|

市场调查报告书

商品编码

1548909

固态继电器:市场占有率分析、产业趋势与统计、成长预测(2024-2029)Solid-state Relay - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

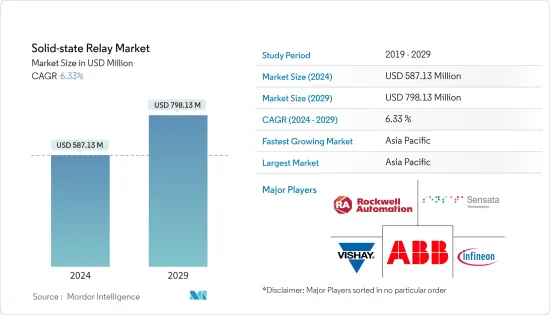

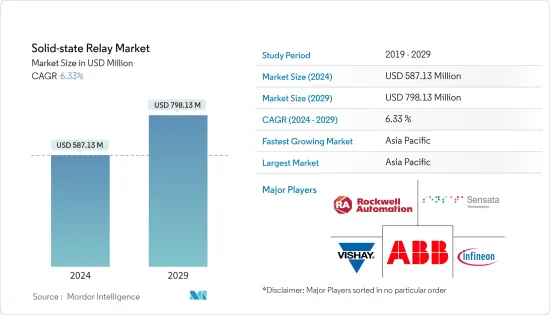

固态继电器(SSR)市场规模预计到2024年为5.8713亿美元,预计到2029年将达到7.9813亿美元,在预测期内(2024-2029年)复合年增长率为6.33%。

儘管固态继电器(SSR) 和电子机械继电器(EMR) 具有通用的功能,但它们的实现和性能却截然不同。 SSR 相当于 EMR 的机械等效物,无需移动部件即可管理电力负载。与依赖机械常开触点的 EMR 不同,SSR 利用 TRIAC、SCR 和开关电晶体等组件来处理交流和直流电流。

一个重要的区别是,在 SSR 中,低电压输入和负载开关输出是电隔离的。另一方面,EMR的特征是接点寿命有限、尺寸大、开关速度慢,特别是在高功率继电器和接触器中,这是SSR所不具备的限制。

世界向太阳能和风能等清洁可再生能源来源的转变产生了对高效能电力转换和控制系统的需求。太阳能逆变器、风力发电机和能源储存系统的日益普及预计将推动可再生能源领域对功率半导体的需求。 SSR在太阳能逆变器中很重要,它可以有效地将太阳能转换为电能。

智慧型家电、HVAC 系统以及笔记型电脑和智慧型手机等电子设备的激增正在增加电力消耗。此外,随着科技的进步,LED照明也逐渐成为消费者喜爱的照明产品。 LED灯销量的激增为固态继电器开闢了巨大的市场前景。这些继电器在智慧照明系统中发挥着至关重要的作用,可实现 LED 照明的高效控制和调光,最终减少功耗。

SSR的初始成本高于EMR,长期来看SSR更划算。这主要是因为EMR维护成本高、功耗大、寿命短。

考虑到综合使用寿命、检查和维护成本等附加成本,使用固态继电器的平均成本明显低于使用电磁继电器的平均成本,并且由于继电器而导致的低效率较低。此外,根据应用的不同,可能需要额外的成本来防止触点振动并确保机械继电器的可靠接触。

经济成长、通货膨胀、政府支出、全球贸易和地缘政治动态等全球趋势影响不同国家的製造业生态系统。俄罗斯-乌克兰衝突和美国紧张局势等事件造成的供应链中断正在对製造业产生重大影响。例如,中国国家统计局的数据显示,2023年中国电子製造业付加价值成长率达3.4%,为同期最高。这一增长在 2019 年和 2020 年有所下降,并于 2021 年恢復。

固态继电器市场趋势

汽车和运输业成为成长最快的应用

- 固态继电器在汽车系统中用于配电和马达控制功能。为方向灯、雨刷和冷却风扇等组件提供可靠的开关。这些继电器可以处理高电流并具有快速开关速度,使其适合汽车应用。

- 固态继电器在电动车电力电子系统中发挥重要作用。此继电器用于电池管理系统、马达控制单元和充电系统。这些继电器能够有效率且可靠地切换电动车中的高电压、高电流电路。

- 随着电动车市场尤其是动力传动系统市场的成长,固态继电器的需求预计将进一步增加。汽车产业的电子元件对于安全至关重要,并且暴露在极端电压和环境条件下。这迫使製造商开发新的汽车固态继电器产品线。

- 推动SSR成长的因素包括汽车产量的增加和电动车需求的增加。此外,物联网的引入以及对自动驾驶汽车、联网汽车和低排放气体生产的有利政府标准等多项技术进步将进一步推动马苏固态继电器市场的成长。

- 例如,2024 年 5 月,NOVOSENSE 宣布推出工业级和汽车级新型 NSI7258 系列电容隔离固态继电器。 NSI7258专为高电压测量和绝缘监测而设计,提供业界领先的耐压和EMI性能,使其适用于工业BMS、光伏、能源储存、充电桩、新能源汽车BMS和OBC等,有助于提高高电压系统的可靠性和稳定性。

- 根据IEA《2024年全球电动车展望》,2024年美国电动车销量预计将比与前一年同期比较增长20%,比2023年增长约50万辆。鑑于最近的事态发展以及严格的二氧化碳排放目标只计划到 2025 年这一事实,欧洲电动车销量成长预计将成为三大市场中最慢的。预计2024年销量将达到约350万辆,与前一年同期比较适度成长10%以内。这些趋势在预测期内创造了对固态继电器的需求。

亚太地区预计将出现显着成长

- 近年来,固态继电器的应用领域显着扩大。固态继电器没有移动部件,这意味着磨损更少,可靠性更高,使用寿命更长。这在汽车行业尤其重要,因为汽车行业的部件经常暴露在振动和恶劣的条件下。固态继电器比电子机械继电器具有更快的开关速度,可提高各种汽车系统的性能,包括 ADAS、配电装置和电动车电池管理系统。

- 中国市场的成长将主要由汽车产业推动。汽车製造业对固态继电器的需求激增是快速成长的主要动力。例如,2024年1月,中国工业协会宣布,我国汽车工业取得年产销量突破3,000万辆的重大成就,显示成长机会庞大。

- 此外,中国已成为混合动力汽车和电动车市场的主要参与者,其雄心勃勃的目标是到 2030 年将电动车占汽车总销量的份额提高到 40%。

- 日本汽车工业,包括不断成长的电动车 (EV) 市场,是固态继电器的重要推动力。这些继电器具有高可靠性和高效率,用于电池管理系统、配电和各种车辆控制系统。

- 历史上对日本GDP贡献率超过89%的日本汽车产业正处于重大转折点。日本雄心勃勃的目标是到 2050 年实现净零排放,到 2030 年将排放量减少 46%,这推动了电动车 (EV) 的普及。政府为此订定了明确的目标。目标是到 2030 年电动车和插电式混合动力汽车(PHEV) 占乘用车销量的 20-30%,其中燃料电池汽车 (FCV) 占 3%。

- 在印度,智慧城市、现代化交通系统等基础建设发展进展迅速,对固态继电器(SSR)的需求不断增加。 SSR 的可靠性和管理高电压应用的能力对于这些计划至关重要。例如,2024 年 2 月,印度议会委员会强调启动政府旗舰智慧城市使命的后续阶段的重要性,并专注于邦首府半径 100 公里范围内的二线城市。

固态继电器产业概况

固态继电器市场正朝向半固体发展,罗克韦尔自动化公司、ABB 有限公司、英飞凌科技股份公司、森萨塔科技公司和 Vishay Intertechnology Inc. 等主要公司纷纷进入该市场。市场上的公司正在采取合作和收购等策略来增强其产品阵容并获得永续的竞争优势。

2024 年 6 月 - 英飞凌科技推出专为汽车电源管理设计的 600V CoolMOS S7TA超接面MOSFET。这种创新产品为对现代车辆的安全性和效率至关重要的各种关键应用提供了增强的解决方案。这些应用包括关键组件,例如电路断流器、高电压电池隔离开关、直流和交流低频开关以及高电压电子熔断器。

2024 年 3 月 - 奥托尼克斯在大阪开设新办事处,瞄准日本西部地区。此举旨在改善客户服务和访问。大阪办事处是日本东部东京办事处的补充,奥托尼克斯的目标是在全国范围内拓展市场。

其他好处:

- Excel 格式的市场预测 (ME) 表

- 3 个月分析师支持

目录

第一章简介

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章市场洞察

- 市场概况

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 买方议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争公司之间的敌对关係

- COVID-19 和其他宏观经济因素对市场的影响

第五章市场动态

- 市场驱动因素

- 增加对再生能源来源的投资

- 住宅和工业领域对节能的需求不断增长

- 市场限制因素

- 与电子机械继电器相比,固态继电器的高成本

第六章 市场细分

- 按安装

- 面板安装

- PCB安装

- DIN 导轨安装

- 按产量

- 继电器固态继电器

- 直流固态继电器

- 继电器直流输出继电器

- 按用途

- 能源和基础设施

- 工业OEM

- 建筑设备

- 饮食

- 汽车/运输设备

- 工业自动化

- 卫生保健

- 按地区

- 北美洲

- 美国

- 加拿大

- 欧洲

- 德国

- 法国

- 英国

- 亚洲

- 中国

- 日本

- 印度

- 澳洲/纽西兰

- 拉丁美洲

- 中东/非洲

- 北美洲

第七章 竞争格局

- 公司简介

- Rockwell Automation Inc.

- ABB Ltd

- Infineon Technologies AG

- Sensata Technologies Inc.

- Vishay Intertechnology Inc.

- Omron Corporation

- Fujitsu Limited

- Broadcom Inc.

- Omega Engineering Inc.

- TE Connectivity Ltd

- Celduc Relais.

- Littelfuse

- Schneider Electric SE

- Autonics Corporation

- Toshiba Corporation

第八章 市场机会及未来趋势

The Solid-state Relay Market size is estimated at USD 587.13 million in 2024, and is expected to reach USD 798.13 million by 2029, growing at a CAGR of 6.33% during the forecast period (2024-2029).

Solid State Relays (SSRs) and electromechanical relays (EMRs) share a common functionality, but their implementation and performance diverge significantly. SSRs, acting as the mechanical counterparts of EMRs, can manage electrical loads sans moving parts. Unlike EMRs that rely on mechanical NO contacts, SSRs leverage components like TRIACs, SCRs, or switching transistors to handle both AC and DC currents.

One key distinction lies in the electrical isolation of the low voltage input from the load-switching output in SSRs, a feature absent in EMRs. EMRs, on the other hand, are characterized by a finite contact life, bulkier dimensions, and slower switching speeds, particularly evident in larger power relays and contactors-limitations not shared by SSRs.

The global shift toward clean and renewable energy sources, such as solar and wind, has created a need for efficient power conversion and control systems. The increasing deployment of solar inverters, wind turbines, and energy storage systems is anticipated to drive the demand for power semiconductors in the renewable energy sector. SSRs are crucial in solar inverters, allowing efficient solar energy conversion into electricity.

The rising uptake of smart home appliances, HVAC systems, and electronic devices, including laptops and smartphones, is driving up power consumption. In addition, with technological advancements, LED lighting has emerged as a favorite lighting among consumers. The surge in LED lamp sales is opening substantial market prospects for solid-state relays. These relays play a pivotal role in smart lighting systems, enabling efficient control and dimming of LED lights, ultimately curbing power usage.

The upfront cost of SSR surpasses that of EMR, and SSR proves more cost-effective in the long term. This is primarily because EMR entails higher maintenance costs, consumes more power, and boasts a shorter lifespan.

Considering additional costs, such as comprehensive service life, inspection and maintenance expenses, and inefficiencies due to unstable or faulty relays, the average cost of using solid-state relays is significantly lower than that of electromagnetic relays. Furthermore, some applications require extra costs to prevent contact vibration and ensure reliable contact in mechanical relays.

Macroeconomic trends like economic growth, inflation, government spending, global trade, and geopolitical dynamics influence various countries' manufacturing ecosystems. Disruptions in supply chains, triggered by events such as the Russia-Ukraine conflict and tensions between the US and China, have significantly impacted the manufacturing sector. For example, the electronics manufacturing industry in China saw a 3.4% growth in value added in 2023, marking the highest point in the given period, as China's National Bureau of Statistics reported. This growth had dipped in 2019 and 2020, only to rebound in 2021.

Solid-state Relay Market Trends

Automotive and Transportation Segment to be the Fastest Growing Application

- Solid-state relays are employed in automotive systems for power distribution and motor control functions. They provide reliable switching for components like turn signals, windshield wipers, and cooling fans. These relays can handle high currents and offer fast switching, making them suitable for automotive applications.

- Solid-state relays play a crucial role in the power electronics systems of electric vehicles. They are used on battery management systems, motor control units, and charging systems. These relays enable efficient and reliable switching of high-voltage and high-current circuits in EVs.

- The growth in the electric vehicle markets, especially power trains, is further expected to increase the demand for solid-state relays. Electronic components in the automotive industry are critical for safety and are subjected to extreme voltages and environmental conditions. This has driven the manufacturers to develop a new line of solid-state relays for automotive applications.

- The factors driving the growth of the SSRs include increased vehicle production and rising demand for electric vehicles. In addition, several technological advancements, such as the implementation of IoT and favorable government standards for the production of autonomous, connected, and low-emission vehicles, are further fueling the market's growth of solid-state relays during the forecast period.

- For instance, in May 2024, NOVOSENSE announced the launch of its new NSI7258 series of capacitive isolation-based solid-state relays, available in both industrial and automotive grades. Designed specifically for high-voltage measurement and insulation monitoring, NSI7258 provides industry-leading voltage withstand capability and EMI performance to help improve the reliability and stability of high-voltage systems such as industrial BMS, PV, energy storage, charging piles, and BMS and OBCs for new energy vehicles.

- According to IEA's Global EV Outlook 2024, in 2024, electric car sales in the United States are projected to rise by 20% compared to the previous year, translating to almost half a million more sales relative to 2023. Based on recent trends and considering that tightening CO2 targets are due to come in only in 2025, the growth in electric car sales in Europe is expected to be the lowest of the three largest markets. Sales are projected to reach around 3.5 million units in 2024, reflecting modest growth of less than 10% compared to the previous year. Such trends are creating a demand for solid-state relays over the forecast period.

Asia Pacific Expected to Witness Significant Growth

- The application field for solid-state relays has significantly broadened recently. Solid-state relays have no moving parts, reducing wear and tear and increasing reliability and longevity. This is particularly important in the automotive sector, where components are subjected to constant vibrations and harsh conditions. Solid-state relays offer faster switching speeds than electromechanical relays, improving the performance of various automotive systems, including ADAS, power distribution units, and battery management systems in EVs.

- China's market growth is poised to be significantly driven by the automotive sector. The surging demand for solid-state relays within automotive manufacturing primarily fuels this surge. For instance, in January 2024, the China Association of Automobile Manufacturers announced a significant achievement for the country's auto industry: production and sales have surpassed 30 million units annually, highlighting the immense growth opportunities in the sector.

- In addition, China emerged as a significant player in the hybrid and electric vehicle market, propelled by its ambitious target: achieving a 40% share of electric vehicles in total car sales by 2030.

- Japan's automotive industry, including the growing electric vehicle (EV) market, is a significant driver of solid-state relays. These relays offer high reliability and efficiency and are used in battery management systems, power distribution, and various vehicle control systems.

- Japan's automotive sector, which historically contributes to over 89% of the nation's GDP, is undergoing a significant shift. Driven by Japan's ambitious targets of achieving net-zero emissions by 2050 and a 46% reduction by 2030, electric vehicles (EVs) are gaining traction. In line with this, the national government has outlined clear targets: aiming for EVs and plug-in hybrid electric vehicles (PHEVs) to constitute 20-30% of passenger car sales by 2030, with fuel cell vehicles (FCVs) targeted at 3%.

- India's rapid infrastructure development, including smart cities and modern transportation systems, boosts the demand for solid-state relays (SSRs). The SSR's reliability and ability to manage high-voltage applications are essential in these projects. For instance, in February 2024, the Indian parliamentary committee underscored the importance of initiating the subsequent phase of the government's primary Smart Cities Mission, focusing on tier-2 cities within a 100-kilometer radius of state capitals.

Solid-state Relay Industry Overview

The solid state relay market is semi-consolidated, with major players like Rockwell Automation Inc., ABB Ltd, Infineon Technologies AG, Sensata Technologies Inc., and Vishay Intertechnology Inc. Players in the market are adopting strategies such as partnerships and acquisitions to enhance their product offerings and gain sustainable competitive advantages.

June 2024 - Infineon Technologies unveiled the 600 V CoolMOS S7TA superjunction MOSFET designed for automotive power management. This innovative product offers an enhanced solution for various important applications crucial to the safety and efficiency of contemporary vehicles. These applications encompass vital components like circuit breakers, high-voltage battery disconnect switches, low-frequency switches for DC and AC, and high-voltage electronic fuses.

March 2024 - Autonics opened a new sales office in Osaka, Japan, targeting the western Japan region. This move aims to improve customer service and accessibility. With the Osaka office complementing the Tokyo office in eastern Japan, Autonics seeks nationwide market expansion.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Impact of COVID-19 Aftereffects and other Macroeconomic Factors on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Increased Investment in Renewable Energy Sources

- 5.1.2 Elevated Requirement of Power Savings in the Residential and Industrial Sectors

- 5.2 Market Restraints

- 5.2.1 High Cost of the Solid-state Relay Compared to Electromechanical Relay

6 MARKET SEGMENTATION

- 6.1 By Mounting

- 6.1.1 Panel Mount

- 6.1.2 PCB Mount

- 6.1.3 DIN Rail Mount

- 6.2 By Output

- 6.2.1 AC Solid State Relay

- 6.2.2 DC Solid State Relay

- 6.2.3 AC/DC Output Relay

- 6.3 By Application

- 6.3.1 Energy and Infrastructure

- 6.3.2 Industrial OEM

- 6.3.3 Building Equipment

- 6.3.4 Food and Beverages

- 6.3.5 Automotive and Transportation

- 6.3.6 Industrial Automation

- 6.3.7 Healthcare

- 6.4 By Geography

- 6.4.1 North America

- 6.4.1.1 United States

- 6.4.1.2 Canada

- 6.4.2 Europe

- 6.4.2.1 Germany

- 6.4.2.2 France

- 6.4.2.3 United Kingdom

- 6.4.3 Asia

- 6.4.3.1 China

- 6.4.3.2 Japan

- 6.4.3.3 India

- 6.4.4 Australia and New Zealand

- 6.4.5 Latin America

- 6.4.6 Middle East and Africa

- 6.4.1 North America

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Rockwell Automation Inc.

- 7.1.2 ABB Ltd

- 7.1.3 Infineon Technologies AG

- 7.1.4 Sensata Technologies Inc.

- 7.1.5 Vishay Intertechnology Inc.

- 7.1.6 Omron Corporation

- 7.1.7 Fujitsu Limited

- 7.1.8 Broadcom Inc.

- 7.1.9 Omega Engineering Inc.

- 7.1.10 TE Connectivity Ltd

- 7.1.11 Celduc Relais.

- 7.1.12 Littelfuse

- 7.1.13 Schneider Electric SE

- 7.1.14 Autonics Corporation

- 7.1.15 Toshiba Corporation