|

市场调查报告书

商品编码

1636480

德国电动汽车电池製造:市场占有率分析、产业趋势、成长预测(2025-2030)Germany Electric Vehicle Battery Manufacturing - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

价格

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

简介目录

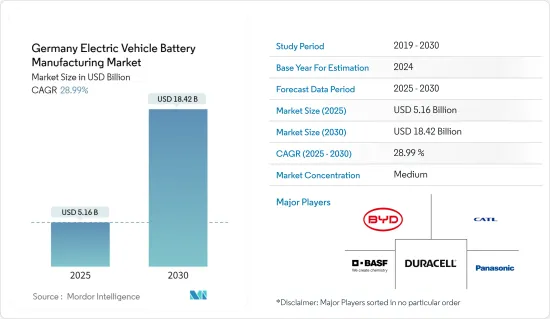

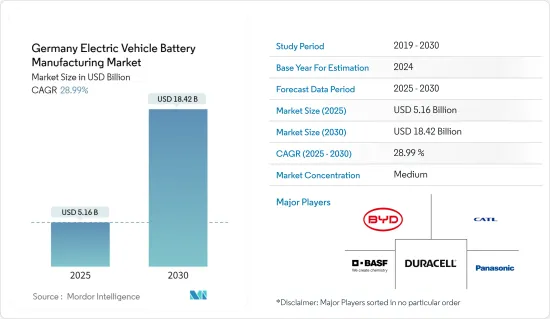

德国电动车电池製造市场规模预计到2025年为51.6亿美元,预计到2030年将达到184.2亿美元,预测期内(2025-2030年)复合年增长率为28.99%。

主要亮点

- 从中期来看,电动车需求的增加、增加电动车电池产能的投资以及电池原料(特别是锂离子)成本的下降预计将在预测期内推动市场发展。

- 另一方面,电池原料成本下降预计将阻碍未来市场的发展。

- 德国电动车的长期雄心勃勃的目标预计将在预测期内创造重大机会。

德国电动车电池製造市场趋势

锂离子电池预计将占较大份额

- 近年来,德国对电动车(EV)的需求显着增加。这些电动车主要依赖电池能源储存系统,这对于全电动、插电式混合动力汽车和混合动力汽车至关重要。

- 大多数插电式混合动力汽车和电动车都配备了锂离子电池。由于锂离子电池组价格的下降及其更高的能量密度、更长的循环寿命和整体效率等优点,插电式混合动力汽车对锂电池材料的需求正在上升。

- 2023年,锂离子电池组价格将比前一年下降14%,稳定在139美元/kWh。除了这些好处之外,正在进行的研究和开发旨在生产更有效、更有效率的电动车锂电池材料。

- 此外,德国正在积极推动锂电池的国内生产,以加强电动车的转型。该策略旨在减少对进口锂的依赖,并为快速成长的电动车市场建立可持续的供应链。

- 例如,2023年6月,ivista Energy宣布计画在德国精製锂用于电动车电池。 ivista Energy 计划于 2026 年开始生产,将与法国领先的石油和天然气服务公司 Technip Energies 合作,主导工厂的设计。

- 此外,2024 年 5 月,Rock Tech Lithium Inc. 获得在德国古本建造精製的批准。该工厂将生产约24,000吨氢氧化锂,这对电动车电池和能源储存系统至关重要。

- 鑑于这种气候和锂离子电池成本的下降,该细分市场有望获得显着的市场占有率。

电动车电池产能投资可望带动市场

- 近年来,德国大幅增加投资,加强电动车电池的国内生产,旨在解决供应链缺口。这些努力不仅增强了当地经济,而且在帮助德国和欧盟整体实现净零目标方面发挥了关键作用。

- 例如,2024年1月,欧盟决定德国向瑞典着名锂离子电池製造商Northvolt提供9.02亿欧元(9.8643亿美元)的国家援助。这笔资金将支持在德国海德建立电动车 (EV) 电池生产设施。

- 德国政府提供各种激励措施和补贴来吸引该领域的投资。此外,随着该国电动车销量的上升,政府可能会采取进一步措施以进一步促进国内电池製造。根据国际能源总署的资料,2023年德国纯电动车(BEV)销量将达到52万辆,高于2022年的47万辆。

- 此外,本土製造商与全球高科技公司之间的合作正在加速电池技术的进步,并巩固德国在国际舞台上的地位。例如,优美科与大众汽车计划于2025年成立合资企业,在大众汽车位于德国的萨尔茨吉特工厂生产电动车正极材料,目标年产能为20GWh。

- 鑑于这些新兴市场的发展和资金支持,投资预计将增加电动车电池的产能,市场预计将向前发展。

德国电动车电池製造业概况

德国电动车电池製造市场规模中等。市场主要企业(排名不分先后)包括比亚迪有限公司、BASF股份公司、当代新能源科技有限公司、金霸王公司和松下控股公司。

其他好处

- Excel 格式的市场预测 (ME) 表

- 3 个月分析师支持

目录

第一章简介

- 调查范围

- 市场定义

- 研究场所

第 2 章执行摘要

第三章调查方法

第四章市场概况

- 介绍

- 2029年之前的市场规模与需求预测(单位:美元)

- 最新趋势和发展

- 政府法规和措施

- 市场动态

- 促进因素

- 投资增加电池产能

- 电池原物料成本下降

- 抑制因素

- 原料蕴藏量不足

- 促进因素

- 供应链分析

- PESTLE分析

- 投资分析

第五章市场区隔

- 电池

- 锂离子

- 铅酸电池

- 镍氢电池

- 其他的

- 电池形式

- 方形

- 袋型

- 圆柱形

- 车辆

- 客车

- 商用车

- 其他的

- 晋升

- 电池电动车

- 油电混合车

- 插电式混合动力电动车

第六章 竞争状况

- 併购、合资、联盟、协议

- 主要企业策略

- 公司简介

- BYD Co. Ltd

- Contemporary Amperex Technology Co. Limited

- Duracell Inc

- EnerSys

- GS Yuasa Corporation

- SK On Co, Ltd

- Hyundai Motor Group

- LG Chem Ltd

- BASF SE

- Panasonic Corporation

- 其他知名公司名单

- 市场排名分析

第七章 市场机会及未来趋势

- 电动车的长期目标

简介目录

Product Code: 50003748

The Germany Electric Vehicle Battery Manufacturing Market size is estimated at USD 5.16 billion in 2025, and is expected to reach USD 18.42 billion by 2030, at a CAGR of 28.99% during the forecast period (2025-2030).

Key Highlights

- Over the medium term, rising demand for electric vehicles, investments to enhance electric vehicle battery production capacity, and a decline in the cost of battery raw materials, especially lithium-ion, are expected to drive the market in the forecast period.

- On the other hand, the decline in the cost of battery raw materials is expected to hamper the market in the future.

- Nevertheless, long-term ambitious targets for electric vehicles in Germany are expected to create a significant opportunity in the forecast period.

Germany Electric Vehicle Battery Manufacturing Market Trends

Lithium-ion Battery is Expected to Have a Major Share

- In recent years, Germany has witnessed a significant surge in the demand for electric vehicles (EVs). These EVs rely on energy storage systems, predominantly batteries, which are crucial for all-electric, plug-in hybrid, and hybrid vehicles.

- Most plug-in hybrids and all-electric vehicles are powered by lithium-ion batteries. The demand for lithium battery materials in plug-in hybrids is on the rise, driven by the declining prices of lithium-ion battery packs and their advantages, including high energy density, extended cycle life, and overall efficiency.

- In 2023, the price of lithium-ion battery packs dropped by 14% from the previous year, settling at USD139/kWh. Beyond these benefits, ongoing research and development efforts aim to produce even more effective and efficient lithium battery materials for electric vehicles.

- Moreover, Germany is actively championing its domestic lithium battery manufacturing, reinforcing its transition to electric vehicles. This strategy seeks to diminish dependence on imported lithium and establish a sustainable supply chain for the burgeoning EV market.

- For example, in June 2023, Livista Energy unveiled plans for a lithium refinery in Germany, targeting electric vehicle batteries. Set to begin production in 2026, Livista Energy has partnered with Technip Energies, a leading French oil and gas services firm, to lead the plant's design.

- Additionally, in May 2024, Rock Tech Lithium Inc. secured approval for a lithium refinery in Guben, Germany. This facility is projected to produce approximately 24,000 tonnes of lithium-hydroxide, essential for electric car batteries and energy storage systems.

- Given this landscape and the declining costs of lithium-ion batteries, the segment is poised to capture a substantial market share.

Investments to Enhance the EV Battery Production Capacity is Expected to Drive the Market

- In recent years, Germany has significantly increased its investments to enhance domestic production of electric vehicle batteries, aiming to address supply chain gaps. These efforts are set to not only strengthen the local economy but also play a crucial role in assisting Germany and the wider EU in achieving their net-zero targets.

- For instance, in January 2024, the European Union greenlit a substantial EUR 902 million (USD 986.43 million) state aid package from Germany to Northvolt, a prominent Swedish lithium-ion battery manufacturer. This financial backing is designated for establishing an electric vehicle (EV) battery production facility in Heide, Germany.

- The German government has rolled out a range of incentives and subsidies to lure investments into this sector. Moreover, with electric vehicle sales on the rise in the country, the government is likely to introduce more policies to further boost domestic battery manufacturing. Data from the International Energy Agency indicates that in 2023, battery electric vehicle (BEV) sales in Germany reached 0.52 million units, a rise from 0.47 million units in 2022.

- Furthermore, partnerships between local manufacturers and global tech firms have sped up advancements in battery technology, solidifying Germany's stature in the international arena. For example, in 2025, Umicore and Volkswagen AG are set to launch a joint venture to produce cathode materials for electric vehicles, targeting an annual capacity of 20 GWh at Volkswagen AG's Salzgitter plant in Germany.

- Given these developments and financial backing, anticipated investments to boost EV battery production capacity are likely to propel the market forward.

Germany Electric Vehicle Battery Manufacturing Industry Overview

The Germany electric vehicle battery manufacturing market is moderate. Some of the major players in the market (in no particular order) include BYD Company Ltd, BASF SE, Contemporary Amperex Technology Co. Limited, Duracell Inc., and Panasonic Holdings Corporation.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Scope of the Study

- 1.2 Market Definition

- 1.3 Study Assumptions

2 EXECUTIVE SUMMARY

3 RESEARCH METHODOLOGY

4 MARKET OVERVIEW

- 4.1 Introduction

- 4.2 Market Size and Demand Forecast in USD, till 2029

- 4.3 Recent Trends and Developments

- 4.4 Government Policies and Regulations

- 4.5 Market Dynamics

- 4.5.1 Drivers

- 4.5.1.1 Investments to Enhance the battery production capacity

- 4.5.1.2 Decline in cost of battery raw materials

- 4.5.2 Restraints

- 4.5.2.1 Lack of Raw Material Reserves

- 4.5.1 Drivers

- 4.6 Supply Chain Analysis

- 4.7 PESTLE ANALYSIS

- 4.8 Investment Analysis

5 MARKET SEGMENTATION

- 5.1 Battery

- 5.1.1 Lithium-ion

- 5.1.2 Lead-Acid

- 5.1.3 Nickel Metal Hydride Battery

- 5.1.4 Others

- 5.2 Battery Form

- 5.2.1 Prismatic

- 5.2.2 Pouch

- 5.2.3 Cylindrical

- 5.3 Vehicle

- 5.3.1 Passenger Cars

- 5.3.2 Commercial Vehicles

- 5.3.3 Others

- 5.4 Propulsion

- 5.4.1 Battery Electric Vehicle

- 5.4.2 Hybrid Electric Vehicle

- 5.4.3 Plug-in Hybrid Electric Vehicle

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Strategies Adopted by Leading Players

- 6.3 Company Profiles

- 6.3.1 BYD Co. Ltd

- 6.3.2 Contemporary Amperex Technology Co. Limited

- 6.3.3 Duracell Inc

- 6.3.4 EnerSys

- 6.3.5 GS Yuasa Corporation

- 6.3.6 SK On Co, Ltd

- 6.3.7 Hyundai Motor Group

- 6.3.8 LG Chem Ltd

- 6.3.9 BASF SE

- 6.3.10 Panasonic Corporation

- 6.4 List of Other Prominent Companies

- 6.5 Market Ranking Analysis

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Long-term ambitious targets for electric vehicles

02-2729-4219

+886-2-2729-4219