|

市场调查报告书

商品编码

1550203

Cap Liner:市场占有率分析、产业趋势、成长预测(2024-2029)Cap Liners - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

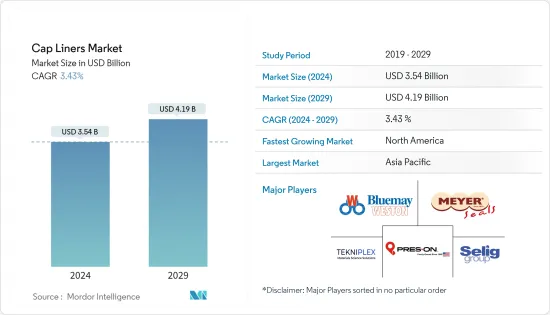

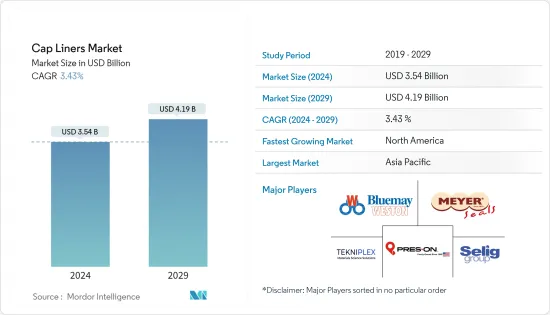

Cap Liner市场规模预计到2024年为35.4亿美元,预计到2029年将达到41.9亿美元,预计在预测期内(2024-2029年)复合年增长率为3.43%。

随着包装行业不断突破界限,包装行业对瓶盖衬垫的需求预计将激增。在食品、饮料和製药等多个最终用户行业中,瓶盖内衬变得比以往任何时候都更加重要。

瓶盖内衬的防篡改功能正在将其需求推向新的高度。各种瓶盖衬垫正在彻底改变包装行业,包括必需品、压感和热感应型。

公司越来越多地转向使用永续材料来减少碳排放。对于产品製造商来说,采用透气感应瓶盖衬垫来解决高海拔地区的瓶子塌陷问题尤其有希望。人们越来越依赖这些衬垫来改善包装产品的密封、品牌和货架可见度。

根据整合式 Liner Technologies 的说法,常见的瓶盖衬垫类型包括硅胶、丁基橡胶、PTFE、聚乙烯和铝箔。每种产品都具有针对最终用户行业的不同需求而客製化的独特优势,选择过程取决于内容化学、温度敏感性和外部脆性等因素。这些考虑因素旨在确保耐化学性、灵活性、缓衝性和法规遵循性,所有这些对于维持品质和安全标准都至关重要。

此外,消费者对食品安全和永续性意识的提高正在推动创新瓶盖内衬材料和设计的采用。此外,製药公司根据其与内容物的兼容性以及保持密封完整性的能力来选择瓶盖衬垫,这对于在储存期间保护样品至关重要。

您还可能面临由于盖子和内衬之间接触不良而导致的密封不良、洩漏和溢出等挑战。 IH 盖内衬的过度加热会损害包装质量,并且是市场上的一个挑战。然而,塑胶或聚酯内衬的使用令有环保意识的公司感到失望,并阻碍了瓶盖内衬的广泛采用。

瓶盖内衬市场趋势

製药业越来越多地使用瓶盖内衬

- 药品生产和包装受到严格监管,包装合作伙伴必须熟悉产业要求。製药公司负责人依靠感应封盖机来确保非处方 (OTC)锭剂、锭剂和液体的安全。

- 根据设计,感应密封提供了核准的防篡改解决方案。容器的边缘会留下衬里残留物,以通知消费者容器已打开。感应密封不仅具有防篡改功能,而且还可透过防止洩漏和保持产品新鲜度在製药业务中发挥作用。感应盖的气密密封可防止氧气和湿气损坏容器中的内容物。

- 根据整合式 Technologies 的说法,製药公司在选择实验室储存容器的瓶盖衬垫时非常谨慎。这些衬垫包括硅胶、丁基橡胶、PTFE、聚乙烯和铝箔,其选择基于其与内容物的兼容性以及保持密封完整性的能力,这对于防止样品污染非常重要。每种衬管类型都具有根据您的製药需求量身定制的独特优势。

- 此外,瓶盖内衬的选择过程取决于内容物的化学性质、温度敏感性以及对外部元素的脆弱性。透过优先考虑耐化学性、灵活性、缓衝和气密密封,公司确保其产品符合严格的监管标准,并维持业界最高的品质和安全基准。

- 由于疾病的增加,製药业也在成长。根据Astra Zeneca,2023年至2027年拉丁美洲医药市场的成长预测为22%,其中拉丁美洲预计占据全球首位,其次是欧洲,成长10.6%。然而,由于各种药品的包装要求不断增加,製药业的崛起可能会进一步提振瓶盖内衬市场。

北美预计将成为最大的成长地区

- 塑胶盖和密封件在许多行业中都至关重要,可提供经济高效的密封解决方案。热感应盖和衬里与多种塑胶(如 PP、HDPE 和 LDPE)相容,不仅可以防止洩漏,还可以提供增强的诈欺性能。这种双重功能将在预测期内推动市场成长。

- 包装饮料和药品的需求正在急剧增加。因此,预计接受调查的市场在预测期内的需求也会增加。消费者的健康意识日益增强,对健康饮品的需求也不断增加。这使得个人更容易获得瓶装水,从而推动了区域瓶盖内衬市场的成长。

- 该地区大量消费非酒精饮料,包括瓶装水。美国拥有广泛的消费群,主导全球瓶装水市场。 FDA 规定,密封在容器中的瓶装水仅供人类饮用,不得含有任何其他成分。根据饮料行销公司和国际瓶装水协会 2023 年 3 月发布的报告,瓶装水将在 2022 年成为美国最受欢迎的饮料,约占所有饮料消费的 25%。

- 此外,根据Monster Beverage Corporation的数据,就2023年美国非酒精饮料销售成长率而言,能量饮料类别将以8.3%领先,其次是碳酸饮料,成长3.6%。因此,饮料成长率的上升预计将加强全部区域的瓶盖内衬市场。

瓶盖内衬产业概况

瓶盖内衬市场由多家从事该行业的公司组成,例如 Tekni-Plex Inc.、Meyer Seals GmbH、Bluemay Weston Limited、Press-On Corporation、Selig UK Limited 和 B&B Cap Liners LLC。公司专注于透过收购、合作、合併和其他策略来扩展业务。

- 2024 年 1 月,TekniPlex 推出了一系列新的可回收纸基底感应热封衬垫。 ProTecSeals 可回收 IHS 衬垫由树浆製成的可回收纸製成。与传统 IHS 内衬相同的标准,提供防潮和阻隔性、防洩漏、防止污染并延长保质期。

- 2023 年 6 月 Selig UK Limited 宣布推出推出容器密封和通风技术的新网站,扩大业务。新网站整合了多个旧网站的内容,以展示 Selig 的多样化解决方案和产品。为了反映公司的全球影响力和基本客群,该网站提供五种语言版本:英语、普通话、法语、德语和西班牙语。

其他好处

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第一章简介

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章市场洞察

- 市场概况

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 买方议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争公司之间的敌对关係

- 产业价值链分析

第五章市场动态

- 市场驱动因素

- 安全可靠地处理、储存和运输产品

- 製药业需求增加

- 市场限制因素

- 不合适的内衬会缩短保存期限或导致产品洩漏。

第六章 市场细分

- 依材料类型

- 橡皮

- 金属

- 塑胶

- 纸

- 按用途

- 瓶子

- 瓶子/容器

- 依产品类型

- 导热帽内衬

- 一件

- 两件套

- 半月班轮

- 其他导热帽衬

- 压感衬里

- 其他产品类型

- 导热帽内衬

- 按最终用户产业

- 食品

- 饮料

- 个人护理和化妆品

- 化学品/肥料

- 油、润滑剂、润滑脂

- 居家护理

- 其他最终用户产业

- 按地区

- 北美洲

- 美国

- 加拿大

- 欧洲

- 法国

- 德国

- 西班牙

- 英国

- 土耳其

- 亚太地区

- 中国

- 印度

- 日本

- 泰国

- 澳洲/纽西兰

- 拉丁美洲

- 巴西

- 墨西哥

- 中东/非洲

- 阿拉伯聯合大公国

- 沙乌地阿拉伯

- 埃及

- 南非

- 北美洲

第七章 竞争格局

- 公司简介

- Meyer Seals GmbH

- Tekni-Plex Inc.

- Bluemay Weston Limited

- Press-On Corporation

- B&B Cap Liners LLC

- Low's Cap Seal Sdn Bhd

- Tien Lik Cap Seal Sdn Bhd

- Captel International Pvt. Ltd

- The Cary Company

- Selig UK Limited

- MFI Capliners

第八章主要企业概况热图分析

第九章公司分类分析-新兴企业和现有公司

第十章投资分析

第十一章 市场未来展望

The Cap Liners Market size is estimated at USD 3.54 billion in 2024, and is expected to reach USD 4.19 billion by 2029, growing at a CAGR of 3.43% during the forecast period (2024-2029).

The demand for cap liners in the packaging industry is poised to surge as the industry pushes its boundaries. Cap liners are gaining unprecedented importance in multiple end-user industries, such as food, beverage, and pharmaceuticals, driven by the growing reliance of the affluent population.

Cap liners' ability to establish tamper evidence propels their demand to new heights. A wide array of cap liners, including essential, pressure-sensitive, and heat induction, is revolutionizing the packaging industry.

Businesses are increasingly turning to sustainable materials to shrink their carbon footprints. Adopting vented induction cap liners to tackle the high-altitude bottle collapsing issue is particularly promising for product manufacturers. Industries increasingly rely on these liners to enhance the sealing, branding, and shelf appeal of their packaged product.

According to Integrated Liner Technologies, the prevalent cap liner types include silicone, butyl rubber, PTFE, polyethylene, and foil. Each offers distinct advantages tailored to different end-user industry needs, with the selection process hinging on factors like content chemistry, temperature sensitivity, and external vulnerability. These considerations aim to ensure chemical resistance, flexibility, cushioning, and regulatory compliance, all pivotal for upholding quality and safety standards.

Moreover, heightened consumer awareness of food safety and sustainability is driving the adoption of innovative cap liner materials and designs. Also, pharmaceutical companies select cap liners based on their compatibility with the contents and ability to maintain seal integrity, which is crucial for safeguarding samples in storage.

The market might also face challenges, such as poor cap-liner contact, leading to inadequate sealing, leaks, and spills. Excessive heating of induction cap liners compromises packaging quality and challenges the market. However, using plastic or polyester liners is a letdown for eco-conscious businesses, hindering the wider adoption of cap liners.

Cap Liners Market Trends

Increased Use of Cap Liners in the Pharmaceutical Industry

- Pharmaceutical production and packaging are subject to stringent regulations, necessitating packaging partners to be well-versed in the industry's demands. Pharmaceutical packagers rely on induction cap sealers to secure over-the-counter (OTC) prescription pills, tablets, and liquids.

- By design, induction seals offer an approved tamper-evident solution. They leave a liner residue on the container lip, signaling to consumers of any prior opening. Beyond tamper-evidence, induction seals also aid pharmaceutical operations by ensuring leak prevention and preserving product freshness. The airtight seal on the induction cap prevents oxygen and moisture from compromising the container's contents.

- According to Integrated Liner Technologies, pharmaceutical companies meticulously select cap liners for their lab storage containers. These liners, including silicone, butyl rubber, PTFE, polyethylene, and foil, are chosen based on their compatibility with the contents and ability to maintain seal integrity, which is crucial for preventing sample contamination. Each liner type offers distinct advantages tailored to the pharmaceutical product's needs.

- Additionally, the selection process of cap liners depends on content chemistry, temperature sensitivity, and vulnerability to external elements. By prioritizing chemical resistance, flexibility, cushioning, and hermetic sealing, companies ensure their products meet stringent regulatory standards, upholding the industry's highest quality and safety benchmarks.

- The pharmaceutical industry is also growing owing to the rise in diseases. According to AstraZeneca, the projected pharmaceutical market growth between 2023 and 2027 in Latin America is expected to be 22%, with Latin America taking the top position globally, followed by Europe recording a 10.6% growth. However, a rise in the pharmaceutical industry would further boost the cap liners market, with growing packaging requirements for various medicines and drugs.

North America is Expected to be the Largest-growing Regional Market

- Plastic caps and closures are pivotal in many industries, offering a cost-effective sealing solution. Heat induction cap liners, compatible with a range of plastics like PP, HDPE, and LDPE, not only prevent leaks but also enhance tamper-proof features. This dual functionality is set to drive market growth over the forecast period.

- The demand for packaged beverages and pharmaceutical drugs has been increasing enormously. As a result, the market studied is also expected to register increased demand during the forecast period. Consumers are becoming increasingly health-conscious, and the demand for healthy beverages is rising. This has made bottled water more accessible to individuals, aiding the regional cap liner market's growth.

- The region witnesses vast consumption of non-alcoholic beverages, including bottled water. The United States dominates the global market for bottled water, boasting an extensive consumer base. The FDA specifies that bottled water, sealed in its container, is solely intended for human consumption and must not contain any additional ingredients. According to a report published by the Beverage Marketing Corporation and the International Bottled Water Association in March 2023, bottled water was the most popular drink in the United States in 2022, accounting for about 25% of all beverage consumption.

- Further, according to Monster Beverage Corporation, in terms of sales value growth of non-alcoholic beverages in the United States in 2023, the energy drinks segment took the top position with 8.3%, followed by carbonated soft drinks with 3.6% in the same year. Therefore, rising beverage growth is expected to bolster the cap liners market across the region.

Cap Liners Industry Overview

The cap liners market is fragmented, with various players, such as Tekni-Plex Inc., Meyer Seals GmbH, Bluemay Weston Limited, Press-On Corporation, Selig UK Limited, and B&B Cap Liners LLC, operating in the industry. The players are focused on expanding their business through acquisitions, collaborations, mergers, and other strategies.

- January 2024: TekniPlex launched a new series of recyclable, paper-based induction heat seal liners designed to seal dry pharma, nutrition, and food products in bottles and jars with protective properties identical to conventional solutions. The ProTecSeals Recyclable IHS Liners are made of recyclable paper from tree pulp. They offer moisture and oxygen barrier properties, resist leaks, prevent contamination, and prolong shelf life to the same standard as traditional IHS liners.

- June 2023: Selig UK Limited announced that it was expanding its business by launching a new website that consolidates its container sealing and venting technologies. The new site integrates content from several legacy websites and exhibits Selig's diverse solutions and products. To reflect the company's global presence and customer base, the website was made available in five languages: English, Mandarin, French, German, and Spanish.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumption and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces' Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Industry Value Chain Analysis

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Safe and Secure Handling, Storage, and Transport of Products

- 5.1.2 Increased Demand from the Pharmaceutical Industry

- 5.2 Market Restraints

- 5.2.1 Improper Liners May Shorten Shelf Life or Cause Leakage of Products

6 MARKET SEGMENTATION

- 6.1 By Material Type

- 6.1.1 Rubber

- 6.1.2 Metal

- 6.1.3 Plastic

- 6.1.4 Paper

- 6.2 By Application

- 6.2.1 Bottles

- 6.2.2 Jars & Containers

- 6.3 By Product Type

- 6.3.1 Heat-induction Cap Liners

- 6.3.1.1 One-piece

- 6.3.1.2 Two-piece

- 6.3.1.3 Halfmoon Liner

- 6.3.1.4 Other Heat-induction Cap Liners

- 6.3.2 Pressure Sensitive Liners

- 6.3.3 Other Product Types

- 6.3.1 Heat-induction Cap Liners

- 6.4 By End-user Industry

- 6.4.1 Food

- 6.4.2 Beverage

- 6.4.3 Personal Care & Cosmetics

- 6.4.4 Chemicals & Fertilizers

- 6.4.5 Oil, Lubricants, and Grease

- 6.4.6 Home Care

- 6.4.7 Other End-user Industries

- 6.5 By Geography

- 6.5.1 North America

- 6.5.1.1 United States

- 6.5.1.2 Canada

- 6.5.2 Europe

- 6.5.2.1 France

- 6.5.2.2 Germany

- 6.5.2.3 Spain

- 6.5.2.4 United Kingdom

- 6.5.2.5 Turkey

- 6.5.3 Asia-Pacific

- 6.5.3.1 China

- 6.5.3.2 India

- 6.5.3.3 Japan

- 6.5.3.4 Thailand

- 6.5.3.5 Australia and New Zealand

- 6.5.4 Latin America

- 6.5.4.1 Brazil

- 6.5.4.2 Mexico

- 6.5.5 Middle East and Africa

- 6.5.5.1 United Arab Emirates

- 6.5.5.2 Saudi Arabia

- 6.5.5.3 Egypt

- 6.5.5.4 South Africa

- 6.5.1 North America

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Meyer Seals GmbH

- 7.1.2 Tekni-Plex Inc.

- 7.1.3 Bluemay Weston Limited

- 7.1.4 Press-On Corporation

- 7.1.5 B&B Cap Liners LLC

- 7.1.6 Low's Cap Seal Sdn Bhd

- 7.1.7 Tien Lik Cap Seal Sdn Bhd

- 7.1.8 Captel International Pvt. Ltd

- 7.1.9 The Cary Company

- 7.1.10 Selig UK Limited

- 7.1.11 M.F.I. Capliners