|

市场调查报告书

商品编码

1641941

混合复合材料:市场占有率分析、产业趋势与统计、成长预测(2025-2030 年)Hybrid Composites - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

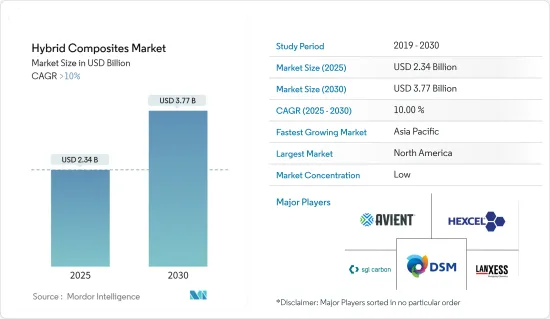

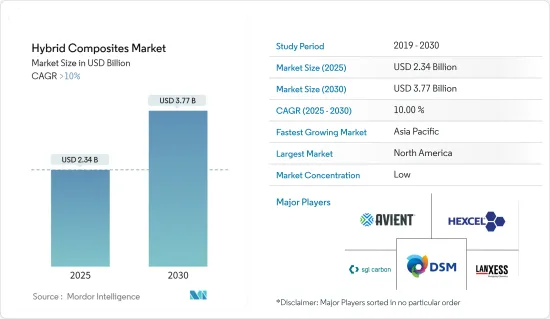

混合复合材料市场规模预计在 2025 年将达到 23.4 亿美元,预计到 2030 年将达到 37.7 亿美元,预测期内(2025-2030 年)的复合年增长率将超过 10%。

COVID-19 疫情对混合复合材料市场的影响好坏参半。虽然这带来了眼前的挑战,但也凸显了这种材料的潜力,并引发了可能有助于其长期成长的趋势。

封锁和旅行限制扰乱了原材料和成品的流动,导致生产延迟和材料短缺。航太、汽车和风力发电等严重依赖混合复合材料的行业由于出行限制和经济放缓而遭受了严重景气衰退,从而减少了对材料的需求。另一方面,疫情凸显了医疗设备和设备对先进材料的需求,为矫正器具、植入和手术器材中的生物相容性混合复合材料创造了机会。

关键亮点

- 轻型车辆领域对复合材料的采用日益广泛,以及混合复合材料相对于传统复合材料所表现出的优异性能,是受调查市场的主要驱动因素。

- 然而,混合复合材料的加工和製造通常涉及复杂且劳动密集的技术,这可能会增加成本并抑制所调查市场的成长。

- 对复合材料製造自动化、数位化和积层製造的探索可以简化流程、降低成本并提高产品一致性,从而在全球市场上提供有利可图的机会。

- 由于中国的需求旺盛,预计亚太地区将在预测期内出现最高成长率。

混合复合材料市场趋势

碳/玻璃占市场主导地位

- 最常用的混合复合材料是玻璃纤维增强聚合物(GFRP)和碳纤维增强聚合物(CFRP)复合材料,其次是酰胺纤维和天然纤维增强复合材料。

- 碳纤维-玻璃纤维混合材料为汽车和运输、建筑和施工以及其他工业市场中的传统玻璃纤维和金属应用提供了一种轻质、高强度的替代品。

- 这种混合材料具有碳纤维的性能优势,但成本与高性能玻璃纤维相似。

- 混合复合材料越来越多地应用于自动化和高速製造工艺,以满足汽车和其他领域大规模生产的需求。

- 根据国际汽车製造商协会(OICA)的数据,2022年全球汽车产量将达到约8,501万辆,而2021年为8,020.5万辆,成长率为5.99%。 2022年全球乘用车产量约6,000万辆,较2021年成长近7.35%。

- 使用案例可以以比使用碳纤维低得多的成本获得高达90%的碳效益。

- 由这些混合复合材料製成的零件具有高强度重量比,并且不会腐蚀。它的使用寿命很长,几乎不需要维护。其特殊的性能满足了安全性和强度至关重要的应用需求。

- 在建筑领域,许多复合材料产品和应用由于其独特的性能(例如耐腐蚀、隔热、轻质等)而越来越受欢迎。从用于混凝土加固的复合钢筋到用于窗框和复合屋瓦的拉挤型材,复合产品不仅可以实现更永续的设计,还可以有效地修復、升级和加固现有建筑物和桥樑。本文提供了一种解决方案。

- 据 JEC Composites 称,人们对材料回收和再利用的兴趣很高,复合材料行业的主要企业正在采取许多倡议。例如,欧洲风电产业承诺在2025年实现100%的风力涡轮机叶片的再利用、再循环和回收。

- 由于上述因素,碳/玻璃纤维类型很可能在预测期内占据市场主导地位。

亚太地区成长率最高

- 近年来,亚太基础设施产业健康成长。因此,预计该地区在评估期内水泥板市场将呈现惊人的成长率。

- 亚太地区目前正在经历住宅和商业建筑的高投资,尤其是中国、日本、台湾、韩国、印度、马来西亚、印尼和越南等新兴经济体。

- JEC Composites 表示,展望未来,随着新兴亚洲引领经济成长,长期趋势将得以恢復。预计中国的成长速度将超过5%的复合年增长率,超过欧洲和美国,印度、菲律宾、印尼和马来西亚也有望实现类似的成长。从中期来看(2021-2026 年),复合材料市场应在所有地区恢復成长,尤其是亚洲(能源、电子电气等)仍显示出巨大的长期成长潜力。

- 在汽车领域,这些独特的材料结合了各种纤维和树脂的优点,实现了减轻重量、提高性能和改善燃油经济性的完美结合,从而增加了亚太市场对混合复合材料的消费量。

- 中国是世界上最大的汽车製造业国家。 2022年产业略有成长,产销量增加。预计 2021 年将继续保持类似的趋势,2022 年产量将成长 3%。据中国工业协会称,汽车产量预计将继续成长,比亚迪和上汽集团等公司将推动燃油和电动车领域的产销量。

- 据中国汽车工业协会称,预计 2022 年中国汽车工业的电动和混合动力汽车汽车销量将达到约 940 万辆,低于去年的 690 万辆。该协会进一步预测,2024年销售量将持续成长,达到 1,150 万台。

- 例如,中国汽车巨头比亚迪计划在 2023 年销售超过 300 万辆电动车,其中包括 160 万辆由电池和汽油动力来源的全电动车,以及另外 140 万辆混合动力汽车。与 2022 年相比,成长了 62%。据比亚迪公司称,该公司也已实现收益,去年上半年利润增长两倍,达到 15 亿美元。

- 根据《今日印度》报道,2023年国内市场汽车销量为410.8万辆。这是自然年度内销售首次突破400万台。 2022年销量为379.2万台。在印度,由于库存未售出,玛鲁蒂、现代、塔塔、本田和马恆达等主要汽车製造商已停止生产。预计这将在不久的将来对印度汽车生产产生重大负面影响。

- 中国是世界上最大的医疗保健产业之一。中国政府在「十三五」规划中将健康和技术创新列为优先事项,预计这将在预测期内带动医疗设备製造业的投资增加。此外,由于新冠疫情爆发,该国对医疗保健领域的投资正在逐渐增加。

- 混合复合材料可以达到极佳的强度重量比,在某些情况下甚至超过钢。这使得它们成为承重结构、桥樑和抗震建筑的理想选择。

- 中国的成长也受到住宅和商业建筑行业快速扩张以及国家经济不断增长的推动。中国正在推动并持续推动都市化进程,预计2030年都市化率将达70%。因此,中国等国家建筑活动的活性化预计将刺激该地区黏合剂产业的发展。所有这些因素都倾向于增加全部区域黏合剂的需求。

- 根据中国国家统计局的数据,预计 2022 年建筑业产值将达到 31.2 兆元(4.5 兆美元),高于 2021 年的 29.31 兆元(4.2 兆美元)。此外,根据住宅及城乡建设部的预测,预计2025年后中国建筑业将占GDP的比重维持在6%。

- 根据印度投资局的数据,到 2025子部门,印度建筑业预计将达到 1.4 兆美元。科技在U的技术推动下,印度建筑业将迎来新纪元。

- 此外,亚洲、北美和太平洋地区的强劲需求,使得2022年韩国建筑商的海外建筑订单连续第三年超过300亿美元。

- 所有这些因素均受到该地区人口成长、都市化和购买力增强的推动。目前亚太地区许多地区正在实施有关VOC排放的法规,这也可能鼓励使用纤维水泥板(FCB)和水泥黏结塑合板(CBPB)等水泥板。

- 因此,由于上述因素,亚太地区很可能在预测期内见证最高成长。

混合复合材料产业概况

混合复合材料市场适度细分。主要参与企业(不分先后顺序)包括朗盛、帝斯曼、Avient Corporation、赫氏公司和西格里碳素。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第 1 章 简介

- 调查结果

- 调查前提

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场动态

- 驱动程式

- 轻型车辆领域复合材料的使用增加

- 某些混合动力汽车可抵御多种威胁

- 其他驱动因素

- 限制因素

- 加工製造成本高

- 对永续性和环境影响的担忧

- 产业价值链分析

- 波特五力分析

- 供应商的议价能力

- 买家的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第 5 章 市场区隔(以金额为准的市场规模)

- 光纤类型

- 碳/玻璃

- 碳/芳香聚酰胺

- HMPP/碳

- 木材/塑料

- 其他纤维类型(天然纤维、玄武岩纤维等)

- 树脂类型

- 热固性树脂

- 热塑性树脂

- 其他树脂类型(例如 PEEK(聚醚醚酮))

- 最终用户产业

- 汽车和运输设备

- 建筑基础设施

- 航太和国防

- 海洋

- 其他终端使用者产业(体育用品、医疗等)

- 地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 马来西亚

- 泰国

- 印尼

- 越南

- 其他亚太地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 北欧的

- 土耳其

- 俄罗斯

- 欧洲其他地区

- 南美洲

- 巴西

- 阿根廷

- 哥伦比亚

- 南美洲其他地区

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 奈及利亚

- 卡达

- 埃及

- 阿拉伯聯合大公国

- 其他中东和非洲地区

- 亚太地区

第六章 竞争格局

- 併购、合资、合作与协议

- 市场占有率(%)**/排名分析

- 主要企业策略

- 公司简介

- Avient Corporation

- DSM

- Gurit Services AG

- Hexcel Corporation

- Huntsman International LLC

- KINECO-KAMAN

- LANXESS

- Mitsubishi Chemical Carbon Fiber and Composites, Inc.

- RTP Company

- Owens Corning

- SABIC

- SGL Carbon

- Simcas Composites

- Solvay

- TEIJIN LIMITED

- Textum OPCO, LLC

- Toray Advanced Composites

第七章 市场机会与未来趋势

- 混合复合材料在各市场的应用日益广泛

- 探索复合材料製造的自动化、数位化和积层製造技术

The Hybrid Composites Market size is estimated at USD 2.34 billion in 2025, and is expected to reach USD 3.77 billion by 2030, at a CAGR of greater than 10% during the forecast period (2025-2030).

The impact of the COVID-19 pandemic on the hybrid composites market was mixed. While it presented immediate challenges, it also highlighted the potential of these materials and triggered trends that could contribute to long-term growth.

Lockdowns and travel restrictions disrupted the flow of raw materials and finished products, leading to production delays and material shortages. Industries heavily reliant on hybrid composites, such as aerospace, automotive, and wind energy, experienced significant downturns due to travel restrictions and economic slowdown, dampening demand for material. On the flip side, the pandemic highlighted the need for advanced materials in medical devices and equipment, creating opportunities for biocompatible hybrid composites in prosthetics, implants, and surgical instruments.

Key Highlights

- The growing adoption of composite materials in the light vehicle sector and compared to traditional composites, better properties exhibited by hybrid composites in comparison to the traditional composites is a major driving factor for the market studied.

- On the flip side, the processing and manufacturing of hybrid composites often involve complex and labor-intensive techniques, driving up costs and may act as a hindrance to the growth of the market studied.

- Exploring automation, digitalization, and additive manufacturing techniques for composite production can streamline processes, reduce costs, and improve product consistency can provide lucrative opportunities in the global market.

- Asia-Pacific is expected to witness the highest growth rate during the forecast period owing to the high demand from China.

Hybrid Composites Market Trends

Carbon/Glass to Dominate the Market

- The most commonly used hybrid composites are glass fiber-reinforced polymer (GFRP) and carbon fiber-reinforced polymer (CFRP) composites, followed by composites reinforced by aramid or natural fibers.

- Hybrid carbon fiber/glass fiber material is a lightweight and high-strength alternative for traditional fiberglass and metal applications in the automotive & transportation, building & construction, and other industrial markets.

- The hybrid material offers the performance benefits of carbon fiber at a cost similar to high-performance fiberglass.

- Increased application of hybrid composites in automation and fast-paced manufacturing processes meet mass production requirements in automotive and other sectors.

- According to the Organisation Internationale des Constructeurs d'Automobiles (OICA), in 2022, around 85.01 million vehicles were produced across the globe, witnessing a growth rate of 5.99% compared to 80.205 million vehicles in 2021, thereby indicating an increased demand for metal hoses from the automotive industry. In 2022, around 60 million passenger cars were manufactured worldwide, up nearly 7.35% compared to 2021.

- Users can get up to 90% of carbon's benefits at a cost much lower than what they would have to incur in case of using carbon fiber.

- Parts made out of these hybrid composites provide a high strength-to-weight ratio and are devoid of corrosion. These have extended service life, requiring less maintenance. Their particular properties meet the needs of applications that lay utmost importance on safety and strength.

- In building and construction, many composite products and applications are gaining more and more traction thanks to their unique properties (e.g., corrosion resistance, insulation, lightweight). From composite rebars for reinforcing concrete to pultruded profiles for window frames and composite roofing tiles, composite products not only enable more sustainable designs but also provide an effective solution to repair, upgrade, or strengthen existing buildings, bridges, etc.

- As per JEC Composites, interest in recycling and reusing materials is high, and key players in the composites industry are involved in many initiatives. The application sectors are also setting ambitious goals in this area, e.g., Europe's wind industry is committing to reusing, recycling, or recovering 100% of turbine blades by 2025.

- Owing to the factors mentioned above, carbon/glass fiber type is likely to dominate the market during the forecast period.

Asia-Pacific to Witness the Highest Growth Rate

- The infrastructure industry in Asia-Pacific has been growing at a healthy rate in recent times. Hence, it is estimated that the region will witness a tremendous growth rate in the cement board market over the assessment period.

- The Asia-Pacific region is currently experiencing high investments in residential and commercial construction, especially in China, Japan, Taiwan, and South Korea, and in developing economies such as India, Malaysia, Indonesia, and Vietnam.

- According to JEC Composites, In the future, long-term trends should resume, with economic growth driven by emerging Asia: China's growth is expected to exceed 5% CAGR per annum, higher than Europe and the US; India, Philippines, Indonesia, and Malaysia should grow at a comparable rate. In the mid-term (2021-2026), the composites market should resume growth in all regions, and there is still substantial potential for long-term growth, especially in Asia (energy, E&E, ...).

- In automotive, these unique materials, combining the strengths of various fibers and resins, offer a winning combination of lightweight, enhanced performance, and improved fuel efficiency, leading to increased consumption of hybrid composites in the Asia-Pacific market.

- The Chinese automotive manufacturing industry is the largest in the world. The industry witnessed a slight growth in 2022, wherein production and sales increased. A similar trend continued in 2021, with production witnessing a 3% incline in 2022. According to the China Association of Automobile Manufacturers (CAAM), automotive production is expected to grow in the future, with companies like BYD, SAIC Motors, and more increasing their automotive production sales in the fuel-run and electric vehicles segment.

- According to the China Association of Automobile Manufacturers, Chinese automakers are anticipated to report sales of approximately 9.4 million electric vehicles and hybrids in the previous year, up from 6.9 million in 2022. The association further projects a continued increase in sales for 2024, reaching 11.5 million units.

- For Example, China's automotive giant BYD sold over 3 million battery-powered cars in 2023, of which both batteries and gasoline power 1.6 million fully electric vehicles and another 1.4 million hybrids. Together, that is a 62 percent increase over 2022. BYD is also making money, tripling its profit to USD 1.5 billion in the first half of last year, according to BYD.

- According to India Today, 4,108,000 cars were sold in the domestic market in 2023. This was the first time during a calendar year that over 4 million units were sold in the country. In 2022, the industry witnessed sales of 3,792,000 units. In India, major automotive manufacturers, like Maruti, Hyundai, Tata, Honda, and Mahindra, have shut down their production owing to the unsold stock. This is expected to have a substantial negative impact on India's automotive production in the near future.

- China has one of the largest healthcare sectors in the world. Under the 13th Five-Year Plan, the Government of China prioritized health and innovation, which is expected to increase investments in the medical device manufacturing sector during the forecast period. Additionally, due to the COVID-19 outbreak, investment in the healthcare sector has been gradually growing in the country.

- Hybrid composites can achieve exceptional strength-to-weight ratios, exceeding even steel in some cases. This makes them ideal for load-bearing structures, bridges, and earthquake-resistant buildings.

- China's growth is also fueled by rapid expansion in the residential and commercial building sectors and the country's expanding economy. China is encouraging and enduring a continuous urbanization process, with a projected rate of 70% by 2030. As a result, increased building activity in nations like China is projected to fuel the region's adhesive industry. All such factors tend to increase the demand for adhesives across the region.

- According to the National Bureau of Statistics of China, the value of construction output accounted for CNY 31.2 trillion (USD 4.5 trillion) in 2022, up from CNY 29.31 trillion (USD 4.2 trillion) in 2021. Moreover, as per the forecast given by the Ministry of Housing and Urban-Rural Development, China's construction sector is expected to maintain a 6% share of the country's GDP going into 2025.

- As per Invest India, the construction industry in India is expected to reach USD 1.4 Trillion by 2025, and the construction industry in India works across 250 sub-sectors with linkages across sectors and over 54 global innovative construction technologies identified under a Technology Sub-Mission of PMAY-U to start a new era in Indian Construction Sectors.

- Furthermore, South Korean builders' overseas building orders have surpassed 30 billion US dollars for the third consecutive year in 2022, owing to strong demand from Asia, North America, and the Pacific Ocean regions.

- All of these factors will be supported by the ever-increasing population in the region, urbanization, ion, and their increasing purchasing power. Regulations related to VOC emissions are currently being implemented in many regions of Asia-Pacific, and this might also drive the usage of cement boards such as fiber cement board (FCB) and cement bonded particleboard (CBPB).

- Hence, owing to the factors mentioned above, Asia-Pacific is likely to witness the highest growth during the forecast period.

Hybrid Composites Industry Overview

The hybrid composites market is moderately fragmented in nature. The major players (not in any order) include LANXESS, DSM, Avient Corporation, Hexcel Corporation, and SGL Carbon, among others.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Deliverables

- 1.2 Study Assumptions

- 1.3 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Increasing Use of Composite Material in Light Vehicle Segment

- 4.1.2 Specific Hybrids offer Multi-threat Protection

- 4.1.3 Other Drivers

- 4.2 Restraints

- 4.2.1 High Processing and Manufacturing Costs

- 4.2.2 Concerns about Sustainability and Environmental Impact

- 4.3 Industry Value Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Buyers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION (Market Size In Value)

- 5.1 Fiber Type

- 5.1.1 Carbon/Glass

- 5.1.2 Carbon/Aramid

- 5.1.3 HMPP/Carbon

- 5.1.4 Wood/Plastic

- 5.1.5 Other Fiber Types (Natural Fibers, Basalt Fibers, etc.)

- 5.2 Resin Type

- 5.2.1 Thermoset Resins

- 5.2.2 Thermoplastic Resins

- 5.2.3 Other Resin Types (PEEK(Polyether Ether Ketone), etc.)

- 5.3 End-user Industry

- 5.3.1 Automotive and Transportation

- 5.3.2 Construction and Infrastructure

- 5.3.3 Aerospace and Defense

- 5.3.4 Marine

- 5.3.5 Other End-user Industries (Sporting Goods, Medical, etc.)

- 5.4 Geography

- 5.4.1 Asia-Pacific

- 5.4.1.1 China

- 5.4.1.2 India

- 5.4.1.3 Japan

- 5.4.1.4 South Korea

- 5.4.1.5 Malaysia

- 5.4.1.6 Thailand

- 5.4.1.7 Indonesia

- 5.4.1.8 Vietnam

- 5.4.1.9 Rest of Asia-Pacific

- 5.4.2 North America

- 5.4.2.1 United States

- 5.4.2.2 Canada

- 5.4.2.3 Mexico

- 5.4.3 Europe

- 5.4.3.1 Germany

- 5.4.3.2 United Kingdom

- 5.4.3.3 France

- 5.4.3.4 Italy

- 5.4.3.5 Spain

- 5.4.3.6 NORDIC

- 5.4.3.7 Turkey

- 5.4.3.8 Russia

- 5.4.3.9 Rest of Europe

- 5.4.4 South America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Colombia

- 5.4.4.4 Rest of South America

- 5.4.5 Middle-East & Africa

- 5.4.5.1 Saudi Arabia

- 5.4.5.2 South Africa

- 5.4.5.3 Nigeria

- 5.4.5.4 Qatar

- 5.4.5.5 Egypt

- 5.4.5.6 UAE

- 5.4.5.7 Rest of Middle-East & Africa

- 5.4.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Share (%)**/Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 Avient Corporation

- 6.4.2 DSM

- 6.4.3 Gurit Services AG

- 6.4.4 Hexcel Corporation

- 6.4.5 Huntsman International LLC

- 6.4.6 KINECO - KAMAN

- 6.4.7 LANXESS

- 6.4.8 Mitsubishi Chemical Carbon Fiber and Composites, Inc.

- 6.4.9 RTP Company

- 6.4.10 Owens Corning

- 6.4.11 SABIC

- 6.4.12 SGL Carbon

- 6.4.13 Simcas Composites

- 6.4.14 Solvay

- 6.4.15 TEIJIN LIMITED

- 6.4.16 Textum OPCO, LLC

- 6.4.17 Toray Advanced Composites

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Rising Adoption of Hybrid Composites into Various Markets

- 7.2 Exploring Automation, Digitalization, and Additive Manufacturing Techniques for Composite Production