|

市场调查报告书

商品编码

1642142

印尼自动化与控制系统:市场占有率分析、产业趋势与成长预测(2025-2030 年)Indonesia Automation And Control System - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

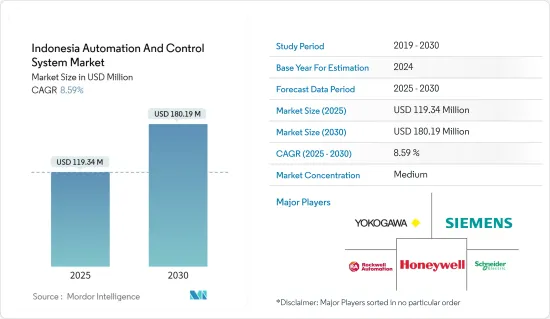

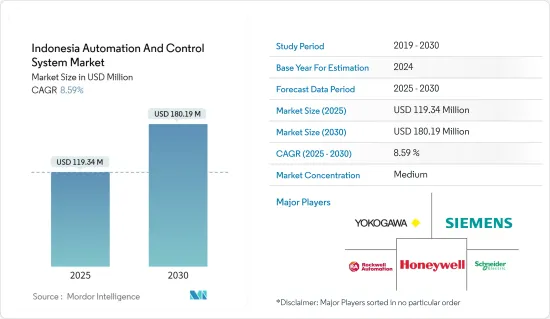

印尼自动化和控制系统市场规模预计在 2025 年为 1.1934 亿美元,预计到 2030 年将达到 1.8019 亿美元,预测期内(2025-2030 年)的复合年增长率为 8.59%。

随着印尼稳步融入全球经济,自动化和控制系统对于降低成本至关重要。

关键亮点

- 自动化和控制系统是指监督和控制涉及商品和服务生产和分配的广泛过程的系统。从组装到发电厂,许多通用和基本服务都依赖自动化和控制系统。例如,维持现代国家社会、工业和经济福祉的大部分公共产业和通讯基础设施都依赖自动化和控制系统。

- 印尼是着名的工业製造国,自动化程度很高。製造业对该国的国内生产毛额贡献巨大。例如,根据印尼统计局的预测,到2022年,印尼製造业将占国内生产总值(GDP)的18%以上,成为该国经济的最大贡献者。预计印尼和马来西亚强劲的製造业活动将推动研究市场的需求。

- 政府加大资金投入,鼓励众多产业领域的自动化系统,各製造业对自动化的需求强劲,工业机器人创新不断增加,製造业技术进步迅猛,为满足不断增长的人口,大规模生产和相关供应链是推动印尼自动化和製程控制系统市场成长的关键因素。

- 印尼矿产资源丰富且尚未开发,是世界上最大的锡、棕榈油和动力煤出口国。它也是镍、铜、矾土、橡胶、锰、锌和铅的主要出口国之一。矿业约占印尼GDP的十分之一,多年来在该国经济发展中发挥关键作用。对金属和矿物的需求不断增长,以及对半导体和电子产品的需求不断增加,推动了采矿业采用自动化系统。

- 在能源领域,智慧城市计画的出现正在增加对自动化和控制系统的需求。印尼在这方面发挥着主导作用,推出了“100 个智慧城市计划”,这是一项旨在应对都市化挑战的综合数位化计划。该倡议是政府应对都市化计画的一部分,该计画预测到 2045 年,印尼 83% 的人口将居住在都市区。

- 印尼也鼓励透过创新的生物质混烧计画利用生物质来改善现有蒸气发电厂的绿化程度。该计画的目标是到 2025 年建成 52 个生物质混烧站点,目前已经有 37 个站点混烧生物质,使用 306,000 吨生物质,到 2023 年达到 108 万吨的目标。此类计划以及发展该国电力和公共产业部门的新计划和投资预计将为该国实施自动化和控制系统创造新的市场机会。

- 然而,与自动化和控制系统相关的初始成本很高。客製化和整合的复杂性增加了总体成本。此外,引入自动化设备可能需要改变工厂现有的基础设施。这可能包括改变布局、电气系统和安全功能以适应新设备,从而产生额外的成本。这些因素可能会阻碍市场成长。

印尼自动化和控制系统市场趋势

食品和饮料推动印尼自动化和控制系统市场

- 食品和饮料产业在印尼经济中占有重要地位,是该国 GDP 的重要贡献者。该行业受益于丰富的自然资源和不断增长的国内需求,增强了其韧性。尤其是2022年第二季度,食品饮料产业占非石油和天然气产业GDP的38.38%,巩固了其作为印尼GDP贡献领先子部门的地位。

- 根据印尼统计局 (BPS) 的资料,2022 年食品和饮料 (F&B) 行业以年度为基础为 4.90%,达到 8,130.62 亿印尼盾。这种情况与食品、饮料本身产量的增加密不可分。根据CRIF的2023年预测,食品和饮料行业预计与前一年同期比较%。影响这种成长的一个因素是食品和饮料产业对经济环境变化的高度敏感性。 CRIF也认为,该产业仍具有良好的前景,尤其是在COVID-19疫情后国家经济復苏的背景下。

- 「打造印尼4.0」策略旨在到2030年使印尼跻身世界十大经济体之列,该策略将物联网(IoT)、自动化、机器人、人工智慧和感测器技术等关键技术置于核心地位。我们将其定位为一个重要元素。在该策略的重点细分领域中,食品饮料产业尤为突出。因此,预计国内食品和饮料行业对数位转型的需求将增加,从而导致自动化和控制系统的增加。为配合该国的工业 4.0 工业策略,印尼政府正在鼓励当地食品和饮料产业采用数位化进步,并在生产中使用当地原料。

- 食品安全是食品和饮料产业的重要组成部分,而新冠肺炎疫情使得食品安全变得更加重要。製造商被迫检查并加强其食品安全措施。引进机器人可以帮助提高食品安全,消除人工干预,从而显着降低食品生产设施交叉污染的风险。此外,包括印尼在内的全球对包装食品的需求正在激增,导致食品包装设施采用先进的机械来取代体力劳动。

- 此外,根据印尼统计局的资料,Z世代和千禧世代消费者占全国人口的52%,为了迎合他们,企业正在不断发展,努力跟上数位化发展的步伐。正面的影响。食品和饮料 (F&B) 製造业正在采用 IIoT、AI、PLC 和机器人等工具来提高产量和品质。即时资料处理和预测分析的发展进一步促进了利用资料产生有效决策见解的新方法的引入。

DCS 主导印尼自动化与控制系统市场

- 分散式控制系统 (DCS) 是一种整合控制架构,包含一个监督层级的控制,可监督管理局部製程复杂性的多个整合子系统。 DCS 主要用于石油和气体纯化以及石油生产等工业製程。这些系统专门设计了冗余和诊断功能,以提高控制的可靠性和效能。它为控制分散式离散现场设备及其操作站提供了更大的灵活性。

- 分散式控制系统 (DCS) 的可扩展性是一个关键优势。它最初可以部署为一个完整的整合系统,也可以部署为一个可以根据需要扩展的独立系统。预计对市场成长产生积极影响的因素包括电力能源领域的需求不断增长以及该国工业基础设施的发展。

- DCS 系统列出了显着的优点,包括分散式控制器、工作站和其他计算元素之间的P2P存取。石化、核能、石油和天然气等製程工业对能够在设定点附近提供精确控制和製程接受度的控制器的需求越来越大。印尼石油和天然气产业的投资不断增加,为DCS应用创造了新的机会。 DCS 广泛应用于石油和天然气工业,以更好地控制生产过程。

- 印尼是世界知名天然气生产国,天然气蕴藏量位居亚太地区第三位,仅次于澳洲和中国。该国已提案分配10个石油和天然气区块,包括南海区块,以促进能源生产和探勘。 2022 年将有 13 个天然气田拍卖。此外,SKK Migas 致力于扩大 Gendallo Gehem计划,到2022 年和2027 年实现天然气产量高峰8.44 亿立方英尺/天,但须遵守修订后的开发计划,该计划将纳入埃尼现有的附近天然气生产设施。预计产业这些重大进步将推动该领域 DCS 设备的采用。

- 此外,由于该地区水产业对 DCS 的采用、投资数位化程度不断提高,预计市场将出现巨大的需求。印尼当地水务公司 PDAM 正在透过采用数位技术来实现业务和服务的现代化。客户抄表、数位计费、申诉管理、员工资料库、薪资核算等应用程式已成功整合,从而实现了更快、更有效率的管理流程。

- 2023 年,Perumdam Tirta Sanjiwani 和 Bima Sakti Alterra 同意实施全面的 SWGM 解决方案,并在 Blahbatuh 科技区试行。这项进展将提高水处理业务的效率、可靠性和安全性,同时降低营运成本和环境影响,并可视为广泛采用 DCS 的积极一步。

印尼自动化控制系统市场竞争模式

印尼自动化和控制系统市场竞争适中,由几家大型企业组成。从市场占有率来看,目前少数几家大公司占据着市场主导地位。凭藉显着的市场占有率,这些主要企业正致力于扩大其在多个国家的基本客群。

2022 年 5 月,ETAP 和施耐德电机宣布将 EcoStruxure Power Operation 与 ETAP 操作员训练模拟器 (eOTS) 和 ETAP 电力系统监控与类比 (PSMS) 整合。这种特殊的整合确保所有 EcoStruxure Power Operation 系统都持续连接到 ETAP数位双胞胎。

2022 年 4 月,罗克韦尔自动化与新加坡工业 4.0 技术供应商 CAD-IT 建立最新合作,加强了其合作伙伴网路。 CAD-IT 在东南亚拥有广泛的网络,业务范围涵盖包括印尼在内的多个国家。透过此次合作,CAD-IT 将提供罗克韦尔自动化的智慧製造解决方案、自动化解决方案等。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第 1 章 简介

- 研究假设和市场定义

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场洞察

- 市场概况

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 买家的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争对手之间的竞争强度

- COVID-19 工业影响评估

第五章 市场动态

- 市场驱动因素

- 印尼电力产业蓬勃发展,发电量不断增加

- 印尼无线通讯协定与无线感测器网路技术的演进与发展

- 投资工业发展和能力建设

- 市场限制

- 高资本投入

- 大宗商品价格波动与经济情势动盪

第六章 市场细分

- 产品

- 可程式逻辑控制器

- 监控和资料采集

- 集散控制系统

- 人机介面

- 安全系统

- 工业机器人

- 马达(包括交流、直流、EC、伺服和步进马达)

- 驱动器(包括交流、直流和伺服)

- 最终用户产业

- 石油和天然气

- 力量

- 化工和石化

- 饮食

- 金属与矿业

- 用水和污水

- 其他的

第七章 竞争格局

- 公司简介

- Yokogawa Corporation

- Siemens AG

- Honeywell International Inc.

- Rockwell Automation Inc.

- Schneider Electric Co.

- ABB Ltd.

- Emerson Electric Co.

- PT FANUC Indonesia

第八章马达及工业机器人进口分析

第九章投资分析

第十章:投资分析市场的未来

The Indonesia Automation And Control System Market size is estimated at USD 119.34 million in 2025, and is expected to reach USD 180.19 million by 2030, at a CAGR of 8.59% during the forecast period (2025-2030).

With Indonesia's steady amalgamation with the world's economy, Indonesia's Automation and Control System will be essential in bringing costs down.

Key Highlights

- Automation and Control System refers to systems that oversee and control a wide range of processes involved in manufacturing and distributing goods and services. Many universal and essential services depend on Automation and Control Systems, from assembly lines to power stations. For example, many utility or telecommunication infrastructures that maintain a modern nation's social, industrial, and economic well-being rely on Automation and Control Systems.

- Indonesia is a prominent industrial manufacturer that highly adopts automation in its industries. Manufacturing contributes a considerable amount to a country's GDP. For instance, according to Statistics Indonesia, in 2022, Indonesia's manufacturing sector contributed over 18 percent of the country's GDP, the most significant contributor to the nation's economy. The robust manufacturing activities in Indonesia and Malaysia will likely augment the demand for the studied market.

- Growing government funding to encourage automated systems in numerous industrial verticals, booming demand for automation from different manufacturing sectors, increasing innovations in industrial robotics, swelling technological advancements in manufacturing, and the need for mass production and related supply chains to cater to the rising population are the crucial factors driving the growth of automation and process control systems market in Indonesia.

- Indonesia's mineral resources are vast and unexplored, and it is the world's largest exporter of Tin, palm oil, and thermal coal. It is also one of the major exporters of Nickel, Copper, Bauxite, Rubber, Manganese, Zinc, and Lead, among others. Mining accounts for about a tenth of Indonesia's GDP and has played a vital role in the country's economic development over the years. The rising demand for metals and minerals, with the growing demand for semiconductors and electronics, fuels the adoption of automated systems in the mining sector.

- The energy sector is experiencing an increase in demand for automation and control systems due to the emergence of smart city programs. Indonesia has taken the lead in this regard by launching the 100 Smart Cities Movement, a comprehensive digitalization program aimed at addressing urbanization challenges. This initiative is part of the government's plan to tackle the issue of urbanization, with projections indicating that 83 percent of the Indonesian population will reside in urban areas by 2045.

- Indonesia is also encouraging the use of biomass to improve the greening of existing Steam Power Plants through the innovative Biomass Co-Firing program. The program aims to co-fire biomass in 52 locations by 2025 and has already co-fired biomass in 37 areas, using 306 thousand tons to reach the 1.08 million ton target by 2023. Such programs and new projects and investments to develop the power and utility sector of the country are expected to create new market opportunities for the implementation of automation and control systems in the country.

- However, the initial costs associated with automation and control systems are high. The complexity of customization and integration adds to the overall costs. Moreover, installing automation equipment may require modifications to the existing infrastructure of the factory. This can include changes to the layout, electrical systems, and safety features to accommodate new equipment, which incur additional costs. Such factors might hinder the market growth.

Indonesia Automation and Control System Market Trends

Food and Beverages to Drive the Indonesia Automation and Control System Market

- The food and beverage sector holds a prominent position in Indonesia's economy, serving as a vital contributor to the nation's GDP. The industry benefits from abundant natural resources and a growing domestic demand, bolstering its resilience. Notably, during the second quarter of 2022, the food and beverage sector accounted for a substantial 38.38 percent of the non-oil and gas industry's GDP, solidifying its status as the leading sub-sector in terms of GDP contribution within Indonesia.

- Based on data from Statistics Indonesia (BPS), the food and beverage (F&B) industry increased by 4.90 percent on an annual basis in 2022 to IDR 813.062 billion. This condition is inseparable from the increased production of the food and beverage commodity itself. According to CRIF forecasts for 2023, the food and beverage industry is expected to experience an increase of around 5 percent compared to the previous year. Factors influencing this growth are the high sensitivity of the food and beverage industry to changes in the economic environment. CRIF also considers that this industry still has good prospects, especially in the context of national economic recovery after the COVID-19 pandemic.

- The Making Indonesia 4.0 strategy, which aims to position Indonesia as a global Top 10 economy by 2030, has identified critical technologies such as the Internet of Things (IoT), automation, robotics, artificial intelligence, and Sensor technology as its core components. Among the priority sectors in this strategy, the food and beverage industry stands out. Consequently, the country's food and beverage sector is expected to experience a growing demand for digital transformation, leading to an increase in automation and control systems. In line with the national Making Industry 4.0 industrial strategy, the Indonesian government is urging the local food and beverage industry to embrace digital advancements and transition towards using local raw ingredients for manufacturing.

- Food safety is a crucial element in the food and beverage industry, with COVID-19 further intensifying its significance. Manufacturers have been compelled to scrutinize and enhance their food safety measures. The deployment of robots can aid in improving food safety by eliminating the need for human intervention, thereby significantly reducing the risk of cross-contamination in food manufacturing facilities. Additionally, the demand for packaged food is surging globally, including in Indonesia, where sophisticated machines in food packaging facilities have replaced manual methods.

- Moreover, As per the data from the Indonesia Bureau of Statistics, the country comprises 52 percent of Gen Z and millennial consumers, and in order to deal with them, companies are evolving and working towards catching up in terms of digital evolutions, thus positively impacting the demand for automation and industrial control equipment and technologies. Food & Beverage (F&B) manufacturing has embraced IIoT, AI, PLC, Robotics, and more such tools to move up production and quality. Developments in real-time data processing and predictive analytics further help introduce new ways of utilizing data to generate insights for effective decision-making.

DCS Holds a Dominant Position in Indonesia Automation and Control System Market

- A Distributed Control System (DCS) is an integrated control architecture that includes a supervisory level of control overseeing multiple integrated sub-systems responsible for managing the intricacies of a localized process. DCS is primarily utilized in industrial processes such as oil and gas refineries, oil production, etc. These systems are specifically designed with redundancy and diagnostic capabilities to enhance control reliability and performance. They offer increased flexibility in controlling distributed discrete field devices and their operating stations.

- The scalability of a Distributed Control System (DCS) is a significant advantage. It can be initially implemented as a comprehensive, integrated system or as a standalone system that can be expanded as required. Anticipated positive influences on market growth include the growing demand in the power and energy sectors and the development of industrial infrastructure in the country.

- DCS systems offer significant benefits, including peer-to-peer access between distributed controllers, workstations, and other computing elements. In process industries such as petrochemical, nuclear, and oil and gas, there is a growing demand for controllers that provide precise control and process tolerance around a set point. The Indonesian oil and gas sector's increasing investments are creating new opportunities for DCS applications. DCS is widely used in the oil and gas industry and provides enhanced control over the production process.

- Indonesia is a prominent natural gas producer globally, possessing the third-largest gas reserves in the Asia Pacific region, following Australia and China. The nation has proposed the allocation of ten oil and gas working areas, including a block in the South China Sea, to enhance energy production and exploration. In 2022, 13 oil and gas fields were auctioned. Additionally, SKK Migas has projected that the Gendalo-Gehem project will reach a peak gas output of 844 million cfd by 2022, with production commencing in 2027, subject to a revised development plan that incorporates Eni's existing gas production facilities nearby. These significant advancements in the industry will promote the adoption of DCS devices in the sector.

- The market is also expected to witness a significant demand owing to the rising adoption of DCS, investments, and digitization in the region's water industry. Indonesia's local water companies, known as PDAMs, have embarked on a process of modernizing their operations and services by incorporating digital technology. They have successfully integrated applications for customer meter reading, digital billing, complaint management, employee databases, and payroll, resulting in faster and more efficient administrative processes.

- In 2023, Perumdam Tirta Sanjiwani and Bima Sakti Alterra agreed to implement a comprehensive SWGM solution, which was piloted in the Blahbatuh technical zone. This development can be seen as a positive step towards the widespread adoption of DCS, as it enhances the efficiency, reliability, and safety of water treatment operations while also reducing operational costs and environmental impacts.

Indonesia Automation and Control System Market Competitive Landscape

The Indonesian automation and control system market is moderately competitive and consists of several major players. In terms of market share, few major players currently dominate the market. These major players with a prominent market share are focusing on expanding their customer base across numerous countries.

In May 2022, ETAP and Schneider Electric announced the integration of EcoStruxure Power Operation with ETAP Operator Training Simulator (eOTS) and ETAP Power System Monitoring & Simulation (PSMS), enabling model-driven power system training and predictive analysis for operators and engineers. This specific integration ensures that all EcoStruxure Power Operation systems are connected to the ETAP Electrically Digital Twin continuously on a genuine time basis.

In April 2022, Rockwell Automation strengthened its partner network with its latest partnership with CAD-IT, a Singapore-based Industry 4.0 technologies provider. CAD-IT has a vast network in Southeast Asia, with a presence in multiple countries, including Indonesia. Through the partnership, CAD-IT will offer Rockwell Automation's smart manufacturing and automation solutions, among other solutions.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitute Products

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Assessment of the impact of COVID-19 on the industry

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Flourishing Power Sector and Increased Power Generation Capacities in Indonesia

- 5.1.2 Evolution and Development of Wireless Protocols and Wireless Sensor Network Technology in Indonesia

- 5.1.3 Development of Industries and Investments to Increase Capacities

- 5.2 Market Restraints

- 5.2.1 High Capital Investments

- 5.2.2 Fluctuating Commodity Prices and Volatile Economic Scenario

6 MARKET SEGMENTATION

- 6.1 Product

- 6.1.1 Programmable Logic Controller

- 6.1.2 Supervisory Control and Data Acquisition

- 6.1.3 Distributed Control System

- 6.1.4 Human Machine Interface

- 6.1.5 Safety Systems

- 6.1.6 Industrial Robotics

- 6.1.7 Electric Motors (includes AC, DC, EC, Servo and Stepper Motors)

- 6.1.8 Drives (includes AC,DC and Servo)

- 6.2 End-User Industry

- 6.2.1 Oil & Gas

- 6.2.2 Power

- 6.2.3 Chemical & Petrochemical

- 6.2.4 Food & Beverage

- 6.2.5 Metals & Mining

- 6.2.6 Water and Wastewater

- 6.2.7 Other End-User Industries

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Yokogawa Corporation

- 7.1.2 Siemens AG

- 7.1.3 Honeywell International Inc.

- 7.1.4 Rockwell Automation Inc.

- 7.1.5 Schneider Electric Co.

- 7.1.6 ABB Ltd.

- 7.1.7 Emerson Electric Co.

- 7.1.8 PT FANUC Indonesia