃物减少了 65%。这项成果是该公司重新思考其传统回收方法的结果。

- 新安装的系统可以追踪每种物品的重量,监控使用者分类物品的效率并评估他们处理可回收物品的方式。利用这些资料,Envac 能够超越先前的标准来优化其係统。技术的进步意味着可以精确设定係统容量和收集间隔,从而提高回收率并使系统永续且智慧化。

- 随着世界各国政府和国际组织采取重大措施减少塑胶废弃物,安装光学分类机的需求强劲。例如,2023年,联合国环境规划署(UNEP)发布蓝图,提案2040年将全球塑胶污染减少80%的措施。只要各国和各企业接受重大政策和市场变化,并利用现有的技术,这个目标是可以实现的。

- 经合组织预测,到2060年,全球塑胶废弃物产生量将增加两倍,达到10亿吨以上。造成这种激增的主要原因是人口快速成长和经济扩张。

- 公司正在开发创新解决方案,以在技术先进的市场中保持竞争力并满足客户的多样化需求。例如,总部位于丹麦的Cimbria公司于2024年7月宣布推出一款新型光学分类机,该分选机可对塑胶进行先进的分选和精确的材料分离,使分选后的塑胶精製高达99.99%。

亚太地区实现强劲成长

- 由于人们越来越重视食品安全和废弃物管理,亚太地区对光分类机的需求显着增加。这一趋势在中国、印度和日本等国家尤为明显,这些国家对高效分类解决方案的需求日益增加。

- 人工智慧、机器学习和高光谱遥测影像等先进技术的融合,大大提高了光学分类机的功能。这些创新可以更准确地对各种材料(包括食品、塑胶和金属)进行分类,这对于寻求提高效率和减少废弃物的行业至关重要。

- 消费者对食品安全的意识不断增强,推动了亚太食品加工产业采用光学分选技术。这些系统可有效去除加工过程中的任何缺陷或污染物,确保只有高品质的产品才能到达消费者手中。这对于农业部门规模庞大的国家尤其重要,因为维持品质对于国内消费和出口都至关重要。

- 韩国食品和饮料市场对国际参与企业和品牌来说具有巨大潜力。韩国作为世界第十大经济体,人均GDP较高,为市场提供了丰厚的机会。在韩国,GS25(GS Holdings Corp.)、CU(BFG Retail)、7-Eleven(包括乐天集团的 Ministop)等主要企业在全国经营超过 48,000 家便利商店(CVS)。因此,预计该国食品和饮料行业的成长将为所研究的市场提供丰厚的成长机会。

- 此外,印度的食品生态系统提供了巨大的投资机会,令人鼓舞的经济刺激措施和有吸引力的财政激励措施刺激了食品零售业的成长。印度政府透过食品加工工业部(MoFPI)采取一切必要措施鼓励对印度食品加工产业的投资。例如,PMKSY(Pradhan Mantri Kisan Sampada Yojana)旨在发展现代化食品加工基础设施。

- 此外,受城市人口比重增加、饮食习惯改变等因素影响,日本食品饮料产业也蓬勃发展。例如,根据《全球有机贸易指南》,日本包装有机食品消费量预计将在 2025 年达到 4.271 亿美元,而 2018 年为 4.014 亿美元。

光学分类机产业概况

光学分类机市场高度细分,既有全球参与企业,也有中小型企业。市场的主要企业包括TOMRA Systems ASA、Eagle Vizion Inc.、Key Technology Inc.(Duravant LLC 旗下子公司)、合肥美亚光电科技有限公司和Machinex Industries Inc.市场参与企业正在采取联盟和收购等策略来加强其产品供应并获得可持续的竞争优势。

- 2024 年 7 月-TOMRA 的 GAINnext 分选机专为 UBC 设计。新型包装分类分类机利用深度学习技术(人工智慧和机器学习的一部分)来区分输送机上的不同容器。 GAINnext 目前已在北美上市。 Tomra 相信该技术为从 UBC 中回收铝提供了一种高通量解决方案,无需人工分类即可保证纯度超过 98%。

- 2024 年 1 月-Duravant 食品分类与处理解决方案部门旗下的 Key Technology 推出了一款专为蛋白质加工产品设计的光学分类机。这些产品包括冷冻鸡块、鸡柳、鱼条和植物性肉类替代品。光学分类机,特别是 COMPASS 和 VERYX 型号,旨在快速去除废品和异物(FM)。这样做可以提高产品品质、增加产量比率并减少劳动力需求。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第 1 章 简介

- 研究假设和市场定义

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场洞察

- 市场概况

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 买家的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争对手之间的竞争强度

- 产业价值链分析

- 新冠疫情后遗症及其他宏观经济趋势对市场的影响

第五章 市场动态

- 市场驱动因素

- 更加重视自动化以提高各行业的生产力

- 更重视食品安全,对加工食品的需求不断成长

- 市场限制

- 设备的初始成本和维护成本高

第六章 市场细分

- 依技术分类

- X射线透射

- 相机解决方案

- 近红外线感测器

- 其他技术(高光谱遥测、雷射等)

- 按最终用户产业

- 食品加工

- 回收利用

- 矿业

- 其他的

- 按地区

- 北美洲

- 欧洲

- 亚洲

- 澳洲和纽西兰

- 拉丁美洲

- 中东和非洲

第七章 竞争格局

- 公司简介

- TOMRA Systems ASA

- Eagle Vizion Inc.

- Key Technology Inc.(A Duravant LLC)

- Hefei Meyer Optoelectronic Technology Inc.

- Machinex Industries Inc.

- Raytec Vision SPA

- Cimbria Inc.(AGCO Corporation)

- Satake Corporation

- Sesotec GmbH

- Buhler Group

第八章 市场展望

The Optical Sorter Market size is estimated at USD 3.42 billion in 2025, and is expected to reach USD 5.49 billion by 2030, at a CAGR of 9.93% during the forecast period (2025-2030).

Optical sorting is the process of automating the sorting of solid products by using cameras and sensors individually or in conjunction with each other. Optical sorters can recognize an object's color, size, shape, structural properties, and chemical composition, subject to the type of sensors used and the effectiveness of the image processing system deployed. The optical sorter is an automated process that enables the user to sort solid products using cameras or, lasers, or both working in conjunction with sensors and software-driven image processing systems.

Key Highlights

- Optical sorting systems are deployed to identify and remove defective objects from production lines based on accepted/defined criteria and to remove foreign material from the production line. They are also used to make products of different grades or types of materials. The deployment of optical sorting systems improves product quality, maximizes throughput, and increases yields while simultaneously reducing labor costs.

- Automation enables businesses to enhance performance by minimizing errors and increasing productivity. Several industries are increasingly adopting automation to accelerate processes and maintain product quality. This strategy reduces manual labor, improves hygiene, and speeds up operations. The rising automation in key industries such as food, recycling, and mining, primary markets for optical sorters, indicates positive market growth.

- Enhancements in food processing have improved both the taste and shelf life of products. Processed foods, which include items that undergo varying degrees of processing, range from moderately to highly processed. Continuous innovations in processing technology and the growing demand for processed foods are projected to fuel the development of the food and beverage processing equipment market.

- The high initial investment required for optical sorters is a significant barrier to the market's growth. These systems are often more expensive than other traditional solutions, which can deter potential buyers, especially small and medium-sized enterprises. The difficulty in maintaining these systems further adds to the overall cost, affecting their sales and market penetration.

- IMF had predicted advanced economies would see an especially harsh growth slowdown, from 2.7% in 2022 to 1.3% in 2023. The North American region, which is among the leading markets in adopting advanced solutions, is also facing economic instability, with multiple financial institutions collapsing. Many economic experts believe that a combination of steep rises in interest rates, high inflation, and slowdowns in Europe and China will further impact the growth prospects across geographies in 2024.

Optical Sorter Market Trends

Food Industry to Hold Significant Market Share

- The recycling segment includes the study of various technologies, such as X-ray transmission, camera solutions, laser, and NIR sensors, used in the recycling industry for efficient sorting processes worldwide. The recycling segment covered as a part of the study includes metal and scrap recycling, municipal waste recycling, electronic waste recycling, different types of plastic waste recycling, and textile waste recycling.

- Optical waste sorting is a contemporary and environmentally conscious recycling technique that leverages advanced camera systems, sensors, and machine learning algorithms. These technologies swiftly and precisely identify and categorize various waste materials for optimal disposal or recycling. The process is user-friendly, employing color-coded bags tailored to different recyclable materials. Users simply deposit these bags into a common waste bin or inlet. Subsequently, at the sorting plant, the bags are segregated by color and directed to their respective containers.

- Optical sorters have revolutionized the recycling industry by enhancing waste management processes' efficiency, accuracy, and overall effectiveness. They employ advanced camera systems, sensors, and machine learning algorithms to efficiently and accurately identify and sort various waste materials. These systems can detect the unique spectral signatures of different materials, allowing for precise identification and separation. This technology is particularly useful for sorting post-consumer waste, including plastics, glass, paper, and metal.

- An optical sorting system can be used with the automated waste collection system or can be added to traditional methods of waste collection to modernize them. For instance, Envac has, in collaboration with the Grow Smarter project at Valla Torg, Stockholm, achieved a significant 65% reduction in household general waste. This achievement followed the company's overhaul of traditional recycling methods.

- The newly implemented system tracks weight per fraction, monitors user sorting efficiency, and assesses the disposal methods of recyclables. By leveraging this data, Envac has optimized the system, surpassing conventional standards. Technological advancements allow precise configuration of the system's capacity and collection intervals, enhancing recycling rates and establishing the system as both sustainable and intelligent.

- Governments and international organizations worldwide are taking significant measures to reduce plastic waste, which is creating a significant demand for the implementation of optical sorters. For instance, in 2023, the UN Environment Program (UNEP) unveiled a roadmap, proposing measures to reduce global plastic pollution by 80% by 2040. This target is achievable and contingent on nations and corporations embracing substantial policy and market changes and leveraging technologies already at their disposal.

- The OECD forecasts a tripling of global plastic waste generation by 2060, surpassing a staggering one billion metric tons. This surge is primarily attributed to burgeoning populations and economic expansion.

- Companies are developing innovative solutions to remain competitive in the technologically advanced market and cater to customers' varying needs. For instance, in July 2024, Cimbria, a Denmark-based company, released new optical sorters that provide advanced sorting of plastics with precise material separation to enable the purification of up to 99.99% of the sorted plastic.

Asia Pacific to Register Major Growth

- Optical sorters are significantly witnessing increasing demand in the Asia-Pacific due to a growing emphasis on food safety and waste management. This trend is particularly evident in countries like China, India, and Japan, where the demand for efficient sorting solutions is on the rise.

- The integration of advanced technologies such as AI, machine learning, and hyperspectral imaging has significantly enhanced optical sorters' capabilities. These innovations allow for more precise sorting of various materials, including food products, plastics, and metals, which is crucial for industries looking to improve efficiency and reduce waste.

- With rising consumer awareness regarding food safety, the food processing industry in Asia-Pacific is increasingly adopting optical sorting technologies. These systems ensure that only high-quality products reach consumers by effectively removing defective items and containments during processing. This is particularly important in countries with large agricultural sectors, where maintaining quality is essential for both domestic consumption and export.

- South Korea's food and beverage market offers tremendous potential for international players and brands. As the 10th largest economy with a high per-capita GDP, South Korea presents a lucrative opportunity for the market. The country has over 48,000 convenience stores (CVS) across the country with major players, including GS25 (GS Holdings Corp.), CU (BFG Retail), and 7-Eleven (including Ministop, Lotte Group). Thus, the growing food & beverage industry in the country is expected to add lucrative growth opportunities for the market studied.

- Moreover, India's food ecosystem offers immense investment opportunities by stimulating growth in the food retail sector, promoting economic policies, and attractive fiscal incentives. The Government of India has taken all necessary measures to encourage investments in the Indian food processing industry through the Ministry of Food Processing Industries (MoFPI). For example, Pradhan Mantri Kisan Sampada Yojana (PMKSY) aims to develop a modern food processing infrastructure.

- Moreover, the food and beverage industry in Japan is also prospering owing to factors such as a higher share of the urban population and changing food consumption habits, among others. For instance, according to the Global Organic Trade Guide, the consumption of packaged organic food in Japan is anticipated to reach a value of USD 427.1 million by 2025, compared to USD 401.4 million in 2018.

Optical Sorter Industry Overview

The Optical Sorter Market is highly fragmented, with the presence of global players and small and medium-sized enterprises. Some of the major players in the market include TOMRA Systems ASA, Eagle Vizion Inc., Key Technology Inc. (A Duravant LLC), Hefei Meyer Optoelectronic Technology Inc., and Machinex Industries Inc. Market players are adopting strategies such as partnerships and acquisitions to enhance their product offerings and gain sustainable competitive advantage.

- July 2024 - TOMRA's GAINnext sorting device was specifically designed for UBCs. This new packaging sorter leverages deep learning technology, a branch of AI and machine learning, to distinguish various containers on a conveyor belt. Currently, GAINnext is being rolled out in North America. Tomra boasts that this technology provides a high-throughput solution for aluminum recovery from UBCs, ensuring 98% or above purity without manual sorting.

- January 2024 - Key Technology, part of Duravant's Food Sorting and Handling Solutions division, introduced optical sorters designed for processed protein products. These products range from frozen chicken nuggets and tenders to fish sticks and plant-based meat alternatives. The optical sorters, notably the COMPASS and VERYX models, are designed to eliminate defects and foreign materials (FM) swiftly. By doing so, they enhance product quality, boost yields, and cut labor requirements.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitute Products and Services

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Industry Value Chain Analysis

- 4.4 Impact of COVID-19 Aftereffects and Other Macroeconomic Trends on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Growing Focus on Automation for Increasing Productivity in Various Industries

- 5.1.2 Growing Emphasis on Food Safety and Rising Demand for Processed Foods

- 5.2 Market Restraints

- 5.2.1 High Initial and Maintenance Cost of the Equipment

6 MARKET SEGMENTATION

- 6.1 By Technology

- 6.1.1 X-ray Transmission

- 6.1.2 Camera Solutions

- 6.1.3 NIR-Sensors

- 6.1.4 Other Technologies (Hyperspectral, Laser, etc.)

- 6.2 By End-user Industries

- 6.2.1 Food Processing

- 6.2.2 Recycling

- 6.2.3 Mining

- 6.2.4 Other End-user Industries

- 6.3 By Geography

- 6.3.1 North America

- 6.3.2 Europe

- 6.3.3 Asia

- 6.3.4 Australia and New Zealand

- 6.3.5 Latin America

- 6.3.6 Middle East and Africa

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 TOMRA Systems ASA

- 7.1.2 Eagle Vizion Inc.

- 7.1.3 Key Technology Inc. (A Duravant LLC)

- 7.1.4 Hefei Meyer Optoelectronic Technology Inc.

- 7.1.5 Machinex Industries Inc.

- 7.1.6 Raytec Vision SPA

- 7.1.7 Cimbria Inc. (AGCO Corporation)

- 7.1.8 Satake Corporation

- 7.1.9 Sesotec GmbH

- 7.1.10 Buhler Group