|

市场调查报告书

商品编码

1640653

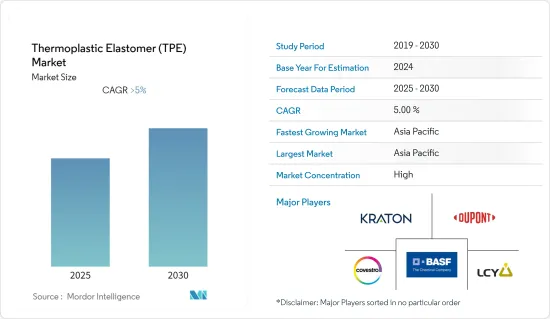

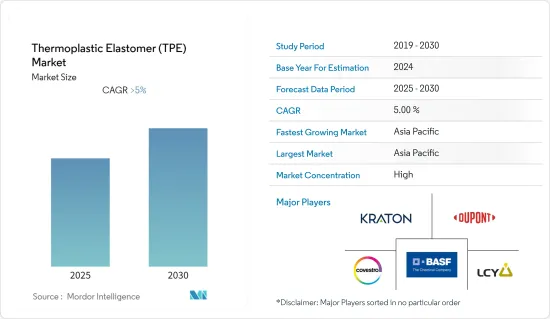

热可塑性橡胶(TPE) -市场占有率分析、产业趋势与统计、成长预测(2025-2030 年)Thermoplastic Elastomer (TPE) - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

预测期内,热可塑性橡胶市场预计将以超过 5% 的复合年增长率成长。

COVID-19 疫情导致全国封锁、製造活动和供应链中断以及全球生产停顿,对 2020 年的市场产生了负面影响。然而,情况在 2021 年开始好转,预测期内市场的成长轨迹开始回升。

关键亮点

- 推动市场成长的主要因素是汽车产业的广泛需求和 HVAC 产业不断增长的应用。

- 预计原物料价格波动将阻碍未来的市场需求。

- 对生物基热可塑性橡胶不断增长的需求可能会在未来几年为市场创造机会。

- 预计亚太地区将主导市场,并在预测期内以最高的复合年增长率成长。

热可塑性橡胶(TPE) 市场趋势

扩大在汽车和运输领域的应用

- 热可塑性橡胶(TPE) 是一种高性能材料,在汽车工业中的应用正在迅速扩大。 TPE 在汽车行业有多种应用,包括生产高品质的汽车仪錶面板、车轮罩、仪表板组件、柱饰、车门衬里和把手、座椅靠背和安全带组件。

- 汽车工业对所用材料的要求特别高。在极端压力下,材料必须保持尺寸稳定,并且在剧烈的温度变化时不会弯曲,这导致了对 TPE 的需求。

- 根据国际汽车工业组织(OICA)预测,2021年全球汽车产量将达到8,010万辆,较上年的7,760万辆成长4%。由于消费需求增加而导致的汽车产量增加是推动市场成长的主要因素。

- TPE 是一种比金属便宜的特殊塑料,具有重量轻、耐用、耐腐蚀、坚韧、设计灵活、弹性好、性能高且成本低等特点,是提高汽车能源效率的理想选择。 TPE 重量轻,可以让车辆更加省油。据估计,车辆重量每减轻 10%,燃料消耗就会减少 5% 至 7%。

- 高性能热可塑性橡胶为製造商提供与钢相当的设计优势和强度,有助于减轻重量和减少温室气体排放。

- 据天然橡胶生产国协会(ANRPC)称,4 月全球橡胶产量从 3 月的 904,000 吨增至 914,000 吨。

- 根据美国联邦航空管理局(FAA)预测,由于航空货运需求的不断增长,到2037年民航机的总数将达到8,270架。此外,由于现有机队老化,美国主干线航空公司预计每年将把机队飞机数量增加到 54 架。

- 预计这些因素将在预测期内推动对热可塑性橡胶的需求。

亚太地区占市场主导地位

- 预计亚太地区将主导市场。在该地区,中国和印度是成长最快的经济体,目前也是全球最大的製造业基地之一。

- 该地区是最大的汽车製造地,占全球汽车产量的近60%。 2022年1月,本田的中国合资企业东风汽车公司宣布在武汉建立电动车製造厂。东风本田新厂将于2024年投产,年产能12万辆。

- 此外,中国建筑业也正在经历强劲成长。根据中国国家统计局的数据,2021年中国建筑业产值约4.29兆美元。

- 根据JEITA(电子情报技术产业协会)统计,2022年11月,电子产业总产值达70.9834亿美元。 2022年12月,日本电子设备出口总额为83.9545亿美元。

- 在印度,电子产品市场的需求不断成长,市场规模正在快速成长。 2022 年 12 月,印度电子产品出口额为 166.7 亿美元,而 2021 年同期为 109.9 亿美元。印度和中国电子和家用电子电器市场的成长可能会进一步推动亚太地区的市场成长。

- 根据印度品牌资产基金会 (IBEF) 的数据,印度是全球前 20 大医疗设备市场之一。预计2021年印度医疗设备出口额将达25.3亿美元,到2025年将增加至100亿美元。例如,2021年9月,政府核准在奥拉加丹(泰米尔纳德邦)建立一个医疗设备园区,预计将吸引4.7205亿美元的投资。

- 2021年泰国天然橡胶产量为483万吨,约占全球天然橡胶产量的35%。泰国已成为世界主要天然橡胶生产国之一。 2021年泰国天然橡胶产量与前一年同期比较增1%。

- 由于上述因素,预计未来几年该地区的热可塑性橡胶市场将出现巨大的需求。

热可塑性橡胶(TPE) 产业概况

热可塑性橡胶市场正在经历整合的本质。市场的主要企业(不分先后顺序)包括杜邦、BASF、科思创、李长荣集团、科腾公司等。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第 1 章 简介

- 调查前提条件

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场动态

- 驱动程式

- 汽车和运输业的广泛需求

- 扩大暖通空调产业的应用

- 限制因素

- 采用软质热可塑性橡胶3D 列印的挑战

- 产业价值链分析

- 波特五力分析

- 供应商的议价能力

- 消费者议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第五章 市场区隔(市场规模(基于数量))

- 产品类型

- 苯乙烯嵌段共聚物 (TPE-S)

- 热塑性烯烃 (TPE-O)

- 合成橡胶合金(TPE-V 或 TPV)

- 热塑性聚氨酯 (TPU)

- 热塑性共聚酯

- 热塑性聚酰胺

- 应用

- 汽车和运输

- 建筑和施工

- 鞋类

- 电气和电子

- 医疗

- 其他用途(家用产品、黏合剂、密封剂)

- 地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 其他亚太地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 义大利

- 法国

- 欧洲其他地区

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地区

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 其他中东和非洲地区

- 亚太地区

第六章 竞争格局

- 併购、合资、合作与协议

- 市场占有率(%)*/排名分析

- 主要企业策略

- 公司简介

- Apar Industries Ltd

- Arkema Group

- Asahi Kasei Corporation

- Avient Corporation

- BASF SE

- Celanese Corporation

- Covestro AG

- DSM

- DuPont

- Evonik Industries AG

- Exxon Mobil Corporation

- Grupo Dynasol

- Huntsman International LLC

- KRATON CORPORATION

- LANXESS

- LCY GROUP

- LG Chem

- LyondellBasell Industries Holdings BV

- Mitsubishi Chemical Corporation

- SABIC

- Sumitomo Chemicals Co. Ltd

- The Lubrizol Corporation

第七章 市场机会与未来趋势

- 生物基热可塑性橡胶的需求不断增加

- 在医疗产业的应用日益广泛

The Thermoplastic Elastomer Market is expected to register a CAGR of greater than 5% during the forecast period.

Due to the COVID-19 outbreak, nationwide lockdowns around the globe, disruption in manufacturing activities and supply chains, and production halts negatively impacted the market in 2020. However, the conditions started recovering in 2021, restoring the market's growth trajectory during the forecast period.

Key Highlights

- The major factors driving the market's growth are extensive demand from the automotive industry and growing applications in the HVAC industry.

- Volatility in raw material prices is expected to hinder future market demand.

- The growing demand for bio-based thermoplastic elastomers will likely create opportunities for the market in the coming years.

- The Asia-Pacific region is expected to dominate the market and is also likely to witness the highest CAGR during the forecast period.

Thermoplastic Elastomers (TPE) Market Trends

Increasing Usage in the Automotive and Transportation Applications

- Thermoplastic elastomers (TPE) are high-performance materials whose application in the automotive industry is rapidly increasing. TPE serves the automotive industry in myriad applications, including manufacturing high-quality automotive instrument panels, wheel covers, dashboard components, pillar trims, door liners and handles, seat backs, and seat belt components.

- The automotive industry places particularly high requirements on the materials used. Under extreme stresses, the materials must be dimensionally stable and must not warp, even when faced with great temperature variations, which is, in turn, catering to the demand for TPE.

- According to the International Organization of Motor Vehicle Manufacturers (OICA), in 2021, global vehicle production reached 80.1 million units, with an increase of 4% from the previous year's production of 77.6 million units. The increasing production of vehicles owing to the growing need from consumers is the key factor for driving the market growth.

- TPEs are special types of plastic that are cheaper than metals and help make automobiles more energy-efficient by reducing weight, providing durability, corrosion resistance, toughness, design flexibility, resiliency, and high performance at low cost. The light weight of TPE enables more fuel-efficient vehicles. Every 10% reduction in vehicle weight is estimated to result in a 5-7% reduction in fuel usage.

- High-performance thermoplastic elastomers offer manufacturers advantages of design and the comparable strength of steel, which help reduce the weight and control greenhouse gas emissions.

- According to the Association of Natural Rubber Producing Countries (ANRPC), the global rubber production volumes increased in April to 914 thousand tons from 904 thousand tons in March.

- According to the Federal Aviation Administration (FAA), the total commercial aircraft fleet is expected to reach 8,270 in 2037, owing to the growth in air cargo. Also, the US mainliner carrier fleet is expected to grow to 54 aircraft per year due to the existing fleet getting older.

- All the factors above, in turn, are expected to drive the demand for thermoplastic elastomers during the forecast period.

Asia-Pacific Region to Dominate the Market

- The Asia-Pacific region is expected to dominate the market. In the region, China and India are the fastest emerging economies and have become one of the biggest production houses in the world today.

- The region is the largest automotive manufacturing hub, with almost 60% share of global automotive manufacturing. In January 2022, Honda's Chinese joint venture with Dongfeng Motor Corporation Ltd. announced the development of an electric-vehicle manufacturing factory in Wuhan. The new Dongfeng-Honda Automobile facility will be opened in 2024 with a production capacity of 120,000 units per year.

- Furthermore, China is experiencing massive growth in its construction sector. According to the National Bureau of Statistics of China, in 2021, the construction output in China will be valued at approximately USD 4.29 trillion.

- According to JEITA (Japan Electronics and Information Technology Industries Association), in November 2022, the total production of the electronics industry reached USD 7,098.34 million. In December 2022, Japan exported a total of electronics worth USD 8,395.45 million.

- In India, the electronics market witnessed a growth in demand, with market size increasing at a rapid growth rate. India's electronic goods exports fetched USD 16.67 billion in December 2022, compared to USD 10.99 billion in the same month of 2021. The growing electronics and appliances market in India and China may push the market growth further in Asia-Pacific.

- According to India Brand Equity Foundation (IBEF), India is among the top 20 markets for medical devices worldwide. The export of medical devices from India stood at USD 2.53 billion in 2021 and is expected to rise to USD 10 billion by 2025. For instance, in September 2021, the government approved a medical devices park in Oragadam (Tamil Nadu) that is expected to attract an estimated investment of USD 472.05 million.

- In 2021, Thailand produced 4.83 million metric tons of natural rubber, accounting for approximately 35% of the global natural rubber production. It made Thailand the world's leading natural rubber-producing country. Natural rubber output in Thailand increased by 1% in 2021 compared to the previous year.

- Owing to the factors above, the market for thermoplastic elastomers in the region is expected to witness huge demand in the coming years.

Thermoplastic Elastomers (TPE) Industry Overview

The thermoplastic elastomer market is consolidated in nature. The market's key players (not in any particular order) include DuPont, BASF SE, Covestro AG, LCY GROUP, and KRATON CORPORATION, among others.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Extensive Demand from the Automotive and Transportation Industry

- 4.1.2 Growing Application in the HVAC Industry

- 4.2 Restraints

- 4.2.1 Challenges of 3D Printing with Soft Thermoplastic Elastomers

- 4.3 Industry Value-Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Consumers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION (Market Size in Volume)

- 5.1 Product Type

- 5.1.1 Styrenic Block Copolymer (TPE-S)

- 5.1.2 Thermoplastic Olefin (TPE-O)

- 5.1.3 Elastomeric Alloy (TPE-V or TPV)

- 5.1.4 Thermoplastic Polyurethane (TPU)

- 5.1.5 Thermoplastic Copolyester

- 5.1.6 Thermoplastic Polyamide

- 5.2 Application

- 5.2.1 Automotive & Transportation

- 5.2.2 Building & Construction

- 5.2.3 Footwear

- 5.2.4 Electricals & Electronics

- 5.2.5 Medical

- 5.2.6 Other Applications(Household Goods, ahdesives & sealants)

- 5.3 Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 India

- 5.3.1.3 Japan

- 5.3.1.4 South Korea

- 5.3.1.5 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 Italy

- 5.3.3.4 France

- 5.3.3.5 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Rest of South America

- 5.3.5 Middle-East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 South Africa

- 5.3.5.3 Rest of Middle-East and Africa

- 5.3.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Share (%)*/Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 Apar Industries Ltd

- 6.4.2 Arkema Group

- 6.4.3 Asahi Kasei Corporation

- 6.4.4 Avient Corporation

- 6.4.5 BASF SE

- 6.4.6 Celanese Corporation

- 6.4.7 Covestro AG

- 6.4.8 DSM

- 6.4.9 DuPont

- 6.4.10 Evonik Industries AG

- 6.4.11 Exxon Mobil Corporation

- 6.4.12 Grupo Dynasol

- 6.4.13 Huntsman International LLC

- 6.4.14 KRATON CORPORATION

- 6.4.15 LANXESS

- 6.4.16 LCY GROUP

- 6.4.17 LG Chem

- 6.4.18 LyondellBasell Industries Holdings B.V.

- 6.4.19 Mitsubishi Chemical Corporation

- 6.4.20 SABIC

- 6.4.21 Sumitomo Chemicals Co. Ltd

- 6.4.22 The Lubrizol Corporation

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Growing Demand for Bio-based Thermoplastic Elastomers

- 7.2 Increasing Applications in the Medical Industry