|

市场调查报告书

商品编码

1629810

拉丁美洲自动储存和搜寻系统:市场占有率分析、行业趋势和成长预测(2025-2030)Latin America Automated Storage and Retrieval System - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

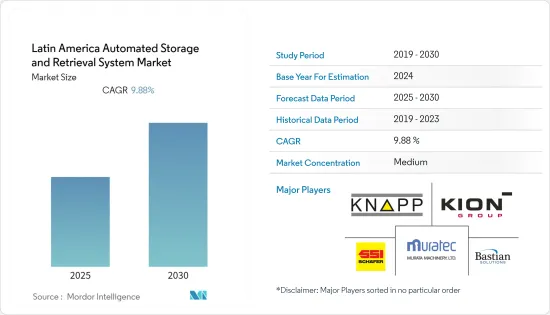

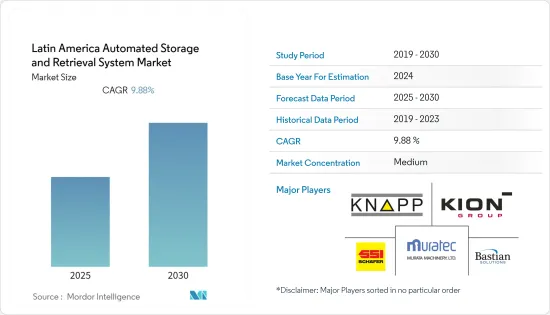

拉丁美洲自动化储存和搜寻系统市场预计在预测期内复合年增长率为 9.88%

主要亮点

- 拉丁美洲国家正在转型为快速成长的新兴经济体。在中国设有製造工厂的公司正在将部分生产转移到墨西哥和巴西,以降低供应链风险并服务美国市场。

- 此外,自动化正在彻底改变该地区的仓储业务,使公司能够降低管理成本,并以一致性和准确性提高生产力。人工智慧在实现这一目标方面发挥着关键作用。线上零售商正在尽一切努力减少向客户交付产品所需的时间。

- 许多汽车和电子製造商正在投资新技术以降低成本并提高效率。例如,仓库机器人市场的知名供应商 Mecalux 在其大陆工厂(墨西哥)安装了一台自动箱子堆垛机机,以及其他输送系统和行李进出点的电脑化操作。预计在预测期内,起重机作为此类补充解决方案的使用案例将会增加。

- 拉丁美洲市场成长的主要驱动力是都市化的加速、电子商务销售的增加以及技术提供者的强大存在。这些公司投资研发活动并提供创新解决方案以保持竞争力。

- 此外,凭藉几乎为零的市场进入障碍和高度发展的工业基础,墨西哥已发展成为美国自动化的最大买家。拉丁美洲靠近欧洲和北美,这有助于零件供应商的出现,并影响了对适合此类需求的 AS/AR 系统的需求。

拉丁美洲自动搜寻系统市场趋势

汽车产业可望占据较大市场占有率

- 巴西和哥伦比亚的汽车产业正在经历积极的转型。此外,巴西和阿根廷签署了汽车领域的自由贸易协定。两国将逐步取消汽车业的贸易关税。这些预计将为汽车行业引入自动化,并为该地区的 AS/RS 铺平道路。

- 此外,Festo 等组织正在准备向墨西哥和中美洲发货的战略地点。费斯托最近发布新闻稿称,其辛辛那提工厂地理位置优越,毗邻机场,并且有能力支持墨西哥的预期增长,正在成为公认的汽车行业中心。

- 冠状病毒危机已经打击了世界各地的汽车生产,但巴西受到的打击最为严重。汽车製造商协会Anfave的数据显示,2020年6月巴西汽车产量较2020年5月成长129%,但较2019年同月仍下降58%。它还预测2020年汽车产量与前一年同期比较下降45%,出口量将年减53%。

- 此外,过去十年来,电动和混合动力汽车的出现彻底改变了汽车製造。汽车生产变得更加精密和复杂。不断发展的政府安全法规和行业标准使组装操作变得更加复杂。

- 这创造了汽车产业对自动装置的巨大需求。最大限度地减少人为错误导致的运输过程中的产品损坏,并提高工作站之间的底盘搬运速度以允许与组装工人的互动是首要任务。这些趋势预计将推动该地区所有行业采用仓库机器人。

预计墨西哥将占较大市场占有率

- 千禧世代人口的成长和可支配收入的增加为亚马逊等零售商创造了许多推出新产品线的机会,并对先进的仓储设备产生了巨大的需求。在这些高吞吐量仓库中,AMR 可以帮助提高效率并减少劳动力挑战。

- 2020 年 10 月,亚马逊宣布投资 1 亿美元在墨西哥开设新仓库,其中包括人口稠密的大都会区以外的第一个配送中心,以提供更快的配送服务。新地点包括两个履约中心,一个靠近北部城市蒙特雷,另一个靠近中部城市瓜达拉哈拉。此外,该公司正在向巴西扩张,最近在该国开设了第五个也是最大的履约中心,面积达 100,000平方公尺。所有这些投资预计将加速 ASRS 在仓库中的使用。

- 此外,许多巴西人透过电子商务购买饮料、饼干和洗髮精等日常用品。零售市场预计将在预测期内快速成长,并有助于零售业越来越多地采用自动化。

- 此外,先进技术正在创造正在改变该国食品和饮料行业的设备和流程。食品和饮料行业传统上依赖人力来完成配送和储存等功能,但正在开发和引入机器人来简化流程并生产更稳定的产品。

- 在食品自动化中,必须对机器进行适当消毒,以避免产品污染并保护消费者免受食物中毒。目前的自动化趋势证实了新技术的发展,可以为墨西哥某些加工食品的生产提供端到端自动化。

拉丁美洲自动仓储与搜寻系统产业概况

由于初始投资较高,拉丁美洲的自动化储存和搜寻系统市场适度集中。一些大公司主导市场,例如 KION GROUP AG、Bastian Solutions, LLC、SSI Schaefer AG、Murata Machinery Ltd. 和 KNAPP AG。这些拥有压倒性市场份额的大公司正致力于扩大海外基本客群。这些公司利用策略合作措施来扩大市场占有率并提高盈利。然而,随着技术进步和产品创新,中小企业正在透过赢得新契约和开拓新市场来增加其市场份额。

- 2020 年 9 月 - KUKA AG 推出水平关节臂机器人 KR SCARA,该机器人极其紧凑,具有最佳成本绩效。机器人的运行距离为 500 毫米或 700 毫米,循环时间短,仅 0.36 或 0.38 秒。 KR SCARA机器人是在成本敏感市场中推动自动化的理想选择。

- 2020 年 8 月 - Geek+Inc. 继美国和墨西哥之后,扩展其第一个南美洲计划。该公司宣布透过第一个机器人计划向南美洲扩张,为该国最大的超级市场沃尔玛智利提供智慧物流解决方案。沃尔玛智利将Geek+AMR带到南美,升级供应链业务。

其他好处

- Excel 格式的市场预测 (ME) 表

- 3 个月分析师支持

目录

第一章简介

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章市场洞察

- 市场概况

- 产业价值链分析

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 买方议价能力

- 新进入者的威胁

- 竞争公司之间的敌对关係

- 替代品的威胁

第五章市场动态

- 市场驱动因素

- 日益重视职业安全

- 人们对人事费用的担忧日益加剧

- 市场限制因素

- 对熟练劳动力的需求以及对人工替代的担忧

- COVID-19 对市场的影响

第六章 市场细分

- 依产品类型

- 固定通道法

- 轮播(水平轮播+垂直轮播)

- 垂直升降模组

- 按最终用户产业

- 飞机场

- 车

- 饮食

- 一般製造业

- 小包裹

- 零售业

- 其他的

- 按国家/地区

- 墨西哥

- 巴西

- 阿根廷

- 其他拉丁美洲

第七章 竞争格局

- 公司简介

- Murata Machinery Ltd.

- KNAPP AG

- Bastian Solutions, LLC

- KION GROUP AG

- Schaefer Systems International Pvt Ltd

- Hanel Storage Systems

- Flex Inc.

- Kubo systems

- Automation Logistics Corporation

- Beumer Group

第八章投资分析

第9章市场的未来

The Latin America Automated Storage and Retrieval System Market is expected to register a CAGR of 9.88% during the forecast period.

Key Highlights

- Latin American nations have transformed themselves into a set of fast-growing, emerging economies. Companies with manufacturing plants in China are moving some production to Mexico and Brazil to reduce supply chain risk and serve the American market.

- Moreover, automation has revolutionized the warehouse business in the region, thereby helping companies reduce overhead costs and increase productivity with consistency and accuracy. Artificial intelligence plays a significant role in achieving this. Online retailers are making every effort to reduce the time it takes to deliver products to customers.

- Many automotive and electronic companies are investing in new technologies to reduce their cost and attain efficiency. For instance, Mecalux, a prominent vendor in the warehouse robotics market, installed automated stacker cranes for boxes in Continental's plant (Mexico), along with other conveyor systems and computerized operations at cargo entrance and exit. Such use cases of cranes as a complementing solution are expected to increase over the forecast period.

- The primary driving forces for the growth of the Latin America regional segment are the rising urbanization, rising e-commerce sales, and the significant presence of technology providers. These players invest in research and development activities to offer innovative solutions to stay competitive.

- Further, with virtually zero market access barriers and a highly developed industrial base, Mexico has evolved to become the largest purchaser of automation from the United States. The proximity of the Latin American region with Europe and North America has helped the emergence of component suppliers, impacting demand for AS/AR systems suited for such needs.

Latin America Automated Storage & Retrieval System Market Trends

Automotive is Expected to Hold Significant Market Share

- The automotive industry is undergoing a positive transition in Brazil and Columbia. Moreover, Brazil and Argentina signed a free trade agreement for the automotive sector. Both the countries will gradually phase out trade tariffs for each other in the automotive industry. These are expected to bring automation to the automotive industry, thus paving the way for AS/RS in this region.

- Further, organizations like Festo are preparing strategic locations for shipments to Mexico and Central America. Recently, Festo published a news release stating that a facility in Cincinnati, which is strategically close to the airport and could support the expected growth in Mexico, is becoming a recognized hub for the automotive industry.

- The coronavirus crisis has struck auto production around the world but hit Brazil the hardest. According to the automakers association, Anfave, Brazil's automobile production rose in June 2020 from May 2020 by 129% but remains 58% lower compared with the same month in 2019. It also expects auto production to fall by 45% in 2020 compared to a year ago, while exports will lose 53% in the same period.

- Moreover, the advent of electric vehicles and hybrid cars has revolutionized automobile manufacturing in the past decade. Automobile production has become far more sophisticated and complex. The ever-evolving government safety regulations and industry standards are further complicating the assembly line tasks.

- This has created a significant demand for automation in the automotive sector. Minimizing products damage during transit (caused by human error) and increasing the speed of handling the chassis between workstations (which would allow interaction with assembly-line workers) are receiving the utmost priority. Such trends are expected to boost the adoption of warehouse robotics across industries in the region.

Mexico is Expected to Account For Significant Market Share

- The expanding millennial population and the increase in disposable incomes create many opportunities for retailers like Amazon to introduce new product lines, creating a considerable need for advanced warehouse facilities. In such high throughput warehouses, AMRs can help scale up the efficiencies and mitigate labor challenges.

- In October 2020, Amazon announced USD 100 million logistics investment in opening new warehouses in Mexico, including its first shipping centers outside the populous capital area, to offer faster deliveries. The new sites include two fulfillment centers, one near the northern city of Monterrey and another near the central city of Guadalajara. Additionally, the company is also striving to make inroads in Brazil, where it recently opened its fifth and biggest fulfillment center in the country, with 100,000 square meters. All these investments are expected to drive the utilization of ASRS in the warehouse.

- Further, many people in the country opting for e-commerce for their daily necessities, such as drinks, biscuits, and shampoos. The retail market is expected to experience rapid growth during the forecast period and help increase the adoption of automation in retails.

- Moreover, advanced technology has given rise to equipment and processes that have transformed the country's food and beverage sector. The food and beverage industry has traditionally relied on human workers to handle functions like distribution and storing; robotics are being developed and implemented to streamline the process and produce more consistent output.

- In food automation, it is essential to ensure properly sanitized machinery to avoid product contamination, resulting in consumers contracting foodborne illnesses. The current trend of automation has witnessed the development of new technologies that can provide end-to-end automation for the production of certain processed foods in Mexico.

Latin America Automated Storage & Retrieval System Industry Overview

The Latin American automated storage and retrieval system market is moderately concentrated due to higher initial investments. It is dominated by a few significant players like KION GROUP AG, Bastian Solutions, LLC, SSI Schaefer AG, Murata Machinery Ltd., and KNAPP AG. With a prominent share in the market, these significant players are focusing on expanding their customer base across foreign countries. These companies are leveraging strategic collaborative initiatives to increase their market share and increase their profitability. However, with technological advancements and product innovations, mid-size to smaller companies are growing their market presence by securing new contracts and tapping new markets.

- September 2020 - KUKA AG launched the KR SCARA horizontal jointed-arm robots that are ultra-compact and at the same time deliver maximum cost-effectiveness. The robot reaches 500 or 700 millimeters, a short cycle time of just 0.36 or 0.38 seconds. The KR SCARA robots are ideal for pushing ahead with automation in cost-sensitive markets.

- August 2020 - Geek+ Inc is expanding with its first South American project, following the US & Mexico deployments. The company announced its expansion into South America with its first robotics project, providing intelligent logistics solutions to Walmart Chile, the largest supermarket chain in the country. Walmart Chile brought Geek+ AMRs to South America, upgrading its supply chain operations.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Value Chain Analysis

- 4.3 Industry Attractiveness - Porter's Five Forces Analysis

- 4.3.1 Bargaining Power of Suppliers

- 4.3.2 Bargaining Power of Buyers

- 4.3.3 Threat of New Entrants

- 4.3.4 Intensity of Competitive Rivalry

- 4.3.5 Threat of Substitute Products

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Increased Emphasis on Workplace Safety

- 5.1.2 Increasing Concerns about Labor Costs

- 5.2 Market Restraints

- 5.2.1 Need for Skilled Workforce and Concerns over Replacement of Manual Labor

- 5.3 Impact of COVID-19 on the Market

6 MARKET SEGMENTATION

- 6.1 By Product Type

- 6.1.1 Fixed Aisle System

- 6.1.2 Carousel (Horizontal Carousel + Vertical Carousel)

- 6.1.3 Vertical Lift Module

- 6.2 By End-User Industries

- 6.2.1 Airports

- 6.2.2 Automotive

- 6.2.3 Food and Beverage

- 6.2.4 General Manufacturing

- 6.2.5 Post and Parcel

- 6.2.6 Retail

- 6.2.7 Other End-user Industries

- 6.3 By Country

- 6.3.1 Mexico

- 6.3.2 Brazil

- 6.3.3 Argentina

- 6.3.4 Rest of Latin America

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Murata Machinery Ltd.

- 7.1.2 KNAPP AG

- 7.1.3 Bastian Solutions, LLC

- 7.1.4 KION GROUP AG

- 7.1.5 Schaefer Systems International Pvt Ltd

- 7.1.6 Hanel Storage Systems

- 7.1.7 Flex Inc.

- 7.1.8 Kubo systems

- 7.1.9 Automation Logistics Corporation

- 7.1.10 Beumer Group