|

市场调查报告书

商品编码

1639434

全球合成橡胶-市场占有率分析、产业趋势与统计、成长预测(2025-2030)Global Fluoro Elastomers - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

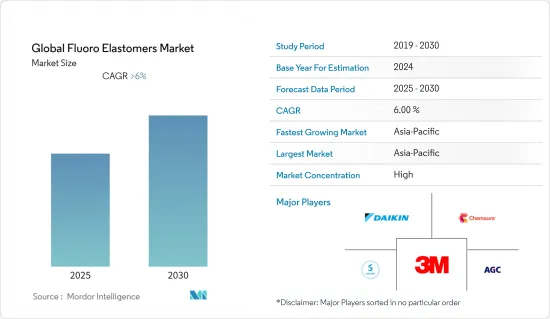

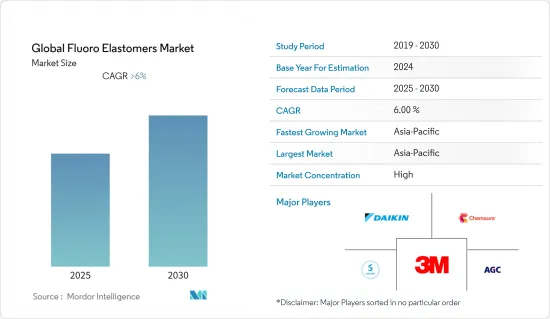

预计全球合成橡胶市场在预测期内复合年增长率将超过 6%。

COVID-19 的爆发导致世界各地的营运关闭、製造活动和供应链中断以及生产暂停,对市场产生了负面影响。然而,情况发生了逆转,并在预测期内恢復了市场的成长轨迹。

主要亮点

- 市场成长的关键因素是密封应用的使用量增加以及汽车产业应用的快速增加。

- 日益严格的环境法和危险的工作条件可能会减缓市场成长。

- 未来几年,市场应该能够利用全氟化碳合成橡胶的新用途。

- 亚太地区在市场上占据主导地位,预计在预测期内仍将保持最高的复合年增长率。

合成橡胶市场趋势

氟碳合成橡胶需求增加

- 氟碳合成橡胶是含氟量较高的碳基聚合物。用于需要耐受刺激性化学物质和臭氧的地方。然而,也有一些特殊等级的碳氟化合物,其氟含量高并具有低温性能。

- 氟碳合成橡胶在密封件製造中发挥至关重要的作用。由于氟碳橡胶具有广泛的化学相容性、较宽的温度范围、较低的压缩永久变形和优异的老化性能,是多年来开发的最重要的合成橡胶。

- 碳氟化合物比合成橡胶更能耐受多种化学品,并且在高温下具有卓越的性能。因此,在全球范围内,由碳氟化合物製成的 O 形环和其他客自订密封件比其他类型的合成橡胶使用得更频繁。

- 这些合成橡胶在暴露于汽油、紫外线或臭氧时不会膨胀或降解。氟碳合成橡胶在 4°F 时硬化,但可以在较低温度下使用。然而,这些化合物不适合在低温下需要良好柔韧性的应用。

- 此外,还有其他具有不同单体成分和氟含量的材料(65-71%,以提高对低温、高温和化学品的耐受性)。氟碳合成橡胶具有低透气渗透性,使其适用于真空服务应用和许多其他工业应用。

- 国防部使用氟碳合成橡胶製造高性能机械,这些机械需要在极端耐用条件下保持稳定的优质零件。氟碳合成橡胶也为航太和汽车产业提供解决方案。

- 在美国,2021 年飞机数量增加,通用航空公司机队持有至 204,405 架飞机,租赁持有机队减少至 5,815 架。美国是世界上最大的航空市场之一。美国航空公司运送的旅客数量比其他国家的航空公司都要多,而且世界十大收益航空公司中约有一半位于美国。

- 中国国内商业航空业的蓬勃发展是收入、旅游业和商业活动不断增长的结果,所有这些都是国内和国际旅行的驱动力。中国民航局宣布,2035年,大型商业服务机场总合将达到450个。换句话说,民航预计将继续成长。

- 截至2021年6月,中国营运的通用航空飞机数量为3,066架,较2020年成长4%。自2014年以来,我国通用航空飞机保有量稳定成长近103%。

- 由于这些因素,预计在预测期内全球合成橡胶市场将成长。

亚太地区主导市场

- 预计亚太地区将主导市场。中国和印度是该地区最大的经济体。该国的製造业是世界上最大的製造业之一,对合成橡胶产生了巨大的需求。

- 合成橡胶在工业和化学加工行业中用于製造液压 O 形圈密封件、止回阀球、隔膜、工业辊套、V 形圈封隔器等。

- 根据国家统计局的数据,2021年中国製造业产值将成长至31.4兆元(4.64兆美元),约占全球製造业的30%。

- 近年来,中国飞机工业经历了显着成长。据波音公司称,中国航空公司将需要8,700架新飞机,比上年度预期的8,600架增加1.2%。预计到2040年将达到1.47兆美元。

- 根据OICA统计,2021年汽车总产量为8,015万辆,与前一年同期比较增加3%。由于这些因素,预计该地区的合成橡胶市场在预测期内将稳定成长。

合成橡胶行业概况

合成橡胶市场已部分整合。该市场的主要企业(排名不分先后)包括 3M、大金工业有限公司、索尔维、科慕公司和 AGC 公司。

其他好处

- Excel 格式的市场预测 (ME) 表

- 3 个月分析师支持

目录

第一章简介

- 调查先决条件

- 调查范围

第二章调查方法

第三章执行摘要

第四章市场动态

- 促进因素

- 扩大密封应用的应用范围

- 汽车产业应用快速成长

- 抑制因素

- 日益严格的环境法规与危险的工作环境

- 其他限制因素

- 产业价值链分析

- 波特五力分析

- 供应商的议价能力

- 消费者议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第五章市场区隔(市场规模(基于数量))

- 产品类型

- 氟碳合成橡胶

- 硅橡胶

- 全氟碳合成橡胶

- 目的

- 隔膜

- 阀门

- O 型环、密封件、密封剂

- 其他用途(燃油软管、接头)

- 最终用户产业

- 车

- 航太

- 石油和天然气

- 工业的

- 其他最终用户产业(化学、国防)

- 地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 其他亚太地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 义大利

- 法国

- 欧洲其他地区

- 其他的

- 巴西

- 沙乌地阿拉伯

- 南非

- 其他的

- 亚太地区

第六章 竞争状况

- 併购、合资、联盟、协议

- 市场占有率(%)**/排名分析

- 主要企业策略

- 公司简介

- 3M

- AGC Inc.

- All Seals Inc.

- Daikin Industries Ltd

- Eagle Elastomer Inc.

- Freudenberg Sealing Technologies

- GARLOCK

- Gujarat Fluorochemicals Limited

- HaloPolymer

- KUREHA CORPORATION

- LANXESS

- Minor Rubber Products

- Parker Hannifin Corp.

- Precision Associates, Inc.

- Shanghai Fluoron Chemicals Co.Ltd.

- Solvay

- Stockwell Elastomerics Inc.

- The Chemours Company

- Trp Polymer Solutions Limited

- Zhonghao Chenguang Research Institute of Chemical Industry

- Zrunek Gummiwaren GmbH

第七章 市场机会及未来趋势

- 全氟碳合成橡胶的新应用

The Global Fluoro Elastomers Market is expected to register a CAGR of greater than 6% during the forecast period.

Due to the COVID-19 outbreak, there were nationwide lockdowns around the world, disruptions in manufacturing activities and supply chains, and production halts that negatively impacted the market. However, the conditions started recovering, restoring the market's growth trajectory during the forecast period.

Key Highlights

- The major factors driving the market's growth are rising usage in sealing applications and the surge in applications in the automotive industry.

- Environmental laws that are getting stricter and dangerous working conditions are likely to slow the growth of the market.

- In the coming years, the market should be able to take advantage of new ways to use perfluorocarbon elastomers.

- The Asia-Pacific region is expected to dominate the market and to register the highest CAGR during the forecast period.

Fluoroelastomers Market Trends

Increasing Demand for Fluorocarbon Elastomers

- Fluorocarbon elastomers are carbon-based polymers that have a lot of fluorine added to them. They are used in places where they need to be resistant to harsh chemicals and ozone. There are, however, specialty-grade fluorocarbons that can provide high fluorine content with low-temperature properties.

- Fluorocarbon elastomers have become of vital importance in seal manufacturing. Due to its wide chemical compatibility, wide temperature range, low compression set, and excellent aging characteristics, fluorocarbon rubber is the most significant single elastomer developed over the years.

- Fluorocarbons are more resistant to a wider range of chemicals and work better at high temperatures than elastomers. Because of this, O-rings and other custom seals made from fluorocarbons are used more often than other types of elastomers around the world.

- These elastomers are very resistant to swelling and breaking down when they are exposed to gasoline, UV light, and ozone. Fluorocarbon elastomers can get hard at 4 °F, but they can still be used at low temperatures. However, these compounds are not ideal for applications that need good flexibility at low temperatures.

- Additionally, some of the other materials are also present with a differing composition of monomers and fluorine content (65-71% for improved resistance against low and high temperatures or chemicals). Fluorocarbon elastomers provide low gas permeability, making them suitable for vacuum service applications and many other industrial applications.

- The Ministry of Defense uses fluorocarbon elastomers to build high-performance machinery that needs premium quality components to provide stability in extreme endurance conditions. Fluorocarbon elastomers also offer a solution to the aerospace and automotive industries.

- In the United States, the number of aircraft increased in 2021; the general aviation fleet was 204,405 and the for-hire carrier fleet decreased to 5,815 aircraft. The United States has one of the world's largest aviation markets. More people are transported by U.S. airlines than by airlines from any other nation, and about half of the top ten revenue-generating airlines in the globe are based in the United States.

- A thriving domestic Chinese commercial aviation industry is the result of rising incomes, tourism, and business activity, which are all driving factors in domestic and international travel. The Civil Aviation Administration of China says that by 2035, there will be a total of 450 large commercial service airports. This means that commercial aviation is expected to keep growing.

- By June 2021, there were 3,066 general aviation aircraft operating in China, an increase of four percent compared to 2020. Since 2014, the number of general aviation aircraft in China has grown steadily by nearly 103 percent.

- Owing to all these factors, the market for fluoroelastomers is expected to grow across the world during the forecast period.

Asia-Pacific Region to Dominate the Market

- The Asia-Pacific region is expected to dominate the market. China and India are among the region's largest economies. The country's manufacturing sector has become one of the biggest production houses in the world, thus providing huge demand for fluoroelastomers.

- Fluoroelastomers are used in the industrial and chemical processing industries to make things like hydraulic O-ring seals, check valve balls, diaphragms, industrial roll covers, V-ring packers, and so on.

- According to the National Bureau of Statistics, China's manufacturing output grew to CNY 31.4 trillion (USD 4.64 trillion) in 2021, up from around 30% of the global manufacturing sector.

- The Chinese aircraft industry has depicted significant growth over the years. According to Boeing, Chinese airlines will need 8,700 new airplanes, 1.2% more than its previous prediction of 8,600 planes made the previous year. These would be worth USD 1.47 trillion by 2040.

- Nearly 60% of the world's cars are made in this area, making it the biggest center for making cars.According to OICA, the total production of vehicles stood at 80.15 million units in 2021, an increase of 3% compared to the previous year.

- Due to all these factors, the fluoroelastomers market in the region is expected to have steady growth during the forecast period.

Fluoroelastomers Industry Overview

The fluoroelastomers market is partially consolidated in nature. Some of the major players (not in any particular order) in the market include 3M, Daikin Industries Ltd, Solvay, The Chemours Company, and AGC Inc.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Rising Usage in Sealing Applications

- 4.1.2 Surging Applications in the Automotive Industry

- 4.2 Restraints

- 4.2.1 Increasingly Stringent Environmental Regulations and Hazardous Working Conditions

- 4.2.2 Other Restraints

- 4.3 Industry Value-chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Consumers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION (Market Size in Volume)

- 5.1 Product Type

- 5.1.1 Fluorocarbon Elastomers

- 5.1.2 Fluorosilicone Elastomers

- 5.1.3 Perfluorocarbon Elastomers

- 5.2 Application

- 5.2.1 Diaphragms

- 5.2.2 Valves

- 5.2.3 O-rings, Seals, and Sealants

- 5.2.4 Other Applications (Fuel Hoses, Joints)

- 5.3 End-user Industry

- 5.3.1 Automotive

- 5.3.2 Aerospace

- 5.3.3 Oil and Gas

- 5.3.4 Industrial

- 5.3.5 Other End-user Industries (Chemical, Defense)

- 5.4 Geography

- 5.4.1 Asia-Pacific

- 5.4.1.1 China

- 5.4.1.2 India

- 5.4.1.3 Japan

- 5.4.1.4 South Korea

- 5.4.1.5 Rest of Asia-Pacific

- 5.4.2 North America

- 5.4.2.1 United States

- 5.4.2.2 Canada

- 5.4.2.3 Mexico

- 5.4.3 Europe

- 5.4.3.1 Germany

- 5.4.3.2 United Kingdom

- 5.4.3.3 Italy

- 5.4.3.4 France

- 5.4.3.5 Rest of Europe

- 5.4.4 Rest of the World

- 5.4.4.1 Brazil

- 5.4.4.2 Saudi Arabia

- 5.4.4.3 South Africa

- 5.4.4.4 Rest of the World

- 5.4.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Share (%)**/Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 3M

- 6.4.2 AGC Inc.

- 6.4.3 All Seals Inc.

- 6.4.4 Daikin Industries Ltd

- 6.4.5 Eagle Elastomer Inc.

- 6.4.6 Freudenberg Sealing Technologies

- 6.4.7 GARLOCK

- 6.4.8 Gujarat Fluorochemicals Limited

- 6.4.9 HaloPolymer

- 6.4.10 KUREHA CORPORATION

- 6.4.11 LANXESS

- 6.4.12 Minor Rubber Products

- 6.4.13 Parker Hannifin Corp.

- 6.4.14 Precision Associates, Inc.

- 6.4.15 Shanghai Fluoron Chemicals Co.Ltd.

- 6.4.16 Solvay

- 6.4.17 Stockwell Elastomerics Inc.

- 6.4.18 The Chemours Company

- 6.4.19 Trp Polymer Solutions Limited

- 6.4.20 Zhonghao Chenguang Research Institute of Chemical Industry

- 6.4.21 Zrunek Gummiwaren GmbH

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Novel Applications of Perfluorocarbon Elastomers