|

市场调查报告书

商品编码

1549711

自动物料输送(AMH):市场占有率分析、产业趋势与统计、成长预测(2024-2029 年)Automated Material Handling (AMH) - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

价格

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

简介目录

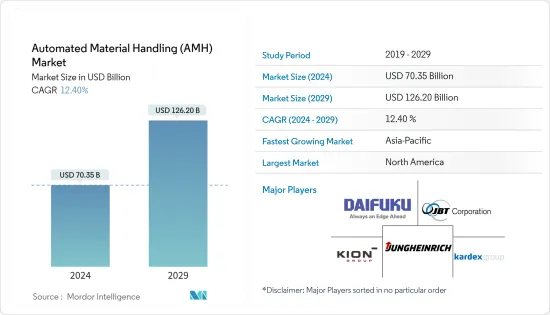

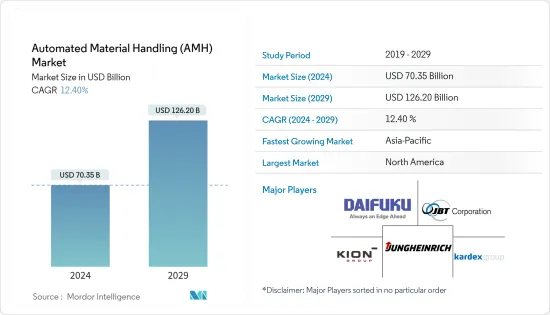

自动化物料输送市场规模预计到2024年为703.5亿美元,预计到2029年将达到1262亿美元,在预测期内(2024-2029年)复合年增长率为12.40%。

主要亮点

- 技术进步、对人事费用和安全的担忧日益增加、製造和仓储营运效率提高、全球製造业显着復苏、工业自动化需求增加、製造设备和仓储设施对机器人的需求不断增长、新兴产业的成长。是推动自动化物料输送市场的主要因素。至于其他好处,供应链业务的数位化将在预测期内扩大,订单客製化和个人化的增加将进一步提振市场。

- 自动物料输送(AMH) 系统简化了各种环境中的物料移动,包括製造设施、仓库、零售店、机场和物流中心。这些系统有助于材料的无缝移动,无论是在同一区域内、部门之间,甚至在不同建筑物之间。 AMH 系统依赖製造执行系统 (MES) 指定的路线。这些系统采用多种技术,包括光学字元辨识 (OCR)、条码、RFID、超宽频室内追踪和近距离通讯。

- 过去 70 年来,物料输送经历了重大变革,重塑了产业格局。机器和机器人正在取代体力劳动并刺激各个领域的成长。汽车产业尤其引人注目,成长了 10 倍,令人印象深刻。加拿大在工业 4.0 和尖端製造业方面的进步正在彻底改变不同气候下产品的设计、交货和维护。从机器人和自动化到积层製造(3D 列印),这些技术在电子商务、汽车、农业和製药等广泛领域中得到了效用。无论是在国内市场还是在竞争激烈的全球舞台上,加拿大的创新者在创造复杂、高价值的产品方面都处于领先地位。他们的工作不仅改善了当地实践,也为合资企业奠定了基础,定义了先进自动化技术的发展轨迹。

- 儘管第一台 AGV 于 1953 年首次亮相,但其在生产和仓储企业中的广泛采用却受到多种因素的阻碍。典型的自动导引运输车成本在 60,000 美元到 100,000 美元之间,但具有导航辅助和感测器等先进功能的系统可能要贵得多。这些高昂的初始成本加上维护挑战正在抑制市场成长。领先的公司正在努力控製成本,同时不影响创新或研发投资。

- COVID-19 的疫情对跨部门自动化的采用产生了重大影响,重塑了业务规范并带来了社交距离和非接触式操作等挑战。组织面临需求激增和劳动力萎缩的问题,促使他们实施增强的安全通讯协定。自2020年以来,感染在美国工人中蔓延,迫使企业迅速实施新的安全措施。虽然食品製造等一些行业由于病毒的严重性而经历了停工,但许多其他行业透过采取严格的卫生措施来维持营运。

自动物料输送(AMH) 市场趋势

工业4.0投资将显着推动市场成长

- 随着各国采用工业 4.0 和物联网技术,市场不断发展。透过使用机器人技术,工业 4.0 正在彻底改变物料输送方式。机器人技术在仓库和配送设施中变得越来越流行。例如,国际机器人联合会报告称,美国製造商正在大力投资自动化,到 2023 年,安装的工业机器人数量将增加 12%,达到 44,303总合。机器人可以用来挑选和包装订单、装卸卡车,甚至清洁仓库地板。机器人提高了职场的准确性和生产力。机器人还使公司能够透过减少所需的体力劳动来降低成本。

- 例如,仓库很大,员工必须步行很长的距离才能找到 SKU 并将订单交付到包装和运输区域。每年,仓库平均浪费 6.9 週在不必要的步行和其他活动上,相当于 2.65 亿工时,成本达 43 亿美元。协作机器人还可以最大限度地减少分类过程每个阶段在功能区域之间长途行走的需要。物料输送设备订单的增加可能会显着推动所研究的市场。

- 此外,机器人、自动化和积层製造(3D 列印)等技术在加拿大电子商务、汽车、农业和製药等行业有着广泛的应用。加拿大创新者正在共同为国内和竞争激烈的全球市场生产技术复杂和高价值的产品,并共用改进的实践并塑造高度自动化技术的未来,我们正在为即将形成的合作关係奠定基础。

- 德国也重点关注其 2030 年工业 4.0 愿景的三个策略行动领域:自主性、互通性和永续性。在这 2030 年愿景中,工业 4.0 平台相关人员提出了塑造数位生态系统的整体方法。其目标是根据社会市场经济的需求建立未来资料经济的框架,重点是开放的生态系统、多样性以及德国工业基础在自动化市场和已建立的具体情况。

- 此外,政府对采购计画的大力支持使中国能够迈向工业 4.0。例如,中国工业机器人製造商新松隶属于中国科学院,同时也与政府合作。各公司采用工业控制系统是该国的一个显着趋势。先进的系统有利于工厂生产。这也表明,依赖体力劳动的公司正在逐渐转向基于先进技术的系统,以实现设备自动化。

- 影响所研究市场的关键趋势是对智慧製造方法的关注。 IBEF资料显示,印度政府制定了雄心勃勃的目标,到2025年将製造业对国内生产总值(GDP)的贡献从16%提高到25%。智慧先进製造和快速转型中心 (SAMARTH) Udyog Bharat 4.0倡议旨在提高印度製造业对工业 4.0 的认识,并使相关人员能够应对与自动化物料输送相关的挑战。

亚太地区预计将成为成长最快的市场

- 中国是亚太地区 AMH 市场成长的主要贡献者。製造业、汽车和电子商务等行业对 AMH 产品的需求不断增长,正在推动市场成长。中国人口众多,正在推行产业政策。过去十年,以购买力平价计算,中国已成为全球最大的经济体,也是全球最大的出口国和贸易国。中国目前正从製造业和建设业主导经济转向消费主导经济。

- 根据中国国家统计局的数据,2023年中国消费品市场零售总额约为418,605亿元人民币(57,863.1亿美元)。中国的网路消费者数量从2006年的不到3,400万迅速增加到2023年的超过9.15亿,促进了中国电子商务业务的激增。因此,随着电子商务的成长,预计几年对物料输送设备的需求可能会增加。

- 日本主要是一个製造业国家。日本製造业对名义GDP的贡献接近20%,而其他已开发国家则接近10%。据国际货币基金组织称,由于ICT的扩大引进,日本製造业比服务业实现了更大的工业生产力成长。汽车和电子产业是全国生产力最高的製造业。

- 在产业贡献和「印度製造」宣传活动的支持下,政府增加的基础设施投资可能会推动对自动化物料输送(AMH)系统的需求。鑑于製造业占印度GDP的17%并僱用了超过2,730万人,其在该国经济状况中的重要性是不可否认的。印度政府的愿景是到2025年使製造业占该国经济产出的25%,因此正在实施各种措施和政策。因此,製造业正准备拥抱工业 4.0 和其他数位创新,以实现这一雄心勃勃的目标。

- 韩国已经经历了第四次工业革命。在韩国,智慧工厂将是最重要的领域之一。在韩国,私营和公共部门都致力于增加该国智慧工厂的数量。该公司的目标雄心勃勃:到 2023 年,该公司的目标是在全国运作30,000 家最先进的工厂,配备最新的数位和分析技术。此外,还计划在2030年建立20个智慧工业,以应对韩国劳动年龄人口的下降。作为该计划的一部分,我们的目标是到 2030 年建立 2,000 个新的人工智慧驱动的智慧工厂,以适应第四次工业革命特征的数位化和自动化的快速发展。

自动物料输送(AMH) 产业概述

自动化物料输送(AMH)市场的特点是半固化且竞争激烈。市场上的主要企业主要依靠产品推出、研发方面的大量投资以及建立合作伙伴关係和收购等策略来在激烈的竞争中生存。

- 2024 年 5 月,林德物料输送设备的着名製造商凯傲北美公司 (KION NA) 与 Fox Robotics 建立了非排他性策略合作伙伴关係。作为合作伙伴关係的一部分,KION NA 将在其位于南卡罗来纳州萨默维尔的最先进工厂製造和组装FoxBot 的自动拖车装卸机 (ATL)。

- 2023 年 11 月,物料输送先驱丰田物料输送(TMH) 宣布推出三款尖端电动堆高机机型。这些新型号进一步增强了 TMH 广泛的物料输送解决方案系列。这三种型号包括侧入端骑车、中心骑车堆垛机和工业牵引车。这些车型承诺提高效率、多功能性和一流的性能,并专注于驾驶员的舒适度。

其他好处:

- Excel 格式的市场预测 (ME) 表

- 3 个月分析师支持

目录

第一章简介

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章市场洞察

- 市场概况

- 产业价值链分析

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 消费者议价能力

- 新进入者的威胁

- 竞争公司之间的敌对关係

- 替代品的威胁

- COVID-19 大流行对市场的影响

第五章市场动态

- 市场驱动因素

- 技术进步不断推动市场成长

- 工业 4.0 投资推动自动化和物料输送的需求

- 电商领域快速成长

- 市场挑战

- 初始设备成本高

- 缺乏技术纯熟劳工

第六章 市场细分

- 依产品类型

- 硬体

- 软体

- 服务

- 依设备类型

- 移动机器人

- 自动导引运输车(AGV)

- 自主移动机器人(AMR)

- 自动搜寻系统

- 固定通道

- 旋转木马

- 垂直升降模组

- 自动输送机

- 腰带

- 滚筒

- 调色盘

- 开卖

- 堆垛机

- 传统的

- 机器人

- 分类系统

- 移动机器人

- 按最终用户

- 飞机场

- 车

- 食品/饮料

- 零售/仓库/配送中心/物流中心

- 一般製造业

- 药品

- 小包裹

- 其他最终用户

- 按地区

- 北美洲

- 美国

- 加拿大

- 欧洲

- 德国

- 法国

- 义大利

- 西班牙

- 亚洲

- 中国

- 日本

- 印度

- 澳洲/纽西兰

- 拉丁美洲

- 巴西

- 墨西哥

- 中东/非洲

- 阿拉伯聯合大公国

- 沙乌地阿拉伯

- 南非

- 北美洲

第七章 竞争格局

- 公司简介

- Daifuku Co. Ltd

- Kardex Group

- KION Group AG

- JBT Corporation

- Jungheinrich AG

- TGW Logistics Group GmbH

- SSI Schaefer AG

- KNAPP AG

- Mecalux SA

- System Logistics SpA

- Viastore Systems GmbH

- BEUMER Group GmbH & Co. KG

- Interroll Holding AG

- WITRON Logistik

- Siemens AG

- KUKA AG

- Honeywell Intelligrated Inc.(Honeywell International Inc.)

- Murata Machinery Ltd

- Toyota Industries Corporation

- Visionnav Robotics

- Dearborn Mid-West Company

第八章投资分析

第9章市场的未来

简介目录

Product Code: 53959

The Automated Material Handling Market size is estimated at USD 70.35 billion in 2024, and is expected to reach USD 126.20 billion by 2029, growing at a CAGR of 12.40% during the forecast period (2024-2029).

Key Highlights

- Technological advancements, rising labor costs and safety concerns, improved efficiency in manufacturing and warehouse operations, a significant recovery in global manufacturing, increasing demand for automation in industries, growing need for robots in manufacturing units and warehousing facilities, and the growth of emerging markets are key factors driving the automated material handling market. Additionally, the market will benefit from the expanding digitization of supply chain operations, further supported by increasing order customization and personalization during the forecast period.

- Automated Material Handling (AMH) systems streamline the movement of materials across various settings, including manufacturing facilities, warehouses, retail outlets, airports, and logistics centers. These systems facilitate the seamless transfer of materials, whether within the same area, across departments, or even between distinct buildings. AMH systems rely on routes designated by the manufacturing execution system (MES). These systems employ various technologies, including optical character recognition (OCR), barcodes, RFID, ultra-wideband indoor tracking, and near-field communication.

- Over the past seven decades, material handling has undergone significant transformations, reshaping the industry's landscape. Machines and robots have largely supplanted manual labor, catalyzing growth across sectors. Notably, the automotive industry stands out, boasting a remarkable tenfold expansion. Canada's advancements in Industry 4.0 and cutting-edge manufacturing are revolutionizing product design, delivery, and maintenance, even in diverse climates. From robotics and automation to additive manufacturing (3D printing), these technologies find broad utility in sectors spanning e-commerce, automotive, agriculture, and pharmaceuticals. Canadian innovators are spearheading the creation of sophisticated, high-value products, not only for domestic markets but also for a fiercely competitive global arena. Their initiatives not only elevate local practices but also set the stage for collaborative ventures that will define the trajectory of advanced automation technologies.

- While the first AGV debuted in 1953, widespread adoption across production and warehousing firms has been hindered by various factors, with cost being a primary concern. A typical guided vehicle is priced between USD 60,000 and 100,000, but systems with advanced features like navigation aids and sensors can be considerably pricier. These high upfront costs, coupled with maintenance challenges, are dampening the market's growth. Leading firms are striving to control costs without compromising on innovation or R&D investments.

- The COVID-19 pandemic has significantly impacted the adoption of automation across sectors, reshaping operational norms and introducing challenges such as social distancing and contactless operations. Organizations faced surging demands and reduced workforces, prompting the implementation of enhanced safety protocols. Since 2020, the outbreak affected the US workers, compelling companies to adopt new safety measures swiftly. While some industries, like food production, experienced shutdowns due to the virus's severity, many others adapted by incorporating stringent health measures to sustain operations.

Automated Material Handling (AMH) Market Trends

Industry 4.0 Investments Significantly Drive the Market's Growth

- The market is driven by the developments occurring due to countries adopting Industry 4.0 and IOT technologies. Through the use of robotics, industry 4.0 is revolutionizing how material handling is done. In warehouses and distribution facilities, robotics is becoming more and more prevalent. For instance, the International Federation of Robotics reported that US manufacturers heavily invested in automation, leading to a 12% increase in industrial robot installations, totaling 44,303 units in 2023. In addition to picking and packaging orders, loading and unloading trucks, and even cleaning the warehouse floor, they can also be employed for these activities. Workplace accuracy and productivity can both be enhanced by robotics. Robots can also enable company save money by lowering the quantity of necessary manual work.

- For instance, as warehouses are huge, associates must walk considerable distances to locate SKUs and deliver orders to the packing and shipping regions. Every year, an average warehouse wastes 6.9 weeks on unnecessary walking and other movements, equating to 265 million hours of work at the cost of USD 4.3 billion. During each stage of the selection process, collaborative robots also minimize the need for extended walks between functional areas. The rise in material handling equipment orders will significantly drive the studied market.

- Moreover, robotics, automation, and technologies like additive manufacturing (3D printing) have a wide range of applications in Canadian industries such as e-commerce, automotive, agriculture, and pharmaceuticals. Canadian innovators are producing a comprehensive range of technologically complex, increased-value products for domestic and competitive global markets, sharing enhanced practices and laying the groundwork for collaborations that shape the future of advanced automation technologies.

- Germany is also focused on the 2030 vision for Industry 4.0 in three strategic fields of action: autonomy, interoperability, and sustainability. In this 2030 vision, the stakeholders of the platform Industry 4.0 present a holistic approach to shaping the digital ecosystem. The goal is to create a framework for a future data economy that is by the demands of a social market economy, emphasizing open ecosystems, diversity, and supporting competition between all market stakeholders based on the specific situation and established strengths of the German industry base for the automation market.

- Furthermore, the government's strong support in the acquisition program has enabled China to move toward Industry 4.0. For instance, Siasun, a China-based industrial robot maker, is affiliated with the Chinese Academy of Sciences, which is further linked to the government. The country's adoption of industrial control systems by various companies is a notable trend. The advanced systems allow ease of production in factories. This also points to the gradual shift of companies from depending on manual labor to advanced technology-based systems that will enable the facility's automation.

- A significant trend impacting the market studied is the focus on smart manufacturing practices. According to the data from IBEF, the Government of India set an ambitious target of increasing manufacturing output contribution to 25% of the gross domestic product (GDP) by 2025 from 16%. The Smart Advanced Manufacturing and Rapid Transformation Hub (SAMARTH) Udyog Bharat 4.0 initiative aims to enhance awareness about Industry 4.0 within the Indian manufacturing industry and enable stakeholders to address challenges related to automation material handling.

Asia-Pacific is Expected to be the Fastest Growing Market

- China has been a prominent contributor to the growth of the Asia-Pacific AMH market. The increasing demand for AMH products across industries, such as manufacturing, automotive, and e-commerce, boosts the market's growth. China has a vast population and pursues an industrial policy. Measured on the PPP basis, the country became the largest global economy and the largest global exporter and trader during the current decade. The country is currently transitioning from a manufacturing and construction-led economy to a consumer-led economy.

- According to China's National Bureau of Statistics, total retail sales in China's consumer products market were around CNY 41,860.5 billion (USD 5786.31 billion) in 2023. The number of Chinese online buyers has risen rapidly from under 34 million in 2006 to over 915 million in 2023, enabling China's e-commerce business to proliferate. Hence, with growing e-commerce, the demand for material-handling equipment will likely rise in the forecasted years.

- Japan is predominantly a manufacturing nation. Its manufacturing industry contributes close to 20% to the nominal GDP, whereas it is close to 10% for other developed countries. According to the IMF, the country's manufacturing sector has achieved significant industrial productivity gains over the services sector, owing to the increased adoption of ICT. The automotive and electronics sectors are the most productive manufacturing sectors in the country.

- The government's heightened infrastructure investments, bolstered by industry contributions and the 'Make in India' campaign, are set to propel the demand for automated material handling (AMH) systems. Given that the manufacturing sector accounts for 17% of India's GDP and employs over 27.3 million individuals, its significance in the nation's economic landscape is undeniable. With a vision to derive 25% of the economy's output from manufacturing by 2025, the Indian government is rolling out various initiatives and policies. Consequently, manufacturers are gearing up to embrace Industry 4.0 and other digital innovations to meet this ambitious goal.

- South Korea adopted the 4th Industrial Revolution. In Korea, smart factories will be one of the most important fields. Both the private and public sectors in Korea have committed to ramping up the number of domestic smart factories. Their target is ambitious: they aim to have 30,000 such cutting-edge factories equipped with the latest digital and analytical technologies up and running across the nation by 2023. Furthermore, in a bid to counteract Korea's shrinking working-age population, there are plans to establish 20 smart industrial zones by 2030. As part of this initiative, the goal is to set up 2,000 new AI-powered smart factories by 2030, aligning with the rapid pace of digitalization and automation characteristic of the fourth industrial revolution.

Automated Material Handling (AMH) Industry Overview

The automated material handling (AMH) market is characterized by semi-consolidation and high competitiveness. Key players in the market primarily rely on strategies like product launches, significant investments in R&D, and forming partnerships or making acquisitions to navigate the fierce competition.

- In May 2024, KION North America (KION NA), a prominent manufacturer of Linde Material Handling equipment, and Fox Robotics entered into a strategic non-exclusive partnership. As part of this collaboration, KION NA is expected to manufacture and assemble FoxBot autonomous trailer loader/unloaders (ATLs) at its state-of-the-art facilities in Summerville, South Carolina.

- In November 2023, Toyota Material Handling (TMH), a pioneer in material handling, unveiled three cutting-edge electric forklift models. These additions bolster TMH's already extensive range of material handling solutions. The trio includes a Side-Entry End Rider, a Center Rider Stacker, and an Industrial Tow Tractor. These models promise heightened efficiency, versatility, and top-tier performance, all while emphasizing operator comfort.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Value Chain Analysis

- 4.3 Industry Attractiveness - Porter's Five Forces Analysis

- 4.3.1 Bargaining Power of Suppliers

- 4.3.2 Bargaining Power of Consumers

- 4.3.3 Threat of New Entrants

- 4.3.4 Intensity of Competitive Rivalry

- 4.3.5 Threat of Substitute Products

- 4.4 Impact of the COVID-19 Pandemic on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Incremental Technological Advancements aiding the Market's Growth

- 5.1.2 Industry 4.0 Investments driving the Demand for Automation and Material Handling

- 5.1.3 Rapid Growth of the E-commerce Sector

- 5.2 Market Challenges

- 5.2.1 High Initial Equipment Costs

- 5.2.2 Unavailability for Skilled Workforce

6 MARKET SEGMENTATION

- 6.1 By Product Type

- 6.1.1 Hardware

- 6.1.2 Software

- 6.1.3 Services

- 6.2 By Equipment Type

- 6.2.1 Mobile Robots

- 6.2.1.1 Automated Guided Vehicle (AGV)

- 6.2.1.2 Autonomous Mobile Robot (AMR)

- 6.2.2 Automated Storage and Retrieval System

- 6.2.2.1 Fixed Aisle

- 6.2.2.2 Carousel

- 6.2.2.3 Vertical Lift Module

- 6.2.3 Automated Conveyor

- 6.2.3.1 Belt

- 6.2.3.2 Roller

- 6.2.3.3 Pallet

- 6.2.3.4 Overhead

- 6.2.4 Palletizer

- 6.2.4.1 Conventional

- 6.2.4.2 Robotic

- 6.2.5 Sortation System

- 6.2.1 Mobile Robots

- 6.3 By End User

- 6.3.1 Airport

- 6.3.2 Automotive

- 6.3.3 Food And Beverages

- 6.3.4 Retail/Warehousing/Distribution Centers/Logistic Centers

- 6.3.5 General Manufacturing

- 6.3.6 Pharmaceuticals

- 6.3.7 Post and Parcel

- 6.3.8 Other End Users

- 6.4 By Geography

- 6.4.1 North America

- 6.4.1.1 United States

- 6.4.1.2 Canada

- 6.4.2 Europe

- 6.4.2.1 Germany

- 6.4.2.2 France

- 6.4.2.3 Italy

- 6.4.2.4 Spain

- 6.4.3 Asia

- 6.4.3.1 China

- 6.4.3.2 Japan

- 6.4.3.3 India

- 6.4.4 Australia and New Zealand

- 6.4.5 Latin America

- 6.4.5.1 Brazil

- 6.4.5.2 Mexico

- 6.4.6 Middle East and Africa

- 6.4.6.1 United Arab Emirates

- 6.4.6.2 Saudi Arabia

- 6.4.6.3 South Africa

- 6.4.1 North America

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Daifuku Co. Ltd

- 7.1.2 Kardex Group

- 7.1.3 KION Group AG

- 7.1.4 JBT Corporation

- 7.1.5 Jungheinrich AG

- 7.1.6 TGW Logistics Group GmbH

- 7.1.7 SSI Schaefer AG

- 7.1.8 KNAPP AG

- 7.1.9 Mecalux SA

- 7.1.10 System Logistics SpA

- 7.1.11 Viastore Systems GmbH

- 7.1.12 BEUMER Group GmbH & Co. KG

- 7.1.13 Interroll Holding AG

- 7.1.14 WITRON Logistik

- 7.1.15 Siemens AG

- 7.1.16 KUKA AG

- 7.1.17 Honeywell Intelligrated Inc. (Honeywell International Inc.)

- 7.1.18 Murata Machinery Ltd

- 7.1.19 Toyota Industries Corporation

- 7.1.20 Visionnav Robotics

- 7.1.21 Dearborn Mid-West Company

8 INVESTMENT ANALYSIS

9 FUTURE OF THE MARKET

02-2729-4219

+886-2-2729-4219