|

市场调查报告书

商品编码

1640401

特种聚合物:市场占有率分析、产业趋势与统计、成长预测(2025-2030 年)Specialty Polymers - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

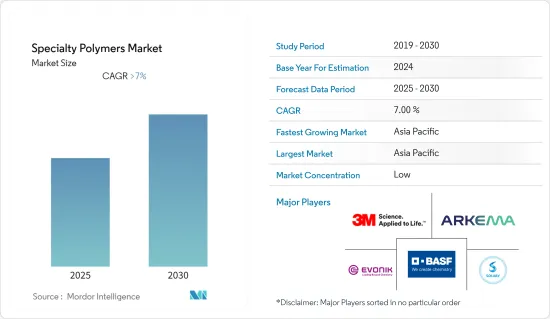

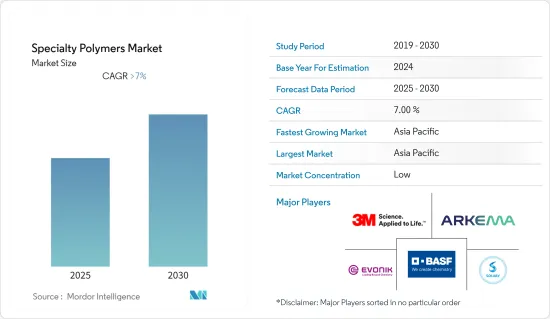

预计预测期内特种聚合物市场复合年增长率将超过 7%。

2020 年,市场受到了 COVID-19 疫情的负面影响。疫情迫使多个国家实施封锁,导致供应链中断、工作停顿和劳动力短缺。然而,自从限制解除以来,该行业已经恢復良好。住宅销售量的增加和新计画的推出推动了对被覆剂、密封剂和建筑化学品的需求。过去两年,医疗保健和电气电子产业的需求不断增长,带动了市场復苏。

主要亮点

- 推动市场发展的主导因素包括建筑和电子产业的应用不断增加、汽车和航太应用的轻质聚合物的商业化以及天然气和原油加工原料的供应不断增加。

- 由于最终用户的需求不断变化,获取原材料的营运成本波动和技术过时预计会阻碍市场成长。

- 特种聚合物技术在各种工业应用中的兴起以及工程聚合物和特种薄膜产品的积极商业化可能会在预测期内为市场研究带来机会。

- 预计亚太地区将成为最大的市场,并预计在预测期内以最高的复合年增长率成长。亚太地区占据主导地位的原因是中国、日本和印度等国家的需求旺盛。

特种聚合物市场趋势

汽车和运输业主导市场

- 特种聚合物因其优异的耐热性、耐磨性、易于加工和设计以及耐疲劳性等优良性能,广泛应用于汽车和运输业。

- 这些材料具有出色的耐热性,对于汽车而言是可靠且安全的。它还以具有竞争力的价格为您的车辆提供精緻的美感。

- 人们对更轻、更省油的汽车的需求日益增长,推动了汽车零件使用聚合物来取代重金属以减轻重量。据估计,汽车重量每减轻 10%,燃料消耗就会减少 5-7%。

- 特种聚合物在汽车製造中发挥着至关重要的作用,随着全球汽车销售的不断增长,对这些材料的需求也不断增长。

- 汽车聚合物复合材料产业推动整个汽车供应链的经济活动,并透过产业和消费者支付的工资间接推动经济活动。轻型汽车产业是各种特种聚合物的重要客户,面临激烈的竞争,尤其是来自铝和钢铁的竞争。

- 根据OICA的数据,2021年汽车产量为80,145,988辆,较2020年成长3%。 2021年,欧洲汽车产量为16,330,509辆,美洲汽车产量为16,151,639辆,非洲汽车产量为931,056辆。

- 根据日本汽车工业协会(JAMA)的报告,2021年乘用车和轻型车产量为7,846,955辆。

- 因此,汽车製造中使用的聚合物数量不断增加,对轻型汽车的需求也不断增长,因此汽车和运输领域对特种聚合物的使用预计将增长。

亚太地区占市场主导地位

- 预测期内,特种聚合物市场预计将在亚太地区成长最快。中国和印度的新兴市场扩张和汽车和电子产业的市场发展预计将推动该地区的特殊聚合物市场的发展。此外,经济成长和人均收入的提高是推动亚太地区特种聚合物市场成长的关键因素之一。

- 中国是经济健康成长的新兴国家之一。中国政府的政策符合实施经济改革的提案目标,从而确保了该国在预测期内的健康发展。

- 中国主要致力于扩大电动车的生产和销售。为此,政府计划在 2020 年将电动车 (EV) 产量提高到每年 200 万辆,到 2025 年提高到每年 700 万辆。如果这一目标实现,到2025年电动车在中国新车总产量中的占比预计将提升至20%。

- 根据OICA的数据,2021年印度的工业产量约为4,399,112辆,包括乘用车、商用车、三轮车、两轮车和四轮车。 「Aatma Nirbhar Bharat」和「印度製造」计画等政府改革很可能在不久的将来推动汽车产业的发展。

- 特种聚合物提供更大的设计灵活性和创新性。这些多功能解决方案具有多种有益特性,可实现电子设备的小型化和可靠性能。

- 据日本电子情报技术产业协会(JEITA) 称,随着数位化的进步刺激需求并扩大出口,预计 2021 年日本电子和 IT 公司的全球产值与前一年同期比较增长8%,达到37.3 兆美元。 (~ 2853.9亿美元)。预计电子业的成长将在未来几年推动对乙苯的需求。

- 特种聚合物广泛应用于汽车、电子和半导体产业。因此,随着这些行业的强劲增长和政府的支持,预计在预测期内对特种聚合物的需求将以健康的速度增长。

特种聚合物产业概况

特种聚合物市场较为分散。市场的主要参与者(不分先后顺序)包括 3M、阿科玛集团、BASF公司、赢创工业集团和索尔维。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第 1 章 简介

- 调查前提条件

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场动态

- 驱动程式

- 在建筑和电子产业的应用日益增多

- 轻质聚合物在汽车和航太领域的商业化应用

- 增加天然气和原油加工原料的供应

- 限制因素

- 采购原料的营运成本波动

- 由于最终用户需求的不断变化导致技术过时

- 产业价值链分析

- 波特五力分析

- 供应商的议价能力

- 买家的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第 5 章 市场区隔(以金额为准的市场规模)

- 按类型

- 特殊合成橡胶

- 特殊复合材料

- 特种热塑性塑料

- 特殊热固性树脂

- 其他类型

- 按最终用户产业

- 汽车和运输

- 消费品

- 建筑和施工

- 被覆剂、黏合剂、密封剂

- 电气和电子

- 卫生保健

- 其他最终用户产业

- 按地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 其他亚太地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 义大利

- 法国

- 其他欧洲国家

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地区

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 其他中东和非洲地区

- 亚太地区

第六章 竞争格局

- 併购、合资、合作与协议

- 市场占有率(%)**/排名分析

- 主要企业策略

- 公司简介

- 3M

- Arkema Group

- Ashland Inc.

- Associated industries Inc.

- BASF SE

- Braskem

- Chemtura Corporation

- Covestro

- Croda International PLC

- Elantas GmbH

- Endurance Technologies Limited

- Evonik Industries AG

- Hexion Inc.

- Huntsman Corp.

- Koninklijke DSM NV

- PolyOne

- S&E Specialty Polymers LLC

- Solvay

- Speciality Polymers Pvt Ltd

第七章 市场机会与未来趋势

- 特种聚合物技术在各种工业应用中的兴起

- 积极推进工程聚合物和特殊薄膜产品的商业化

The Specialty Polymers Market is expected to register a CAGR of greater than 7% during the forecast period.

The market was negatively impacted by the COVID-19 outbreak in 2020. Owing to the pandemic scenario, several countries went into lockdown, which led to supply chain disruptions, work stoppages, and labour shortages. However, the sector is recovering well since restrictions were lifted. An increase in house sales and new project launches have led to a rise in the demand for coatings, sealants, and construction chemicals. The increasing demand for healthcare, electrical, and electronics is leading the market recovery over the last two years.

Key Highlights

- The major factors driving the market studied are the increasing applications in the construction and electronic industries, the commercialization of lightweight polymers for automotive and aerospace applications, and the growing availability of feedstock derived from natural gas and crude oil processing.

- Fluctuating operational costs to derive feedstock and technological obsolescence due to constantly changing end-user needs are expected to hinder the market's growth.

- Emerging specialty polymer technologies in various industrial applications and prolific commercialization of engineered polymer and specialty film products are likely to act as opportunities for the market studied over the forecast period.

- Asia-Pacific emerged as the largest market and is expected to witness the highest CAGR during the forecast period. This dominance of Asia-Pacific is attributed to the high demand in countries such as China, Japan, and India.

Specialty Polymers Market Trends

Automotive and Transportation Industry to Dominate the Market

- Owing to their suitable properties, such as excellent thermal resistance, wear resistance, ease of processing and designing, and fatigue endurance, speciality polymers are extensively used in the automotive and transportation industries.

- These materials are reliable and safe for vehicles due to their exceptional thermal resistance. They provide sophisticated aesthetic appeal to cars at competitive prices.

- With the rise in demand for lightweight and fuel-efficient cars, polymers use increased in automotive parts to replace heavy metals to reduce weight. It is estimated that every 10% reduction in vehicle weight results in a 5-7% reduction in fuel usage.

- As speciality polymers play a crucial role in automobile manufacturing, the demand for these materials is increasing with the rising sales of vehicles worldwide.

- The automotive polymer composite industry indirectly fosters economic activity throughout a vehicle's supply chain and through the payrolls paid by the industry and consumers. The light vehicle industry is an essential customer for various specialty polymers, and significant competition exists, especially with aluminum and steel.

- According to OICA, the total number of vehicles produced in 2021 was 80,145,988 and witnessed a growth rate of 3% compared to 2020. Europe made a total of 16,330,509 units of motor vehicles, America had 16,151,639 units, and Africa held a production number of 931,056 units in 2021.

- As per reports by the Japan Automobile Manufacturers Association (JAMA), the country produced 7,846,955 units of passenger cars and light vehicles in 2021.

- Thus, with the rise in the number of polymers used during automobile manufacturing and the increasing demand for lightweight vehicles, specialty polymers usage is expected to increase in the automotive and transportation sector.

Asia-Pacific to Dominate the Market

- Asia-Pacific is expected to display the fastest growth in the specialty polymers market over the forecast period. The expanding automotive and electrical industries in China and India, combined with infrastructural development, are expected to drive the specialty polymers market in the region. Moreover, economic growth and increasing per capita income are some of the significant factors triggering the growth of the specialty polymers market in Asia-Pacific.

- China is one of the emerging economies witnessing healthy economic growth. Its government's policies have been in line with the proposed objectives to implement economic reforms, thus ensuring the healthy development of the country during the forecast period.

- China is mainly focusing on increasing the production and sales of electric vehicles in the country. For this purpose, the government planned to increase electric vehicle (EVs) production to 2 million a year by 2020 and 7 million a year by 2025. The target, if achieved, is expected to increase the share of electric vehicles to 20% of the total new car production in China by 2025.

- According to the OICA, in 2021, total industrial production in India was about 4,399,112 vehicles, including passenger, commercial, three-wheeler, two-wheeler, and quadricycles. The government's reforms, such as "Aatma Nirbhar Bharat" and "Make in India" programs, will likely boost the automotive industry in the near future.

- Specialty polymer contributes to improving design flexibility and innovation. These versatile solutions offer a range of beneficial properties to enable miniaturization and reliable performance in electronic devices.

- According to Japan Electronics and Information Technology Industries Association (JEITA), with the advance of digitalization boosting demand and expanding exports, global production by Japanese electronics and IT companies grew by 8% year on year in 2021 to JPY 37,300 billion (~USD 285.39 billion). This growth in the electronics segment will enhance the demand for the ethylbenzene market in the coming years.

- Specialty polymers are widely used in the automotive, electronics, and semiconductors industries. Hence, with robust growth in these industries, and government support, the demand for specialty polymers is projected to increase at a healthy pace during the forecast period.

Specialty Polymers Industry Overview

The speciality polymers market is fragmented in nature. Some of the major players in the market (in no particular order) include 3M, Arkema Group, BASF SE, Evonik Industries AG, and Solvay, among others.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Increasing Applications in the Construction and Electronic Industries

- 4.1.2 Commercialization of Lightweight Polymers for Automotive and Aerospace Applications

- 4.1.3 Increasing Availability of Feedstock Derived from Natural Gas and Crude Oil Processing

- 4.2 Restraints

- 4.2.1 Fluctuating Operational Costs to Derive Feedstock

- 4.2.2 Technological Obsolescence due to Constantly Changing End-user Needs

- 4.3 Industry Value Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Buyers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION (Market Size in Value)

- 5.1 Type

- 5.1.1 Specialty Elastomers

- 5.1.2 Specialty Composites

- 5.1.3 Specialty Thermoplastics

- 5.1.4 Specialty Thermosets

- 5.1.5 Other Types

- 5.2 End-user Industry

- 5.2.1 Automotive and Transportation

- 5.2.2 Consumer Goods

- 5.2.3 Building and Construction

- 5.2.4 Coatings, Adhesives, and Sealants

- 5.2.5 Electrical and Electronics

- 5.2.6 Healthcare

- 5.2.7 Other End-user Industries

- 5.3 Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 India

- 5.3.1.3 Japan

- 5.3.1.4 South Korea

- 5.3.1.5 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 Italy

- 5.3.3.4 France

- 5.3.3.5 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Rest of South America

- 5.3.5 Middle-East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 South Africa

- 5.3.5.3 Rest of Middle-East and Africa

- 5.3.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Share (%)**/Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 3M

- 6.4.2 Arkema Group

- 6.4.3 Ashland Inc.

- 6.4.4 Associated industries Inc.

- 6.4.5 BASF SE

- 6.4.6 Braskem

- 6.4.7 Chemtura Corporation

- 6.4.8 Covestro

- 6.4.9 Croda International PLC

- 6.4.10 Elantas GmbH

- 6.4.11 Endurance Technologies Limited

- 6.4.12 Evonik Industries AG

- 6.4.13 Hexion Inc.

- 6.4.14 Huntsman Corp.

- 6.4.15 Koninklijke DSM NV

- 6.4.16 PolyOne

- 6.4.17 S&E Specialty Polymers LLC

- 6.4.18 Solvay

- 6.4.19 Speciality Polymers Pvt Ltd

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Emerging Specialty Polymer Technologies in a Myriad of Industrial Applications

- 7.2 Prolific Commercialization of Engineered Polymer and Specialty Film Products