|

市场调查报告书

商品编码

1640420

分散式控制系统:市场占有率分析、产业趋势与统计、成长预测(2025-2030)Distributed Control Systems - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

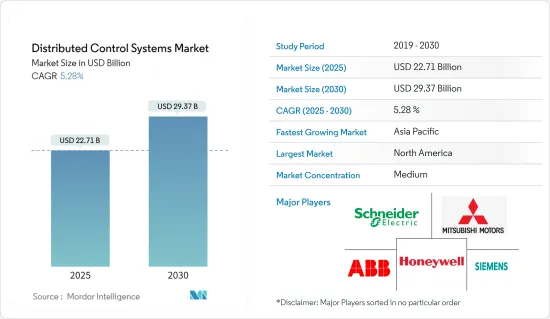

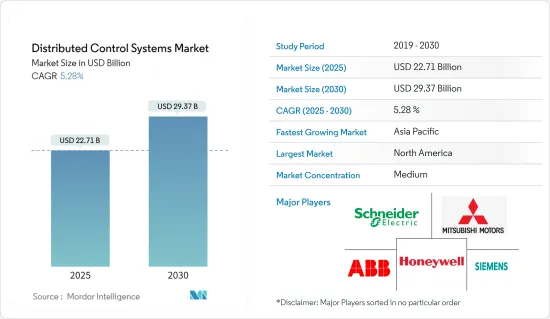

分散式控制系统市场规模预计在 2025 年为 227.1 亿美元,预计到 2030 年将达到 293.7 亿美元,预测期内(2025-2030 年)的复合年增长率为 5.28%。

预计分散式控制系统市场将受到流程工业製造商采用最佳自动化技术以在当前竞争环境中获得竞争优势的趋势的推动。

智慧应用和物联网技术的日益普及是市场发展的主要驱动力。智慧型设备的普及推动了对具有更少时间延迟和更高性能的多功能微电子的需求。

目前,製程工业的运作环境高度复杂,这对控制技术的要求也相应更高。控制技术是製程工业获得竞争力的关键槓桿,特别是如果它能够应对当前和未来的巨大挑战。最新的DCS系统在安全性、与最新技术的兼容性以及操作员效率方面比以前的系统有了显着的改进,引领了分散式控制系统市场。

新冠肺炎疫情对全球各行各业都产生了重大影响。经济快速成长导致世界各国政府采取措施加强工业厂房和办公室的防护,并实施更严格的封锁。由于商业和工业部门对电力的需求急剧下降,封锁对电力产业产生了重大影响。对于全球大多数企业来说,从疫情期间遭受的重大损失中恢復的阶段已接近完成。

欧洲风能协会 (Wind Europe) 称,预计许多新的风电发电工程都会出现延误,开发商可能会错过引入竞标系统的最后期限,并因新冠疫情而面临经济处罚。国际可再生能源机构表示,儘管疫情威胁全球电力产业供应链,但不会阻止该产业向净零碳排放转型。这场疫情也显示了製造自动化对于现代工业运作至关重要。社交距离产生了更大的影响,促使製造商重组业务,并更多地依赖机器人。

然而,现代 DCS 系统在安全性、与最新技术的兼容性以及操作员效率方面比其前代系统有了显着的改进,所有这些都是分散式控制系统的市场驱动力。现代 DCS 包括资产诊断、效能监控、车队管理、故障时的警报处理、讯息优先顺序以及故障时的简化操作等新功能。新的 DCS 旨在整个工厂寿命期内运作。 DCS 可以在线更新,可以安装更新和安全补丁,并且可以在不关闭工厂的情况下添加新功能。

此外,DCS 通常用于大量和连续操作,例如石油精製、发电、有机化学品製造、工艺品、食品和饮料生产、製药製造和水泥。 DCS 可以控制许多不同类型的设备,包括变速驱动器、品管系统、马达控制中心 (MCC)、窑炉、製造设备和采矿设备。

DCS 系统的一大优点是分散式控制器、工作站和其他运算元素之间的数位通讯遵循P2P存取的原则。石油化学、核能、石油和天然气等製程工业越来越需要控制器,这些控制器能够在确定的设定点附近提供指定的製程公差,以实现更高的精度和控制。

这些需求正在推动 DCS 的采用。这些系统降低了操作复杂性、计划风险,并提供了在严苛的应用中实现敏捷製造的灵活性等功能。 DCS 能够整合各种工厂製程控制,如 PLC、涡轮机械控制、安全系统、第三方控制、热交换器、给水加热器、水质等,进一步推动了其在能源领域的应用。

分散式控制系统市场趋势

服务将占据很大市场占有率

在本报告涵盖的范围中,DCS 产业的服务市场是收益相关人员感兴趣的市场。 DCS 应用范围广泛,包括维护、安装、警报管理、升级服务、工厂资产管理、生命週期服务、咨询服务、迁移服务、模拟和培训服务,导致服务业的需求不断增长。因此,预测期内,能源需求和技术进步的增加可能会刺激服务业等的需求。

此外,市场上的顶级供应商继续专注于扩大其在计划和营运维护服务方面的能力,以继续扩大市场。调查范围包括计划管理服务、非合约维护、维修和升级。

目前占 DCS 市场很大一部分的服务市场预计将在预测期内以最快的速度发展,这得益于产业内分散式天线系统服务供应商数量的大幅增加。

随着认识的不断提高,各行各业正致力于部署和实施 IIoT 策略以增强 DCS 网路服务。由于感测器和边缘设备具有与 PC 类似但功能更强大的处理和通讯能力,这种关係正在改变。每个设备都可以充当对等体的角色,而不是被动地监听和回应。

此外,主自动化承包商(MAC)的概念在计划服务中变得越来越重要,即供应商负责计划中所有与自动化相关系统。

这种趋势在大多数大型 DCS计划中日益增长。服务市场涵盖了金字塔的底层,即备件和维修实体,它们被证明有助于提高系统的生产率,降低成本,并透过缩短时间生产单位的运作来延长产品生命週期和系统,因此高效实现卓越运营。

北美占据主要市场占有率

北美快速发展的页岩气产业预计将成为该地区分散式控制系统市场的主要推动力。

美国能源部预计,到 2035 年,页岩气产量将达到美国总产量的近 45%,因此,一个紧密整合的 DCS 至关重要,它可以透过高风险环境中的冗余控制来提供製程永续性。

儘管该市场目前面临全球原油价格下跌的挑战,但预计未来将成为一大产业。页岩气开采需要大量的水,这为水处理厂的DCS系统创造了市场,并且正在大幅扩大整体市场。

此外,北美化工产业也受惠于可靠性的提高、远端监控的简化以及安装成本的降低。此外,化学产业的多家公司正在从过时的 DCS 系统转向更先进的系统,以提高产量、效率、安全性并减少人为错误。

北美石油和天然气产业是流程主导的,具有连续的操作和复杂的监测方法。监控和规范该领域使用的机器的运作对操作员来说是一个挑战。北美的许多公司正在采用 HMI 和控制器 (DCS) 来允许操作员管理营运。这些系统自动化安全程序,例如警报管理系统,并执行设备维护和维修任务。

分散式控制系统对于核能发电厂的管理至关重要,进一步帮助美国市场持续增加核能发电厂的容量和数量。

分散式控制系统产业概况

竞争激烈的分散式控制系统市场有几个主要竞争者。目前,有少数主要竞争对手控制着大部分市场占有率。拥有较大市场占有率的大型公司正致力于扩大消费群。许多公司依靠策略联盟计划来增加市场占有率和盈利。

2022年12月,Honeywell宣布印度Regreen Excel EPC已在印度的40家工厂中部署了Honeywell的PlantCruise by Experion分散式控制系统(DCS)解决方案、模组化系统和现场仪表(FI )。 Regreen Excel EPC India Pvt. Ltd. 是一家酿酒、製糖、汽电共生、生质燃料、零液体排放系统和可再生能源公司。此技术可协助使用者增加生产运作,提高安全性、可靠性和效率,并降低投资和运作成本。

2022 年 5 月,ABB 将对阿拉伯联合大公国 (UAE) 的製程控制系统和水泥磨粉设备进行现代化改造,以提高多个站点的运作和一致性。 ABB 将为阿联酋 Star Super Cement 的水泥磨粉製程提供尖端的集散控制系统 (DCS) 自动化技术。凭藉新的增强系统和跨多个线性化和研磨单元站点的均匀性,Star Cement 将受益于更高的操作员可视性、更轻鬆的维护和更少的停机时间。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第 1 章 简介

- 研究假设和市场定义

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场动态

- 市场概况

- 价值链分析

- 市场驱动因素

- 主要新兴国家能源需求增加

- 智慧应用程式和物联网技术的采用日益广泛

- 现有 DCS 解决方案的现代化有助于服务业的成长

- 市场限制

- 在流程自动化中越来越多地使用替代技术

- 产业吸引力-波特五力分析

- 新进入者的威胁

- 买家的议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争对手之间的竞争强度

第五章 市场区隔

- 按组件

- 硬体

- 软体

- 服务

- 按行业

- 发电

- 石油和天然气

- 化学

- 精製

- 矿业与金属

- 纸和纸浆

- 其他最终用户产业

- 按地区

- 北美洲

- 美国

- 加拿大

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 其他欧洲国家

- 亚太地区

- 中国

- 日本

- 印度

- 其他亚太地区

- 拉丁美洲

- 巴西

- 墨西哥

- 其他拉丁美洲国家

- 中东和非洲

- UAE

- 南非

- 其他中东和非洲地区

- 北美洲

第六章 竞争格局

- 公司简介

- ABB Ltd.

- Honeywell International Corporation

- Siemens AG

- Schneider Electric

- Mitsubishi Motors Corporation

- Rockwell Automation

- Emerson Electric Company

- Metso(Valmet Oyj)

- Omron Corporation

- Novatech Llc(Weir Group)

- Azbil Corporation

- Toshiba International

- Yokogawa Electric Co.

第七章投资分析

第 8 章:未来趋势

The Distributed Control Systems Market size is estimated at USD 22.71 billion in 2025, and is expected to reach USD 29.37 billion by 2030, at a CAGR of 5.28% during the forecast period (2025-2030).

The distributed control system market will be driven in the future by the tendency for manufacturers in the process industry to implement the best automation technologies to obtain a competitive edge in the current competitive environment.

The growing adoption of smart applications and IoT technologies are the key drivers for the market. With the increased adoption of smart devices, there is an increase in the demand for multifunctional microelectronics with reduced time delays and improved performance.

The process industry currently operates in a very complex environment, and the requirements for its control technology are correspondingly demanding. Control technology is a key lever for gaining a competitive edge in the process industry, all the more so if it can meet the tremendous challenges of both today and tomorrow. The latest iterations of DCS systems provide marked improvements over their predecessors regarding security, compatibility with the latest technology, and operator effectiveness, which drives the distributed control systems market.

COVID-19 had a significant impact on all industries worldwide. Because of the rapid growth, governments worldwide took stronger measures for functioning industrial plants and offices, resulting in stricter lockdowns. The lockdown significantly influenced the power sector as power demand from commercial and industrial sectors reduced significantly. For most businesses worldwide, the recovery phase following large losses during the pandemic was nearly completed.

According to Wind Europe, delays were expected in many new wind farm projects, causing developers to miss the deployment deadlines in the auction systems and face financial penalties due to COVID-19, The International Renewable Energy Agency stated that despite the pandemic threatening global supply chains in the power sector, it would not stop the industry from transitioning to net-zero CO2 emissions. The pandemic also showed how essential manufacturing automation was to modern industry functioning, with some fueled by social distancing and some by cyber threats. Social distancing measures had a greater impact as they led the manufacturers to restructure their operations to rely more on robotics.

However, the latest iterations of DCS systems provide marked improvements over their predecessors regarding security, compatibility with the newest technology, and operator effectiveness, a market driver for distributed control systems. Modern DCSs include new capabilities, such as asset diagnostics, performance monitoring, fleet management, alarm handling during the fault, prioritizing messages, and simplifying actions to be taken in the event of a failure. The purpose of the newer DCSs is to serve the entire lifetime of the power plant. The DCSs can be updated online, where updates and security patches are installed, and new features can be added without shutting down the plant.

Moreover, DCS is often employed in batch-oriented or continuous method operations, such as oil purification, power generation, organic compound manufacturing, craft, food and drink manufacturing, pharmaceutical production, and cement. DCSs can control various instrumentality types, including variable speed drives, quality control systems, motor control centers (MCC), kilns, manufacturing equipment, and mining equipment.

One of the significant benefits of DCS systems is that the digital communication between distributed controllers, workstations, and other computing elements follows the peer-to-peer access principle. To achieve greater precision and control in process industries, like the petrochemical, nuclear, and oil and gas industries, there is an increasing demand for controllers which offer specified process tolerance around an identified set point.

These requirements have driven the adoption of DCS, as these systems provide lower operational complexity, project risk, and functionalities, like flexibility for agile manufacturing in highly demanding applications. The ability of DCS to integrate PLCs, turbomachinery controls, safety systems, third-party controls, and various other plant process controls for heat exchangers, feedwater heaters, and water quality, among others, further drives the adoption of DCS in the energy sector.

Distributed Control Systems Market Trends

Services Constitute a Considerable Market Share

The services market in the DCS industry is the most intriguing of all the revenue stakeholders among the other components included in the report's scope. Due to its widespread applicability in maintenance, installation, alarm management, upgrade services, plant asset management, lifecycle services, consulting services, migration services, simulation, and training services, the service segment is also expanding demand for DCS. As a result, rising energy demand and considerable technological advancements will drive demand for the services segment, among others, during the projection period.

Moreover, the top market suppliers continue to emphasize expanding capabilities for projects and operations and maintenance services for continuous market expansion. The different components in the scope of services covered in the market report include project management services, non-contract maintenance, retrofits, and upgrades.

Due to an enormous increase in the number of distributed antenna systems service providers in the industry, the services market, which currently holds a significant part of the DCS market, is anticipated to develop at the fastest rate over the projection period.

With the rising awareness, industry players are focusing on deploying and executing IIoT strategies to enhance the DCS network services. The relationship has changed because sensors and edge devices are far more capable, with some processing and communications abilities similar to a PC. Instead of acting in a passive listen-and-respond role, each device can perform more as a peer.

In addition, the main automation contractor (MAC) concept is increasingly becoming important in project services, where the supplier is responsible for all automation-related systems of the project.

The trend is growing in the majority of the large DCS projects. The services market encapsulates entities from the bottom of the pyramid, i.e., the spare parts and repairs, which prove to be helpful in system productivity, cost curtailment, and extension of the product life cycle and systems by reducing the uptime of production units, thus, efficiently delivering operational excellence.

North America Holds Significant Market Share

The rapidly growing shale gas industry in North America is expected to be a major driver of the Distributed Control Systems market in the region.

According to the Department of Energy, in the United States, The shale gas percentage is expected to reach nearly 45% by 2035, which is likely to result in a parallel growth of the tightly integrated DCS market, which provides sustainability of the process through redundant controls in high-risk environments.

In addition, this market is currently challenged by reducing oil prices globally but can be relied upon to be a sizeable industry in the future. The requirement for a large amount of water in Shale gas extraction has created a market for DCS systems in water treatment facilities, resulting in a significant rise in the overall market.

Moreover, the chemicals sector in North America is benefiting from improved dependability, simplified remote monitoring, and lower installation costs. Additionally, several businesses in the chemicals sector are switching from outdated DCS systems to more advanced ones to improve production, efficiency, and safety and decrease human error.

The oil and gas industry in North America is process-driven, with ongoing operations and intricate monitoring methods. It is challenging for operators to keep an eye on and regulate the operation of the machinery used in the sector. Many North American businesses are implementing the usage of an HMI and a controller, or DCS, which enables operators to manage operations. These systems automate safety procedures, including alarm management systems, and perform equipment maintenance and repair tasks.

Distributed control systems have proven vital in managing nuclear power plants, further helping their market in the United States and continuously increasing its nuclear power plant capacity and numbers.

Distributed Control Systems Industry Overview

There are several significant competitors in the competitive distributed control system market. Few of the big competitors now control most of the market in terms of market share. Major firms with a sizable market share are concentrating on growing their consumer base internationally. Many businesses rely on strategic collaboration projects to improve their market share and profitability.

In December 2022, Honeywell announced that Regreen Excel EPC, India, has deployed Honeywell's PlantCruise by Experion Distributed Control Systems (DCS) solution, modular systems, and field instruments (FI) across its 40 plants in India. Regreen Excel EPC India Pvt. Ltd. is a distillery, sugar and cogeneration, biofuels, zero liquid discharge systems, and renewable energy company. The technology assists users in increasing production uptime, improving safety, dependability, and efficiency, and lowering investments and running costs.

In May 2022, ABB modernizes process control systems and cement grinding equipment in the UAE to improve uptime and consistency across several sites. ABB builds a cutting-edge distributed control system (DCS) automation technology at Star Super Cement cement grinding operations in the United Arab Emirates. With the new enhanced systems and homogeneity throughout the multiple linearization and grinding unit sites, Star Cement will benefit from greater operator visibility, easier maintenance, and little downtime.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Overview

- 4.2 Value Chain Analysis

- 4.3 Market Drivers

- 4.3.1 Growing Energy Demand from Major Emerging Economies

- 4.3.2 Growing Adoption for Smart Applications and Iot Technologies

- 4.3.3 Modernization of Existing DCS Solutions will Contribute to the Growth Of Service Sector

- 4.4 Market Restraints

- 4.4.1 Growing Availability of Alternative Technologies in the Field of Process Automation

- 4.5 Industry Attractiveness - Porter's Five Forces Analysis

- 4.5.1 Threat of New Entrants

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Bargaining Power of Suppliers

- 4.5.4 Threat of Substitute Products

- 4.5.5 Intensity of Competitive Rivalry

5 MARKET SEGMENTATION

- 5.1 By Component

- 5.1.1 Hardware

- 5.1.2 Software

- 5.1.3 Services

- 5.2 By End-User Vertical

- 5.2.1 Power Generation

- 5.2.2 Oil & Gas

- 5.2.3 Chemicals

- 5.2.4 Refining

- 5.2.5 Mining & Metals

- 5.2.6 Paper and Pulp

- 5.2.7 Other End-User Verticals

- 5.3 Geography

- 5.3.1 North America

- 5.3.1.1 United States

- 5.3.1.2 Canada

- 5.3.2 Europe

- 5.3.2.1 Germany

- 5.3.2.2 UK

- 5.3.2.3 France

- 5.3.2.4 Italy

- 5.3.2.5 Rest of Europe

- 5.3.3 Asia-Pacific

- 5.3.3.1 China

- 5.3.3.2 Japan

- 5.3.3.3 India

- 5.3.3.4 Rest of Asia-Pacific

- 5.3.4 Latin America

- 5.3.4.1 Brazil

- 5.3.4.2 Mexico

- 5.3.4.3 Rest of Latin America

- 5.3.5 Middle East and Africa

- 5.3.5.1 UAE

- 5.3.5.2 South Africa

- 5.3.5.3 Rest of Middle East & Africa

- 5.3.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Company Profiles

- 6.1.1 ABB Ltd.

- 6.1.2 Honeywell International Corporation

- 6.1.3 Siemens AG

- 6.1.4 Schneider Electric

- 6.1.5 Mitsubishi Motors Corporation

- 6.1.6 Rockwell Automation

- 6.1.7 Emerson Electric Company

- 6.1.8 Metso (Valmet Oyj)

- 6.1.9 Omron Corporation

- 6.1.10 Novatech Llc (Weir Group)

- 6.1.11 Azbil Corporation

- 6.1.12 Toshiba International

- 6.1.13 Yokogawa Electric Co.