|

市场调查报告书

商品编码

1642182

密度计 -市场占有率分析、产业趋势与统计、成长预测(2025-2030 年)Density Meter - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

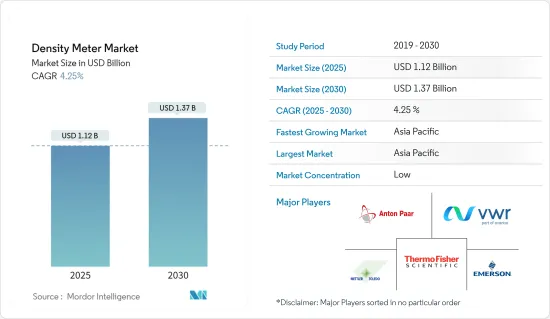

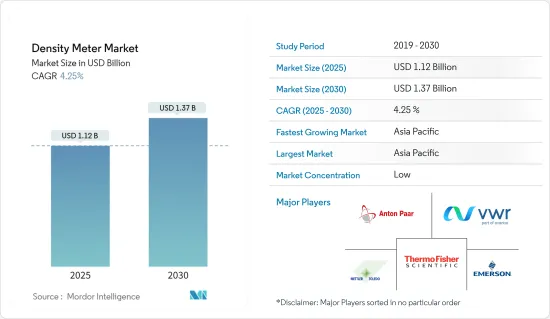

密度计市场规模预计在 2025 年为 11.2 亿美元,预计到 2030 年将达到 13.7 亿美元,预测期内(2025-2030 年)的复合年增长率为 4.25%。

关键亮点

- 密度计市场的成长归因于智慧工厂的发展以及对各种生产过程中使用的流体密度的精确测量的需求不断增长。此外,美国和欧洲国家政府对排放控制的严格规定也推动了市场的成长。

- 涵盖整个生产过程的全面品质保证对于任何工业活动至关重要。密度测量在化学、製药、石化和食品饮料行业尤其常见。密度测量使製造商能够以多种方式分析原材料、半成品、最终产品和生产过程。

- 例如,在化工厂中,出于多种原因,密度计用于测量一般散装化学品、特殊化学品和专有产品。使用密度计测量酸、腐蚀剂、溶剂、树脂、浆液、聚合物、合成橡胶等。此外,也测量纯化学品和溶液。

- 此外,快速的工业化以及水处理技术的进步也对液体密度计的需求起着至关重要的作用。用水和污水行业的高成长和技术创新使得易于维护和操作的实验室设备的需求增加。这导致超音波液体密度计的需求大幅增加。此外,密度计在塑胶和橡胶工业中的广泛应用也创造了成长机会。

密度计市场趋势

石油和天然气产业占很大市场占有率

- 石油和天然气是一个广泛的行业,涵盖许多流程和应用。这些大致分为基本类别:勘探、开采、生产、加工、分配和运输。大多数应用涉及监测各种目的运输的石油和天然气的密度。

- 石油和天然气产业是密度计最大的终端用户之一。在石油和天然气工业中,密度计用于下游工艺,在生产之前测量精製样品的精製和评估程度。此外,密度计也用于各种应用领域,例如油轮和铁路车辆装卸码头的产品识别、多产品管道、生产过程中的产品品管以及飞机用油应用中的品质测量。

- 随着工业化进程的加速和对能源资源的需求,石油和天然气产业也不断扩张。例如,根据国际能源总署(IEA)的数据,亚太地区是世界上最大的天然气进口地区和消费量。光是中国就占了世界天然气需求的三分之二。

- 此外,製程工业依靠技术设备来保持原材料的一致性和质量,其中密度计起着至关重要的作用。石油和天然气生产行业被迫加快生产速度,增加了对机械和测试设备(包括密度计)的需求,这将推动市场成长。

- 石油和天然气产业是密度计的主要终端用户之一。主要市场需求来自下游石油和天然气产业。工厂和精製等下游设施在生产前会测试样品的纯度,以确保安全且有效率的运作。

- 根据OPEC预计,2023年包括生质燃料在内的全球原油需求量将达到1.0221亿桶/日。预测显示,经济活动的活性化可能使石油需求在年终飙升至每天 1.04 亿桶以上。

亚太地区成长强劲

- 亚太地区由于工业化进程迅速,是密度计的潜在市场之一。过程自动化产业也有望利用亚太地区的各种机会。印度得益于其政治和全球改革,预计将在未来几年为流程自动化产业提供更多机会。

- 据印度品牌资产基金会称,2022 年 5 月,印度石油天然气公司宣布计划在 22-25 财年期间投资 40 亿美元,加强其在印度的探勘活动。预计到 2045 年印度的石油需求将成长一倍,达到每天 1,100 万桶。

- 到2050年,亚太地区对石油产品的需求预计将成长到每天3,880万桶。石油产品需求的增加是由于该地区的快速发展,特别是印度、中国、印尼和日本等国家。

- MOSPI的数据显示,化肥产业是印度最大的天然气消费产业,占2023财年总消费量的32%。石化、海绵铁产业以及化肥产业占同年印度天然气非能源消费量的37%左右。

- 此外,亚太地区食品饮料和製药公司的数量不断增加,并致力于扩大其在亚太地区的业务和製造部门,预计将极大地推动对密度计的需求。此外,政府在用水和污水处理行业的主导对于亚太密度计市场的发展至关重要。

密度计行业概况

全球密度计市场竞争激烈。市场参与企业,有大有小,市场集中度较高。所有主要参与者都拥有相当大的市场份额,并致力于扩大全球消费群。

市场的主要企业包括 ABB、Azbil Corporation、Endress+Hausar AG、艾默生电气公司、东芝公司和霍尼韦尔国际公司。为了在预测期内获得竞争优势,公司正在建立多种伙伴关係并投资推出新产品以增加市场占有率。

2023 年 2 月,安东帕开发了 Modulyzer 香精香料,这是一种新型分析系统,结合了密度计、旋光仪和屈光以及自动化选项,可提供有关香精香料行业物质的全面资讯。一个测量週期。品管领域的使用者可以透过各种功能享受成本节约的好处,例如每次测量只需要 10 毫升样品,并且测量后可以回收并重复使用样品。此外,透过与 Anton Paar 的实验室运行软体 AP Connect 集成,您可以直接从桌上型电脑收集、检视和分类测量资料。

2022年3月,数位密度计现在已应用于製药业的品管、研究和开发。赛默飞世尔科技和 Symphogen 扩大了合作,以改善资料工作流程,支持新癌症治疗方法的发现和开发。两家公司正在为生物製药发现和开发实验室提供创新工具和简化的工作流程,以有效表征复杂的治疗性蛋白质。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第 1 章 简介

- 研究假设和市场定义

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场洞察

- 市场概况

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 消费者议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争对手之间的竞争

- COVID-19 对密度计市场的影响

第五章 市场动态

- 市场驱动因素

- 工业化的扩张

- 严格监管食品品质和安全

- 市场问题

- 密度测量设备的精度与成本权衡

第六章 市场细分

- 按类型

- 桌面型

- 模组

- 可携式的

- 按应用

- 科里奥利

- 核能

- 超音波

- 微波

- 重力

- 按最终用户产业

- 用水和污水

- 化学

- 采矿和金属加工

- 饮食

- 医疗和製药

- 电子产品

- 石油和天然气

- 其他终端用户产业(电力和公共产业、研究)

- 按地区

- 北美洲

- 美国

- 加拿大

- 欧洲

- 英国

- 德国

- 法国

- 亚洲

- 中国

- 印度

- 日本

- 澳洲和纽西兰

- 拉丁美洲

- 中东和非洲

- 北美洲

第七章 竞争格局

- 公司简介

- Anton Paar GmbH

- Mettler-Toledo International Inc.

- VWR International(Avantor)

- Berthold Technologies GmbH & Co.KG

- Emerson Electric Co.

- Red Meters LLC

- Schmidt+Haensch GmbH & Co.

- Thermo Fisher Scientific

- RUDOLPH RESEARCH ANALYTICAL

- Rhosonics Analytical BV

- KRUSS Optronic GmbH

- Ametek Inc.

- Yokogawa Electric Corporation

- Koehler Instrument

- Toshiba Infrastructure Systems & Solutions Corporation

第八章投资分析

第九章:市场的未来

The Density Meter Market size is estimated at USD 1.12 billion in 2025, and is expected to reach USD 1.37 billion by 2030, at a CAGR of 4.25% during the forecast period (2025-2030).

Key Highlights

- The growth of the density meter market can be attributed to smart factories' development and the increased demand to accurately measure the density of the fluids used in or during various production processes. Also, the stringent government regulations in the United States and European countries to regulate emissions drive market growth.

- A comprehensive quality assurance covering the entire production process is essential in any industrial operation. Density measurements are commonly used for this purpose, especially in the chemical, pharmaceutical, petrochemical, and food & beverage industries. They allow the manufacturer to analyze raw materials, semi-finished and finished products, and the manufacturing steps regarding several factors.

- For instance, in chemical plants, a density meter is used for many reasons for the common bulk chemicals and the specialty and proprietary products. Acids, caustics, solvents, resins, slurries, polymers, elastomers, and more are measured using a density meter. Furthermore, pure chemicals and solutions are also measured.

- Also, rapid industrialization, in line with the technological advancement in water treatment technology, plays an essential role in the demand for liquid density meters. High growth and innovation in the water and wastewater industry create the need for a simple laboratory device to maintain and operate. Because of this, the demand for ultrasonic liquid density meters increased significantly. Further, growing applications of density meters in the plastics and rubber industry create growth opportunities.

Density Meter Market Trends

Oil and Gas Industry to Hold Significant Market Share

- Oil and gas is a wide-ranging industry encompassing many processes and applications. Some of these might be roughly grouped into basic categories: exploration, extraction, production, processing, distribution, and transportation. Most applications include monitoring the density of oil and gases transported for various purposes.

- The oil and gas sector is one of the largest end-users of density meters. In the oil and gas industry, density meters are utilized in downstream processes, wherein purification and assessment of the purified sample are measured before manufacturing. Also, the dense meter is used in various application sectors such as tanker truck and railcar loading stations, product identification on multi-product pipelines, product quality control in the production process, and mass measurement in aircraft refueling applications.

- The oil and gas industry is expanding with the growth of industrialization and the demand for energy resources. For instance, according to the International Energy Agency, the Asia-Pacific region was the highest importer and consumer of natural gas. China alone accounted for two-thirds of the demand for natural gas globally.

- Moreover, the process industries depend on technical equipment to maintain uniformity and quality throughout the crude material, wherein the density meter plays an important role. The transition would force the oil and gas production sector to accelerate the production rate, increasing demand for machinery and testing equipment, including density meters, thereby driving the market's growth.

- The oil and gas sector is one of the key end users of density meters. The primary market demand comes from the downstream sector of oil and gas. The purity of the sample is measured before manufacturing to ensure operational safety and efficiency in downstream facilities, such as plants and refineries.

- According to OPEC, in 2023, global crude oil demand, inclusive of biofuels, stood at 102.21 million barrels per day. Forecasts anticipate a rise in economic activity, projecting a potential surge in oil demand to over 104 million barrels per day by year-end.

Asia-Pacific to Witness Significant Growth

- The increasing industrialization in Asia-Pacific makes the region one of the potential markets for density meters. The process automation industry is also expected to avail of various opportunities in Asia-Pacific. India is expected to provide more opportunities for the process automation industry in the coming years because of its political and global reformation.

- According to the India Brand Equity Foundation, in May 2022, ONGC announced plans to invest USD 4 billion from FY22-25 to increase its exploration efforts in India. The oil demand in India is projected to register a 2 times growth to reach 11 million barrels per day by 2045.

- The Asia-Pacific's oil product demand by 2050 is expected to rise to 38.8 million b/d. The increased demand for oil products can be ascribed to the rapid development in the region, particularly in countries such as India, China, Indonesia, and Japan.

- According to MOSPI, the fertilizer industry is India's largest natural gas consumer, accounting for 32 percent of total consumption in the financial year 2023. The petrochemical and sponge iron sectors along with the fertilizer industry is approximatly 37 percent of India's non-energy consumption of natural gas that year.

- Further, owing to the increase in the number of food & beverage and pharmaceutical companies in Asia-Pacific and the focus on expanding the operations & manufacturing units across different parts of Asia-Pacific, the demand for density meters is predicted to grow substantially. Moreover, the water and wastewater treatment industry's government initiative is vital in developing the density meter market across the Asia-Pacific region.

Density Meter Industry Overview

The global density meter market is very competitive. The market is highly concentrated due to the presence of various small and large players. All the major players account for a large share of the market and are focusing on expanding their consumer base across the world.

Some of the significant players in the market are ABB Ltd, Azbil Corporation, Endress+Hausar AG, Emerson Electric Corporation, Toshiba Corporation, Honeywell International Inc., and many more. The companies are increasing the market share by forming multiple partnerships and investing in introducing new products to earn a competitive edge during the forecast period.

In February 2023, Modulyzer Flavour and Fragrance is a new analytical system developed by Anton Paar that combines density meters, polarimeters, and refractometers with an automated option to provide comprehensive information - in a single measurement cycle - on substances in the flavor and fragrance industry. Users in the quality control field can benefit from cost-reduction opportunities due to a variety of features, such as the requirement for only 10 ml sample per measurement and the ability to recover and reuse samples after a measurement. Additionally, the system can be integrated with AP Connect - Anton Paar's lab execution software - to enable the collection, review, and categorization of measurement data directly from a desktop computer.

In March 2022, digital density meters were used in the pharmaceutical industries for quality control, research, and development. Thermo Fisher and Symphogen have extended the collaboration involving improved data workflow, which supports the discovery and development of new cancer treatments. The companies provide biopharmaceutical discovery and development laboratories with innovative tools and streamlined workflows to characterize complex therapeutic proteins efficiently.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Consumers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Impact of COVID-19 on the Density Meter Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Expansion in Industrialization

- 5.1.2 Stringent Regulations with Regard to Food Quality and Safety

- 5.2 Market Challenges

- 5.2.1 Tradeoff Between the Accuracy and Cost of the Density Meter Equipment

6 MARKET SEGMENTATION

- 6.1 By Type

- 6.1.1 Benchtop

- 6.1.2 Module

- 6.1.3 Portable

- 6.2 By Application

- 6.2.1 Coriolis

- 6.2.2 Nuclear

- 6.2.3 Ultrasonic

- 6.2.4 Microwave

- 6.2.5 Gravitic

- 6.3 By End-user Industry

- 6.3.1 Water and Wastewater

- 6.3.2 Chemicals

- 6.3.3 Mining and Metal Processing

- 6.3.4 Food and Beverage

- 6.3.5 Healthcare and Pharmaceuticals

- 6.3.6 Electronics

- 6.3.7 Oil and Gas

- 6.3.8 Other End-user Industries (Power and Utilities, Research)

- 6.4 By Geography

- 6.4.1 North America

- 6.4.1.1 United States

- 6.4.1.2 Canada

- 6.4.2 Europe

- 6.4.2.1 United Kingdom

- 6.4.2.2 Germany

- 6.4.2.3 France

- 6.4.3 Asia

- 6.4.3.1 China

- 6.4.3.2 India

- 6.4.3.3 Japan

- 6.4.4 Australia and New Zealand

- 6.4.5 Latin America

- 6.4.6 Middle East and Africa

- 6.4.1 North America

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Anton Paar GmbH

- 7.1.2 Mettler-Toledo International Inc.

- 7.1.3 VWR International (Avantor)

- 7.1.4 Berthold Technologies GmbH & Co.KG

- 7.1.5 Emerson Electric Co.

- 7.1.6 Red Meters LLC

- 7.1.7 Schmidt + Haensch GmbH & Co.

- 7.1.8 Thermo Fisher Scientific

- 7.1.9 RUDOLPH RESEARCH ANALYTICAL

- 7.1.10 Rhosonics Analytical BV

- 7.1.11 KRUSS Optronic GmbH

- 7.1.12 Ametek Inc.

- 7.1.13 Yokogawa Electric Corporation

- 7.1.14 Koehler Instrument

- 7.1.15 Toshiba Infrastructure Systems & Solutions Corporation