|

市场调查报告书

商品编码

1642946

水刀切割机:市场占有率分析、产业趋势与统计、成长预测(2025-2030 年)Waterjet Cutting Machine - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

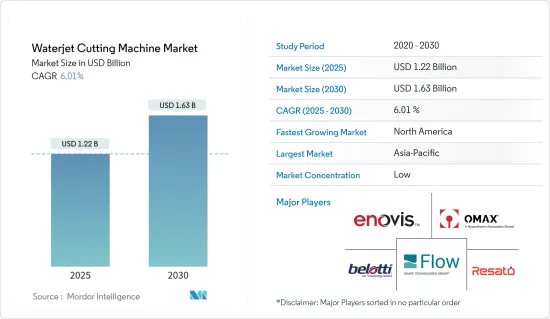

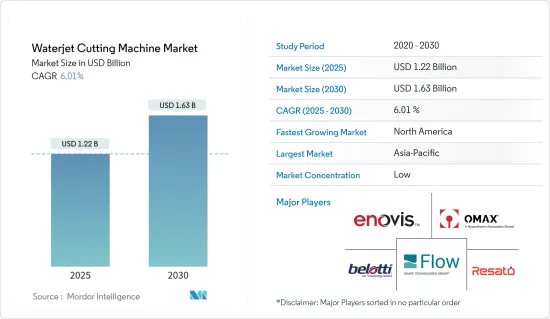

预计 2025 年水刀切割机市场规模为 12.2 亿美元,到 2030 年将达到 16.3 亿美元,预测期内(2025-2030 年)的复合年增长率为 6.01%。

水刀切割市场是更广泛的工业机械产业中一个充满活力且快速发展的领域。水刀切割技术以其精确度和多功能性而闻名,已成为汽车、航太、电子和建筑等多个行业的必备技术。该技术可以切割各种各样的材料,从金属和复合材料到陶瓷和玻璃,而不会损害它们的结构完整性,使其成为现代製造工艺的重要组成部分。

水刀切割设备与技术

多样化的设备类型:水刀切割设备分为几种类型,每种类型都旨在满足特定的工业需求。这些包括机器人系统、3D 系统和微水刀系统。机器人系统提供自动化功能并透过减少体力劳动来提高生产力。另一方面,微水刀系统专为超精密应用而设计,特别是在需要复杂切割微小部件的行业。

技术进步 最近的进步大大提高了水刀切割机的效率和准确性。高压水柱系统与电脑数值控制(CNC) 技术相结合,彻底改变了切割过程,可以以最少的人为错误切割出精确、复杂的形状。水刀切割的非热特性消除了热影响区,使其成为温度敏感材料的理想选择。

扩大製造业的应用

航太与汽车:航太和汽车工业是水刀切割机市场的主要驱动力之一。在航太工业中,精确切割钛和复合材料等材料对于生产高品质的零件至关重要。在汽车工业中,水刀切割用于在铝、钢和塑胶等材料上创造复杂的形状和设计,对现代汽车製造至关重要。向电动车(EV)的转变和轻量材料的使用将进一步推动对水刀切割技术的需求。

电子和半导体製造:电子产业,尤其是半导体製造,需要对硅晶片和印刷电路基板(PCB) 等精密材料采用高精度的切割方法。水刀切割,特别是微水刀系统,由于其能够进行精细、复杂的切割而不会损坏精密零件,在该领域越来越受欢迎。随着对更小、更复杂的电子设备的需求不断增加,预计该行业对水刀切割技术的采用将会增加。

技术创新推动市场成长

高压水柱切割系统:高压和超高压水柱系统的发展扩大了水刀切割技术的应用范围。这些系统可以加快切割较厚、较硬的材料的速度,从而提高工作效率。此外,泵浦技术的创新使水刀切割更加节能,降低了营运成本并使其更容易被中小型企业(SMEs)使用。

透过 CNC 整合提高精度:CNC 技术与水刀切割机的整合改变了整个切割格局,实现了自动化、高精度的切割操作。 CNC 控制的水刀系统可以在最少的人为干预下加工出复杂的形状和图案,从而显着减少材料浪费并提高生产力。该技术在航太和电子等需要高精度的行业特别有用。

水刀切割机的市场趋势

磨料和水刀切割机的成长潜力

磨料水刀切割机的成长:磨料水刀切割机因其能够高精度地处理金属、陶瓷和复合材料等具有挑战性的物料输送而越来越受欢迎。透过整合先进的 CNC 系统,这些机器的功能进一步增强,能够生产复杂的设计并支援大规模生产。在保持材料完整性非常重要的行业中,无热损伤切割的能力尤其有利。

经济和环境效益:虽然水刀切割机的初始成本可能很高,但减少材料浪费和提高生产效率等长期效益使其成为经济高效的解决方案。这些优势对于产业正在成长的新兴市场尤其有吸引力。此外,水刀技术的进步,例如减少水流滞后和 3D 切割中的锥形切割,也使这些机器更加环保,因为它们不会产生有毒废物并且不需要冷却剂。

将自动化水刀切割製程引入主要产业

- 自动化正在彻底改变产业:将自动化引入水刀切割流程,透过提高生产力、精度和成本效益来改变产业。自动化系统能够在最少的人为干预下实现连续运行,从而减少错误并实现全天候生产週期。这对于航太和汽车等高度重视高精度和高效率的领域尤其有益。

- 自动化背后的技术创新:对高精度和可客製化製造流程的需求推动了对自动化水刀切割解决方案的需求。微型、3D和机器人水刀切割机等技术创新使最终用户能够提高生产力并实现精确的切割操作。这些进步对于医疗设备和电子设备等要求高精度的领域至关重要。随着技术的不断发展,自动水刀切割系统的采用预计将成长,从而进一步推动市场扩张。

水刀切割机产业概况

市场结构分散:水刀切割机市场分散,由全球企业集团和区域专业化参与者组成。竞争格局不断变化,没有一家公司能主导市场。这种多样性鼓励了各种规模的公司(从跨国公司到小众企业)之间的创新和竞争。

领先公司的创新和扩张:OMAX Corporation、Enovis(Colfax Corporation)和 Flow International Corporation 等主要企业因其透过持续的技术创新、扩大产品系列和策略併购取得的强大市场地位而受到认可。这些公司凭藉其全球影响力和在研发方面的投入在市场上保持竞争力。

专注于技术进步:水刀切割机市场越来越注重整合先进技术和提高成本效率。该公司正在投资自动化、人工智慧主导流程和节能係统,以提高效能并降低营运成本。未来该市场的成功将取决于企业的创新能力,以满足航太、汽车和製造等行业不断变化的需求。

在技术进步、应用范围不断扩大和自动化程度不断提高的推动下,水刀切割机市场预计将持续成长。随着产业优先考虑精度、效率和永续性,水射流切割技术将继续成为全球製造环境中的重要工具。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第 1 章 简介

- 调查结果

- 调查前提

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场动态

- 当前市场概况

- 市场驱动因素

- 製造业和汽车业需求激增

- 技术进步

- 市场限制

- 初期投资及维护成本高

- 市场机会

- 在开发中地区扩大使用

- 技术进步

- 产业吸引力-波特五力分析

- 新进入者的威胁

- 购买者/消费者的议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争对手之间的竞争强度

- 地缘政治与疫情将如何影响市场

第五章 市场区隔

- 依产品类型

- 机器人水刀切割

- 3D水刀切割

- 微水刀切割

- 按最终用户

- 自动化设备

- 电子产品

- 航太

- 建造

- 矿业

- 其他行业

- 按地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 北美其他地区

- 南美洲

- 巴西

- 阿根廷

- 欧洲

- 德国

- 英国

- 法国

- 俄罗斯

- 西班牙

- 其他欧洲国家

- 亚太地区

- 印度

- 中国

- 日本

- 其他亚太地区

- 中东

- 阿拉伯聯合大公国

- 沙乌地阿拉伯

- 其他中东地区

- 北美洲

第六章 竞争格局

- 市场集中度概览

- 公司简介

- OMAX Corporation

- Enovis(Colfax Corporation)

- Hypertherm Inc.

- Flow International Corporation

- Wardjet, Belotti SPA

- KMT Waterjet

- Resato International BV

- Jet Edge Inc.

- Dardi International Corporation

- Jekran Ltd

- International Waterjet Machines

- Kennametal Inc.

- CERATIZIT SA

- GMA Garnet Pty. Ltd.

- Hornet Cutting Systems*

第七章:市场的未来

第 8 章 附录

The Waterjet Cutting Machine Market size is estimated at USD 1.22 billion in 2025, and is expected to reach USD 1.63 billion by 2030, at a CAGR of 6.01% during the forecast period (2025-2030).

The waterjet cutting machine market is a dynamic and rapidly evolving segment within the broader industrial machinery industry. Known for its precision and versatility, waterjet cutting technology has become essential across various industries, including automotive, aerospace, electronics, and construction. This technology allows for cutting diverse materials-ranging from metals and composites to ceramics and glass-without compromising their structural integrity, making it indispensable for modern manufacturing processes.

Waterjet Cutting Equipment and Technology

Diverse Equipment Types: Waterjet cutting equipment is categorized into several types, each designed to meet specific industrial needs. These include robotic, 3D, and micro waterjet cutting systems. Robotic systems provide automation capabilities, enhancing productivity by reducing manual intervention. Meanwhile, micro waterjet systems are tailored for ultra-precision applications, particularly in industries where small components require intricate cuts.

Technological Advancements: Recent advancements have significantly improved the efficiency and accuracy of waterjet cutting machines. High-pressure waterjet systems, coupled with Computer Numerical Control (CNC) technology, have revolutionized the cutting process, allowing for precise and complex geometries to be cut with minimal human error. The non-thermal nature of waterjet cutting eliminates heat-affected zones, making it ideal for temperature-sensitive materials.

Expanding Applications in Manufacturing

Aerospace and Automotive Sectors: The aerospace and automotive industries are among the key drivers of the waterjet cutting machine market. In aerospace, the technology's precision in cutting materials like titanium and composites is crucial for producing high-quality components. In the automotive industry, waterjet cutting is used to create intricate shapes and designs in materials such as aluminum, steel, and plastics, essential for modern vehicle manufacturing. The shift towards electric vehicles (EVs) and the use of lightweight materials further boost the demand for waterjet cutting technology.

Electronics and Semiconductor Manufacturing: The electronics industry, particularly in semiconductor manufacturing, demands highly precise cutting methods for delicate materials like silicon wafers and printed circuit boards (PCBs). Waterjet cutting, especially micro waterjet systems, has become increasingly popular in this sector due to its ability to make fine, intricate cuts without damaging sensitive components. As the demand for smaller, more complex electronic devices grows, the adoption of waterjet cutting technology in this industry is expected to increase.

Technological Innovations Driving Market Growth

High-Pressure Waterjet Systems: The development of high-pressure and ultra-high-pressure waterjet systems has expanded the range of applications for waterjet cutting technology. These systems allow for faster cutting of thicker and harder materials, improving operational efficiency. Additionally, innovations in pump technology have enhanced energy efficiency, reducing operational costs and making waterjet cutting more accessible to small and medium-sized enterprises (SMEs).

CNC Integration for Enhanced Precision: The integration of CNC technology into waterjet cutting machines has been a game-changer, enabling automated, highly precise cutting operations. CNC-controlled waterjet systems can execute complex geometries and patterns with minimal human intervention, significantly reducing material wastage and improving productivity. This technology is particularly valuable in industries requiring high precision, such as aerospace and electronics.

Waterjet Cutting Machine Market Trends

Growth Potential of Abrasive Waterjet Cutting Machines

Growth of Abrasive Waterjet Cutting Machines: Abrasive waterjet cutting machines are gaining traction due to their ability to handle challenging materials like metals, ceramics, and composites with high precision. The integration of advanced CNC systems has further enhanced these machines, enabling the production of intricate designs and supporting high-volume manufacturing. Their ability to cut without thermal damage is particularly advantageous in industries where maintaining material integrity is critical.

Economic and Environmental Advantages: While the initial cost of waterjet cutting machines can be high, the long-term benefits, such as reduced material waste and increased production efficiency, make them a cost-effective solution. These advantages are especially appealing in developing markets experiencing industrial growth. Additionally, advancements in waterjet technology, such as reducing stream lag and tapering in 3D cutting, have made these machines more environmentally friendly, as they do not produce toxic byproducts and do not require coolants.

Implementation of Waterjet Cutting Automation Process Across Major Industries

- Automation Revolutionizing the Industry: The adoption of automation in waterjet cutting processes is transforming the industry by enhancing productivity, precision, and cost-efficiency. Automated systems allow for continuous operation with minimal human intervention, reducing errors and enabling around-the-clock production cycles. This is particularly beneficial in sectors like aerospace and automotive, where high precision and efficiency are paramount.

- Innovations Supporting Automation: The growing demand for automated waterjet cutting solutions is driven by the need for high-precision, customizable manufacturing processes. Innovations such as micro, 3D, and robotic waterjet cutting machines enable end-users to increase productivity and achieve precise cutting operations. These advancements are critical in sectors like medical devices and electronics, where high accuracy is required. As technology continues to evolve, the adoption of automated waterjet cutting systems is expected to grow, further driving market expansion.

Waterjet Cutting Machine Industry Overview

Fragmented Market Structure: The waterjet cutting machine market is fragmented, with a mix of global conglomerates and specialized regional players. The competitive landscape is dynamic, with no single company dominating the market. This diversity fosters innovation and competition among companies of various sizes, from multinational corporations to niche players.

Innovation and Expansion by Major Players: Leading companies such as OMAX Corporation, Enovis (Colfax Corporation), and Flow International Corporation are recognized for their strong market positions, achieved through continuous innovation, product portfolio expansion, and strategic mergers and acquisitions. These companies' global reach and investment in research and development have enabled them to maintain a competitive edge in the market.

Focus on Technological Advancements: The waterjet cutting machine market increasingly focuses on integrating advanced technologies and improving cost efficiency. Companies are investing in automation, AI-driven processes, and energy-efficient systems to enhance performance and reduce operational costs. Future success in this market will hinge on the ability of companies to innovate and meet the evolving needs of industries such as aerospace, automotive, and manufacturing.

The waterjet cutting machine market is poised for continued growth, driven by technological advancements, expanding applications, and the increasing adoption of automation. As industries prioritize precision, efficiency, and sustainability, waterjet cutting technology will remain a vital tool in the global manufacturing landscape.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Deliverables

- 1.2 Study Assumptions

- 1.3 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS & DYNAMICS

- 4.1 Current Market Overview

- 4.2 Market Drivers

- 4.2.1 Surging Demand from the Manufacturing and Automotive Sectors

- 4.2.2 Technological Advancements

- 4.3 Market Restraints

- 4.3.1 High Initial Investment and Maintenance Costs

- 4.4 Market Opportunities

- 4.4.1 Increasing Uptake in Developing Regions

- 4.5 Technological Advancements

- 4.6 Industry Attractiveness - Porter's Five Forces Analysis

- 4.6.1 Threat of New Entrants

- 4.6.2 Bargaining Power of Buyers/Consumers

- 4.6.3 Bargaining Power of Suppliers

- 4.6.4 Threat of Substitute Products

- 4.6.5 Intensity of Competitive Rivalry

- 4.7 Impact of Geopolitics and Pandemics on the Market

5 MARKET SEGMENTATION

- 5.1 Product Type

- 5.1.1 Robotic Waterjet Cutting

- 5.1.2 3D Waterjet Cutting

- 5.1.3 Micro Waterjet Cutting

- 5.2 End-User

- 5.2.1 Automative

- 5.2.2 Electronics

- 5.2.3 Aerospace

- 5.2.4 Construction

- 5.2.5 Mining Industry

- 5.2.6 Other Industries

- 5.3 Geography

- 5.3.1 North America

- 5.3.1.1 United States

- 5.3.1.2 Canada

- 5.3.1.3 Mexico

- 5.3.1.4 Rest of North America

- 5.3.2 South America

- 5.3.2.1 Brazil

- 5.3.2.2 Argentina

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 France

- 5.3.3.4 Russia

- 5.3.3.5 Spain

- 5.3.3.6 Rest of Europe

- 5.3.4 Asia-Pacific

- 5.3.4.1 India

- 5.3.4.2 China

- 5.3.4.3 Japan

- 5.3.4.4 Rest of Asia-Pacific

- 5.3.5 Middle East

- 5.3.5.1 United Arab Emirates

- 5.3.5.2 Saudi Arabia

- 5.3.5.3 Rest of the Middle East

- 5.3.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration Overview

- 6.2 Company Profiles

- 6.2.1 OMAX Corporation

- 6.2.2 Enovis (Colfax Corporation)

- 6.2.3 Hypertherm Inc.

- 6.2.4 Flow International Corporation

- 6.2.5 Wardjet, Belotti SPA

- 6.2.6 KMT Waterjet

- 6.2.7 Resato International B.V.

- 6.2.8 Jet Edge Inc.

- 6.2.9 Dardi International Corporation

- 6.2.10 Jekran Ltd

- 6.2.11 International Waterjet Machines

- 6.2.12 Kennametal Inc.

- 6.2.13 CERATIZIT S.A.

- 6.2.14 GMA Garnet Pty. Ltd.

- 6.2.15 Hornet Cutting Systems*