|

市场调查报告书

商品编码

1549889

机器台虎钳:市场占有率分析、产业趋势与统计、成长预测(2024-2029)Machine Bench Vices - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

价格

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

简介目录

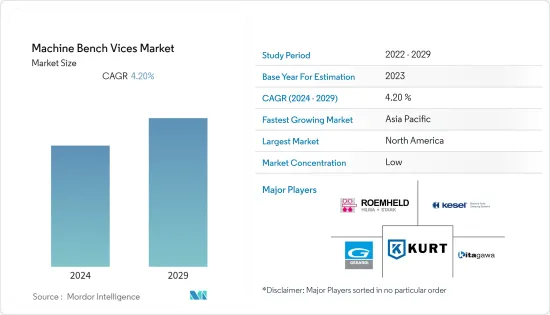

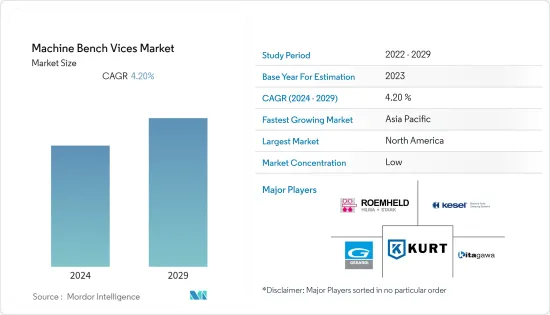

预计机器台虎钳市场在预测期间内复合年增长率为 4.20%

主要亮点

- 机用虎钳或台虎钳与发明家的虎钳类似,是用来夹住金属而不是木材的工具。虎钳的主要用途是在切割或打磨时固定金属。机用虎钳牢牢地固定住您正在加工的物体。它可以安装在铣床或钻床上。机用虎钳通常由手摇曲柄或液压系统操作,可以用适度的力道夹紧物体。

- 随着越来越多的工作场所使用钻床和铣床,工业部门的快速成长需要扩大机用台虎钳的范围。此外,许多製造工具机的公司都将中小型公司製造的虎钳作为其标准设备的一部分。此外,小型企业在公开市场上从各个批发商购买这些虎钳。因此,小企业的成长预计在不久的将来会非常高。

- 中国、印度和印尼等新兴经济体以及日本和韩国等已开发国家正在帮助亚太地区在製造业中占据主导地位,特别是在金属加工设备对机床台虎钳的需求方面。

- 而且,中国还是全世界最大的汽车製造国。由于活性化以及国家的消费促进措施等其他因素对中国乘用车市场产品的贡献,中国已成为最大的乘用车生产国之一。因此,汽车领域对工具机台虎钳的需求不断增加。例如,根据OICA的数据,2022年中国乘用车产量为238万辆,较2021年成长11%。

- 金属加工设备最广泛应用于汽车及相关产业,製造业为第二大消费者。航太和国防等关键领域的工具机虎钳金属加工设备的需求和供应预计在预测期内将会增加。

- 俄罗斯和乌克兰之间的衝突对该行业产生了重大影响。衝突加剧了已经影响该行业的供应链问题和材料短缺。此次中断导致镍、钯、铜、钛、铝和铁矿石等关键原料价格波动,导致材料短缺。从而影响了各种工具机台虎钳的生产。

- 此外,根据乌克兰投资局的数据,2022 年 3 月初铜价上涨至 10,845 美元/吨。俄乌战争、能源成本上涨以及欧洲更严格的废气标准被指出是铜持续短缺的主要原因。

机用台虎钳市场趋势

汽车领域显着成长

- 由于汽车需求的增加,机器台虎钳的使用正在增加。近年来,机器台虎钳在汽车产业的使用显着增加。从相似的晶粒零件到一体式车架製造,现代汽车中的大部分零件都由 CNC 设备和机械製造。因此,随着汽车产业需求的不断增加,所研究市场的需求未来可能会持续成长。

- 例如,全球道路上有超过 13 亿辆汽车,预计到 2035 年将增加至 18 亿辆。其中,乘用车约占74%,轻型商用车、大型卡车、巴士、长途客车和小型客车占其余26%。

- 根据OICA(国际汽车工业协会)的数据,中国是全球最大的汽车市场:2023年中国汽车用户将购买约2,606万辆乘用车。印度是亚洲第二大乘用车市场。

- 此外,亚太地区是所有地区中人口最多的地区。不断增长的城市人口和消费能力使亚太地区成为汽车行业最重要的市场之一。根据中国工业协会的数据,2022年4月中国乘用车销量约96.5万辆,商用车销量约21.6万辆,季减48%和42%。由于汽车销量如此之大,所研究的市场也在成长。

- 随着汽车製造的发展,许多製造商正在采用智慧工厂解决方案。例如,Kurt Workholding 将于 2022 年 3 月推出 DX8 虎钳。这款全新 DX8 虎钳作为全新 8 吋虎钳平台,具有与 DX 系列虎钳相同的关键功能。 Kurt 的 DX8 虎钳是 DX CrossOver 虎钳系列中最新、最广泛的虎钳。 DX8 虎钳将 Kort D810 虎钳和 Kort 3800V 虎钳的最佳功能结合到一个虎钳中,其尖端功能重新定义了精密平面度、平行度和重复性。

亚太市场成长显着

- 亚太国家在各行业开展了製造和研发活动,占该地区市场占有率较高。此外,金属加工和汽车业等行业加大力度确保工人安全也支持了该地区的市场成长。

- 在金属加工中,机用台虎钳最常用于高价数控机床上,并且需要连续操作。因此,最大限度地缩短设定时间至关重要。特别是在大量生产中,需要高度自动化来实现经济高效的重复加工,用于固定物体的夹紧系统至关重要。液压虎钳是最重要的夹紧繫统。液压虎钳可以快速且有力地紧固物体。您始终可以以相同的力度重复夹紧。

- 由于製造业和机械工业的快速发展,印度对工具机配件的需求量很大。印度政府实施了多项政策来帮助企业设立製造单位。其中包括旨在2025年将製造业占GDP比重提高到25%的国家製造业政策,以及2022年推出的旨在使核心製造业达到国际标准的PLI计画。

- 此外,劳动力的供应和零件价格的下降导致製造商将生产转移到该地区,进一步促进了市场的发展。有几个关键因素正在推动该地区的采用,包括靠近供需区域。

- 此外,亚太地区製造工厂的建立正在刺激电脑数值控制(CNC)的使用,以推动机器台虎钳市场的发展。由于汽车製造的自动化程度不断提高,汽车产业预计将成为未来几年成长最快的领域之一。机器台虎钳市场预计将受到汽车和製造业等金属加工行业效率、时间效率、精度和精密度不断提高的推动。

机器台虎钳产业概述

机用台虎钳市场较为分散,由许多公司组成。从市场占有率来看,目前市场由其中一些重要供应商控制。这些拥有重要市场份额的主要企业正致力于扩大海外基本客群。研究市场中的公司不断努力创新先进产品,以满足消费者不断变化的需求。

- 2023 年 11 月 - GEARWRENCH 扩大了其商店用品产品线,并宣布为专业汽车机械师推出两个落地式千斤顶和四个千斤顶支架。此外,三款台虎钳型号和三款瓶子千斤顶产品计划于 2024 年初发布。

- 2023 年 8 月-德国工具机商 Roemheld 宣布将于 9 月 18 日至 23 日在汉诺威举行的 EMO 2023 金属加工贸易展览会上的展位(4 号馆,E54)展示其新型机械定心(自定心)技术。新型 Hilma.UC 125 虎钳采用模组化设计,适用于 3 至 5 轴棱镜加工应用。该设计允许从各个方向轻鬆存取刀具,从而允许在单一设置中使用短刀具进行精密加工。

其他好处

- Excel 格式的市场预测 (ME) 表

- 3 个月分析师支持

目录

第一章简介

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章市场洞察

- 市场概况

- 产业吸引力-波特五力分析

- 新进入者的威胁

- 买家/消费者的议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争公司之间敌对关係的强度

- COVID-19 和其他宏观经济因素对市场的影响

第五章市场动态

- 市场驱动因素

- 金属加工产业需求增加

- 扩大先进加工技术的采用

- 市场限制因素

- 增加使用替代夹持技术

第六章 市场细分

- 依产品类型

- 油压机台虎钳

- 气动机台虎钳

- 按分销管道

- 在线的

- 离线

- 按最终用户产业

- 製造业

- 汽车工业

- 其他最终用户产业

- 按地区

- 北美洲

- 欧洲

- 亚洲

- 澳洲/纽西兰

- 拉丁美洲

- 中东/非洲

第七章 竞争格局

- 公司简介

- Gerardi SpA

- Kurt Manufacturing Company

- KITAGAWA

- Georg Kesel GmbH & Co KG

- Romheld GmbH Friedrichshutte

- Raptor Workholding Products

- Jergens Inc.

- ALLMATIC-Jakob Spannsysteme

- OK-VISE

- LANG Technik GmbH

- 5th Axis Inc.

- SPREITZER GmbH & Co. KG

第八章投资分析

第9章 市场的未来

简介目录

Product Code: 50002512

The Machine Bench Vices Market is expected to register a CAGR of 4.20% during the forecast period.

Key Highlights

- Machine vises and bench vises, like inventor's vises, are tools used to clamp metal instead of wood. The primary purpose of the vise is to hold metal while the cutting and filing process is going on. A machine vise holds the workpiece securely while the work is being done. It can be mounted on a milling or drilling machine. A machine vise is usually operated by a hand crank or a hydraulic system and can clamp the workpieces with moderate force.

- The rapid growth of the industrial sectors has increased the number of workshops utilizing drills and milling machines, thus necessitating an expansion of the machine bench vices. Furthermore, most companies manufacturing machine tools incorporate vices manufactured by small businesses as part of their standard equipment. Moreover, small-scale businesses also purchase these vices from various wholesalers in the open market. Consequently, the growth of small enterprises is expected to be exceptionally high in the near future.

- Developing economies, such as China, India, and Indonesia, among others, along with industrialized countries, such as Japan and South Korea, have assisted the Asia-Pacific (APAC) region to dominate the manufacturing industry in terms of demand, particularly with the demand for machine bench vices for metal fabrication equipment.

- Moreover, China is also the largest manufacturer of automobiles in the world. China is one of the largest producers of passenger cars due to the improving logistics and supply chains, increased business activity, and the country's raft of pro-consumption measures, among other factors contributing to the passenger car market products in the country. Therefore, this has increased demand for machine bench vices for the automotive segment. For instance, according to OICA, in 2022, passenger car production in China amounted to 2.38 million units, which showed an increase of 11% compared to 2021.

- Metal fabrication equipment is the most widely used in the automotive and related industries, with manufacturing companies being the next largest consumers. The demand and supply of machine bench vice metal fabrication equipment for critical sectors, including aerospace and defense, are projected to increase over the forecast period.

- The conflict between Russia and Ukraine significantly impacted this industry. The conflict exacerbated supply chain issues and material shortages that had affected the industry for some time. The disruption resulted in volatile pricing for critical raw materials such as nickel, palladium, copper, titanium, aluminum, and iron ore, resulting in material shortages. This, in turn, impacted the manufacturing of various Machine Bench Vices.

- Further, according to UkraineInvest, copper prices escalated to USD 10,845/mt in early March 2022. The Russia-Ukraine War, high energy costs, and stricter emissions standards in Europe have been noted as the primary reasons for the continued shortage of copper.

Machine Bench Vices Market Trends

Automotive Segment to Register Significant Growth

- Machine bench vice usage has increased due to the increasing demand for Automobiles. In recent years, the automotive industry has seen a significant increase in the use of machine bench vices. From die-casting similar components to unibody frame manufacturing, CNC instruments and machines are responsible for most of the parts found in modern cars. Therefore, with the increasing demand in the automotive industry, the demand of the studied market will continue to grow in the years to come.

- For instance, over 1.3 billion motor cars are on the road worldwide, which is predicted to climb to 1.8 billion by 2035. Passenger automobiles account for around 74% of these figures, with light commercial vehicles and large trucks, buses, coaches, and minibusses accounting for the remaining 26%.

- According to OICA (International Organization of Motor Vehicle Manufacturers), China is the world's largest automotive market: Chinese motorists purchased around 26.06 million passenger cars in 2023. India was the second-largest market for passenger cars in Asia.

- Furthermore, Asia-Pacific has the most people of any region. Owing to an increase in urban population and spending power, Asia-Pacific is one of the most important markets for the automobile industry. According to the China Association of Automobile Manufacturers, approximately 965,000 passenger vehicles and 216,000 commercial automobiles were sold in China in April 2022, representing a 48% and 42% decrease from the previous month, respectively. Such massive vehicle sales will allow the studied market to grow.

- Many manufacturers are embracing intelligent factory solutions as the automotive manufacturing landscape evolves. Kurt Workholding, for example, will be introduced to the DX8 vise in March 2022. This new DX8 vise has the same key features as the DX-series vise as the new 8-inch vise platform. The DX8 vise from Kurt is the most recent and most extensive vise in the family of DX CrossOver vise. The DX8 vise combines the top features of the Kort D810 vise and the Kort 3800V vise into one vise with cutting-edge features that redefine precision flatness, parallelism, and repeatability.

Asia Pacific Market to Grow Significantly

- Due to the growing development in manufacturing and R&D activities in various industries across the Asia Pacific countries, the region holds a high market share. Further, the rising number of initiatives taken to ensure the safety of the workers in industries such as metalworking and automotive also support the market growth in the region.

- In metalworking, machine bench vices are most commonly used in high-priced CNC machines, which must operate continuously. As a result, it is essential to minimize setup time. In this context, the clamping system used to secure the workpieces is of the utmost importance, particularly in series production, where the highest degree of automation is required to produce repetitive processing operations cost-effectively. Hydraulic vices are the most essential type of clamping system. They can fix the workpiece in place quickly and with great strength. The constant repetition of clamping can always be accomplished with the same strength.

- India is a rapidly expanding nation in manufacturing industries and machinery, resulting in a high demand for machine bench accessories. The Indian government has implemented various policies to assist companies in establishing manufacturing units. These include the National Manufacturing Policy, which seeks to increase the manufacturing sector's share of GDP to 25% by 2025, and the PLI Scheme for Manufacturing, initiated in 2022 to bring the core manufacturing sector up to international standards.

- Furthermore, the easy availability of labor and the declining prices of components have resulted in manufacturers shifting their production units in this region, further promoting the market. Several critical factors drive adoption in this region, including its proximity to supply and demand regions.

- In addition, setting up manufacturing plants in the Asia-Pacific region has stimulated the use of computer numerical control (CNC), which drives the machine bench vice market. The automotive industry is expected to be one of the fastest-growing segments in the next few years due to the growing automation of automobile manufacturing. The machine bench vice market is expected to be driven by increased efficiency, time efficiency, accuracy, and precision across metalworking industries like the automotive and manufacturing industries.

Machine Bench Vices Industry Overview

The machine bench vices market is fragmented and consists of many players. Regarding market share, some of these important vendors currently manage the market. These influential players with a noticeable share in the market are concentrating on expanding their customer base across foreign countries. The players in the studied market are striving to constantly innovate advanced products to cater to consumers' evolving needs.

- November 2023 - GEARWRENCH expanded their shop equipment product offering, announcing the launch of two new Floor Jacks and four new Jack Stands available now for the professional Automotive Mechanic. In addition, three models of Bench Vises and three Bottle Jack products will be launched at the beginning of 2024.

- August 2023 - German workholding equipment manufacturer Roemheld announced that it will launch a new, mechanically operated, centric (self-centering) machine vice on its stand (E54 in hall 4) at the forthcoming EMO 2023 metalworking trade show in Hannover, 18th - 23rd September. The new Hilma.UC 125 vice is of modular build, intended for 3 to 5-axis prismatic machining applications. The design ensures easy tool access to the workpiece from all sides, allowing the use of short tools for high-precision machining in a single set-up.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Threat of New Entrants

- 4.2.2 Bargaining Power of Buyers/Consumers

- 4.2.3 Bargaining Power of Suppliers

- 4.2.4 Threat of Substitute Products

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Impact of COVID-19 Aftereffects and Other Macroeconomic Factors on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Increasing Demand from the Metalworking Industry

- 5.1.2 Growing Adoption of Advanced Machining Technologies

- 5.2 Market Restraint

- 5.2.1 Increasing Use of Alternative Clamping Technologies

6 MARKET SEGMENTATION

- 6.1 By Product Type

- 6.1.1 Hydraulic Machine Bench Vices

- 6.1.2 Pneumatic Machine Bench Vices

- 6.2 By Distribution Channel

- 6.2.1 Online

- 6.2.2 Offline

- 6.3 By End-User Industry

- 6.3.1 Manufacturing

- 6.3.2 Automotive

- 6.3.3 Other End-user Industries

- 6.4 By Geography

- 6.4.1 North America

- 6.4.2 Europe

- 6.4.3 Asia

- 6.4.4 Australia and New Zealand

- 6.4.5 Latin America

- 6.4.6 Middle East and Africa

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Gerardi S.p.A.

- 7.1.2 Kurt Manufacturing Company

- 7.1.3 KITAGAWA

- 7.1.4 Georg Kesel GmbH & Co KG

- 7.1.5 Romheld GmbH Friedrichshutte

- 7.1.6 Raptor Workholding Products

- 7.1.7 Jergens Inc.

- 7.1.8 ALLMATIC-Jakob Spannsysteme

- 7.1.9 OK-VISE

- 7.1.10 LANG Technik GmbH

- 7.1.11 5th Axis Inc.

- 7.1.12 SPREITZER GmbH & Co. KG

8 INVESTMENT ANALYSIS

9 FUTURE OF THE MARKET

02-2729-4219

+886-2-2729-4219