|

市场调查报告书

商品编码

1639391

对苯二甲酸 -市场占有率分析、产业趋势/统计、成长预测(2025-2030)Terephthalic Acid - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

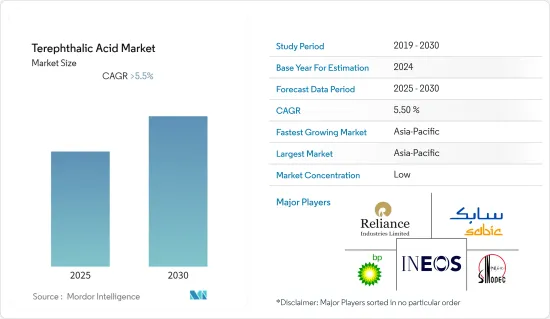

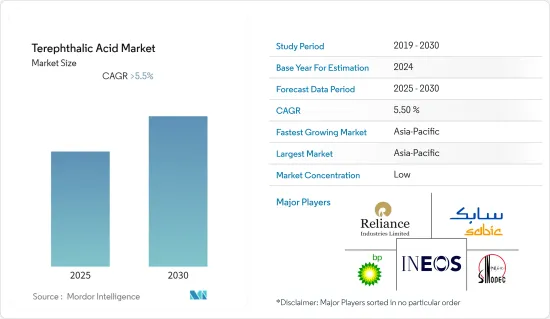

预计对苯二甲酸市场在预测期内的复合年增长率将超过5.5%。

由于2020年和2021年初Covid-19大流行的零星爆发,包装、纺织品、油漆和涂料等关键应用领域对对苯二甲酸的需求因政府禁令和限制以及市场增长有限而受到显着抑制。在下游包装行业,由于商业设施关闭和游客流动,销售低迷。电商食品和零售服务在停工期间有所成长,但无法抵消大型食品和饮料领域销售额的下降。此外,由于人们被限制在家里,对纺织品的需求大幅下降。同时,由于原材料供不应求、工作时间和条件限制以及资金紧张,对苯二甲酸的生产和销售陷入瘫痪。然而,自2021年中疫情消退以来,该产业一直呈现復苏趋势。 2022年,下游需求復苏,对苯二甲酸合约恢復,市场成长动力增强。

主要亮点

- 从中期来看,包装领域下游产品聚对苯二甲酸乙二醇酯(PET)消费量的增加以及亚太纺织业对聚酯纤维的高需求是推动该市场成长的关键驱动力。

- 另一方面,对苯二甲酸的健康和环境毒性预计将在预测期内限制目标产业的成长。

- 对苯二甲酸生产中采用的生产技术的进一步进步可能为全球市场创造利润丰厚的成长机会。

- 亚太地区已成为最大的纺织化学品市场,预计在预测期内仍将维持最高复合年增长率。亚太地区的这一优势归因于中国和印度等不断发展的经济体对包装、纺织品和涂料应用的强劲需求。

对苯二甲酸市场趋势

聚酯纤维需求增加

- 全球生产的对苯二甲酸大部分用于生产聚酯纤维。

- 聚酯纤维具有高强度、弹性和耐久性等特性。聚酯纤维快干、耐洗、抗收缩、抗拉伸、耐磨和耐各种化学物质。聚酯纤维被认为是耐用的合成纤维,用于服装、家居用品(地板材料、窗帘等)、室内装饰、汽车纺织品和工业应用(页岩气裂解、地工织物、过滤、屋顶膜)。的。

- 聚酯纤维防潮、防污,使其成为户外服装、特殊服装和防护服装的首选布料。聚酯纤维因其重量轻且易于染色而广泛用于家居家具和室内装饰织物。

- 服饰是一些国家的重要出口商品。美国拥有蓬勃发展的时尚和服饰。该国多年来一直在加强服饰贸易,2021年出口额达850.7亿美元(根据美国商务部和OTEXA公布),比2020年服装出口增长21.07%。

- 此外,根据国际劳工组织(ILO)的数据,全球服饰出口的60%以上是在新兴国家生产的,其中亚太地区占32%。中国海关总署公布的数据显示,2022年1月至7月,中国作为亚太地区最大的服饰市场,服饰出口额成长17.35%,达到1,893.5亿美元。

- 聚酯纤维因其高强度和模量、优异的形状保持性以及强大的抗紫外线、耐热和耐磨性能而成为汽车座椅套设计的广泛首选材料。除了座椅套之外,聚酯纤维还用于安全气囊、安全带、侧板、车顶内衬等。根据OICA统计,2021年汽车产量达8,014万辆,较2020年同期成长3%。预计这将增加所研究市场的需求。

- 纺织品、汽车生产和其他应用领域不断扩大的市场趋势预计将大幅增加聚酯纤维的消费量,从而增加预测期内对苯二甲酸的需求。

亚太地区主导市场

- 由于中国和印度等国家拥有成熟的下游包装、纺织製造以及食品和饮料产业,亚太地区在全球对苯二甲酸市场占据主导地位。廉价的劳动力和低廉的生产成本支撑了这些国家下游产业的成长。

- 中国对苯二甲酸的产量和需求均领先全球。此外,为了巩固其在下游市场的地位,中国正在对苯二甲酸进行大规模产能扩张。例如,2021年,逸盛石化新建的两条高纯度对苯二甲酸(PTA)生产线开始运作。江苏嘉通能源南通市也计划扩建其PTA生产线,年产能为250万吨。

- 另一方面,中国拥有全球最大的纺织业,对PTA衍生聚酯纤维的需求量大。中国工业和资讯化部资料显示,2022年1-9月中国纺织业持续平稳扩张。中国主要纺织企业营业收入达3.86兆元(5,700亿美元),较去年同期成长3.1%。

- 根据IBEF估计,到2025-2026年,印度纺织服装业预计将达到1,900亿美元。印度在全球纺织品和服装贸易中的份额为4%。 2022年,印度纺织品服饰出口额达444亿美元,与前一年同期比较大幅成长41%。

- 聚对苯二甲酸乙二醇酯 (PET) 源自对苯二甲酸,是包装应用中使用的重要塑胶材料。据印度包装工业协会 (PIAI) 称,过去五年该行业的复合年增长率超过 20%。印度包装产业在进出口方面拥有良好的记录,促进了该国技术和创新的成长,并为各个製造业增加了价值。

- 因此,PTA 生产投资的增加以及各最终用户产业对 PTA 需求的增加预计将推动亚太地区受访市场的成长。

对苯二甲酸产业概况

对苯二甲酸市场是部分分割的。主要参与企业(排名不分先后)包括 SABIC、中国石化、阿科玛、INEOS 和 BP plc。

其他好处

- Excel 格式的市场预测 (ME) 表

- 3 个月分析师支持

目录

第一章简介

- 调查先决条件

- 调查范围

第二章调查方法

第三章执行摘要

第四章市场动态

- 促进因素

- 包装领域聚对苯二甲酸乙二酯消费性扩大

- 亚太地区纺织业对聚酯纤维的庞大需求

- 抑制因素

- 对苯二甲酸毒性

- 产业价值链分析

- 波特五力分析

- 供应商的议价能力

- 买方议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第五章市场区隔(市场规模(基于数量))

- 衍生性商品

- 聚对苯二甲酸乙二酯 (PET)

- 聚丁烯对苯二甲酸酯(PBT)

- 聚对苯二甲酸丙二醇酯 (PTT)

- 对苯二甲酸二甲酯

- 目的

- 包装

- 纤维

- 画

- 胶水

- 其他用途(医药、化学中间体)

- 地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 其他亚太地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 义大利

- 法国

- 欧洲其他地区

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地区

- 中东/非洲

- 沙乌地阿拉伯

- 南非

- 其他中东/非洲

- 亚太地区

第六章 竞争状况

- 併购、合资、联盟、协议

- 市场占有率(%)**/排名分析

- 主要企业策略

- 公司简介

- Arkema

- BP plc

- INEOS

- China Petroleum & Chemical Corporation

- Eastman Chemical Company

- Formosa Petrochemical Co.

- Indian Oil Corporation Ltd

- Indorama Ventures Public Company Limited

- Lotte Chemical Corporation

- Mitsubishi Chemical Corporation

- PetroChina Company Limited

- Reliance Industries Limited

- SABIC

- Samyang Holdings Corporation

第七章 市场机会及未来趋势

- 生产技术的进步

The Terephthalic Acid Market is expected to register a CAGR of greater than 5.5% during the forecast period.

The sporadic outbreak of the COVID-19 pandemic in 2020 and the first half of 2021 drastically curtailed the demand for terephthalic acid in its major application sectors, i.e., packaging, fibers for textile, and paint and coatings, due to imposed government bans and restrictions, thereby limiting the growth of the market. The downstream packaging industry exhibited lackluster sales due to closed commercial places and tourist movements. The increased e-commerce food and retail service during lockdowns could not compensate for the declining sales in large-scale food and beverage sectors. Furthermore, the demand for textiles dropped drastically as people were confined to staying in their houses. Meanwhile, terephthalic acid production and distribution activities were paralyzed owing to scarce raw material supply, limited working hours/labor strength, and constrained financials. However, the industries have been on track for recovery since the pandemic's retraction in mid-2021. The demand from downstream sectors rebounded in 2022, reinstating terephthalic acid contracts, which kick-started the market growth.

Key Highlights

- Over the medium term, the rising consumption of the downstream product polyethylene terephthalate (PET) from the packaging sector and the high demand for polyester fibers in the textile industries of Asia Pacific are the major driving factors augmenting the growth of the market studied.

- On the flip side, the toxic effects of terephthalic acid on health and the environment are anticipated to restrain the growth of the target industry over the forecast period.

- Nevertheless, the growing advancement in production techniques employed in manufacturing terephthalic acid will likely create lucrative growth opportunities for the global market.

- Asia-Pacific emerged as the largest market for textile chemicals and is expected to witness the highest CAGR during the forecast period. This dominance of Asia-Pacific is attributed to the bullish demand for packaging, fibers, and coating applications in growing economies like China and India.

Terephthalic Acid Market Trends

Increasing Demand from Polyester Fibers

- A significant share of the total globally produced terephthalic acid is used for manufacturing polyester fiber, a long-chain polymer with the ester functional group in each repeating unit.

- Polyester fibers carry attributes such as high strength, resilience, and durability. They exhibit quick drying ability, washability, and resistance to shrinkage, stretching, abrasion, and various chemicals. Polyester fibers are recognized as durable synthetic fabric/textiles that find application in apparel, home furnishing (floor coverings, curtains, etc.), upholstery, automotive textiles, and industrial (shale gas cracking, geotextiles, filtration, membranes for roofing) applications.

- Polyester fibers have become a fabric of choice for outdoor, specialty, and protective clothing because they can resist moisture and remain stain resistant. Polyester fabrics are widely used in home furnishing and upholstery fabrics due to being lightweight and presenting the ease of dyeing to form an array of colors and patterns.

- Clothing is a crucial export commodity in several countries. The United States boasts a thriving fashion and clothing industry. The country has strengthened its clothing trade over the years, closing the year 2021 with USD 85,007 million export value (revealed by the US Department of Commerce and OTEXA), up by 21.07% from the apparel export value obtained in 2020.

- Furthermore, as per the International Labour Organization, more than 60% of the world's clothing exports are manufactured in developing countries, with Asia-Pacific accounting for 32% of the share. China, the biggest apparel market in the Asia-Pacific region, registered a 17.35% hike in garment export shipments valued at USD 189.35 billion in the first seven months of 2022, as per the General Administration of Customs China.

- Polyester fibers are widely preferred material for designing automobile seat covers because of their high strength and modulus, good shape retention, and firm performance against UV radiation, heat, and abrasion. Apart from seat covers, polyester fibers are used in airbags, seat belts, side panels, headliners, etc. According to the OICA, in 2021, automobile production reached 80.14 million units, increasing by 3% from the same period in 2020. This is expected to augment the demand for the market studied.

- The growing market trends in the textile, automobile production, and other application sectors are expected to surge the consumption of polyester fibers, thereby increasing the demand for terephthalic acid in the forecast period.

Asia-Pacific to Dominate the Market

- The Asia-Pacific region dominates the global terephthalic acid market owing to the presence of matured downstream packaging, textile manufacturing, and food and beverage industries in countries like China and India. The availability of cheap labor and low production cost back the growth of the downstream industries in these countries.

- China leads the world in terms of both production and demand for terephthalic acid. Moreover, to bolster its position in the downstream markets China is undergoing a massive capacity expansion of terephthalic acid. For instance, in 2021, the country witnessed the commissioning of Yisheng Petrochemical's two new purified terephthalic acid (PTA) production lines, each having a capacity of 3.3 million tons per year. Jiangsu Jiatong Energy Nantong City is also planning to expand its PTA line with the addition of 2.5 million tons per annum capacity.

- On the other hand, China owns the world's largest textile industry where PTA-derived polyester fibers are in high demand. China's textile industry continued steady expansion in the first nine months of 2022, according to data from the country's Ministry of Industry and Information Technology. The combined operating revenue of major textile enterprises in China rose by 3.1% y-o-y reaching CNY 3.86 trillion (USD 570 billion) in that period.

- According to IBEF, the Indian textile and apparel industry is estimated to reach USD 190 billion by 2025-2026. India has a 4% share of the global trade in textiles and apparel. In FY 2022, India's textile and apparel exports amounted to USD 44.4 billion, registering a whopping 41% y-o-y increase.

- Polyethylene terephthalate (PET) derived from terephthalic acid is a crucial plastic material used for packaging applications. According to the Packaging Industry Association of India (PIAI), the sector has grown at a CAGR of over 20% in the past five years. The Indian packaging industry has made a mark with its exports and imports, thus driving technology and innovation growth in the country and adding value to the various manufacturing sectors.

- Thus, the rising investments in PTA production and growing demand for PTA in various end-user industries are projected to propel the growth of the market studied in the Asia-Pacific region.

Terephthalic Acid Industry Overview

The terephthalic acid market is partly fragmented in nature. Some of these major players (not in any particular order) include SABIC, Sinopec Corp., Arkema, INEOS, and BP p.l.c. among others.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Growing Consumption for Polyethylene Terephthalate in the Packaging Sector

- 4.1.2 Significant Demand of Polyester Fibers from the Textile Sector in Asia Pacific

- 4.2 Restraints

- 4.2.1 Toxic Effects of Terephthalic Acid

- 4.3 Industry Value Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Buyers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION (Market Size in Volume)

- 5.1 Derivative

- 5.1.1 Polyethylene Terephthalate (PET)

- 5.1.2 Polybutylene Terephthalate (PBT)

- 5.1.3 Polytrimethylene Terephthalate (PTT)

- 5.1.4 Dimethyl Terephthalate

- 5.2 Application

- 5.2.1 Packaging

- 5.2.2 Fibers

- 5.2.3 Paints and Coatings

- 5.2.4 Adhesives

- 5.2.5 Other Applications (Pharmaceuticals, Chemical Intermediates)

- 5.3 Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 India

- 5.3.1.3 Japan

- 5.3.1.4 South Korea

- 5.3.1.5 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 Italy

- 5.3.3.4 France

- 5.3.3.5 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Rest of South America

- 5.3.5 Middle-East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 South Africa

- 5.3.5.3 Rest of Middle-East and Africa

- 5.3.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Share (%)**/ Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 Arkema

- 6.4.2 BP p.l.c.

- 6.4.3 INEOS

- 6.4.4 China Petroleum & Chemical Corporation

- 6.4.5 Eastman Chemical Company

- 6.4.6 Formosa Petrochemical Co.

- 6.4.7 Indian Oil Corporation Ltd

- 6.4.8 Indorama Ventures Public Company Limited

- 6.4.9 Lotte Chemical Corporation

- 6.4.10 Mitsubishi Chemical Corporation

- 6.4.11 PetroChina Company Limited

- 6.4.12 Reliance Industries Limited

- 6.4.13 SABIC

- 6.4.14 Samyang Holdings Corporation

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Advancement in Production Technology