|

市场调查报告书

商品编码

1630185

金属涂料:市场占有率分析、产业趋势与统计、成长预测(2025-2030)Metal Coatings - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

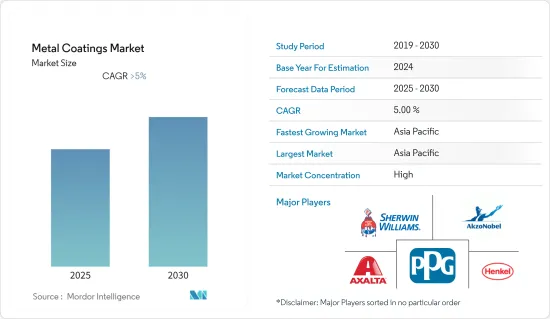

预计金属涂料市场在预测期内复合年增长率将超过 5%。

COVID-19 的爆发导致全球范围内的国家封锁、製造活动和供应链中断以及生产停顿,对 2020 年的市场产生了负面影响。然而,到了2021年,情况开始好转,市场恢復了成长轨迹。

主要亮点

- 推动市场的主要因素是严格的 VOC 法规推动了对水性 DTM 涂料的需求。

- 另一方面,金属涂层不适合恶劣环境,很可能阻碍市场发展。

- 亚太地区主导全球市场,其中中国和印度等国家的消费量最高。

金属涂料市场趋势

水剂领域占市场主导地位

- 水性涂料占整个金属涂料市场的大部分。水性涂料比溶剂型涂料具有优势的主要原因是它们更环保,因为它们通常含有较少的会破坏环境的挥发性有机化合物(VOC)。低气味、耐久性和抗粘连性等其他特性也使水性涂料更受欢迎。

- 水性涂料的环保性和多功能性导致全球需求的增加。

- 水性涂料主要用于汽车漆。因此,随着全球汽车产量的增加,水性涂料的需求也预计会增加。

- REACH 是欧洲政府的一项倡议,旨在保护人类健康和环境免受化学品风险,同时增加欧洲化学工业的竞争。推广评估物质危害的替代方案可以减少动物试验。对低VOC含量涂料(例如水性涂料)的需求正在增加。

- 由于这些因素,它被广泛应用于汽车行业。 OICA公布的资料显示,疫情后时期汽车产量大幅成长。

- 电动车产量也呈现快速成长。根据国际能源总署(IEA)预测,2022年全球电动车销量将超过1,000万辆,预计2023年将再成长35%,达到1,400万辆。根据IEA预测,电动车占整个汽车市场的份额将从2020年的约4%上升至2022年的14%,并在2023年进一步上升至18%。

- 近年来,终端用户寻求具有低气味、易于使用、易于清洗等特点的涂料已成为一种趋势。水性涂料满足这些要求,无需添加低分子单体即可降低黏度。

亚太地区主导市场

- 预计亚太地区将在预测期内主导金属涂料消费市场。中国、日本、韩国和印度等国家对金属涂料的需求正在增加。这是因为製造地位于这些国家。

- 金属涂层也用于电气和电子工业。亚洲地区是全球最大的电气电子设备生产国,其中中国、日本、韩国、新加坡、马来西亚等国家位居榜首。

- 根据中国工业协会统计,中国是全球最大的汽车生产基地,预计2022年汽车产量将达到2,700万辆,比2021年的2,600万辆增加3.4%。此外,中国电动车(EV)产业规模全球第一,占全球电动车产量的64%。与 2021 年相比,2022 年中国新电动车销量成长 82%。到2022年,它将占全球电动车销量的59%,巩固其作为全球最大电动车市场的地位。

- 在印度,根据印度汽车工业协会(SIAM)的数据,该国汽车工业在2022-23财年(2022年4月至2023年3月)生产的汽车数量高于2021年4月至2022年3月。此外,印度电动车销量仅占汽车总销量的不到1%。然而,它有潜力在几年内增长到 5% 以上。印度道路上有超过 50 万辆电动两轮车和数千辆电动车。产业销售波动较大,很大程度取决于政府的奖励。许多公司,包括 Hero Eco、Ather、Electrotherm、Avon、Lohia 和 Ampere,都在继续他们的使命并做出积极的改变。这些因素可能会增加所研究市场的需求。

金属涂装业概况

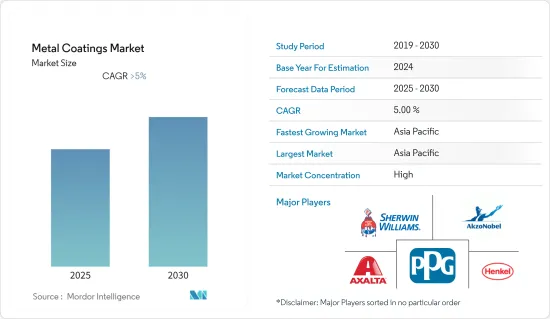

金属涂料市场得到部分完整。主要参与者包括阿克苏诺贝尔公司、艾仕得涂料系统有限公司、PPG工业公司、宣伟公司和汉高公司。

其他好处:

- Excel 格式的市场预测 (ME) 表

- 3 个月分析师支持

目录

第一章简介

- 调查先决条件

- 调查范围

第二章调查方法

第三章执行摘要

第四章市场动态

- 促进因素

- 严格的VOC法规推动对水性直接金属被覆剂的需求

- 其他司机

- 抑制因素

- 不适合恶劣环境

- 其他阻碍因素

- 产业价值链分析

- 波特五力分析

- 供应商的议价能力

- 买方议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第五章市场区隔(以金额为准的市场规模)

- 依树脂类型

- 环氧树脂

- 聚酯纤维

- 聚氨酯

- 其他树脂类型

- 依技术

- 水性的

- LED固化

- 溶剂型

- 粉末

- 紫外线固化

- 按用途

- 建筑学

- 车

- 海洋

- 保护

- 一般工业用途

- 其他用途

- 按地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 其他亚太地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 义大利

- 法国

- 其他欧洲国家

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地区

- 中东/非洲

- 沙乌地阿拉伯

- 南非

- 其他中东和非洲

- 亚太地区

第六章 竞争状况

- 併购、合资、联盟、协议

- 市场占有率/排名分析

- 主要企业策略

- 公司简介

- AkzoNobel NV

- Axalta Coating Systems, LLC

- BASF SE

- Clean Diesel Technologies Inc.

- Hempel A/S

- Henkel AG & Co. KGaA

- Jotun

- Kansai Paint Co. Ltd

- Nippon Paint Holdings Co. Ltd

- PPG Industries, Inc.

- RPM International

- The Sherwin-Williams Company

第七章 市场机会及未来趋势

The Metal Coatings Market is expected to register a CAGR of greater than 5% during the forecast period.

Due to the COVID-19 outbreak, nationwide lockdowns worldwide, disruption in manufacturing activities and supply chains, and production halts negatively impacted the market in 2020. However, the conditions started recovering in 2021, restoring the market's growth trajectory.

Key Highlights

- The major factor driving the market studied is stringent VOC regulation driving the demand for waterborne DTM coatings.

- On the flip side, as the metal coatings are unsuitable for the harsh operating environment, they will likely hinder the market.

- Asia-Pacific dominated the global market with the largest consumption in countries such as China, India, etc.

Metal Coatings Market Trends

Water-borne Segment to Dominate the Market

- Water-borne paints and coatings account for most of the overall metal coatings market. The major reason for its gain over solvent-borne is its environment-friendly nature, as it is generally lower in volatile organic compounds (VOCs), which degrade the environment. Other properties, such as low odor, durability, and block resistance, make water-borne paints preferable.

- Water-borne coatings' increasing environment-friendly nature and versatile properties are increasing global demand.

- Water-borne coatings are majorly required in automotive paints. Hence, with the increase in global automotive production, the demand for water-borne coatings is also expected to increase.

- REACH, a European government initiative, was adopted to protect human health and the environment from the risks of chemicals while enhancing competition in the European chemical industry. Promoting alternative methods for the hazard assessment of substances reduces tests on animals. It is increasing the demand for coatings with low VOC content, such as water-borne coatings.

- Because of these factors, these are widely used in the automotive industry. As per data published by OICA, vehicle production grew significantly in the post-pandemic period.

- Electric vehicle production is also witnessing exponential growth. As per International Energy Agency (IEA), more than 10 million electric cars were sold worldwide in 2022, and sales are expected to grow by another 35% in 2023 to reach 14 million. Electric cars' share of the overall car market rose from around 4% in 2020 to 14% in 2022 and is set to increase further to 18% in 2023, based on IEA projections.

- Recently, there is a propensity to seek coatings with low odor, usability, and water clean-up characteristics among the end-users. Water-borne coatings meet these requirements and facilitate low viscosity without adding low-molecular-weight monomers.

Asia Pacific Region to Dominate the Market

- The Asia-Pacific region is expected to dominate the market for metal coatings consumption during the forecast period. The demand for metal coatings is increasing in countries like China, Japan, South Korea, and India. It is due to the presence of manufacturing bases in these countries.

- Metal Coating is also used in the electrical and electronics industry. The Asian region is the largest producer of electrical and electronics worldwide, with dominating countries such as China, Japan, South Korea, Singapore, and Malaysia.

- According to the China Association of Automobile Manufacturers (CAAM), China includes the largest automotive production base in the world, with a total vehicle production of 27 million units in 2022, registering an increase of 3.4 % compared to 26 million units produced in 2021. Further, China's electric vehicle (EV) industry is the largest globally, accounting for 64% of the global production of EVs. Sales of new EVs in China increased by 82% in 2022 compared to 2021. The country accounted for 59% of global EV sales in 2022, cementing its position as the world's largest electric vehicles market.

- In India, during FY 2022-23 (April 2022 to March 2023), according to the Society of Indian Automobile Manufacturers (SIAM), the country's automotive industry produced a total of 25,931,867 vehicles compared to 23,040,066 units from April 2021 to March 2022. Furthermore, electric vehicle sales in India are less than 1% of the total vehicle sales. However, it includes the potential to grow to more than 5% in a few years. There are more than 500 thousand electric two-wheelers and a few thousand electric cars on Indian roads. The industry volumes are fluctuating, mostly depending on the incentives offered by the government. Many players, such as Hero Eco, Ather, Electrotherm, Avon, Lohia, Ampere, etc., are continuing with the mission and trying to enforce positive change. Such factors are likely to increase the demand for the studied market.

Metal Coatings Industry Overview

The metal coatings market is partially consolidated. Some major players include AkzoNobel NV, Axalta Coating Systems, LLC, PPG Industries Inc., The Sherwin-Williams Company, and Henkel AG & Co. KGaA.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Stringent VOC Regulation is Driving the Demand for Water-borne Direct-To-Metal Coatings

- 4.1.2 Other Drivers

- 4.2 Restraints

- 4.2.1 Not Suitable for Harsh Operating Environment

- 4.2.2 Other Restraints

- 4.3 Industry Value-Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Buyers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION (Market Size in Value)

- 5.1 Resin Type

- 5.1.1 Epoxy

- 5.1.2 Polyester

- 5.1.3 Polyurethane

- 5.1.4 Other Resin Types

- 5.2 Technology

- 5.2.1 Water-borne

- 5.2.2 LED Curing

- 5.2.3 Solvent-borne

- 5.2.4 Powder

- 5.2.5 UV Cured

- 5.3 Application

- 5.3.1 Architectural

- 5.3.2 Automotive

- 5.3.3 Marine

- 5.3.4 Protective

- 5.3.5 General Industrial

- 5.3.6 Other Applications

- 5.4 Geography

- 5.4.1 Asia-Pacific

- 5.4.1.1 China

- 5.4.1.2 India

- 5.4.1.3 Japan

- 5.4.1.4 South Korea

- 5.4.1.5 Rest of Asia-Pacific

- 5.4.2 North America

- 5.4.2.1 United States

- 5.4.2.2 Canada

- 5.4.2.3 Mexico

- 5.4.3 Europe

- 5.4.3.1 Germany

- 5.4.3.2 United Kingdom

- 5.4.3.3 Italy

- 5.4.3.4 France

- 5.4.3.5 Rest of Europe

- 5.4.4 South America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Rest of South America

- 5.4.5 Middle East & Africa

- 5.4.5.1 Saudi Arabia

- 5.4.5.2 South Africa

- 5.4.5.3 Rest of Middle East & Africa

- 5.4.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers & Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Share/Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 AkzoNobel NV

- 6.4.2 Axalta Coating Systems, LLC

- 6.4.3 BASF SE

- 6.4.4 Clean Diesel Technologies Inc.

- 6.4.5 Hempel A/S

- 6.4.6 Henkel AG & Co. KGaA

- 6.4.7 Jotun

- 6.4.8 Kansai Paint Co. Ltd

- 6.4.9 Nippon Paint Holdings Co. Ltd

- 6.4.10 PPG Industries, Inc.

- 6.4.11 RPM International

- 6.4.12 The Sherwin-Williams Company